Project Outsourcing

Outsource your project to the MR CFD simulation engineering team. Our experts are ready to carry out every CFD project in all related engineering fields. Our services include industrial and academic purposes, considering the ANSYS Fluent software's wide range of CFD simulations. By outsourcing your project, you can benefit from MR CFD's primary services, including Consultation, Training, and CFD Simulation. The project freelancing procedure is as follows:

An official contract will be set based on your project description and details.

As we start your project, you will have access to our Portal to track its progress.

You will receive the project's resource files after you confirm the final report.

Finally, you will receive a comprehensive training video and technical support.

What is Marine Engineering?

A marine engineer is responsible for operating, maintaining, and repairing all major mechanical and engineered equipment onboard a ship after studying marine engineering (also known as maritime engineering). Propulsion mechanics, electrical and power generating systems, lubrication, fuel systems, water distillation, lighting, and air conditioning systems are just a few of the mechanical systems that aid in running any vessel.

People who have studied marine engineering (maritime engineering) are responsible for various tasks, including Mechanical system monitoring and maintenance. Each engineer on board is assigned specialized machinery and procedures for maintenance and monitoring. All engineers are responsible for their machinery systems, and each engineer must ensure that their equipment is operational. Marine engineers are also responsible for the maintenance of the deck machinery. Proper record-keeping and maintenance planning — The engine room department works together to ensure that the maintenance plan maintains all mechanical systems.

Marine engineering is a type of engineering that deals with designing, building, operating, and maintaining ships, boats, underwater buildings, and other vessels and structures that are used in the water. Marine engineers are in charge of making sure that these ships and buildings are safe, effective, and good for the environment.

Marine engineering is a broad field that includes marine design, mechanical engineering, electrical engineering, and materials science, among many others. Marine engineers work on a wide range of projects, from designing new ships and offshore platforms to keeping and fixing ships and platforms that are already in use.

– Designing and building ships: Marine engineers work on designing and building new ships and boats, making sure they are seaworthy, efficient, and safe.

– Propulsion systems: Marine engineers are in charge of developing and operating the engines, blades, and other parts that make ships and boats move.

– Electrical systems: Marine engineers also work on ships and boats’ engines, distribution systems, and control systems, which are all parts of the electrical systems.

– Safety and the environment: It is the job of marine engineers to make sure that ships and boats meet safety and environmental standards, such as rules about preventing pollution and having the right safety gear.

Overall, marine engineering is a difficult and fulfilling job that requires a strong understanding of engineering concepts and an appreciation for the unique challenges and opportunities that the marine environment offers.

How can CFD simulation be applied in Marine Engineering Industries?

In today’s rapidly growing digital technology age, it’s critical to figure out how to apply it to the challenging ship design process. Computational Fluid Dynamics (CFD) has become an appealing method for getting important insight into the hydrodynamic properties of surface vessels, riding the tide of fast advances in High-Performance Computing. CFD, especially RANS-based CFD approaches, uses Navier-Stokes equations to simulate fluid flow while accounting for its nonlinear character. In terms of physical modeling, it is a comprehensive approach that allows very little chance. This makes it extremely precise and accurate, but it also makes it computationally costly compared to typical engineering tools. It also necessitates the employment of a highly qualified individual.

Computational Fluid Dynamics (CFD) is a flexible and powerful engineering technique that may provide new levels of detail for various flow phenomena. There is also open-source CFD software available; however, it is difficult to use and requires a specialized user. However, more and more organizations are now offering consulting services that include simulations for design firms. This is a fantastic setup, and it fits in perfectly with the concept of work division. The cost, quality, and speed of these services are all improving, and they’re now where they may be employed in the early stages of design.

To mention a few, extreme wave impacts, green sea loads, slamming, sloshing, seakeeping, flooding, coarse-keeping, and maneuvering. The method’s universality is the quality of CFD that permits it to be employed in such a wide variety of applications. At its most basic level, CFD makes no assumptions regarding the flow phenomena in question, such as wave steepness assumptions, single-valued free-surface elevation, irrotational flow, tiny changes in the wetter surface of the hull, and so on. As a result, the approach may be used to solve a wide range of issues.

Simulation of CFD (Computational Fluid Dynamics) is a useful tool that can be used in many naval engineering fields. Here are some ways that marine engineering can use CFD simulation:

– Wave loads and motions: CFD modeling can be used to figure out how waves affect ships and buildings in offshore waters. This can help builders make buildings that can stand up to the forces of waves and currents.

– Offshore wind farms: CFD modeling can be used to study how wind affects offshore wind blades and the structures that hold them up. This can help builders make buildings that can stand up to the forces of wind and water.

– Marine energy systems: CFD modeling can be used to test the performance of marine energy systems like tidal mills and wave energy exchangers. This can help engineers improve the way these systems work and make more energy by making them more efficient.

– CFD on Simulation of Towing Tanks:

Towing tanks have given naval architects a dependable way of estimating a ship’s performance at sea since the first commercial ship basin was commissioned in 1883. Towing tanks are utilized for both resistance and propulsion testing. Self-propelled ship models are used to establish how much power the engine will need to deliver to attain the speed specified in the shipyard-shipowner contract. Chemical reactors may be designed using CFD fluid-flow patterns and temperature fields and can be approximated using numerous conservation equations relating to fluid motion and energy.

By offering a more refined and efficient design that requires fewer revisions to satisfy contractual commitments, CFD simulation may be utilized to decrease the volume and expense of physical towing tank testing. It’s also true that towing CFD has completely replaced tanks in some areas of the business, like the design of high-performance vessels competing in America’s Cup.

Prediction methods are constantly being developed and refined to account for the impact of waves on power-speed estimates and the consequent propulsion-related energy consumption. The capacity to handle variable shapes and precise information about the near and far flow fields would greatly aid in improving the hull for a more efficient or novel design.

Overall, CFD modeling is a strong tool that can help marine engineers make ships, offshore buildings, and marine energy systems that work better and are more efficient. By modeling how fluids behave in marine settings, engineers can learn more about how water, air, and structures interact with each other. With this knowledge, they can improve the design and performance of marine systems.

MR CFD services in the Marine Engineering Industries

MR CFD conducted numerous outsourced simulation projects for industrial and research Marine Engineering applications. With several years of experience simulating various problems in various CFD fields using ANSYS Fluent software, MR CFD is ready to offer extensive services of simulation configurations.

CFD (Computational Fluid Dynamics) services are widely used in the marine engineering industry to help engineers and planners improve the performance of ships, offshore buildings, and marine energy systems. Here are some of the most popular CFD services used in the marine engineering industry:

– Hull and Submarine Design optimization

CFD services can be used to improve the shape and form of a ship’s hull, including the placing of parts like rudders and propellers. This can help cut down on drag and make the car use less gas. This simulation is about optimizing the design of a submarine using the adjoint solver (RBF Method) and the software ANSYS Fluent. When a structure moves at a certain speed through a continuous fluid, the fluid pulls on its body. For instance, when a submarine goes through water, the sea exerts forces on the body of the submarine. The pull force is an important force to study.

This force is put on the body of the submarine horizontally and in the opposite direction of how the submarine is moving. So, this force makes it harder for the submarine to move. Because of this, this study looked into the drag force on the submarine. When designing and building subs, the drag force must be taken into account. Depending on the shape and size of the submarine, the drag force can be decreased or increased.

With the planning process, the CFD study of the drag force on the submarine is used to find a good shape. There are many ways to make a body shape better. For geometric optimization, the ANSYS Fluent program uses a tool called an adjoint solver. By using a solution method, this tool can make changes to the measurements of the goal geometry. These changes keep happening until the best shape is found.

In this scenario, the drag force is reduced by using an optimization process based on an adjoint solver. With the adjoint solver tool, the optimization process is done in three steps. First, the modeling was done in normal mode with Ansys Fluent software and a simple shape for a submarine.

In this setting, the drag force is worked out. In the second step, a goal value is set up and the adjoint solution is used. (drag force). The adjoint solution figures out which parts of the shape of the submarine are most affected by how much drag force there is. With this work, you can figure out which changes to geometry in which parts of geometry lead to geometrical improvement. In the third step, the process of optimization was done based on a set percentage to lower the goal value. (drag force).

– Propulsion system analysis of a boat propeller

CFD services can be used to look at how well the engine, propeller, and rockets work in a ship’s propulsion system. This can help engineers improve the design of these parts to make them work better and use less fuel. In this project, ANSYS CFX software is used to model the steady spinning of a Boat Propeller.

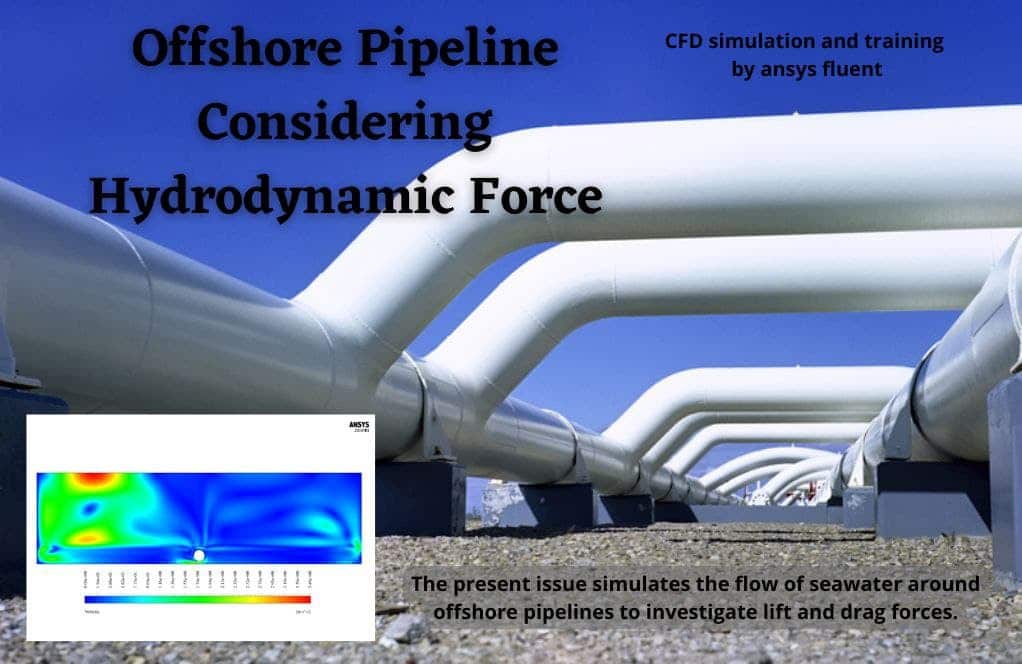

– Structural analysis of offshore pipelines

CFD services can be used to figure out how waves and currents affect oil pipes. This information can help builders make buildings that can stand up to the forces of the sea. ANSYS Fluent software is used to model the flow of seawater around offshore pipes in this case. We do this CFD job and use CFD research to look into it. The pull and lift forces are caused by the movement of ocean waves on offshore pipes. So, these communication pipes must be put in the best place possible to be able to withstand less hydrodynamic forces.

Since seawater moves in waves, you have to use the UDF to describe the input motion as an equation of wave flow. Also, the pressure inside seawater is related to the pressure outside, and the pressure changes as the saltwater moves with waves. So, we use the calculation for the pressure of the air around the wave, which is called the UDF.

In the software, the UDF is used to describe all functions that have to do with the horizontal speed of the entering water flow, the relative wave pressure, the turbulent kinetic energy, and the rate at which the turbulent energy is lost. The goal of this project is to compare the pressure of water on the pipeline over one sea wave time. We do this process to get to the best possible state.

– Analysis of Water Turbine as marine energy systems

CFD services can be used to look at how well marine energy systems like tidal Turbines and wave energy generators work. This can help engineers improve the way these systems work and make more energy by making them more efficient. This training package has 10 different CFD modeling projects for different kinds of Water Turbines that use the ANSYS Fluent program. (Horizontal Axis & Vertical Axis). MR-CFD recommends this package to engineers who are interested in Renewable Energy, especially turbine research. This package shows you how to build and model different kinds of water turbines, taking into account a wide range of related numerical studies.

First, start the training package by validating two papers about a lift-based in-pipe water turbine using the mesh motion method and the performance of a horizontal axis tidal current turbine by blade design using CFD modeling. After making sure our Computational Fluid Dynamics method works, we look at different types of well-known water turbines (Darrieus, Pelton Wheel, Archimedes Screw Turbine (AST), Water Wheel, Kaplan, Francis Turbine, etc.) using different CFD methods (Moving Mesh, Frame Motion (MRF), Fluid Solid Interaction (FSI), Dynamic Mesh, Cavitation, Multiphase VOF model) and different turbine configurations. By studying this great and useful training package, you can say you are an expert at modeling and understanding every CFD simulation related to water turbines and their uses. Then you’ll be ready to work as a CFD engineer in those fields.

– Environmental effect of Sub-Oceanic Volcanic Activity assessment:

CFD services can be used to model how pollutants, like oil spills or wastewater release, move through the sea environment. This can help figure out how marine actions affect the world and help make decisions. This project looks into the volcanoes that happen under the seas. The explosions that happen below the top of the water can be used in different ways in oceanography and ocean engineering. Predicting how the seas will act can be very useful. Predicting how the waves will act in such extreme conditions can give meteorologists and weather forecasters a lot of information and help stop natural disasters like tsunamis.

Overall, CFD services are a useful tool for marine engineers and designers because they show how water, air, and buildings in the marine world interact with each other.

MR CFD is ready to offer extensive modeling, meshing, and simulation services. Our essential simulation services for Marine engineering simulations are categorized as follows:

- CFD Simulation of air conditioning inside the ship’s engine room

- Dynamic mesh simulation of submarines

- CFD Simulation of open channel flow (boats, ships, and submarines)

- FSI analyses of different floating objects

- Simulation of robot swimmers

Marine Engineering MR CFD Projects

There are several MR CFD simulation projects in Marine engineering. Following are some examples of CFD simulation projects:

FSI Method for Water Turbine

This study aims to investigate the water flow around a vertical water turbine with unsteady CFD simulation using ANSYS Fluent software. The study assumes that the turbine blades are affected by the passing fluid flow, which causes deformation or resizing of the turbine body. Therefore, the problem involves both fluid and solid solutions simultaneously, and the FSI method and coupling between the fluid flow and Transient Structural are used.

Introduction

The Fluid-Structure Interaction (FSI) method is commonly applied in simulating water turbines to account for the interaction between fluid flow and the solid structure of the turbine. ANSYS Fluent is a popular software for Computational Fluid Dynamics (CFD) used in FSI simulations.

ANSYS Fluent CFD Simulation Training

– ANSYS Fluent Introduction

– Fundamentals of Fluid Mechanics and CFD

– Mesh Generation

– Boundary Conditions

– Turbulence Modeling

– FSI Modeling

FSI Method for Water Turbine

The FSI method is highly beneficial in simulating water turbines as it accurately predicts the turbine’s performance and structural integrity. By simulating the interaction between fluid flow and the solid structure of the turbine, engineers can optimize the design and ensure safe and efficient turbine operation. The FSI method can be used to simulate various types of water turbines, including:

– Francis Turbines

– Pelton Turbines

– Kaplan Turbines

Conclusion

The FSI method and ANSYS Fluent CFD Simulation Training are valuable tools for engineers involved in water turbine design and optimization. By utilizing these tools, engineers can simulate the complex interaction between fluid flow and solid structures, leading to safer and more efficient designs.

VAWT & HAWT

Vertical Axis Water Turbine (Darrieus) by Dynamic Mesh

This study aims to simulate the water flow around a vertical axis water turbine (VAWT) submerged in water using the Dynamic Mesh method in ANSYS Fluent software. The Darrieus VAWT is a type of water turbine that operates efficiently at low water speeds, making it ideal for use in low-head hydropower systems. To simulate the performance of a Darrieus VAWT, ANSYS Fluent software is used, which requires a strong understanding of the software and its capabilities. ANSYS Fluent Training provides a comprehensive overview of the software and its applications in Darrieus VAWT simulations, covering topics such as fluid mechanics, mesh generation and dynamic mesh. Simulating the performance of a Darrieus VAWT using ANSYS Fluent requires the use of Dynamic Mesh to simulate the rotation of the turbine blades, and the FSI method to account for the interaction between the fluid flow and the solid structure of the turbine blades. The simulation can be used to optimize the design of the Darrieus VAWT, ensuring that it operates efficiently and safely, and to predict the power output of the turbine under different flow conditions. In conclusion, the Darrieus VAWT, Dynamic Mesh, and ANSYS Fluent Training are valuable tools for engineers in the hydropower field, enabling them to simulate the performance of the Darrieus VAWT, optimize its design, and ensure safe and efficient operation.

Horizontal Axis Water Turbine

Water turbines are machines that convert the energy of flowing or falling water into mechanical energy that can be used to generate electricity. Horizontal Axis Water Turbines (HAWT) have a horizontal rotor shaft and blades that rotate around a vertical axis. To simulate the performance of a HAWT, ANSYS Fluent CFD software can be used. ANSYS Fluent Training covers various topics, including fluid mechanics, mesh generation, boundary conditions, turbulence modeling, multiphase flows, and MRF.

MRF (Multiple Reference Frame) is a technique used to simulate rotating machinery in CFD simulations. In the case of HAWTs, MRF can be used to simulate the rotation of the turbine blades. The simulation involves using MRF to create a rotating reference frame in the fluid domain around the turbine blades.

Simulating the performance of a HAWT using ANSYS Fluent and MRF requires accounting for the interaction between the fluid flow and the solid structure of the turbine blades. The simulation can also involve the use of multiphase flows to account for the presence of air in the water flow.

The training can be used to optimize the design of the HAWT, predict its power output under different flow conditions, and ensure safe and efficient operation. ANSYS Fluent Training is a valuable tool for hydropower engineers to simulate the performance of the HAWT, optimize its design, and ensure safe and efficient operation.

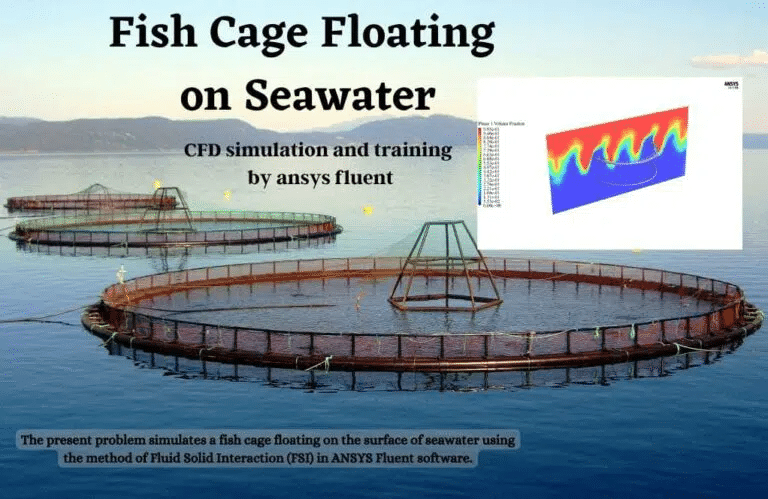

Fish Cage Floating on Seawater

This project aims to use ANSYS Fluent software and the Fluid Solid Interaction (FSI) method to simulate the flow of seawater around a fish cage floating on the surface of the water. Since the cage is floating, the seawater flow collides with it, causing a two-way interaction between the fluid and the solid. To account for this interaction, the FSI method is applied in the ANSYS Workbench software environment. The use of FSI requires a Dynamic Mesh to handle changes in the fluid flow mesh around the geometric model. System coupling is used to solve the model in both Fluent and Transient Structural software, simulating the interaction between the fluid and solid. ANSYS Fluent Training can be used to optimize the design of the fish cage, predict its performance under different flow conditions, and ensure its safe and efficient operation.

Marine Vehicle

Submarine

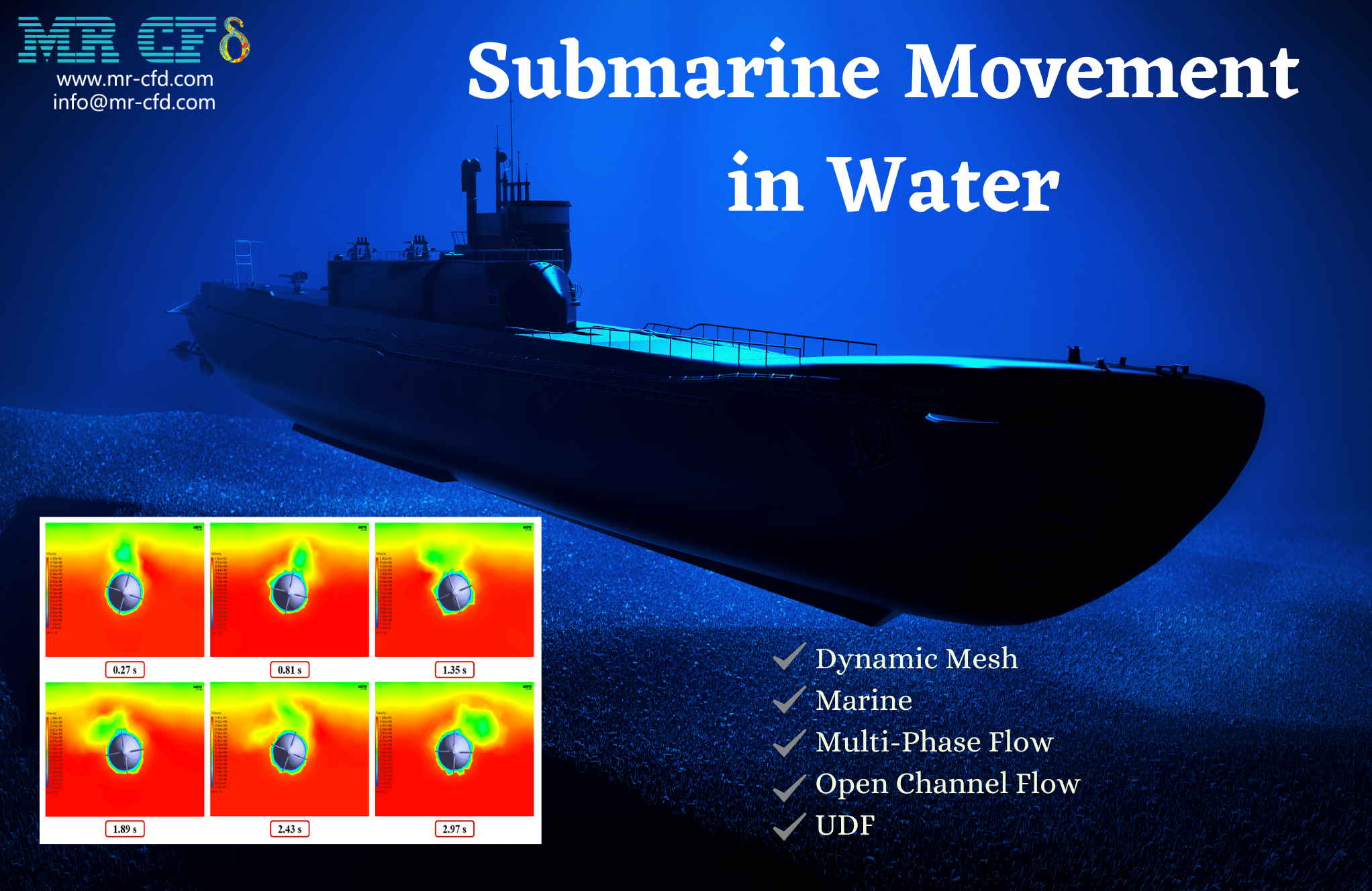

Self-Propelled Submarine Motion by Dynamic Mesh (6-DOF)

This project aims to use ANSYS Fluent software to simulate the movement of a self-propelled submarine on the water’s surface. The dynamic mesh method is used in this simulation, and six degrees of freedom (six-DOF) are defined to describe the model’s dynamic mesh behavior. The six-DOF allows the model to move and relocate in six different directions, and the properties of six-DOF, including mass and moment in different directions, are defined using a User-Defined Function (UDF).

Submarine Movement in Water by Dynamic Mesh (1-DOF)

The purpose of this project is to use ANSYS Fluent software to simulate the movement of a submarine in water using the Dynamic Mesh method. As the submarine moves within the computational domain, it affects the surrounding grid elements, so the meshing needs to change momentarily and time-dependently based on the type of displacement at the adjacent boundaries of the mesh.

The submarine in this simulation has only one degree of freedom, which means it can only rotate around its central axis (x-axis). It cannot move or rotate in other directions. To define this type of movement, a User-Defined Function (UDF) is used while considering one degree of freedom.

Floating Vessel

This project involves using ANSYS Fluent software to simulate the movement of a floating vessel in water using the Dynamic Mesh method. The simulation includes a computational domain of water with a floating vessel designed at a certain height level on the surface of the water. To define the dynamic mesh behavior, six degrees of freedom (6-DOF) are utilized. This means that the model can move and relocate in six different transitional and rotational directions.

Boat Propeller

This tutorial focuses on simulating boat propeller cavitation using computational fluid dynamics (CFD). Cavitation occurs when the static pressure of a liquid drops below the vapor pressure, resulting in small voids filled with vapor in the liquid. When these cavities are exposed to higher pressures, they collapse and create shock waves that can potentially damage machinery. These shock waves are strongest near the bursting bubble and weaken as they move away from it. Cavitation is a significant cause of wear in certain engineering fields. The collapsing cavities that explode near the metal surface cause cyclic stress through repeated bursting, leading to fatigue of the metal surface and wear known as “cavitation.”

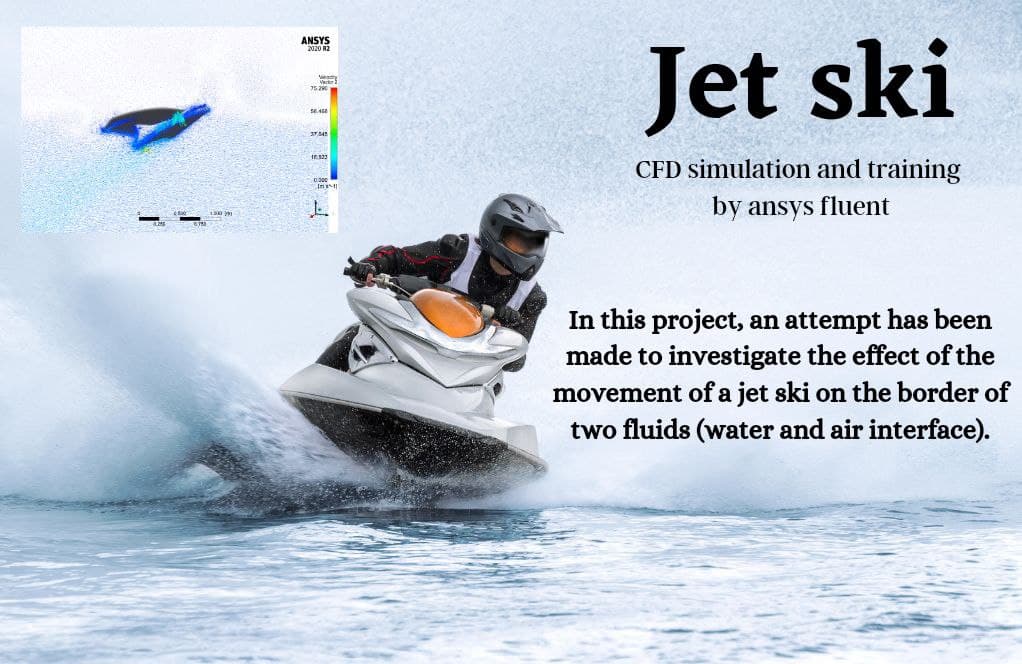

Jet Ski

This project involves using ANSYS Fluent software to investigate the impact of a jet ski’s movement on the interface between two fluids: water and air. The flow around floating objects on a fluid common phenomenon, such as boats, ships, and jet skis. When two fluids are in contact with each other, the phase change and the effect of each phase on one another are important considerations. In this simulation, a two-phase flow study is conducted to analyze the movement of the jet ski and its effect on the water-air interface. The goal is to gain a better understanding of the interaction between the jet ski and the surrounding fluids.

Oscillatory Wave

Sloshing

This ANSYS Fluent CFD simulation training focuses on the sloshing effect of fluid within a tank and its impact on the maneuverability of floating devices such as ships and boats. Previous laboratory studies have shown the importance of understanding sloshing dynamics, including measuring the sloshing dynamics of a tank, experimental and statistical studies of sloshing wave impact loads in a shell tank model, verifying numerical sloshing results of a floating device containing a natural gas tank using experimental results on a two-dimensional section of the reservoir, investigating the maximum long-term sloshing pressures applied to the shell tank to consider the effects of vibration caused by a bump, and an experimental study of pressure distribution due to liquid sloshing in a rectangular tank.

By conducting a CFD simulation using ANSYS Fluent software, we can further investigate the sloshing effect of fluid within a tank and its impact on the maneuverability of floating devices. This can help us gain a better understanding of how fluid sloshing affects the stability and performance of these devices and how we can optimize their design to minimize these effects.

Falling Objects into Water

This ANSYS Fluent CFD simulation training focuses on the fluid flow around two cubes falling into the water using the dynamic mesh method. By simulating this scenario using ANSYS Fluent software, we can investigate the fluid dynamics and understand how the water interacts with the falling cubes. The dynamic mesh method allows us to simulate the motion of the cubes as they fall and the resulting changes in the fluid flow around them.

Through CFD analysis, we can gain insights into the behavior of the fluid and the forces acting on the cubes as they fall. This can help us optimize the design of objects that are meant to be dropped into water, such as boats, buoys, and other marine structures. Overall, this project provides a valuable opportunity to explore the complex fluid dynamics involved in the interaction between falling objects and water, and how we can use CFD analysis to improve the design and performance of these objects.

Pollution Dispersion in Water

Water Pollution in the Meandering River

This ANSYS Fluent CFD simulation training focuses on the pollution of a meandering river and its impact on the ecosystem. By simulating the pollution of the river using ANSYS Fluent software, we can investigate the flow dynamics of the polluted water and how it affects the surrounding environment. Through CFD analysis, we can gain insights into how the pollution spreads, its concentration levels, and how it interacts with the river’s flow.

Water pollution is a significant environmental issue that can have severe consequences for aquatic life and the ecosystem. By studying the pollution of a meandering river, we can better understand the impact of human activities on the environment and how we can mitigate these effects. Overall, this project provides a valuable opportunity to explore the complex fluid dynamics involved in water pollution and how we can use CFD analysis to better understand and address this critical environmental issue.

Pollution Spread in the Stagnant River

Water pollution caused by industrial waste products is a significant environmental issue that can have severe consequences for aquatic life and the ecosystem. The pollution can affect the river’s water quality, making it hazardous for aquatic animals and humans who rely on the river for food and other uses.

By studying the spread of pollution in a stagnant river, we can better understand the impact of industrial activities on the environment and how we can mitigate these effects. This project provides a valuable opportunity to explore the complex fluid dynamics involved in water pollution and how we can use CFD analysis to better understand and address this critical environmental issue.

Marine Industrial Companies

There are many reputable marine industrial companies around the world, each with their own strengths and areas of expertise. Here are some of the best marine industrial companies:

– Maersk – A Danish shipping company that operates the largest container shipping fleet in the world.

– Royal Dutch Shell – A multinational oil and gas company that is a major player in offshore oil and gas production.

– Mitsubishi Heavy Industries – A Japanese company that specializes in marine engineering, including shipbuilding and offshore structures.

– Caterpillar Inc. – An American company that produces engines and power systems for marine applications.

– Hyundai Heavy Industries – A South Korean company that is one of the world’s largest shipbuilders.

– Cargill – An American company that is a major player in the global shipping and logistics industry.

– BAE Systems – A British defense and aerospace company that produces naval vessels and submarines.

– Crowley Maritime Corporation – An American company that offers a wide range of marine services, including shipping, logistics, and offshore energy support.

– Kongsberg Gruppen – A Norwegian company that specializes in marine technology, including underwater robotics and autonomous vessels.

– Statoil – A Norwegian oil and gas company that is a major player in offshore oil and gas production.

MR CFD Industrial Experience in the Marine Field

Following is an example of Marine industrial projects recently simulated and analyzed by MR CFD in cooperation with related companies.

Tidal Turbines

Paper Numerical Validation

Horizontal Axis Tidal Turbine

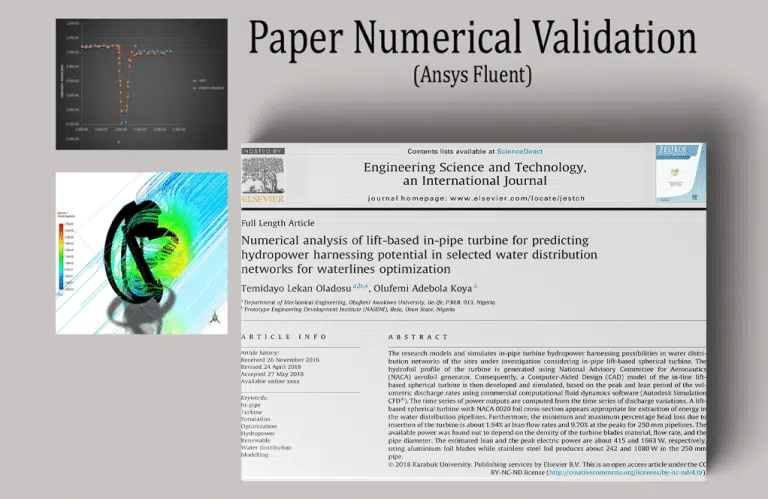

The present study employs ANSYS Fluent software to simulate a water turbine with a horizontal axis. The results of the CFD simulation are compared and verified against the findings of the research paper titled “Performance of horizontal axis tidal current turbine by blade configuration”. Upon completion of the solution process, the software calculates the turbine power based on the torque applied to each blade, and subsequently, the pressure coefficient (Cp) on the blades is determined. Finally, the results are compared and validated against the corresponding values reported in the research article.

Turbine Hydropower in Waterline Optimization

The conservation of water and energy has become a global concern, and various technical solutions have been proposed to generate electricity and regulate water pressure in distribution networks by replacing pressure relief valves with power generators. This process utilizes the hydraulic energy of water to produce electricity, which is a clean energy source that is often overlooked in water resources. It also reduces energy dependence on the power grid and lowers the operating costs of the system. The study concludes that the potential for hydropower utilization in each water distribution system depends on factors such as fluid flow, effective head, pipe diameter, hydrofoil specifications, and turbine components.

MR CFD conducted numerous outsourced CFD simulation projects for industrial companies and research in Marine Engineering applications. With several years of experience simulating various problems in various CFD fields using ANSYS Fluent software, the MR CFD is ready to offer extensive CFD Simulation, Training, and Consultation services.

You may find the Learning Products in the Marine Engineering CFD simulation category in Training Shop. You can also benefit from Marine Engineering Training Packages appropriate for Beginner and Advanced users of ANSYS Fluent. Also, MR CFD is presenting the most comprehensive Marine Engineering Training Course for all ANSYS Fluent users from Beginner to Experts.

Our services are not limited to the mentioned subjects. The MR CFD is ready to undertake different and challenging projects in the Marine Engineering modeling field ordered by our customers. We even carry out CFD simulations for any abstract or concept design you have to turn them into reality and even help you reach the best strategy for what you may have imagined. You can benefit from MR CFD expert Consultation for free and then Outsource your Industrial and Academic CFD project to be simulated and trained.

By outsourcing your project to MR CFD as a CFD simulation consultant, you will not only receive the related project’s resource files (Geometry, Mesh, Case & Data, …), but also you will be provided with an extensive tutorial video demonstrating how you can create the geometry, mesh, and define the needed settings(pre-processing, processing, and post-processing) in the ANSYS Fluent software. Additionally, post-technical support is available to clarify issues and ambiguities.