Project Outsourcing

Outsource your project to the MR CFD simulation engineering team. Our experts are ready to carry out every CFD project in all related engineering fields. Our services include industrial and academic purposes, considering the ANSYS Fluent software's wide range of CFD simulations. By outsourcing your project, you can benefit from MR CFD's primary services, including Consultation, Training, and CFD Simulation. The project freelancing procedure is as follows:

An official contract will be set based on your project description and details.

As we start your project, you will have access to our Portal to track its progress.

You will receive the project's resource files after you confirm the final report.

Finally, you will receive a comprehensive training video and technical support.

What is Chemical Engineering?

Chemical engineering is a multidisciplinary branch of engineering that combines natural and experimental sciences with life sciences (such as biology, microbiology, and biochemistry), as well as mathematics and economics, to design, develop, produce, transform, transport, operate, and manage industrial.

Many chemical engineering processes include chemical reactions, and the area takes cues from chemists seeking novel ways to make goods and research the mechanisms within chemical reactions. Chemical engineers then use this chemical information to create designs. As a result, there are two main subgroups that better answer the question “What is chemical engineering?” – to be more specific:

- Designing, constructing, and running facilities and machinery for the large-scale industrial chemical, biological, or related operations.

- Developing new or modified chemicals for a diverse range of products

Chemical engineers may specialize in one or both subgroups, but a finished product will require effort from both sides. Economic viability, resource management, health and safety, sustainability, and environmental effect will all be factors to consider.

How CFD simulation can be applied in Chemical Industries?

CFD simulation can be applied in chemical industries to analyze and optimize the design of chemical processes, such as reactors, distillation columns, and heat exchangers. CFD can be used to predict the flow of fluids, heat transfer, and chemical reactions in these processes. CFD can also be used to optimize the design of chemical plants, such as the layout of pipes and equipment, to maximize efficiency and safety. CFD can also be used to analyze the environmental impact of chemical processes, such as the release of pollutants into the atmosphere, air pollution ventilation, and combustion pollutants prediction.

CFD is widely utilized in various professions and sectors, including aerospace, chemical production, polymer processing, petroleum exploration, and medical research. Chemical engineers now routinely study and model the interaction between fluid flow and chemical processes using the power of computational fluid dynamics simulation. CFD, for example, may be applied to reactive flows, combustion and heat transfer, and mass transfer. Using CFD tools will assist a chemical engineer in better understanding physical and chemical processes, resulting in significant process and product advancements in the industry.

The use of CFD in the chemical engineering and process industries has reduced the cost of product and process development and optimization activities, shortened time to market, improved design reliability, increased conversions, and yields, and aided in the resolution of environmental, health, and right-to-operate issues. Chemical engineering CFD simulation includes models prepared for flow splits, reactor vessels, gaseous emissions, dosing points, process optimization, membrane impact, contaminated waste, and hazardous emissions. 3D modeling can confirm whether a new chemical engineering design meets objectives or examines why a poorly operating system fails.

The chemical industry is full of applications for CFD, From chemical reactors to investigate fluid flow parameters in each cell to the simulation of evaporation and condensation phenomena in different situations and to melting and solidifying fluids. Fluid dynamics are fundamental to most facets of the Chemical sector. Although real prototypes are standard for later stages of development, design, and optimization during earlier stages can be significantly accelerated with CFD studies.

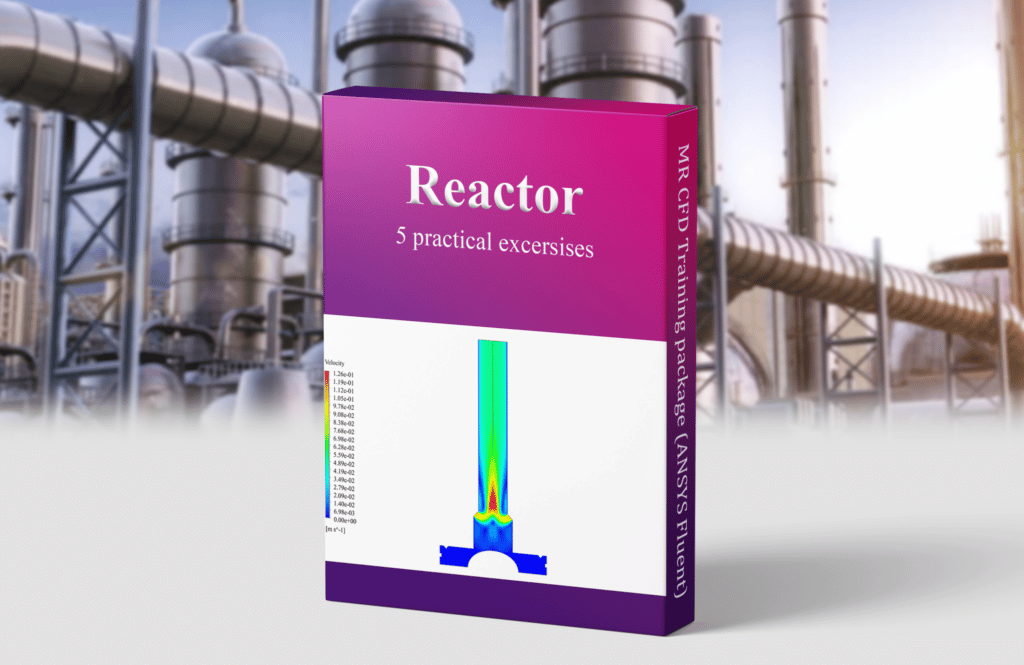

CFD on Simulating Different Reactors

CFD on Simulating Different Reactors

Computational fluid dynamics (CFD) is a powerful tool for simulating different types of reactors. It can be used to simulate the flow of fluids, heat transfer, and chemical reactions in a variety of reactors. CFD can be used to study the performance of different reactor designs, optimize the design of existing reactors, and predict the behavior of new reactor designs. CFD can also be used to analyze the safety and environmental impact of different reactor designs. CFD can be used to simulate a wide range of reactors, including chemical reactors, nuclear reactors, and biological reactors.

Reactor design includes several vital facets: Phase, or state of the reactants and products, reaction type (single, multiple, parallel series, or polymerization); whether a catalyst is involved; flow distribution and mixing; transport of the species; and mode of operation (i.e., batch, semi-batch or continuous). The underlying transport processes are crucial—fluid flow, heat transfer, mass transfer, and reactions—where CFD simulation can add substantial value.

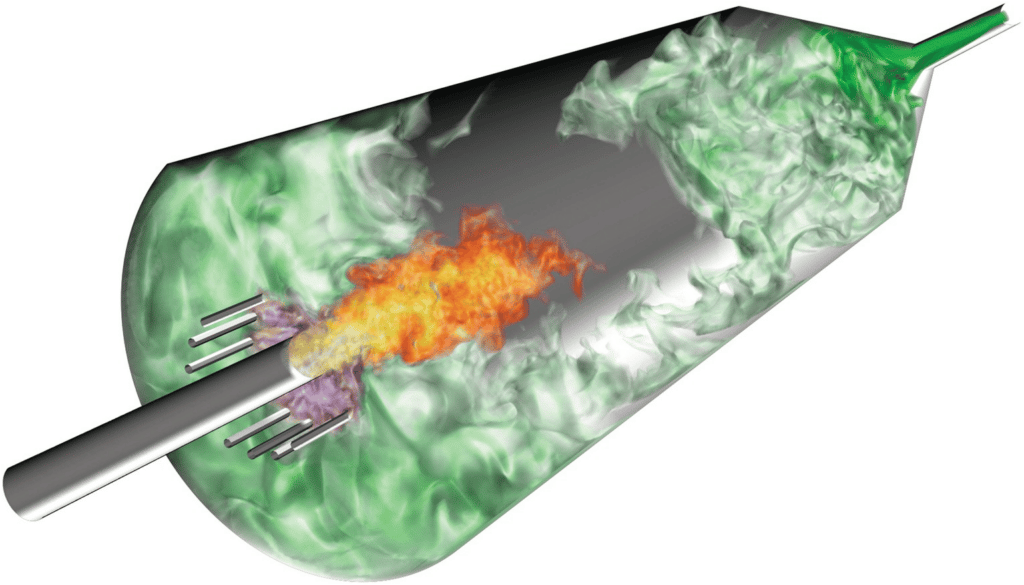

CFD to Predict pollutant in Combustion Chamber

Knowledge about the system’s fluid mechanics must be understood to simulate combustion. All transportation phenomena should be correctly represented in such models. Chemical reaction schemes must also be known to estimate the formation of combustion products and species and predict the ignition, stabilization, and extinction of flames. Radiation also occurs due to the presence of soot formed during combustion, and there is radiative heat transfer from the wall of the combustion chamber. Fuel combustion is a multiphase system, with liquid fuels being a two-phase system consisting of liquid and gas phases and solid fuel being a three-phase system. The challenges faced are to model the breaking up of the liquid fuel, its reaction, and the distribution of the reactants in three-dimensional spatial systems. These models, which form part of CFD, have become an indispensable tool for combustion modeling.

MR CFD services in the Chemical Engineering and Industries

MR CFD conducted numerous outsourced simulation projects for industrial and research Chemical Engineering applications for Beginner, Intermediate, and Advanced ANSYS Fluent users as Training Packages, each including 10 practical CFD projects. With several years of experience simulating various problems in various CFD fields using ANSYS Fluent software, we are ready to offer extensive services of Simulation, Consultation, and Training services.

MR CFD services in the chemical engineering field can include a variety of services such as:

Fluid flow analysis:

Fluid flow analysis:

This involves the use of computational fluid dynamics (CFD) to simulate and analyze the flow of fluids in a system. This can be used to optimize the design of a system, predict the performance of a system, and identify potential problems.

Heat transfer analysis:

This involves the use of CFD to simulate and analyze the transfer of heat in a system. This can be used to optimize the design of a system, predict the performance of a system, and identify potential problems.

Mass transfer analysis:

This involves the use of CFD to simulate and analyze the transfer of mass in a system. This can be used to optimize the design of a system, predict the performance of a system, and identify potential problems. MR CFd offers 2 different Mass Transfer Training Packages for both beginners and advanced ANSYS Fluent users, including 20 various mass transfers (condensation and evaporation), applied in CFD projects.

Reaction kinetics analysis:

This involves the use of CFD to simulate and analyze the reaction kinetics of a system. This can be used to optimize the design of a system, predict the performance of a system, and identify potential problems.

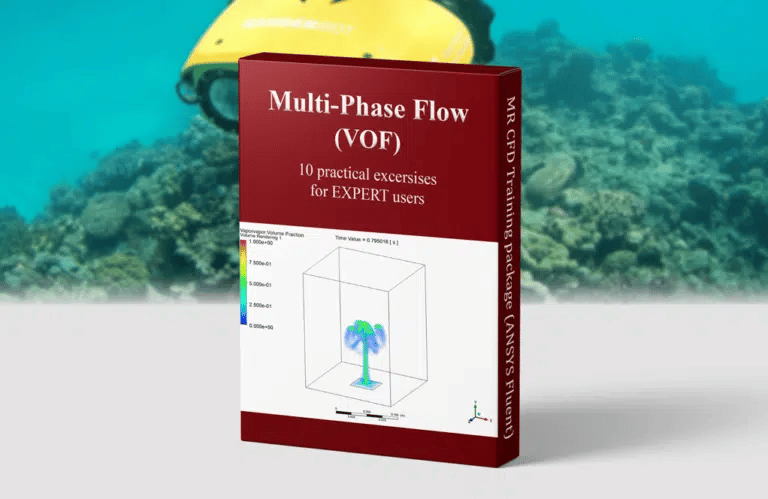

Multiphase flow analysis:

This involves the use of CFD to simulate and analyze the flow of multiple phases in a system. This can be used to optimize the design of a system, predict the performance of a system, and identify potential problems.

Volume of Fluid (VOF) Model:

The Volume of Fluid (VOF) model is a two-phase flow model that tracks the interface between two fluids. It is used to simulate the motion of a single interface between two fluids, such as air and water, or oil and water. The VOF model is based on the conservation of mass and momentum of each phase, and it can be used to simulate a wide range of two-phase flow problems, such as bubble and droplet motion, and the interaction between the two phases.

MR CFD has gathered 70 different VOF practical CFD projects in terms of Training Packages as follows:

- Volume of Fluid (VOF), Package for Beginners, Part 1

- Volume of Fluid (VOF), Package for Beginners, Part 2

- Volume of Fluid (VOF), Package for Intermediates, Part 1

- Volume of Fluid (VOF), Package for Intermediates, Part 2

- Volume of Fluid (VOF), Package for Advanced, Part 1

- Volume of Fluid (VOF), Package for Advanced, Part 2

- Volume of Fluid (VOF), Package for Experts

Eulerian Model:

The Eulerian model is a two-phase flow model that tracks the motion of two fluids in a single domain. It is based on the conservation of mass and momentum of each phase, and it can be used to simulate a wide range of two-phase flow problems, such as the interaction between two fluids, and the motion of particles in a fluid.

MR CFD has gathered 30 different VOF practical CFD projects in terms of Training Packages as follows:

- Eulerian Multiphase CFD Training Package, Beginners

- Eulerian Multiphase CFD Training Package, Intermediates

- Eulerian Multiphase CFD Training Package, Advanced Users

Mixture Model:

The Mixture model is a two-phase flow model that tracks the motion of two fluids in a single domain. It is based on the conservation of mass and momentum of the mixture, and it can be used to simulate a wide range of two-phase flow problems, such as the interaction between two fluids, and the motion of particles in a fluid. The Mixture model is more accurate than the Eulerian model, as it takes into account the effects of turbulence and viscosity on the flow.

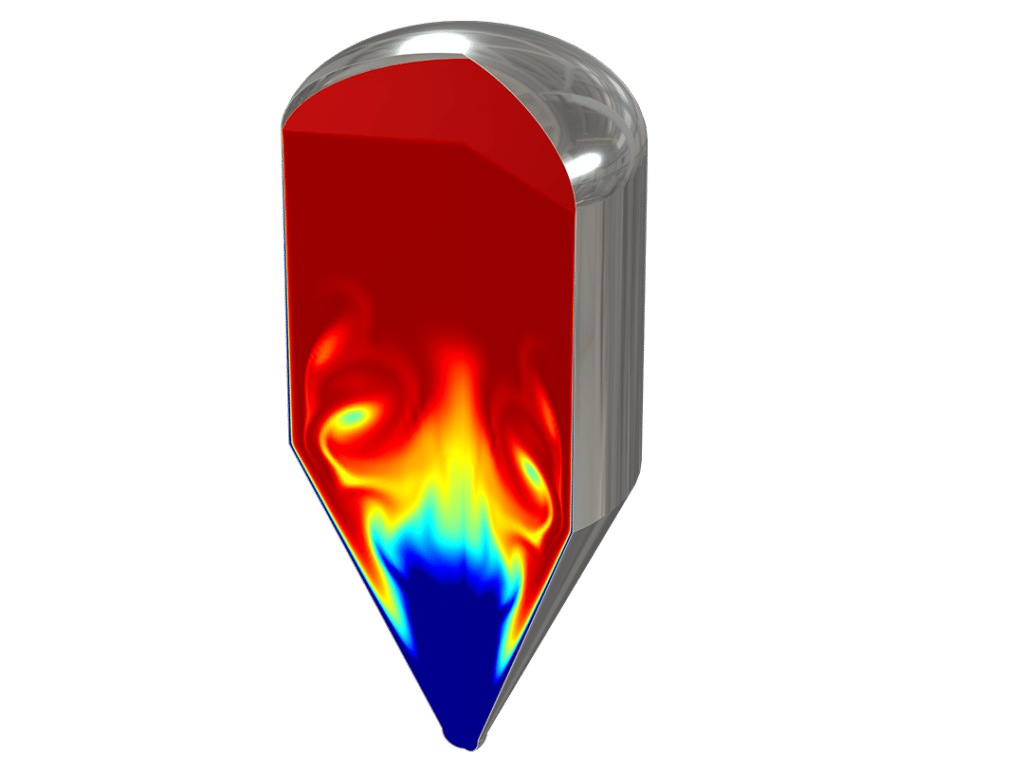

Combustion analysis:

The Combustion CFD Training course is designed to provide a comprehensive overview of the fundamentals of combustion CFD. The course covers topics such as combustion chemistry, turbulence modeling, numerical methods, and combustion CFD software. The course also includes hands-on exercises to help students gain practical experience with combustion CFD. The course is suitable for engineers and scientists who are interested in learning more about combustion CFD and its applications.

The Combustion Training Course includes:

- Introduction to combustion and an overview of available CFD simulation techniques and models in ANSYS Fluent.

- Non-premixed combustion modeling using the Eddy Dissipation

- Premixed combustion modeling using the Eddy Dissipation

- Pollution formation

- Premixed combustion modeling using the Finite rate/No TCI

- Non-premixed combustion with separate inlet boundaries for fuel and air by assuming Chemical Equilibrium among chemical reactants and products

- Non-premixed combustion inside a combustion chamber with separate inlet boundaries for fuel and air by assuming a steady diffusion flamelet

- partially-premixed combustion

- partial differential function (PDF) transport model combustion

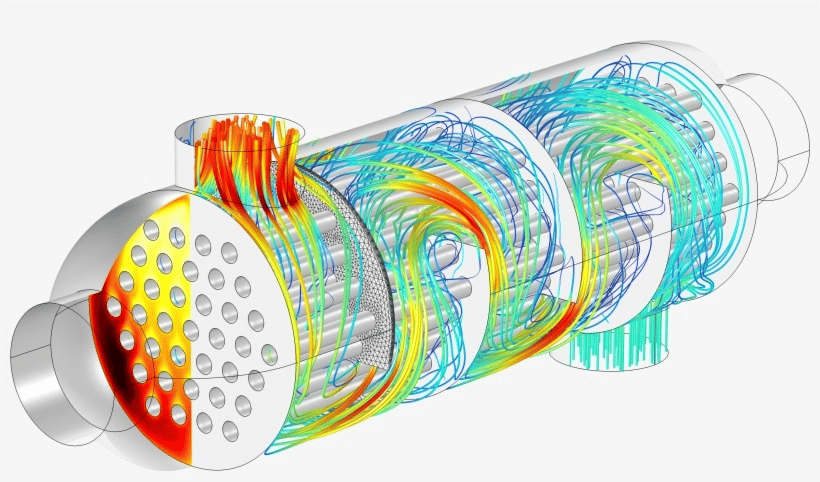

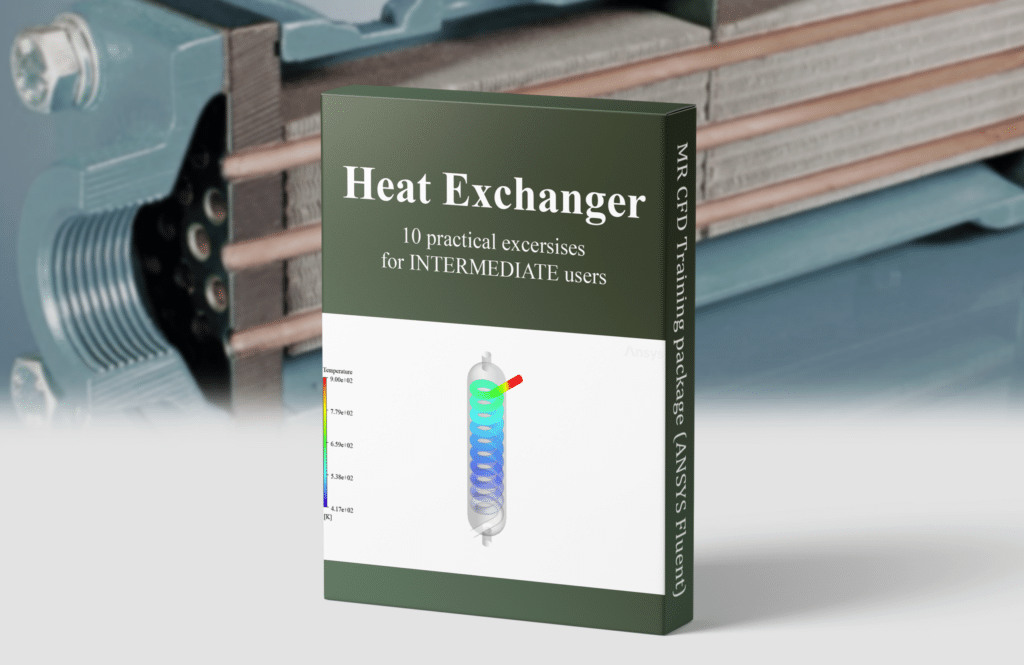

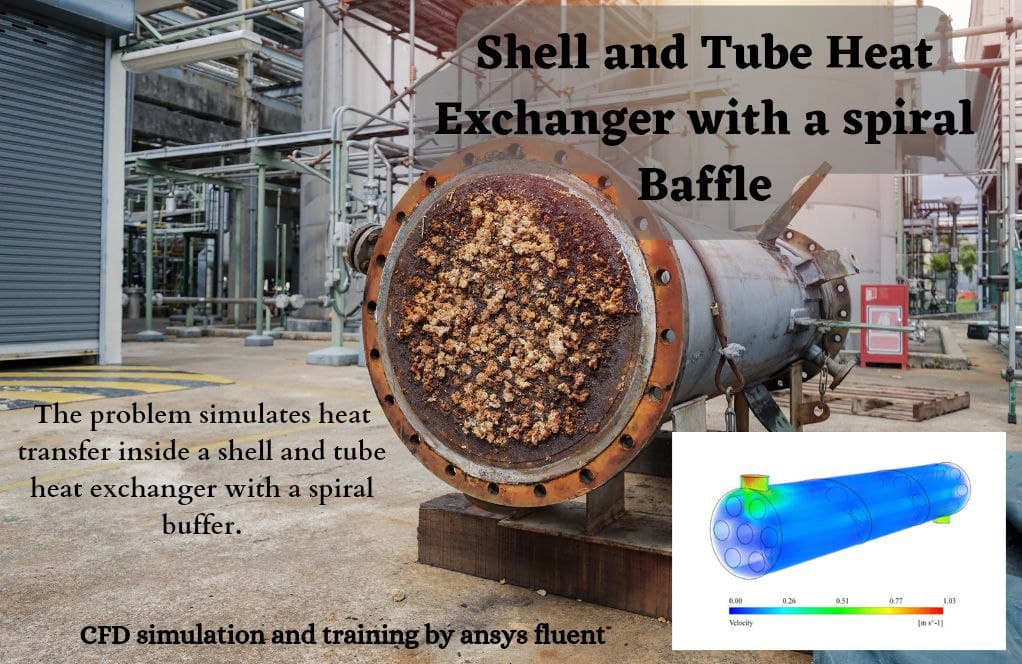

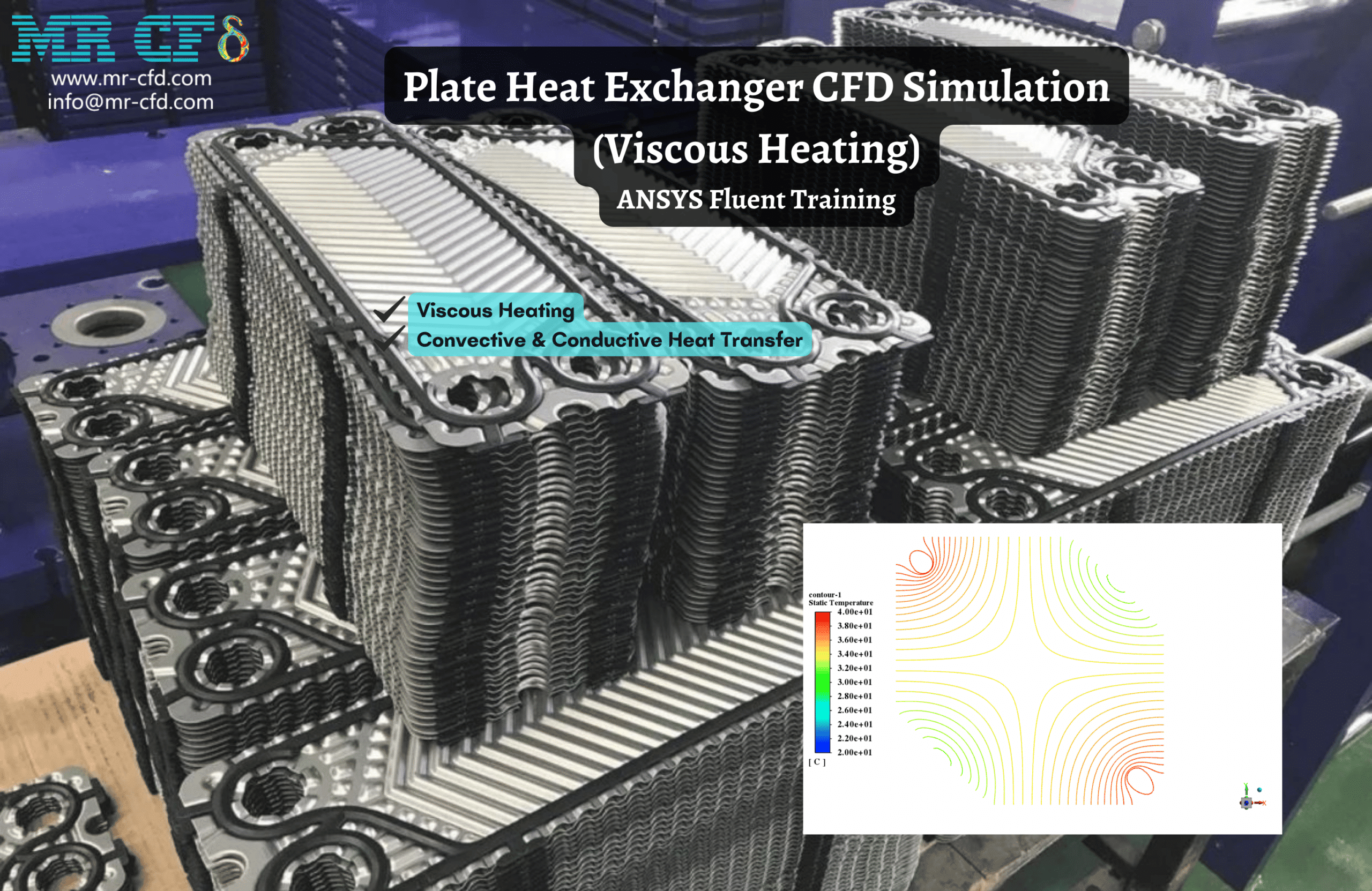

Heat Exchanger analysis:

Heat exchangers are essential components of numerous systems, including power plants, process industries, and heat recovery units. Its unavoidable requirement has required research into efficient and dependable designs, resulting in an optimum share of overall system performance.

CFD is a discipline that applies numerical analysis to solve mathematical equations to understand fluid flow, heat transport, and chemical processes. It is equally helpful in developing a heat exchanger system from the start and troubleshooting/optimization by offering design changes. CFD works on the simple principle of dividing the entire system into small cells or grids and applying governing equations to these discrete elements to find numerical solutions for pressure distribution, temperature gradients, flow parameters, and the like in less time and at a lower cost due to less required experimental work. The CFD findings are of acceptable quality.

In the MR CFD heat exchanger training package, we will study different kinds of Heat Exchangers for all users at beginner, intermediate, and advanced levels.

Beginner:

ANSYS Fluent Tutorials: This package provides a comprehensive set of tutorials to help beginners learn the basics of ANSYS Fluent. It covers topics such as setting up a simulation, meshing, boundary conditions, and post-processing.

- Heat Exchangers with Inner Fins

- Vertical Heat Exchanger

- Shell and Helical Tube Heat Exchanger

- Vertical Shell and Spiral Tube Heat Exchanger

- Finned Shell and Tube Heat Exchanger

- Finned Tube Heat Exchanger

- Double Pipe Heat Exchanger

- Plate Heat Exchanger

Intermediate:

Heat Exchanger CFD Simulation Training with ANSYS Fluent: This package provides an in-depth look at the fundamentals of heat exchanger CFD simulation using ANSYS Fluent. It covers topics such as setting up a simulation, meshing, boundary conditions, and post-processing.

- Conjugated Heat Transfer (CHT) in Heat Exchangers

- Horizontal Shell and Tube Heat Exchanger

- Vertical Shell and Tube Heat Exchanger

- Finned Tube Heat Exchanger

- Triple Heat Exchanger

Advanced:

Advanced Heat Exchanger CFD Simulation Training with ANSYS Fluent: This package provides an advanced look at the fundamentals of heat exchanger CFD simulation using ANSYS Fluent. It covers topics such as setting up a simulation, meshing, boundary conditions, and post-processing.

- Shell and Tube Heat Exchanger

- Triplex Tube Heat Exchanger

- Finned Tube Heat Exchanger

- Double Pipe Heat Exchanger

- Porous Heat Exchanger

- Solar Heat Exchanger

- Plate Heat Exchanger

Numerical simulation of chemical reactions:

Reaction engineering is a chemical engineering discipline that deals with designing and optimizing chemical reactors. The purpose is to optimize the transport processes (heat transfer, mass transfer, and mixing) to increase the yield/conversion of desired products while ensuring the reactor’s safety. This implies maximizing yield while decreasing expenditures. These expenses might be connected to feedstock, energy input, heat removal or cooling, stirring or agitation, pumping to increase pressure, frictional pressure loss, etc.

From computational fluid dynamics, reaction engineering applies transport phenomena and chemical kinetics knowledge to industrial systems.

Combustion Analysis:

In the combustion training package, we will study different kinds of Combustion CFD projects (30 practical CFD analyses) for all users at beginner, intermediate, and advanced levels.

MR CFD offers a variety of training packages for users of all levels. For beginners, we offer a training package. This course covers the basics of CFD, including the fundamentals of fluid flow, turbulence, and combustion. For intermediate users, we offer a training package. This course covers more advanced topics such as multiphase flow, reacting flow, and combustion. Finally, for advanced users, MR CFD offers another training package. This course covers topics such as advanced turbulence modeling, advanced combustion modeling, and advanced multiphase flow modeling.

Solidification and Melting CFD simulation:

This CFD training package is prepared for beginner, intermediate, and advanced users of ANSYS Fluent software who are interested in the Solidification & Melting modules, including 10 practical exercises. You will learn and obtain comprehensive training on how to simulate projects. The achieved knowledge will enable you to choose the most appropriate modeling approaches and methods for applications and CFD simulations.

This training package is designed to provide an introduction to the fundamentals of CFD simulation of solidification and melting processes. It covers the basics of CFD simulation, including governing equations, numerical methods, and boundary conditions. It also covers the application of CFD to solidification and melting processes, including the modeling of heat transfer, fluid flow, and phase change material (PCM). The package includes a series of tutorials and exercises that will help the user gain a better understanding of the principles and techniques involved in CFD simulation of solidification and melting processes. The package also includes a set of sample problems that can be used to practice and apply the concepts learned in the tutorials.

Chemical Engineering MR CFD Projects

With several years of experience in simulating various problems in different CFD fields using ANSYS Fluent software, the MR CFD is ready to offer extensive modeling, meshing, and simulation services. Following is a brief list of the CFD simulation projects for Chemical Engineering by MR CFD:

Species Transport Model

The Species Transport training package is designed to provide users with the necessary skills and knowledge to effectively use ANSYS Fluent for species transport modeling. The package includes tutorials and exercises that cover the fundamentals of species transport modeling, as well as more advanced topics such as turbulence modeling, boundary conditions, and post-processing. The package also includes a comprehensive set of reference materials and resources to help users become proficient in using ANSYS Fluent for species transport modeling. MR CFD presents 50 various applications of the species transport model in terms of 5 training packages. These training packages are as follows:

- Beginner users part 1

- Beginner users part 2

- Intermediate users part 1

- Intermediate users part 2

- Advanced users

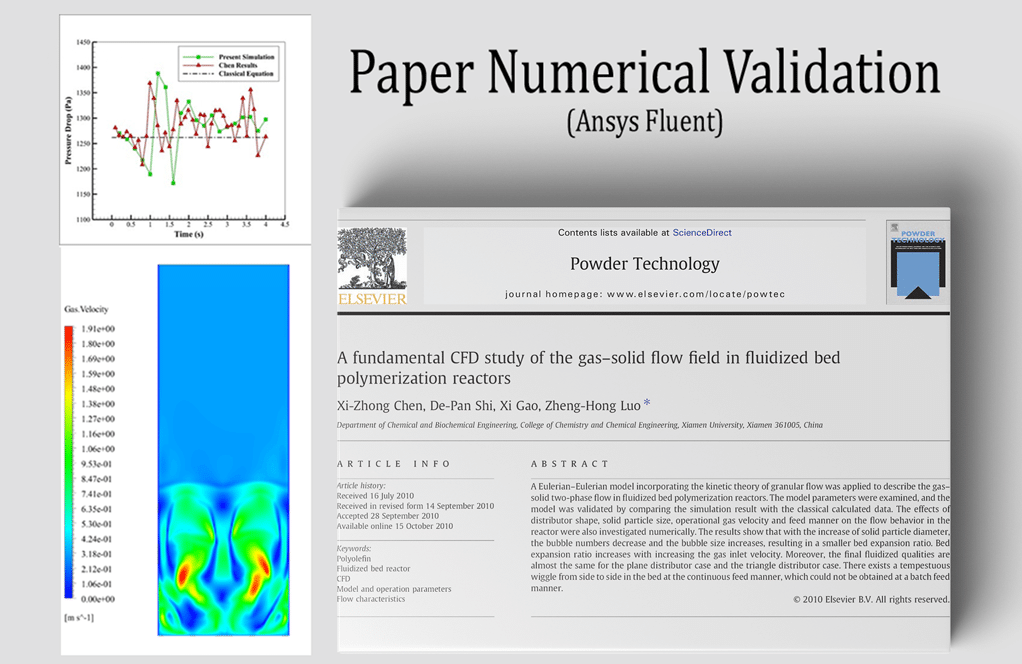

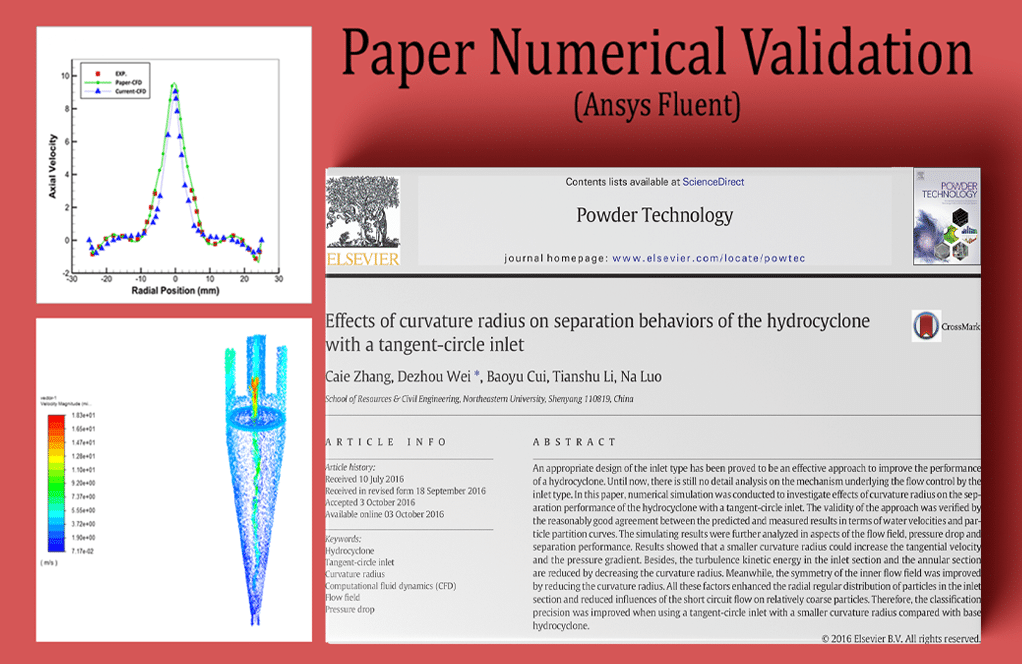

Modeling of a Gas-Solid Fluidized Bed Reactor

This simulation is about a fluidized bed polymerization reactor via ANSYS Fluent software. We perform this CFD project and investigate it by CFD analysis. The results are compared and validated with a paper called “A fundamental CFD study of the gas-solid flow field in fluidized bed polymerization reactors.”

CFD modeling of a gas-solid fluidized bed reactor is a powerful tool for understanding the behavior of the reactor and optimizing its performance. CFD models can be used to simulate the hydrodynamics of the reactor, including the flow of the gas and solid particles, the heat transfer, and the chemical reactions. The model can also be used to predict the performance of the reactor under different operating conditions. CFD models can be used to optimize the design of the reactor, such as the size and shape of the bed, the gas flow rate, and the operating temperature. CFD models can also be used to analyze the effects of different operating parameters on the performance of the reactor, such as the particle size distribution, the gas flow rate, and the operating temperature.

Simulation of a Gas-Liquid Reactor

CFD simulation of a gas-liquid reactor can be used to study the flow of the gas and liquid phases in the reactor, as well as the chemical reactions that occur between them. The simulation can be used to analyze the performance of the reactor, such as the temperature, pressure, and concentration profiles of the reactants and products. It can also be used to optimize the design of the reactor, such as the size and shape of the reactor vessel, the type of catalyst used, and the operating conditions. CFD simulation can also be used to study the effects of different operating parameters on the reactor performance, such as the flow rate, temperature, and pressure.

Modeling of a Catalytic Reactor

The present problem simulates the flow inside a Catalytic Reactor using ANSYS Fluent software. We perform this CFD project and investigate it by CFD analysis. We simulate the flow inside a catalytic reactor using ANSYS Fluent software. In the internal structure of this reactor, compressed air is mixed with the fuel spray into the reactor and the catalyst material to cause the reaction.

CFD modeling of a catalytic reactor is a powerful tool for understanding the complex chemical and physical processes that occur in a catalytic reactor. CFD modeling can be used to simulate the flow of reactants, products, and catalysts through the reactor, as well as the heat transfer and chemical reactions that occur. CFD modeling can also be used to optimize the design of the reactor, such as the size and shape of the catalyst bed, the flow rate of reactants, and the temperature and pressure of the reaction. CFD modeling can also be used to predict the performance of the reactor under different operating conditions, such as different reactant concentrations, temperatures, and pressures.

Simulation of a Membrane Separation Process

Reverse osmosis CFD Simulation using ANSYS Fluent software is the subject of this simulation. Fluid has a tendency to migrate from a solution with a lower concentration to one with a greater concentration until the concentration on both sides is balanced, as demonstrated by the natural phenomenon known as osmosis. Imagine that pure and impure water is separated by a semi-permeable membrane.

The performance of a membrane separation system can be evaluated using CFD simulation of a membrane separation process. The feed and permeate streams’ flow rate, pressure drop, and concentration may all be calculated using the simulation. Additionally, it can be used to examine how various operational factors, like temperature, pressure, and feed concentration, affect the performance of the membrane. Additionally, the simulation can be utilized to maximize the efficiency of the membrane system’s design.

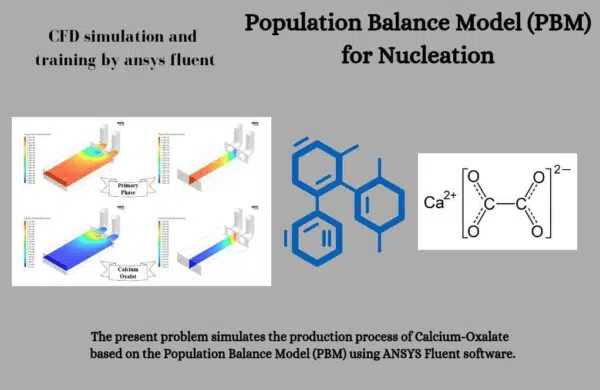

Population Balance Model (PBM) CFD Simulation

Population Balance Model (PBM) CFD Simulation

The creation, growth, and displacement of production particles are used to examine the PBM in this project after the calcium-oxalate manufacturing process is initially modeled (Nucleation).

A numerical method for simulating particle behavior in a fluid is the Population Balance Model (PBM) CFD simulation. In a range of fields, including aerosol science, chemical engineering, and environmental engineering, it is used to examine the movements of particles. The population balance equation, a mathematical formula that depicts how the quantity of particles in a system changes over time, serves as the foundation for the PBM CFD simulation. Particle size distribution, velocity, and interactions with other particles and the surrounding fluid are all predicted using the PBM CFD simulation. The effects of turbulence on particle mobility and cluster formation can also be studied using the PBM CFD simulation.

Modeling of a Distillation Column

The current issue uses the ANSYS Fluent program to simulate the two-phase flow of air and water in a distillation column tray. The separation of the material happens in tray towers. A tray distillation tower works by having a liquid stream enter the chamber from the upper half of the chamber through a large aperture while hot, rising steam enters the room from the lower section of the chamber through multiple small holes and flows upwards. This causes the air vapor and liquid flow to collide on one or more trays inside the chamber.

A distillation column’s behavior can be better understood and its performance can be optimized with the use of CFD modeling. The flow of fluids through the column, the exchange of heat and mass between the fluids and the column’s walls, and the flow of fluids through the column may all be simulated using CFD modeling. The performance of the column can be studied using CFD modeling to determine how various operating conditions affect them. CFD modeling can be used to optimize the column’s design, increase the column’s effectiveness, and lower the cost of operation.

Simulation of a Gas-Solid Separation Process

This product is a simulation of Cyclone by DPM using ANSYS Fluent software. We carry out this CFD project and do a CFD analysis to look at it. One of the most popular industrial devices for dewatering air, removing dust, or separating solid particles from the gas flow is the cyclone. Without the use of filters, these systems separate solid particles from gas flows using centrifugal and gravitational forces. Cyclones are used to return solid particles to the production cycle in addition to lowering air pollution. For example, cement, wood, and other industries frequently use these systems to create suspended solid particles.

A gas-solid separation process can be simulated using CFD simulation. This kind of simulation can be used to examine how gas and solid particles move through a cyclone separator or other form of separation equipment. The efficiency of the separation procedure and the pressure drop across the device can both be assessed using the simulation. By altering the shape and operating parameters to enhance the efficiency of the separation process, the simulation can also be used to optimize the device’s design.

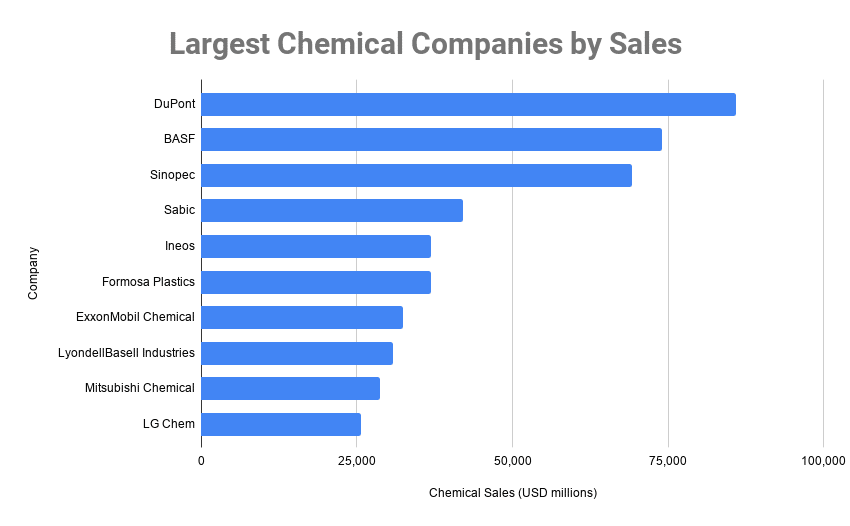

Chemical Industrial Companies

Chemical industrial companies are responsible for the production of a wide range of products, from everyday household items to industrial chemicals. These companies are responsible for the production of a variety of products, including plastics, paints, adhesives, detergents, and fertilizers. They also produce specialty chemicals for use in the medical, automotive, and aerospace industries. Chemical industrial companies are essential to the global economy, as they provide the raw materials needed to create a variety of products.

The pioneer Chemical companies that apply CFD simulations are:

BASF

Dow Chemical

DuPont

AkzoNobel

Solvay

Evonik

Air Products

Eastman Chemical

Huntsman

LyondellBasell

MR CFD Industrial Experience in the Chemical Field

Following are two examples of Chemical industrial projects that are recently simulated and analyzed by MR CFD in cooperation with related companies.

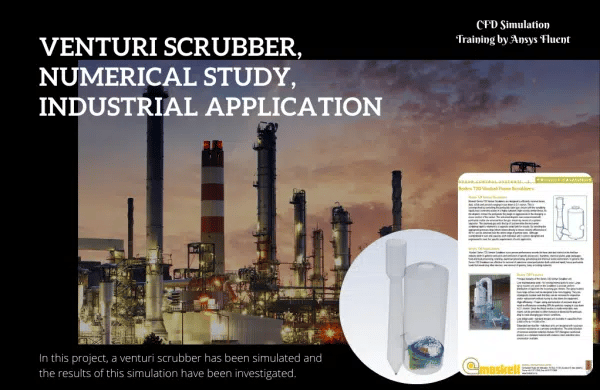

Venturi Scrubber, Numerical Study, Industrial Application

- In this project, the performance of an industrial 720-2 series venturi scrubber is numerically investigated by ANSYS Fluent.

- Studying the removal of sand particles

- Using a two-way Discrete Phase Model (DPM) & VOF multiphase model

- The simulation is performed in Transient.

A numerical study of a venturi scrubber is a computational fluid dynamics (CFD) simulation that can be used to analyze the performance of a venturi scrubber in an industrial application. The simulation can be used to determine the efficiency of the scrubber in removing pollutants from the air, as well as the pressure drop across the scrubber. The simulation can also be used to optimize the design of the scrubber for a particular application.

The CFD simulation can be used to analyze the flow of air through the scrubber, including the velocity, pressure, and temperature of the air.

The CFD simulation can be used to analyze the performance of the scrubber in terms of the removal efficiency of pollutants, as well as the pressure drop across the scrubber.

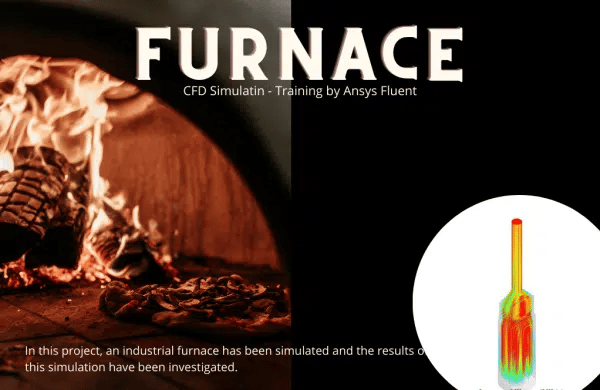

Furnace, Numerical Study, Industrial Application

Furnace, Numerical Study, Industrial Application

- The problem numerically simulates Furnace using ANSYS Fluent software.

- We design the 3-D model with the Design Modeler software.

- We Mesh the model with ANSYS Meshing software, and the element number equals 7800000.

- We use the Species Transport model to define the combustion reaction between methane and air.

The use of numerical simulations in industrial applications is becoming increasingly popular. Computational Fluid Dynamics (CFD) simulations are used to study the performance of furnaces, such as those used in the steel and aluminum industries. CFD simulations can be used to analyze the flow of air and heat within the furnace, as well as the temperature distribution and the effects of different operating parameters. This can help to optimize the design of the furnace and improve its efficiency. CFD simulations can also be used to study the effects of different fuel types and operating conditions on the performance of the furnace. Additionally, CFD simulations can be used to study the effects of different materials and insulation on the performance of the furnace. This can help to reduce energy consumption and improve the safety of the furnace.

MR CFD conducted numerous outsourced CFD simulation projects for industrial companies and research in Chemical Engineering applications. With several years of experience simulating various problems in various CFD fields using ANSYS Fluent software, the MR-CFD team is ready to offer extensive services of CFD Simulation, Training, and Consultation.

You may find the learning products in the Chemical Engineering CFD simulation category in Training Shop. You can also benefit from Chemical Engineering training packages appropriate for Beginner, Intermediate, and Advanced users of ANSYS Fluent. Also, MR CFD is presenting the most comprehensive Chemical Engineering Training Course for all ANSYS Fluent users from Beginner to Experts.

Our services are not limited to the mentioned subjects, and the MR CFD is ready to undertake different and challenging projects in the Chemical Engineering modeling field ordered by our customers. We even carry out CFD simulations for any abstract or concept design you have in your mind to turn them into reality and even help you reach the best design for what you may have imagined. You can benefit from MR CFD expert consultation for free and then outsource your Industrial and Academic CFD project to be simulated and trained.

By outsourcing your project to MR CFD as a CFD simulation consultant, you will not only receive the related project’s resource files (Geometry, Mesh, Case & Data, …), but also you will be provided with an extensive tutorial video demonstrating how you can create the geometry, mesh, and define the needed settings(pre-processing, processing, and post-processing) in the ANSYS Fluent software. Additionally, post-technical support is available to clarify issues and ambiguities.