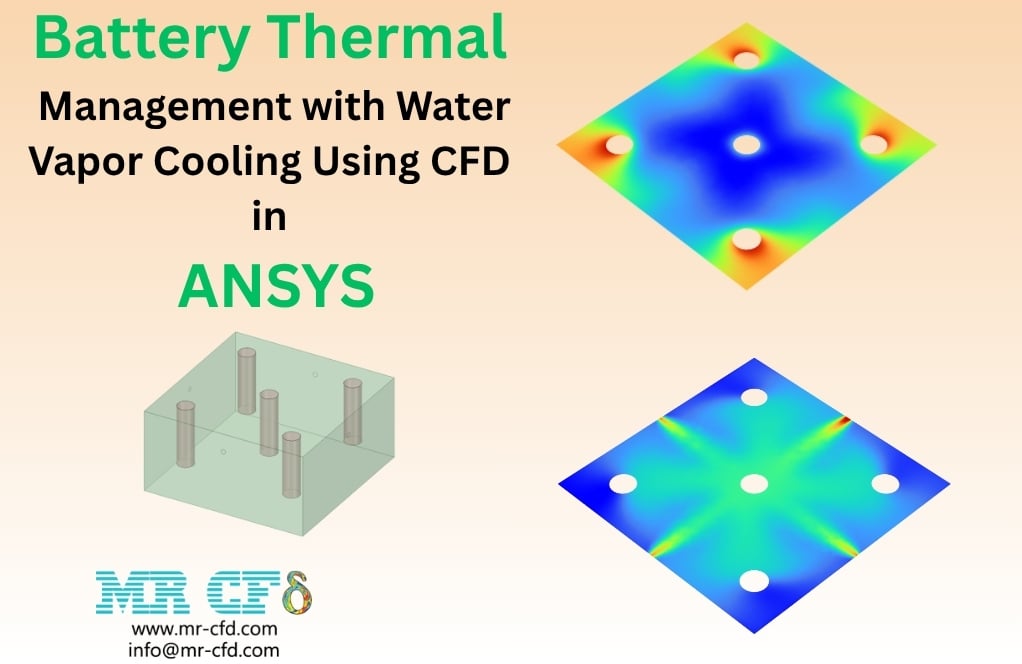

Battery Thermal Management with Water Vapor Cooling Using CFD in ANSYS

$120.00 $48.00 HPC

- In Battery Thermal Management project simulates battery thermal management using water vapor injection cooling in ANSYS Fluent.

- A five-cell vertical battery pack is modeled in SpaceClaim, with unstructured mesh and wall boundary layers applied for accuracy.

- Air and water vapor at 18°C are injected from side nozzles at 0.5 m/s to reduce battery temperatures.

- The model runs species transport in pseudo-transient mode, includes a grid independence study, and analyzes the effectiveness of vapor cooling on temperature reduction.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Battery Thermal Management with Water Vapor Cooling

Project Description

In the Battery Thermal project, we aim to design a cooling system for a battery system using water vapor injection. The geometry consists of 5 battery cells. Batteries are positioned vertically. A gap will be between the bottom of the battery and the box’s bottom. The geometry is designed using ANSYS SpaceClaim software. Then, it is meshed in ANSYS Meshing software. Moreover, an unstructured grid and a boundary layer on battery walls are used, increasing the accuracy near the walls.

The top and side walls are assumed to be isolated, while the mass transfers from the bottom wall. A heat flux of 3 W/m^2 is applied to battery walls. The air and water vapor (18°C) are injected with a velocity of 0.5 m/s from the employed nozzles on the side walls. Thus, a species transport module is employed, and the equations are solved in pseudo-transient mode.

Grid Independence Study

As mentioned, the generated grid over the computational domain for the Battery Thermal project consists of tetrahedron elements and a boundary layer on battery walls. Four mesh grids are tested, as shown in the table below. Mesh #1 with 75000 elements reports the average temperature of the battery walls as 20.16 °C, while mesh #2, with 172000 elements, reports it at 19.93°C. There is more than a 1% difference in value. Thus, another mesh #3 with a finer grid is generated. As a result, the average temperature reaches 19.88°, about a 0.25% difference in value from the previous grid. To conclude, Mesh #2 is selected as the best-fitted mesh grid. It is worth mentioning that, to ensure the study’s accuracy, mesh #4 is also tested, which corroborates the qualification of mesh #2.

| Mesh# | Element Size | No. | Avg. temp (°) | Error(%) |

| 1 | 16mm | 75000 | 20.16 | — |

| 2 | 8mm | 172000 | 19.93 | -1.15404 |

| 3 | 4mm | 263000 | 19.88 | -0.25151 |

| 4 | 2mm | 990000 | 19.86 | -0.25176 |

Results

A steady simulation was performed in the first step, ignoring the water vapor injection to investigate the Battery Thermal. The results show that the batteries reach 27°C if no cooling system is applied. The standard operating temperature range for most batteries, such as lithium-ion, is typically between 20°C and 30°C (68°F to 86°F). However, the specific range can vary depending on the type and design of the battery. Hiring a water vapor cooling system reduces the battery temperature to about 20°C. In other words, the cooling system could affect the system by 5 degrees.

Also, as seen in contours, the corners of the box experience a higher temperature, and hot air is trapped within these areas. This proves the nozzle`s placement can affect the cooling system, which requires an accurate design. Moreover, two animations were extracted and will be sent as attachments.

You must be logged in to post a review.

Reviews

There are no reviews yet.