Project Outsourcing

Outsource your project to the MR CFD simulation engineering team. Our experts are ready to carry out every CFD project in all related engineering fields. Our services include industrial and academic purposes, considering the ANSYS Fluent software's wide range of CFD simulations. By outsourcing your project, you can benefit from MR CFD's primary services, including Consultation, Training, and CFD Simulation. The project freelancing procedure is as follows:

An official contract will be set based on your project description and details.

As we start your project, you will have access to our Portal to track its progress.

You will receive the project's resource files after you confirm the final report.

Finally, you will receive a comprehensive training video and technical support.

What is Clean Water Engineering?

The study of technology and procedures that can be used to enhance the quality of water for drinking, irrigation, and other purposes is the subject of the engineering discipline known as “clean water engineering.” To rid water sources of impurities, a variety of methods including filtration, disinfection, and desalination are used. Engineering for the safe and effective distribution of clean water also includes the design of infrastructure and the creation of systems to monitor and control water quality.

Today, the lack of clean water resources worldwide is the most important human challenge. In general, less than 3% of the world’s water resources are clean water. Population growth and excessive increase in household water consumption, increase in water consumption in industry, increase in water consumption in agriculture, etc., are the factors that reduce the available water resources in the world. The increase in industrial activities, the growth of greenhouse gases, the increase in air pollution, and finally, the overheating of the earth are also factors that reduce the possibility of water compensation in the cycle of nature through rainfall.

So, water desalination is one of the most important issues in the world. Water desalination is not a new science and has been progressing for several years in different countries. Many researchers and engineers are working on this issue to provide designs and methods that increase the efficiency of the water desalination process.

Water desalination means a set of processes carried out to purify salty and impure water; through it, all the soluble substances in water are separated. It should be noted that desalination does not simply mean the separation of water-soluble salt; Moreover, the operation of water purification by removing water impurities such as bacteria and viruses is also considered part of this industry.

How CFD simulation can be applied in Clean Water Industries?

Clean water businesses can use CFD simulation to improve the design of water treatment systems including filtration, sedimentation, and flocculation. CFD can be used to examine the water flow through the system, spot areas of turbulence and stagnation, and enhance the system’s design to boost performance and lower energy usage. The performance of water treatment systems under various environmental circumstances, such as temperature, pressure, and flow rate, can also be examined using CFD. Additionally, CFD can be used to optimize the design of water treatment systems to lower the risk of contamination and mimic the behavior of contaminants in water, such as bacteria, viruses, and other particles.

- thermal desalination

- membrane desalination

Many definitions are provided to express the difference between thermal and membrane methods. The main difference between these two methods is that in the thermal method, a phase change occurs, while in the membrane method, phase change never occurs.

Each desalination method has specific uses, according to its advantages and disadvantages. Therefore, choosing the right system to produce purified water optimally is important. It is necessary to properly analyze the performance of the mentioned systems to achieve the right choice. By analyzing the performance of these systems, one can understand their capabilities.

Experimental methods are not a suitable way to investigate the performance of these systems; because it requires a lot of money and, on the other hand, a lot of time is wasted. So we can turn to numerical simulations. Modeling of the study case, the definition of desired fluids, and the use of solver and discretization methods are included in the subject of computational fluid dynamics (CFD).There is much commercial software for solving numerically. One of the most powerful and accurate software is ANSYS Fluent software. We have numerically simulated several types of water desalination systems with ANSYS Fluent software.

The thermal method of desalination works like the natural water cycle. This means that salt water evaporates by receiving heat. The produced steam is pure and free of salt and impurities. Now, it is enough for this steam to be placed in a cold environment so that it causes condensation by losing its heat. The water resulting from condensation is completely pure. So, this method must have a heat source to change the phases. For this reason, this category of desalination systems is called the thermal method.

The most important challenge in the thermal method is the efficiency of these systems. The main disadvantage of thermal methods is that they require a heat source. Using a heat source causes high energy consumption and, therefore, high cost. For this reason, the thermal method is mainly used in large-scale power plants.

Making the system multi-stage and using thermal recovery methods helps to increase efficiency in the thermal system. In addition, these thermal systems are usually used vicinity of large water sources such as seas, rivers, and oceans. This is because a large volume of water can be desalinated on a large scale.

MR CFD services in the Clean Water Engineering and Industries

A variety of CFD simulation services are offered by Clean Water Engineering to assist clients comprehend and improve their water systems. Among these services are:

CFD Analysis: We employ CFD analysis to pinpoint inefficiencies in the system and offer suggestions for enhancements. This entails locating turbulence, pressure dips, and other trouble spots.

CFD Optimization: To determine the most effective design for a water system, we apply CFD optimization. In order to increase efficiency, pipes, pumps, and other components’ layouts must be optimized.

CFD Visualization: We employ CFD visualization to produce in-depth representations of water systems. This enables us to comprehend water flow more fully and spot locations that may benefit from improvement.

MR CFD conducted numerous outsourced simulation projects for industrial and research Clean Water Engineering applications for Beginner, Intermediate, and Advanced ANSYS Fluent users as Clean Water Training Packages, including 7 practical CFD projects:

Water Distiller

Now, if the thermal systems are to be modeled on a small scale, their numerical analysis becomes important to investigate their performance. One of the methods of producing purified water is the use of household water distillers. The dimensions of this device are small, and the freshwater production rate is low. The most important feature of this system is its small size. Therefore, this device is used at home and can carry and move easily. In addition, its small size consumes less energy and therefore costs less to build.

This device has an almost cylindrical body with small dimensions. Its lower part is the saltwater tank. An electric heater is placed under this part to heat the water. So its lower part is called the evaporator. A tube with a low screw pitch is placed in its upper part. A fan is placed above this part to transfer the cooling to the rotating tube.

The tank water evaporates by receiving heat. When evaporation occurs, pure water turns into steam, and salt and impurities settle inside the tank. Now, this pure steam goes into the cooling pipe, and the temperature decreases. As a result of condensation, the steam turns into pure water. We have simulated this model using ANSYS Fluent software. We have presented the results of this simulation with some animations and some contours.

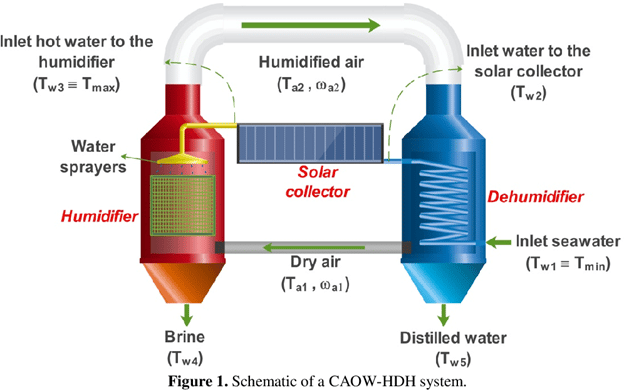

Humidification – DeHumidification

One of the methods in this category is desalinating by humidification and dehumidification (DHD). These systems consist of two main parts. A cylindrical chamber acts as a dehumidifier or condenser, and a cylindrical chamber acts as a humidifier or evaporator. The desalination process in this system is a cycle. The saltwater is heated by a heat source and enters the humidifier.

In this section, hot water droplet is sprayed on the membrane layers. On the other hand, dry air enters this chamber’s bottom and collides with hot water in these membrane layers. The contact between these two fluids leads to separating impurities from water. Pure water evaporates and mixes with dry air to produce pure moist air. Humid air exits from the top of the humidifier and enters the dehumidifier chamber.

Inside this section, there are pipes carrying cold flows. After contact with the cold pipes, humid air decreases the temperature and condenses. As a result, fresh water is produced at the end of the cycle. We have simulated this model using ANSYS Fluent software. We have presented the results of this simulation with some animations and some contours.

Solar Distillation

The most important issue in thermal desalination methods is their energy consumption. The product production to energy consumption ratio should be the right amount; in other words, the system’s efficiency should be high. The use of new energies can be a good solution in this field. Solar energy is the most available and cheapest energy to replace fuel sources.

There are several thermal desalination methods using solar energy. In one of these systems, inclined glass surfaces are used. Solar rays pass through the glass and reach the water’s surface inside the system. Heating the water surface causes surface evaporation. The produced steam is pure and impure materials settled at the bottom of the system. This pure steam hits the inner surface of the inclined glass and causes condensation by losing heat. The slope used for the glasses causes the drops of distilled water to slide on the surface of the glass and be directed to the system’s outlet. We have simulated this model using ANSYS Fluent software. We have presented the results of this simulation with some animations and some contours.

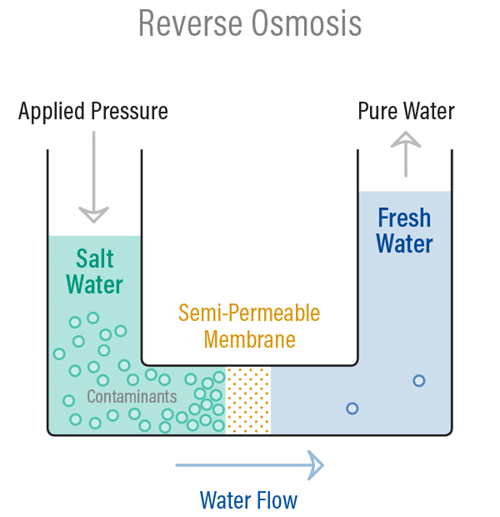

Reverse Osmosis

There are several membrane methods for producing fresh water. The most famous membrane method is reverse osmosis systems. This system is considered the most suitable method for efficiency and energy consumption if two fluids with different concentrations are placed next to each other.

Fluid flow naturally tends to flow from a solution of lower concentration to a higher concentration until the concentration on both sides is balanced. This movement continues until equilibrium is established in terms of concentration. So, the surface difference is created in two parts, which, as a result, causes the pressure difference. This pressure difference is called the osmotic pressure difference.

Now, if a pressure greater than the osmotic pressure is applied to the impure part of the system, the direction of the natural movement of water is reversed. The reverse osmosis desalination system creates pressure beyond the osmotic pressure using a pump and passes through a special membrane to remove nitrates, minerals, chemicals, and bacteria. We have simulated this model using ANSYS Fluent software. We have presented the results of this simulation with some animations and some contours.

Membrane Distillation

Sometimes it is possible to design systems that are a combination of both thermal and membrane methods. This means that the phase change happens inside the system, and a membrane is also used. The main reason for designing such systems is to increase their efficiency. The membrane distillation method is included in this category of desalination systems. In this type of system, there are two separate paths. On one side of the system, the flow of saline feed water moves and is heated by a heat source. Then this flow of warm salt water enters from the other side of the system.

A membrane layer is placed between the two hot and cold fluid paths. The hot stream enters the membrane and condenses in contact with the wall of the cold water channel. These membrane distillation systems are divided into categories: DCMD, AGMD, VMD, and SGMD. In direct contact membrane distillation (DCMD), the hot fluid flow directly hits the outer surface of the cold duct.

In air gap membrane desalination (AGMD), an air gap is also placed between the membrane layer and the cold duct. This air gap is where condensation occurs. In vacuum membrane desalination (VMD), a special layer vacuums the steam with a vacuum pump to be condensed outside the system by a condenser, producing fresh water. In sweeping gas membrane desalination (SGMD), a special layer sweeps the gas stream to be condensed outside the system by a condenser, producing fresh water. We have simulated this model using ANSYS Fluent software. We have presented the results of this simulation with some contours.

Evaporation and Condensation inside the Desalination System

Using ANSYS Fluent, the current simulation examines the evaporation and condensation inside the desalination system. Evaporation and condensation occur in the upper and bottom portions of this two-stage desalination system. Impure water evaporates and turns into steam when it receives heat from the system’s floor in these two components of the desalination system. The condensation and creation of pure water then take place when the hot steam comes into touch with the cool surface above it.

Condensed water flows down these chilly surfaces and is directed to the system exit. At the beginning of the system, impure water is at a specific height and temperature of 300 K. Heat transfer and evaporation occur because of the system’s floor surface, which has a temperature of 353 K. The VOF (Volume of Fluid) multiphase model defines a number of different fluids as part of the system in this simulation.

The three primary phases of the intended multiphase flow are air, water, and vapor. Additionally, it is necessary to establish the mass transfer mechanism between water and steam so that, depending on the temperature and pressure of the system’s interior, either evaporation (from water to vapor) or condensation (from vapor to water) takes place. Mass transfer is a procedure that is defined by a UDF (user-defined function).

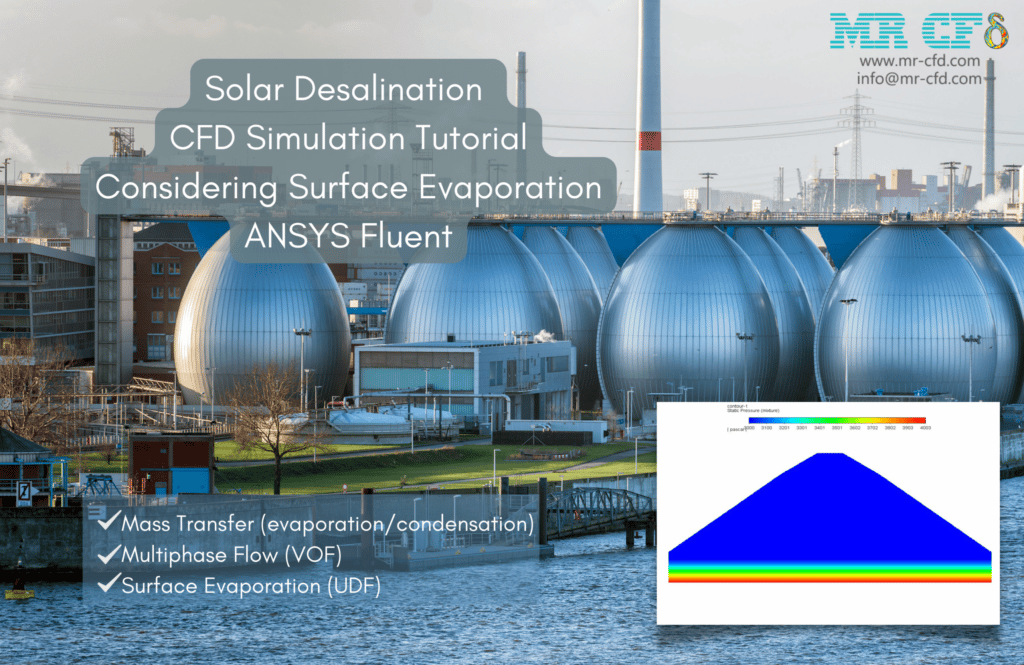

Solar Desalination Considering Surface Evaporation

You will acquire the skills and information necessary to model solar desalination processes utilizing surface evaporation after completing this ANSYS Fluent training course. You will learn how to put up, solve, and evaluate a CFD model of a solar desalination system. The physics of surface evaporation, numerical methods for solving the equations, and methods for post-processing the findings will all be covered in the course. Additionally, you will discover how to utilize ANSYS Fluent to construct a solar desalination system in 3D and how to simulate the procedure. By the end of the course, you will be well-versed in the fundamentals of solar desalination as well as able to simulate the procedure using ANSYS Fluent.

Using ANSYS Fluent software, this simulation explores surface evaporation in solar desalination. We carry out this CFD project and do a CFD analysis to look at it. In this simulation, a straightforward solar still made of tilted glass plates is created. Solar rays enter the system through the glass and strike the water’s surface. Evaporation of the water’s surface is brought on by heating.

With several years of experience simulating various problems in various CFD fields using ANSYS Fluent software, we are ready to offer extensive services of Simulation, Consultation, and Training services. MR CFD services in the Clean Water engineering field can include a variety of services such as:

- Simulation and analysis of Humidification, Dehumidification, HDH, etc.

- Simulation of flow in case of Solar Distillation, Domestic Water Distiller, etc.

- Flow simulation in Reverse Osmosis, Reverse Pressure, etc.

- CFD Simulation of various kinds of Membrane Distillation.

Clean Water Engineering MR CFD Projects

With several years of experience in simulating various problems in different CFD fields using ANSYS Fluent software, the MR CFD is ready to offer extensive modeling, meshing, and simulation services. Following is a brief list of the CFD simulation projects for Clean Water Engineering by MR CFD:

Single Slope Solar Still

The use of ANSYS Fluent CFD simulation for the verification of single slope solar stills will be introduced in this training course. The course will go over the foundations of CFD simulation, covering the essentials of mass, heat, and fluid flow. The numerical validation of single slope solar stills will also be covered in the course, including how to use the ANSYS Fluent CFD simulation to verify the still’s performance. The use of paper numerical validation to evaluate the still’s performance will also be covered in the course. The course will also discuss how to optimize the still’s design using ANSYS Fluent CFD simulation.

The current issue uses the ANSYS Fluent program to simulate the surface evaporation process within a solar desalination system. We carry out this CFD project and do a CFD analysis to look at it. The information for this simulation was taken from a reference paper titled “Productivity estimation of a single-slope solar still: Theoretical and numerical study,” and the results of the simulation were compared and verified against those of the reference article.

In general, evaporation is a surface process that takes place on the liquid surface at any temperature. In this simulation, a single slope solar still with a predetermined volume of water and height is created. The glass-covered, sloping surface of the solar still transfers heat from the sun to the water’s surface. As heat is transferred to the water from solar radiation that passes through the glass, surface evaporation occurs.

Solar Still Desalination Training Package

This training bundle comprises 5 CFD simulation tasks for solar still desalination using ANSYS Fluent software. For people with an interest in renewable energy engineering, particularly solar energy analysis for the clean water method, MR-CFD recommends this package.

- Paper Validation

- Step, Single Slope, and Double Slope Solar Still Desalination

- Clean Water & Renewable Energy

- Surface Evaporation UDF

- VOF Multiphase & Species Transport

This training bundle comes with 5 ANSYS Fluent CFD simulation projects. The assignments are made to teach you the fundamentals of solar still desalination and how to model the procedure using ANSYS Fluent. The projects address subjects like:

- calculating the water flow in a solar still

- reenacting a solar still’s heat transmission in a computer

- enhancing the solar still’s design

- investigating how various materials affect a solar still’s performance

- examining how various operational circumstances affect a solar still’s performance

You may get started on each project with the help of step-by-step instructions, example data, and detailed instructions. The tasks are made to be finished in a short amount of time so that you can understand the fundamentals of ANSYS Fluent and solar still desalination.

Wire Mesh Demister (DDPM)

The current issue uses the ANSYS Fluent software to simulate the movement of water vapor through a demister containing saline water particles. The information for this simulation was taken from the reference article “Eulerian-Lagrangian modeling and computational fluid dynamics simulation of wire mesh demisters in MSF plants,” and its results were cross-checked and verified against those of the article. The multistage flash (MSF) desalination system is connected to this demister. The metal wire mesh used in this demister’s construction separates the salt water vapor stream’s droplets of water. Consequently, a multiphase flow model must be defined in order to define the flow in this modeling.

Using the Eulerian-Lagrangian approach of computational fluid dynamics (CFD), the eulerian multiphase model is coupled with the dense discrete phase model in the current simulation (DDPM). Thus, a continuous phase related to water vapor and a discrete phase associated to salt water droplets are defined. Separate salt water droplets enter the system from the bottom, and water vapor, which has passed through metal wire mesh, leaves the system from the top. The goal of this research is to determine how much pressure is lost as a result of the flow passing through these wire meshes. With a temperature of 373.15 K and a speed of 2-4 m.s-1, water vapor enters the system.

A mist eliminator called a mesh demister (DDPM) is used to clear liquid droplets from a gas stream. It is made of a mesh of wires that are organized in a particular way to give the gas stream a winding course. After being captured in the mesh, the droplets are expelled from the gas stream.

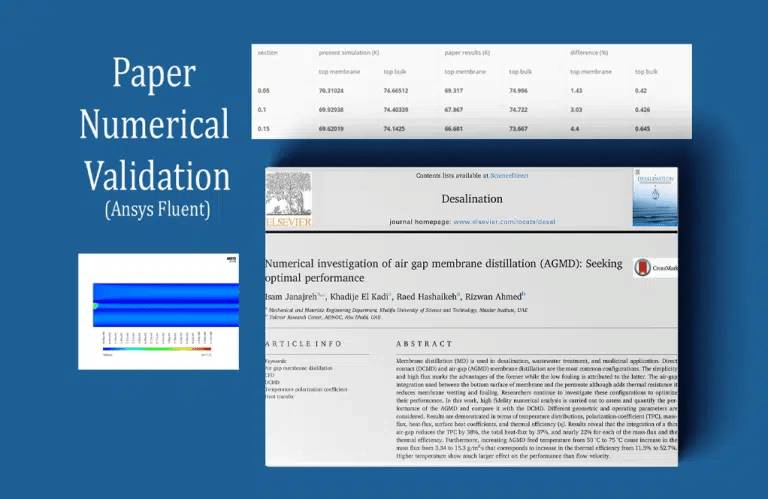

The method known as “paper numerical validation” is used to check the precision of numerical models used in engineering applications. In this process, the numerical outcomes are contrasted with experimental information or analytical conclusions. Once the numerical results agree with the experimental data or analytical answers, the numerical model is updated.

A course called ANSYS Fluent CFD Training teaches engineers how to run computational fluid dynamics (CFD) simulations using the ANSYS Fluent software. Mesh generation, boundary conditions, turbulence models, and post-processing are some of the subjects covered in the course. Additionally, the course offers practical tasks that allow students to practice using the software.

Air Gap Membrane Distillation (AGMD)

This study uses ANSYS Fluent to demonstrate a numerical validation of the Air Gap Membrane Distillation (AGMD) process. A hydrophobic membrane is used in the AGMD process, a membrane-based distillation method, to separate water from a saline solution. An AGMD process two-dimensional model was used for the numerical validation. A laboratory-scale AGMD system’s experimental data were used to validate the model. The numerical validation results revealed good concordance between the numerical and experimental findings. The saline solution temperature and concentration profiles in the AGMD system could be precisely predicted by the numerical model. The outcomes of the numerical validation show how ANSYS Fluent may be used to simulate AGMD processes.

The current issue uses the ANSYS Fluent program to simulate the air gap membrane distillation (AGMD). The information from the reference article “Numerical investigation of air gap membrane distillation (AGMD): Seeking optimal performance” served as the basis for this simulation.

Comparing and validating its findings with those in the article. These membrane distillation systems’ chambers are divided into four sections: a space for the flow of saline water, which serves as the system feed water, a space for the flow of cold water, a space for the air gap, and a space for the membranes or filters.

It is set up between the hot water and air. These membrane distillation systems function in a manner whereby the flow of hot salt water enters its chamber from one side and the flow of cold water enters it from the opposite side. When these vapors eventually collide with the cool surface of the space used for the flow of cold water, they lose their heat and distill, becoming clean fresh water.

The hot salt water flow, the air flow, and the cold water flow are all assumed to have inlet velocities of 0.1 m/s, with the hot salt water flow flowing from left to right and the air and cold water flow flowing from right to left. It is also assumed that the water flow inside the model has a Reynolds number of 100. The system works by transferring heat from the space connected to the flow of hot salt water to the membrane portion of the model, and then the membrane portion transfers the same quantity of heat to the space for airflow.

Distillation Column Tray

ANSYS Two-phase flow in a distillation column tray can be simulated using fluent CFD simulation training. The simulation can be used to examine the pressure and temperature distributions, as well as the liquid and vapor flow in the tray. The simulation can be used to evaluate the tray’s performance, including the effectiveness of the separation procedure. The design of the tray can also be improved for greater performance using the simulation.

The current issue uses the ANSYS Fluent program to simulate the two-phase flow of air and water in a distillation column tray. The separation of the material happens in tray towers. A tray distillation tower works by having a liquid stream enter the chamber from the upper half of the chamber through a large aperture while hot, rising steam enters the room from the lower section of the chamber through multiple small holes and flows upwards. This causes the air vapor and liquid flow to collide on one or more trays inside the chamber.

On the other hand, this contact raises the temperature of the falling liquid, which causes some of the light, low-boiling-point liquid particles to convert to steam sooner; on the other hand, it lowers the temperature of the ascending steam, which causes some of the steam to be distilled. Due to this process, the liquid is left with heavier particles that aggregate and eventually raise the boiling point of the remaining liquid, resulting in vapor that is rich in volatile substances (substances with lower boiling points or greater pressures).

Of course, the separation procedure will be more effective the more contact that is produced between the liquid and gas phases in the tray. The current work does not replicate heat transmission or the evaporation and distillation processes; instead, it just models the fluids of a two-phase model and examines how the liquid and gas phases behave in respect to one another at the tray position. The multi-phase VOF model has been utilized since the current model comprises two phases of air and water.

While pure water with a mass flow rate of 4 kg.s-1 enters the chamber through a side hole and exits through a hole embedded in the bottom of the model by moving downward, pure air moves upward through five small circular holes embedded in the lower part of the chamber at a speed of 23.35 m.s-1 and exits through five open-facing holes at the top of the chamber. A tray with five circular holes on its surface serves as the location for the two-phase contact in the center of the tower enclosure. Water flows through the tray.

Clean Water Industrial Companies

- SUEZ Water Technologies & Solutions

- Xylem Inc.

- Dow Water & Process Solutions

- Pall Corporation

- GE Water & Process Technologies

- Nalco Water

- Kurita Water Industries

- Evoqua Water Technologies

- Veolia Water Technologies

MR CFD conducted numerous outsourced CFD simulation projects for industrial companies and research in Clean Water Engineering applications. With several years of experience simulating various problems in various CFD fields using ANSYS Fluent software, the MR-CFD team is ready to offer extensive services of CFD Simulation, Training, and Consultation.

You may find the learning products in the Clean Water Engineering CFD simulation category in Training Shop. You can also benefit from Clean Water Engineering training packages appropriate for Beginner, Intermediate, and Advanced users of ANSYS Fluent. Also, MR CFD is presenting the most comprehensive Clean Water Engineering Training Course for all ANSYS Fluent users from Beginner to Experts.

Our services are not limited to the mentioned subjects, and the MR CFD is ready to undertake different and challenging projects in the Clean Water Engineering modeling field ordered by our customers. We even carry out CFD simulations for any abstract or concept design you have in your mind to turn them into reality and even help you reach the best design for what you may have imagined. You can benefit from MR CFD expert consultation for free and then outsource your Industrial and Academic CFD project to be simulated and trained.

By outsourcing your project to MR CFD as a CFD simulation consultant, you will not only receive the related project’s resource files (Geometry, Mesh, Case & Data, …), but also you will be provided with an extensive tutorial video demonstrating how you can create the geometry, mesh, and define the needed settings(pre-processing, processing, and post-processing) in the ANSYS Fluent software. Additionally, post-technical support is available to clarify issues and ambiguities.