Project Outsourcing

Outsource your project to the MR CFD simulation engineering team. Our experts are ready to carry out every CFD project in all related engineering fields. Our services include industrial and academic purposes, considering the ANSYS Fluent software's wide range of CFD simulations. By outsourcing your project, you can benefit from MR CFD's primary services, including Consultation, Training, and CFD Simulation. The project freelancing procedure is as follows:

An official contract will be set based on your project description and details.

As we start your project, you will have access to our Portal to track its progress.

You will receive the project's resource files after you confirm the final report.

Finally, you will receive a comprehensive training video and technical support.

What are Multiphase Flows?

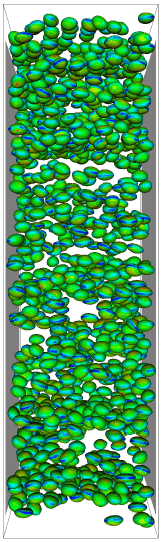

A multiphase flow is defined as a flow in which more than one phase (i.e., gas, solid, and liquid) exist. Such flows are ubiquitous in the industry: gas-liquid flows in evaporators and condensers, gas-liquid-solid flows in chemical reactors, solid-gas flows in pneumatic conveying, etc. This introductory article attempts to give an overview, with more detailed material appearing on each type of multiphase flow in separate entries. In Gas-solid and Liquid-Solid Flows, the dispersed phase is always in the solid phase because solid particles never coalesce with each other. On the other hand, in Gas-Liquid and Liquid-Liquid flows, the dispersed phase is determined mainly by the flow rates of both phases since the interface between them is deformable, and the dispersed phase coalesces and finally becomes the continuous phase as the flow rate increases. For example, in gas-liquid flows, the gas phase is dispersed when the gas flow rate is low compared with the liquid flow rate.

On the other hand, the liquid phase is dispersed when the liquid flow rate is small compared with gas flow. One of the essential features common to all types of dispersed flows is that mass, momentum, and energy transfer between the phases is carried out from each particle (here, particle means solid particle, bubble, a droplet in gas and liquid) surrounding continuous phase. Therefore, a single particle’s mass, momentum, and energy transfer mechanisms control the interaction between phases. The correlations for phase interactions are usually based on a single particle, with some modification due to the multi-particle effect of the dispersed phase’s volume fraction or mass fraction.

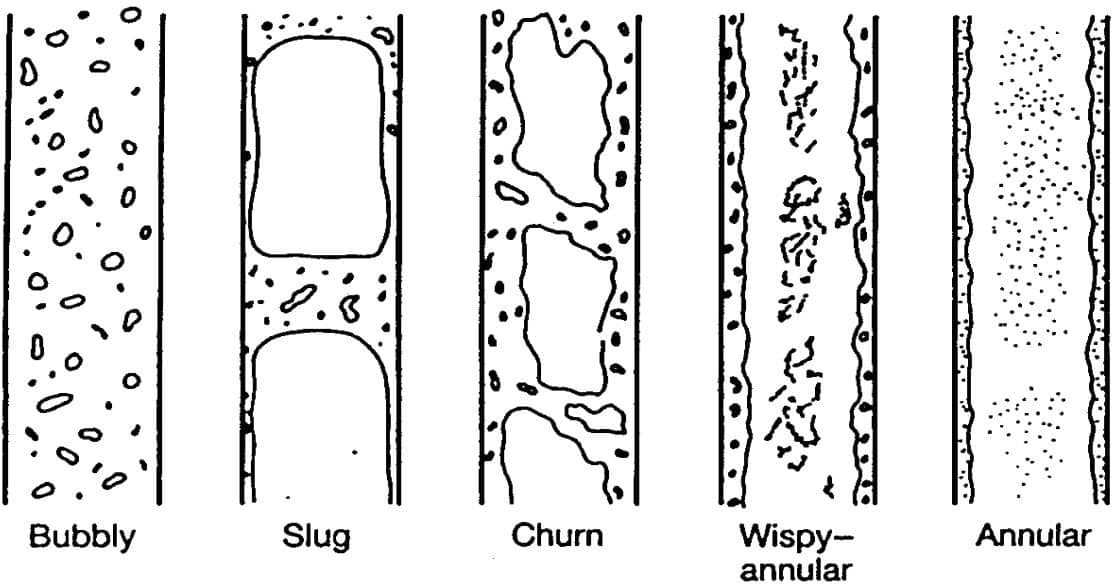

In the bubbly regime, bubbles of various sizes are distributed throughout the liquid. As the gas flow rate increases, the average bubble size increases. The next regime occurs when the gas flow rate increases to the point when many bubbles coalesce to produce gas slugs. The gas slugs have spherical noses and occupy almost the entire tube’s cross-section, being separated from the wall by a thin liquid film. Between slugs of gas, there are slugs of liquid in which there may be small bubbles entrained in the wakes of the gas slugs. This well-defined flow pattern is destroyed at higher flow rates, and a chaotic type of flow, generally known as churn flow, is established. Over most of the cross-section, there is a churning motion of irregularly shaped gas and liquid portions.

Further increase in the gas flow rate causes separation of the phases. The liquid flows mainly on the tube wall, and the core gas is generally referred to as annular flow. Liquid drops or droplets are carried in the core: it is the competing tendency for drops to impinge on the liquid film and for droplets to be entrained in the core by the break-up of waves on the film’s surface that determine the flow regime. The main differences between the wispy-annular and the annular flow regimes are that the entrained liquid is present as relatively large drops in the former, and the liquid film contains gas bubbles. In contrast, the entrained droplets do not coalesce to form larger drops in the annular flow regime.

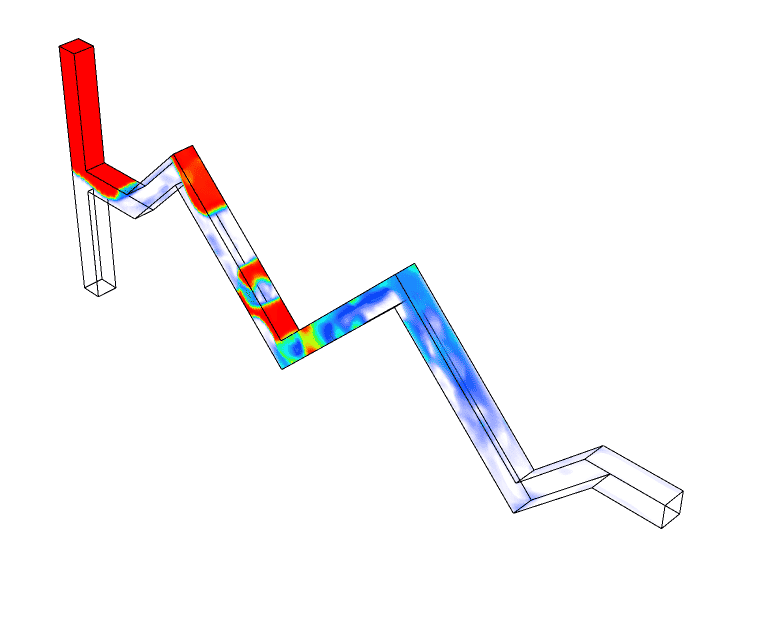

You can see the project Nano Fluid Flows in a Heat Source Channel, Applying Mixture Multiphase Model link below, which is carried out by the MR-CFD team:

MR-CFD, an Expert in the Field of CFD Simulations

With several years of experience in simulating various problems in various CFD fields using ANSYS Fluent software, the MR-CFD team is ready to offer extensive modeling, meshing, and simulation services based on the need of our customers. Our services are not limited to the mentioned subject, and the MR-CFD team is ready to undertake different and challenging projects. You can consult with our experts freely and without charge and order your project by sending the problem details to us using the following address.

By outsourcing your project to the MR-CFD as a CFD simulation freelancer, you will not only receive the related project’s files (Geometry, Mesh, …), but also you will be provided with an extensive tutorial video demonstrating how you can create the geometry, mesh, and define the needed settings(pre-processing, processing and post-processing) in the ANSYS Fluent software all by yourself. Additionally, post-technical support is available to clarify issues and ambiguities.