Project Outsourcing

Outsource your project to the MR CFD simulation engineering team. Our experts are ready to carry out every CFD project in all related engineering fields. Our services include industrial and academic purposes, considering the ANSYS Fluent software's wide range of CFD simulations. By outsourcing your project, you can benefit from MR CFD's primary services, including Consultation, Training, and CFD Simulation. The project freelancing procedure is as follows:

An official contract will be set based on your project description and details.

As we start your project, you will have access to our Portal to track its progress.

You will receive the project's resource files after you confirm the final report.

Finally, you will receive a comprehensive training video and technical support.

What are Newtonian and Non-Newtonian Flows?

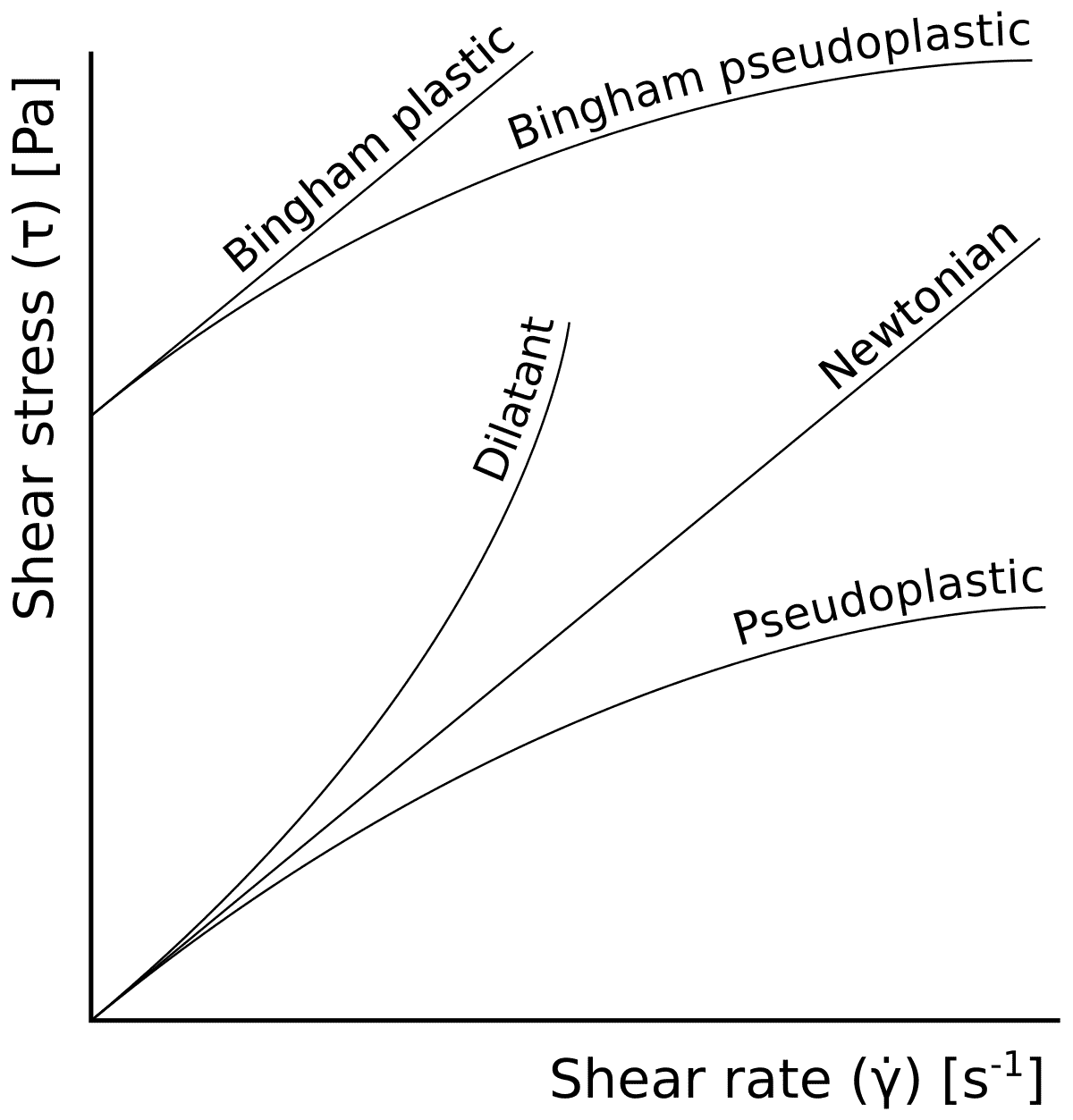

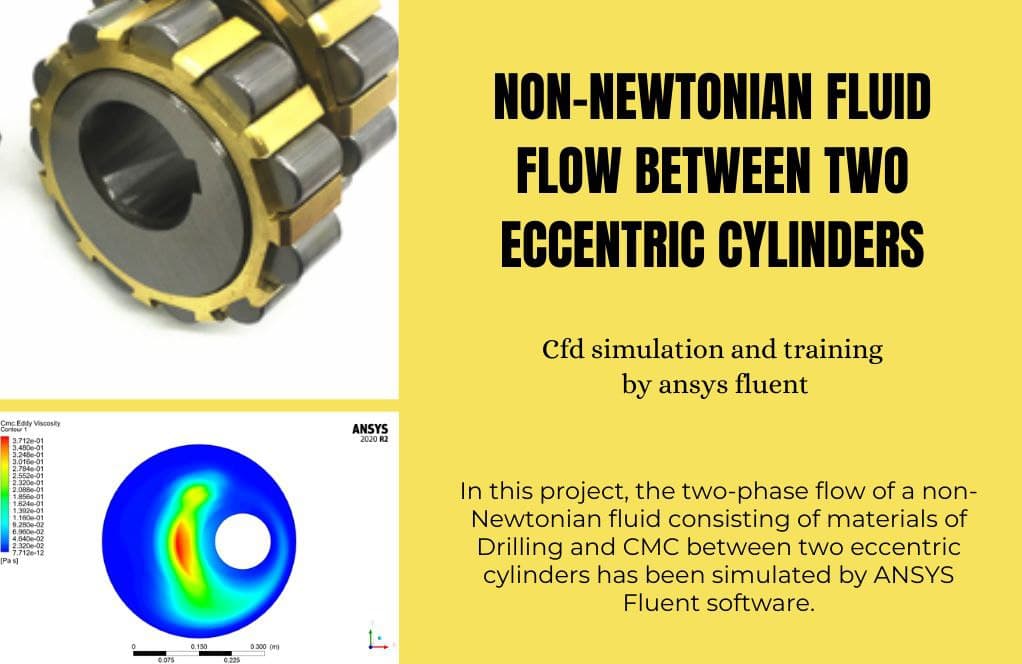

A Newtonian Fluid has a linear relationship between stress and strain rate: the ratio of stress to strain rate is the fluid’s viscosity. A Hookean solid has a linear relationship between stress and strain: the ratio of stress to strain is the modulus of the solid. Many materials have intermediate properties between a Newtonian fluid and a Hookean solid. If the properties are predominantly solid-like, the materials are called non-Hookean, described as viscoelastic. If they are predominantly fluid-like, they are called non-Newtonian, and the materials are defined as elastic viscous.

A non-Newtonian fluid has, therefore, a simultaneously elastic and viscous nature. All fluids are non-Newtonian on an appropriate time scale, though the time scale is concise for many common fluids such as air and water. When the time-scale of a flow tf is much less than the relaxation time tr of an elasticoviscous material, elastic effects dominate. Conversely, when tf is much greater than tr, elastic effects relax sufficiently for viscous effects to dominate. The ratio tf/tr is a dimensionless number of particular significance in the study of the flow of non-Newtonian fluids: depending on the circumstances, this number is called the Deborah number or the Weissenberg number. If the Deborah or Weissenberg number is small, elastic effects can be neglected and the non-Newtonian fluid treated as a purely viscous material, albeit with a non-constant viscosity. Non-Newtonian fluids are divided into time-dependent and time-independent, or purely viscous.

Time-Independent Fluids are those fluids for which the shear rate at a given point only depends upon the instantaneous shear stress. These materials are sometimes referred to as “non-Newtonian viscous fluids” or “purely viscous fluids.”

In some fluids, the viscosity varies with time when the shear rate is constant. Two different types of behavior can be distinguished, thixotropic and rheopectic. Viscosity decreases with increasing time; viscosity increases with increasing time for a rheopectic fluid. The viscosity variation with time is associated with changes in the fluid-structure. When straining the fluid breaks down that structure, for example, by destroying local linkages within the fluid, viscosity decreases with increasing time, and the fluid is thixotropic. A similar argument can be advanced for the decrease in viscosity with an increasing shear rate for a pseudoplastic fluid.

In contrast, when straining builds up the structure, for example, by causing local alignment in the fluid, viscosity increases with increasing time, and the fluid is rheopectic. Again, a similar argument can be advanced for increasing viscosity with a dilatant fluid’s increasing shear rate. Therefore, an analogy exists between thixotropy and pseudo-plasticity on the one hand and between rheopexy and dilatancy on the other. Nevertheless, viscosity variation with time differs from, and should not be confused with, variation with shear rate.

You can see the project Non-Newtonian Blood Flow in a Clogged Vessel link below, which is carried out by the MR-CFD team:

https://www.mr-cfd.com/shop/non-newtonian-blood-flow-in-a-clogged-vessel-cfd-simulation/

MR-CFD, an Expert in the Field of CFD Simulations

With several years of experience in simulating various problems in various CFD fields using ANSYS Fluent software, the MR-CFD team is ready to offer extensive modeling, meshing, and simulation services based on the need of our customers. Our services are not limited to the mentioned subject, and the MR-CFD team is ready to undertake different and challenging projects. You can consult with our experts freely and without charge at first, and then order your project by sending the problem details to us using the following address.

By outsourcing your project to the MR-CFD as a CFD simulation freelancer, you will not only receive the related project’s files (Geometry, Mesh, …), but also you will be provided with an extensive tutorial video demonstrating how you can create the geometry, mesh, and define the needed settings(pre-processing, processing and post-processing) in the ANSYS Fluent software all by yourself. Additionally, post-technical support is available to clarify issues and ambiguities.