Cohesion and Adhesion Effect on the Fluid, ANSYS Fluent Simulation Training

$80.00 Student Discount

The present problem simulates the effect of cohesion and adhesion on a fluid using ANSYS Fluent software.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Project Description

The present problem simulates the effect of cohesion and adhesion on a fluid using ANSYS Fluent software. In this project, it is assumed that there is a T-shaped computational domain; So that the fluid flow enters from the bottom and exits from the top. Initially, this area consists of only air, and then water flows at a rate of 0.001 m.s-1 vertically and upward into the computational domain. In this case, the water flow is in contact to the air flow and the wall surfaces. Therefore, the property of cohesion in water flow and adhesion property between the solid surfaces of the model and water flow will affect the kinetic behavior of water flow. The simulation is transient; So that the time step size is equal to 0.001 s.

Also, since this simulation is necessary to define two phases of air and water, the multiphase flow model is used. The multiphase model used in this simulation is the VOF model; Because this model can distinguish the interface between two fluids.

Geometry & Mesh

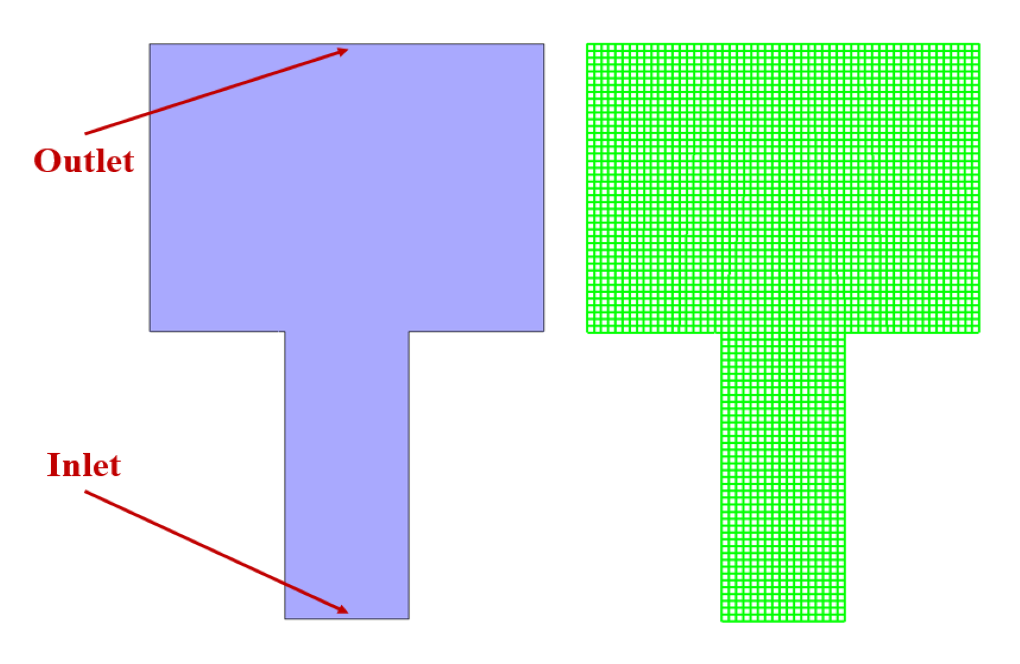

The present model is designed in two dimensions using Design Modeler software. The model’s geometry consists of a T-shaped computational region whose lower boundary with a smaller cross-section is defined as the flow input. Its upper boundary with a larger cross-section is defined as the output.

We carry out the model’s meshing using ANSYS Meshing software, and the mesh type is structured. The element number is 3024. The following figure shows the mesh.

Cohesion and Adhesion CFD Simulation

We consider several assumptions to simulate the present model:

- We perform a pressure-based solver.

- The simulation is unsteady.

- The gravity effect on the fluid is ignored.

The following table represents a summary of the defining steps of the problem and its solution:

| Models | ||

| Viscous | Laminar | |

| Multiphase Model | VOF | |

| formulation | implicit | |

| number of eulerian phases | 2 (water & air) | |

| interface modeling | sharp | |

| Boundary conditions | ||

| Inlet | Velocity Inlet | |

| velocity magnitude | 0.001 m.s-1 | |

| water volume fraction | 1 | |

| air volume fraction | 0 | |

| Outlet | Pressure Outlet | |

| gauge pressure | 0 pascal | |

| wall motion | stationary wall | |

| Methods | ||

| Pressure-Velocity Coupling | SIMPLE | |

| Pressure | PRESTO | |

| momentum | second-order upwind | |

| volume fraction | compressive | |

| Initialization | ||

| Initialization methods | Standard | |

| gauge pressure | 0 pascal | |

| x-velocity & y-velocity | 0 m.s-1 | |

| water volume fraction | 0 | |

Cohesion and Adhesion Results & Discussions

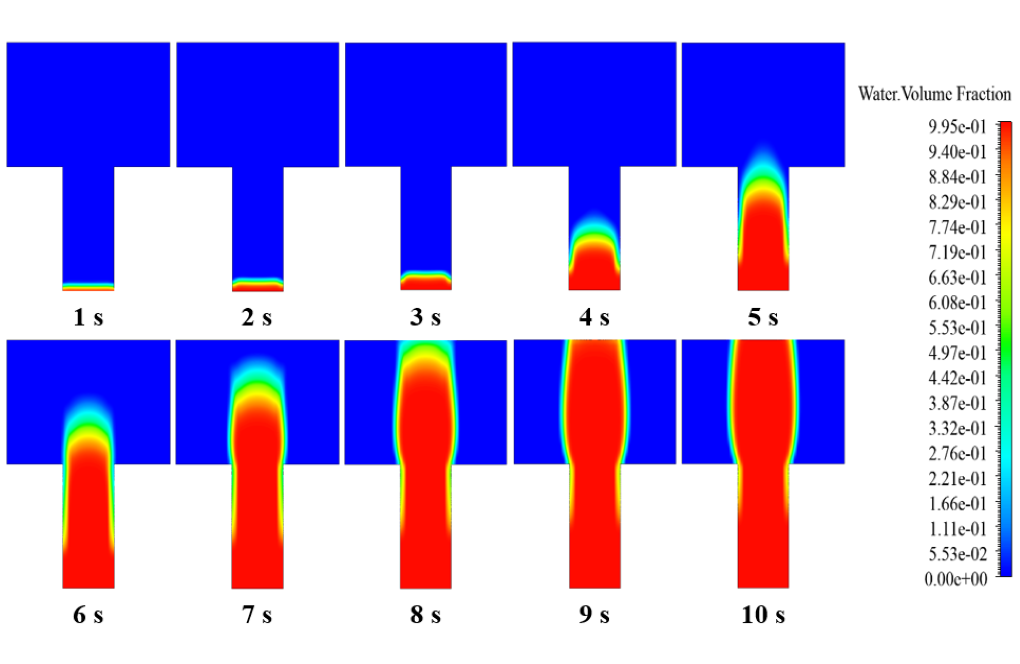

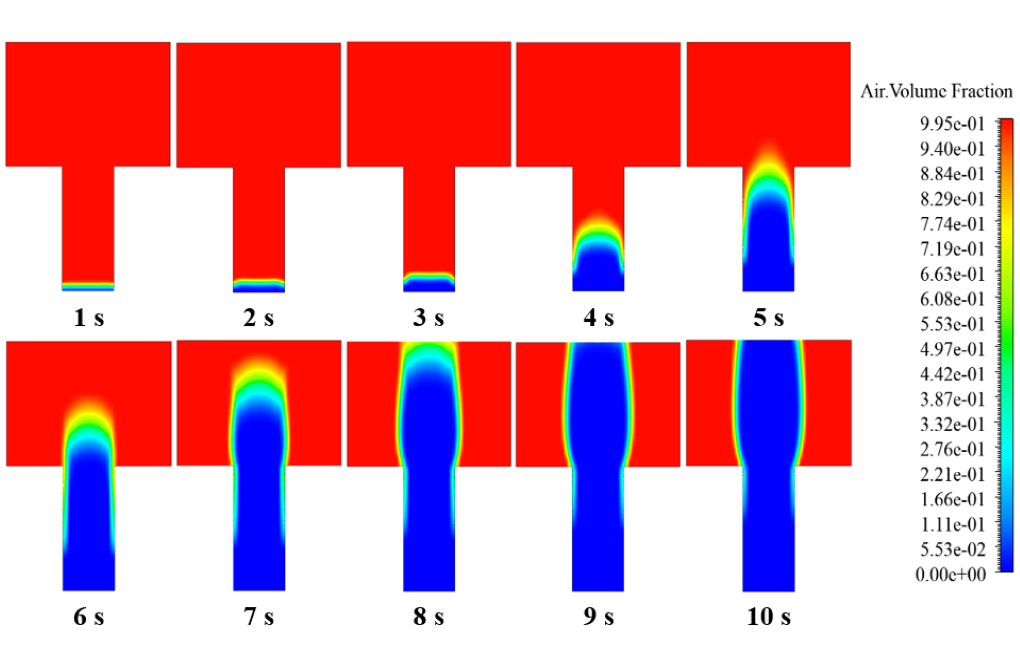

At the end of the solution process, two-dimensional contours related to the volume fraction of each water and air phase are obtained. The performed solver is unsteady, and the total simulation time is defined as 0.1 s. Contours related to the volume fraction of water and air were obtained at different time intervals of 0.01 s. The images show that in both sections, which have a smaller and larger cross-section than the model, the flow cohesion is higher than the water adhesion on the wall surfaces. For this reason, the water flow tries to maintain its uniform shape and resist complete dispersion on solid surfaces.

Jeromy Bernier –

How does this simulation handle the modeling of fluid-structure interaction?

MR CFD Support –

This simulation includes a detailed model for fluid-structure interaction, which is critical for accurately simulating the behavior of fluids in many situations. The model takes into account the effects of fluid forces on the structure and the response of the structure, providing a comprehensive picture of fluid-structure interaction phenomena.

Coy Heidenreich –

The training is thorough in detailing the involvement of cohesion and adhesion in a multiphase CFD simulation. Understanding how these forces involve and are a present model is key to mastering flow dynamics in various engineering applications. A job well done by MR CFD’s team!

MR CFD Support –

Thank you for appreciating our training on the effects of cohesion and adhesion in fluid flow simulations. We’re delighted to hear that the content was useful and clear. Should you have any more questions or need deeper insight into flow dynamics, please feel free to reach out!

Thad Stiedemann V –

Can this simulation be used to study the behavior of non-Newtonian fluids?

MR CFD Support –

Yes, this simulation can be adapted to study the behavior of non-Newtonian fluids. By modifying the fluid properties and the models for cohesion and adhesion, you can simulate a wide range of non-Newtonian fluids, including shear-thinning and shear-thickening fluids.

Libby Beahan –

The simulation results and discussions mention ‘flow cohesion is higher than the water adhesion on the wall surfaces.’ Can you explain how this phenomenon is observed in the simulation?

MR CFD Support –

In the simulation, you can observe the phenomenon through the shape and behavior of the water flow as it interacts with the wall surfaces. Higher cohesion will cause water droplets to maintain their shape and form beads that do not spread out extensively on the surface. The contours of the volume fraction of water at different time intervals illustrate that despite contact, the water flow maintains its shape instead of spreading out, meaning cohesion within the water flow is dominating over adhesion with the wall surfaces.

Mike Murazik –

How does this simulation handle the modeling of turbulence?

MR CFD Support –

This simulation includes a detailed model for turbulence, which is critical for accurately simulating the behavior of fluids in many situations. The model takes into account the effects of both large-scale and small-scale turbulent fluctuations, providing a comprehensive picture of turbulence phenomena.

Gustave Quitzon –

This course sounds fascinating! Does it include practical workshops where we can apply these concepts on our own simulation models?

MR CFD Support –

Absolutely! Our training includes hands-on workshops where you’re encouraged to practice and apply the concepts of cohesion and adhesion on different simulation models. This provides a comprehensive learning experience, ensuring you have a strong grasp of the theoretical and practical aspects of the simulation.

Kamren Rutherford –

Honestly, the detail level in the project description for the Cohesion and Adhesion Effect simulation is amazing. It really helps to understand the complex phenomenon of fluid behaviors!

MR CFD Support –

Thank you for taking the time to review our product. We’re thrilled to hear that you found the project description detailed and helpful. Understanding fluid dynamics can indeed be complex, and we’re glad our simulation could shed light on the effects of cohesion and adhesion. We appreciate your positive feedback!

Miss Hosea Heaney –

The course was extremely informative about the use of fluid dynamics, specifically focusing on cohesion and adhesion properties in a T-shaped domain simulation. The clarity in explaining VOF models for tracking interface between two fluids and detailing the simulation initialization was superb.

MR CFD Support –

Thank you for your kind words and appreciation! We are very pleased to hear that the course was clear and informative for you. Your feedback is valuable to us, and we hope to continue providing high-quality learning experiences on computational fluid dynamics and other related topics. Should you have any more questions or need further assistance, please don’t hesitate to reach out.

Jerry Rowe IV –

I am truly impressed by how the simulation discusses the interaction between cohesion and adhesion effects on the fluid behavior. This detailed observation is especially useful for those in fluid dynamics research.

MR CFD Support –

Thank you for your positive feedback on the cohesion and adhesion simulation training! We’re thrilled to hear that you found the detailed analysis of fluid behavior and its interactions useful for research in fluid dynamics.