CFD Project Outsourcing

Outsource your CFD project to the MR CFD simulation engineering team. Our experts are ready to carry out every CFD project in all related engineering fields. Our services include industrial and academic purposes, considering the ANSYS Fluent software's wide range of CFD simulations. By outsourcing your project, you can benefit from MR CFD's primary services, including CFD Consultant, CFD Training, and CFD Simulation.

The project freelancing procedure is as follows:

An official contract will be set based on your project description and details.

As we start your project, you will have access to our Portal to track its progress.

You will receive the project's resource files after you confirm the final report.

Finally, you will receive a comprehensive training video and technical support.

What is Heat Transfer Engineering?

Heat transfer engineering studies how heat travels through and is transferred across materials. The study of how and why heat is transferred from one area to another makes up this field of study. Energy, manufacturing, and transportation fields rely heavily on heat transfer engineers.

Three primary processes exist to transmit heat: conduction, convection, and radiation. Heat is conducted through a material when molecules come into close touch. Heat is transferred to them when fluids like air or water are in motion. When energy is transferred via electromagnetic waves like light, it is called radiation.

Engineers specializing in heat transfer work to create and analyze systems that use these processes. Heat exchangers are devices designed by engineers to transfer heat between fluids of various temperatures. They might also develop HVAC systems for buildings or cooling systems for electronics. Power plants rely on heat transfer engineering through nuclear reactors and gas turbines to produce electricity.

Efficient, secure, and cost-effective system design is the focus of heat transfer engineering. Engineers have to think about things like fluid flow rates, temperatures, and the materials utilized in the system. Engineers may create systems that serve various purposes by learning the fundamentals of heat transmission.

How can CFD simulation be applied in Heat Transfer Engineering Industries?

CFD simulation has several potential uses in the Heat Transfer Engineering sector. Some instances are as follows:

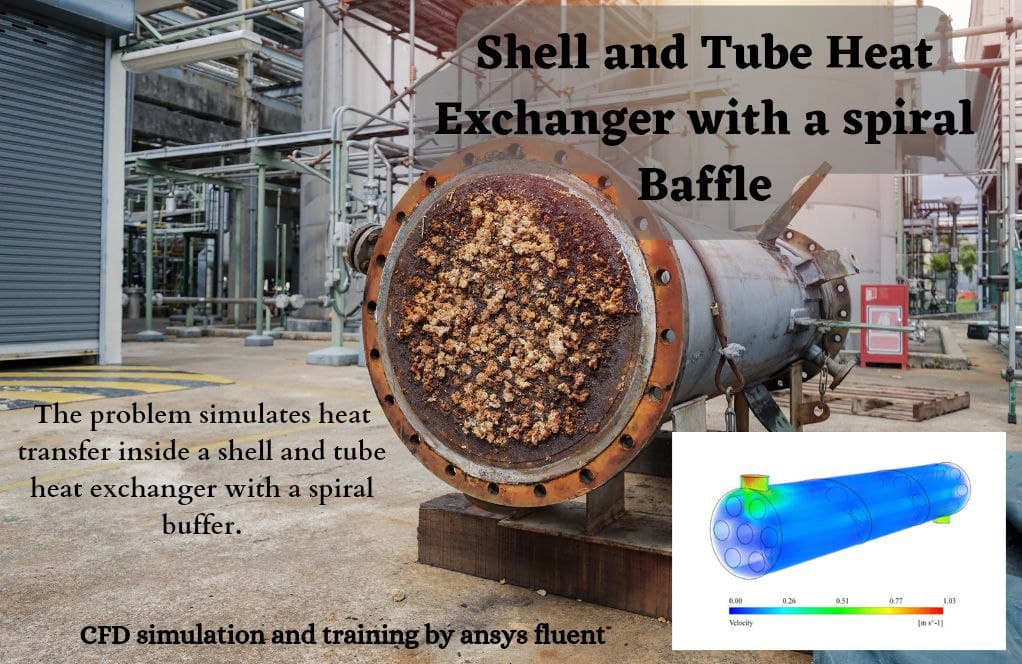

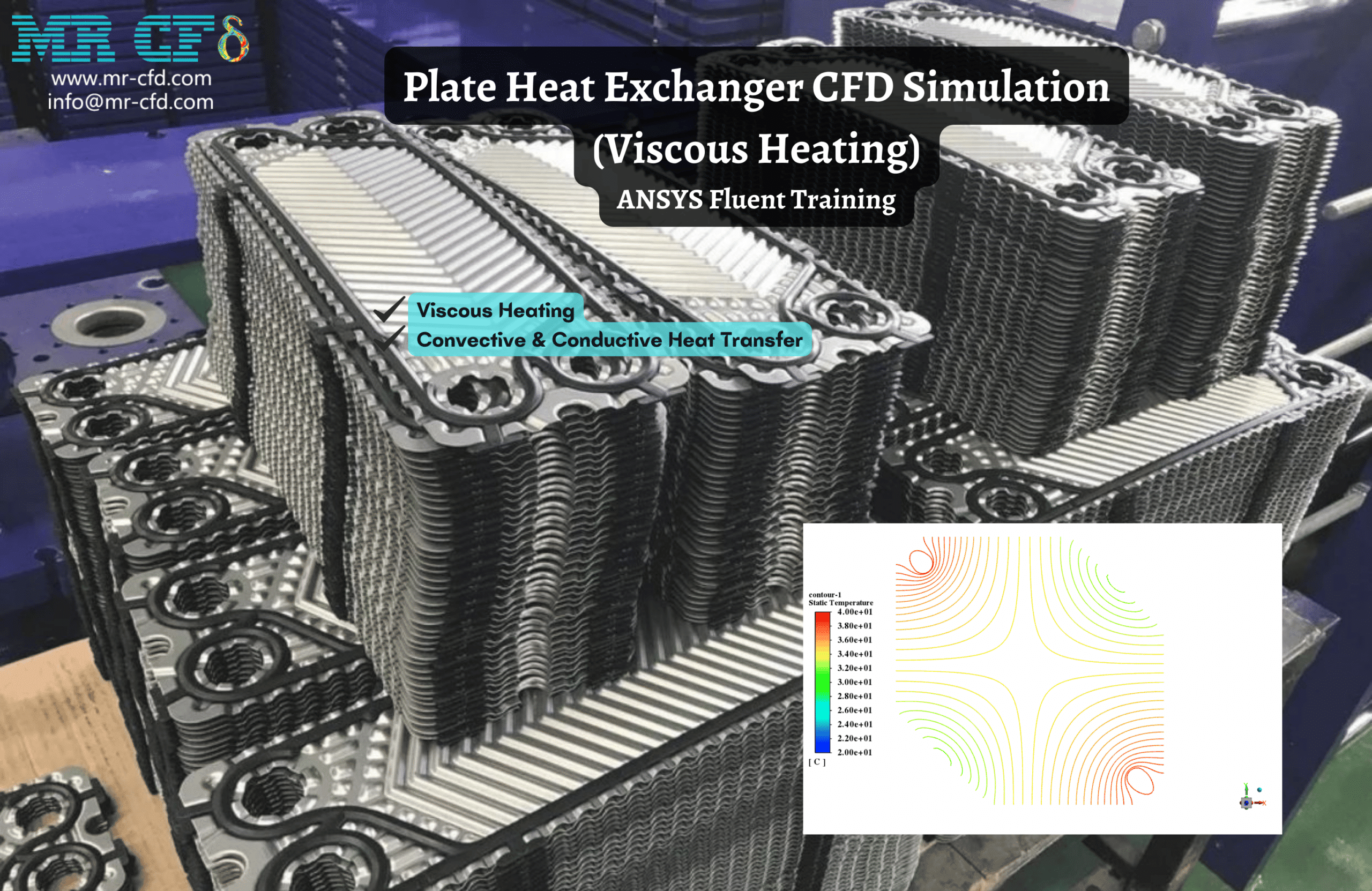

Design of Heat Exchangers

Heat exchangers can be designed more efficiently with the help of computational fluid dynamics (CFD) simulations. Heat exchanger performance can be evaluated by simulating fluid flow to pinpoint hot and cold spots. With this knowledge, we can make the heat exchanger as efficient and effective as possible.

Engineers and scientists can learn to model and simulate heat exchangers with CFD software with the help of the MR CFD heat exchanger CFD simulation training packages for Beginner, Intermediate, and Advanced users. Topics, including heat transfer, fluid flow, turbulence modeling, and mesh generation, are covered in theoretical and hands-on instruction. Expert CFD engineers will be instructing you, and you’ll get plenty of hands-on practice and analysis of real-world examples. In conclusion, anyone interested in learning more about CFD simulation for heat exchangers might choose the MRCFD training package.

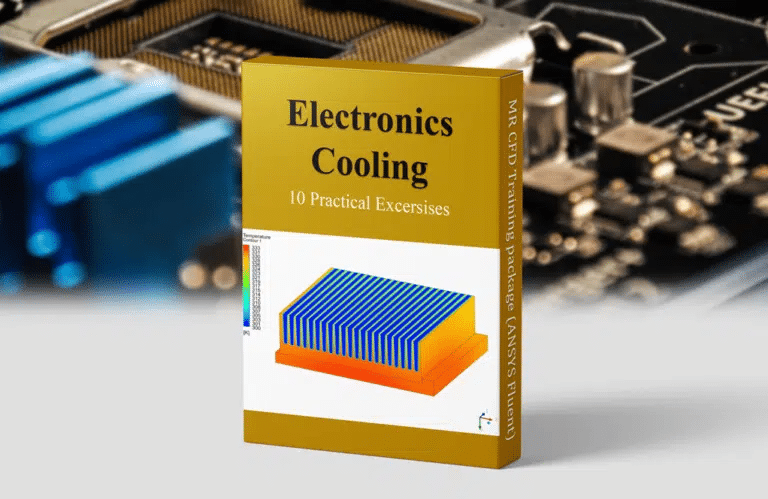

Cooling of Electronic Devices

MR CFD also provides instructions on how to use CFD simulation to cool electronic gadgets. This course is meant to teach engineers and scientists how to use CFD software for modeling and simulating the cooling of electronic equipment. Heat transfer, fluid dynamics, and thermal management of electrical devices are all included in the package. Experienced CFD engineers present both theoretical and practical components of the ANSYS Fluent software. A CFD simulation will be built up for electronic cooling purposes, and participants will learn how to analyze and understand the findings. The Electronic Cooling CFD Simulation Training Package includes practical activities and case studies to assist learners in putting what they’ve learned into practice. If you’re interested in learning more about CFD simulation for cooling electrical equipment, the MR CFD training package is highly recommended.

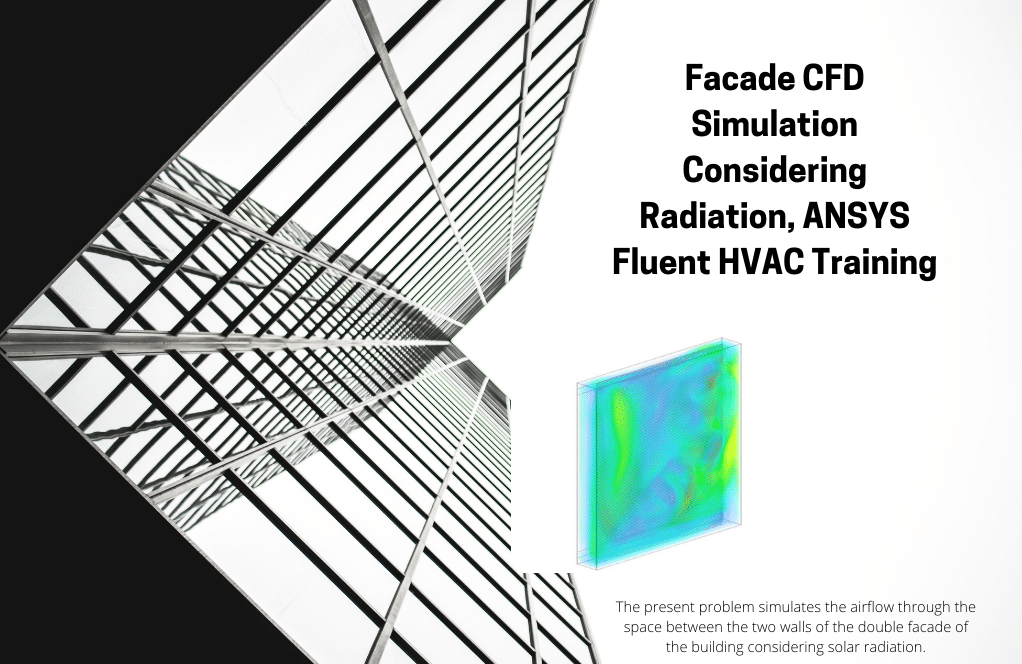

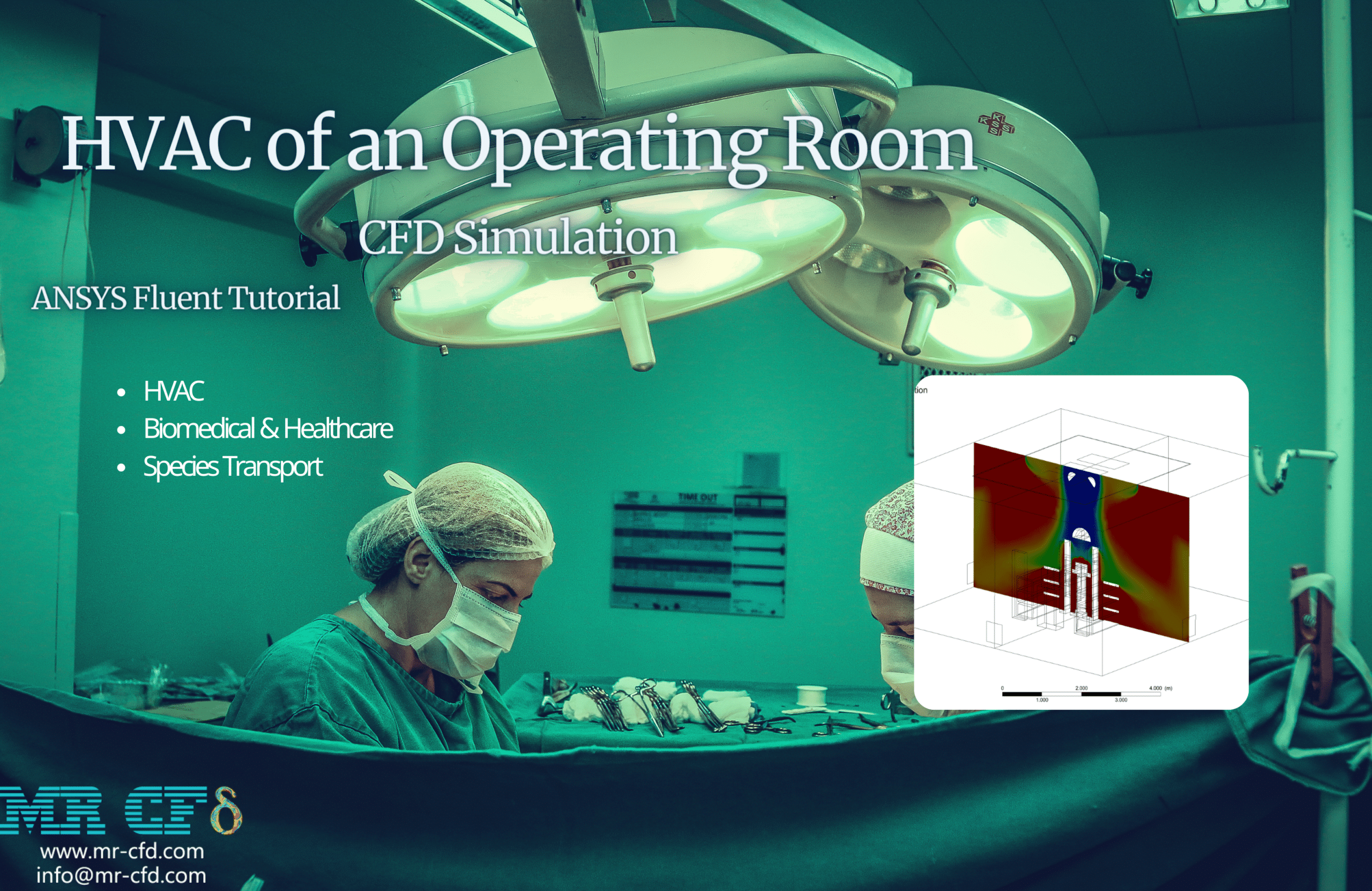

Thermal Management in Buildings

Buildings can benefit from computational fluid dynamics (CFD) simulations to improve thermal management. Engineers can better design the heating, ventilation, and air conditioning (HVAC) system for a building by simulating the airflow through the structure to pinpoint hot and cold spots.

This course will teach engineers and scientists how to use CFD software to model and simulate HVAC systems. Heat transfer, fluid flow, and indoor air quality are just a few areas covered by the package. Seasoned CFD engineers present both theoretical and practical components. A CFD simulation will be built for HVAC applications, and participants will learn how to analyze and understand the findings. The HVAC CFD Simulation Training Package includes practical activities and case studies to assist learners in putting what they’ve learned into practice for Beginner, Intermediate, and Advanced users. If you’re interested in learning more about HVAC CFD simulation, the MRCFD training package is highly recommended.

Design of Power Generation Systems

Power production systems like nuclear reactors and gas turbines can be improved with the help of computational fluid dynamics (CFD) simulations. Engineers can optimize the system’s Design for safety and efficiency by modeling the flow of fluids through the system to pinpoint hot spots and pressure spikes. Generally speaking, CFD simulations can be a valuable tool for the Heat Transfer Engineering Industries, allowing engineers to optimize the Design of systems better, increase efficiency, and guarantee safety.

MR CFD services in the Heat Transfer Engineering Industries

MR CFD conducted numerous outsourced simulation projects for industrial and researched Heat Transfer Engineering applications. With several years of experience simulating various problems in various CFD fields using ANSYS Fluent software, MR CFD is ready to offer extensive services of simulation configurations.

MR CFD is ready to offer extensive modeling, meshing, and CFD simulation services. Our essential simulation services for Heat Transfer engineering simulations are categorized as follows:

· The Design of heat exchangers, such as shell-and-tube and plate-and-frame heat exchangers, can be optimized with the help of computational fluid dynamics (CFD) simulations.

· Designing and optimizing cooling systems for electronics, engines, and other applications can be simulated with CFD software.

· The Design of heating, ventilation, and air conditioning (HVAC) systems for buildings can be optimized with the help of computational fluid dynamics (CFD) simulations, which relate to building thermal management.

· The Design of power plants, such as nuclear reactors, gas turbines, and steam turbines, can be optimized with the help of computational fluid dynamics (CFD) simulations.

· CFD simulations can represent combustion processes in industrial processes, including boilers, furnaces, gas turbines, and the resulting pollutants.

· CFD simulations can be utilized to study heat transport in porous media, such as packed beds or heat exchangers using the porous medium.

· Optimization of cooling systems for electronics, such as microprocessors, servers, and other electronic equipment, can be achieved with the help of computational fluid dynamics (CFD) simulations.

· Batteries, such as those used in electric vehicles, generate much heat, so keeping them cool is essential. Computational fluid dynamics (CFD) simulations can help with this.

· Heat transfer in boiling and condensing flows are two multiphase flows that can be modeled with CFD simulations.

· The Design of heat management systems for aerospace applications, including spacecraft, satellites, and aircraft, can be optimized with the help of computational fluid dynamics (CFD) simulations.

· …

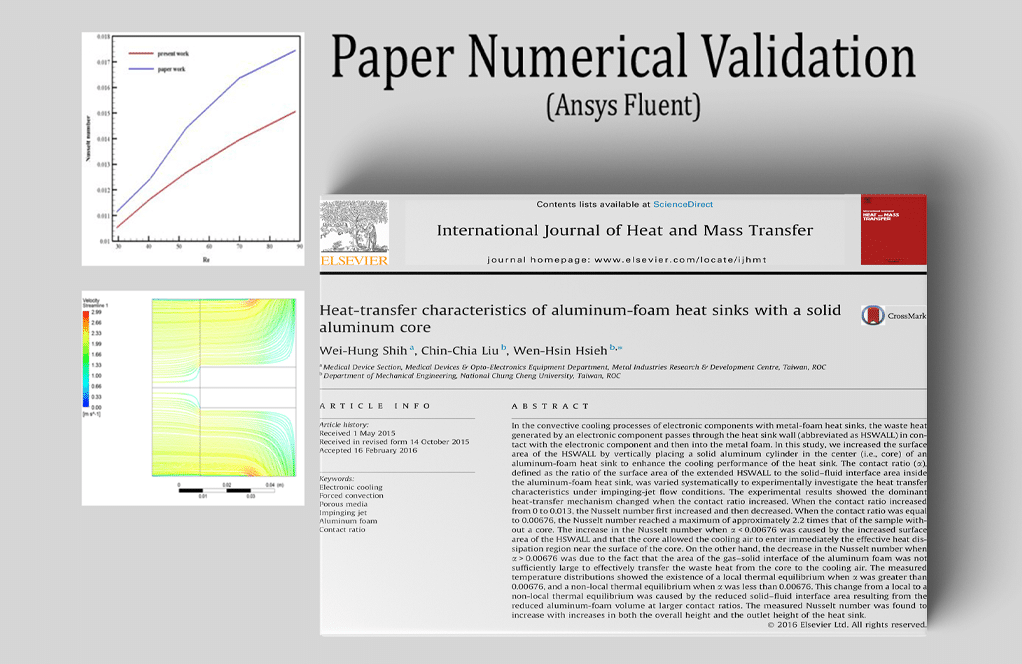

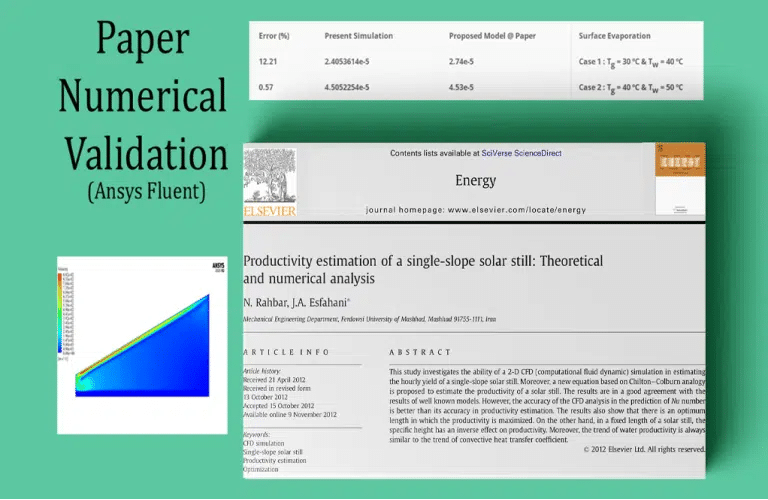

One of the valuable services of MR CFD is Paper Validation. In this way, we prove the applying CFD methodology for every project, comparing our CFD results with published and credited papers. In other words, every Numerical simulation should start with a paper verification to approve the accuracy of the CFD method.

Productivity estimation of single-slope solar still: Theoretical and numerical analysis

ANSYS Fluent models surface evaporation as part of a solar desalination system. We use CFD analysis to execute this project and learn more about it. Results from this simulation are compared and validated with those from a reference publication [Productivity estimation of single-slope solar still: Theoretical and numerical analysis].

Regardless of the temperature of the liquid’s surface, evaporation always occurs there. A solar still with a single slope is modeled here and filled with water to a specific depth. Heat is transferred from the sun to the water surface via the sloped glass surface of the solar still. Solar radiation passes through the glass and heats the water, causing the water’s surface to rise and evaporate.

This service aims to verify the accuracy of CFD models of improved heat transfer in nanofluids at varying nanoparticle concentrations. They are compared to previously published experimental data to verify the correctness and consistency of the CFD simulations. The service provides a full report on the validation outcomes, including comparing the simulated and experimental data and suggestions for enhancing the simulation’s accuracy. Based on the simulation results, the paper also contains the optimal concentration of nanoparticles for heat transfer augmentation. This service will benefit researchers and engineers working on nanofluid heat transfer systems. In conclusion, MR CFD’s nanofluid heat transfer enhancement paper validation service is an excellent tool for researchers and practitioners in heat transfer and CFD modeling.

Nanofluids, solid-liquid composites, outperform base fluids in thermal conductivity and convection heat transfer. As a result, heat transport can be improved with the use of nanotechnology. Many studies have shown that heat transmission is related to nanoparticle concentration, making nanoparticle concentration a crucial element in improving heat transfer under free convection.

In addition, knowing how the optimal concentration of nanoparticles improves heat transport is crucial. Many scientists are also engaged in natural convection analysis, which involves using mathematical models for the various features of nanofluids. This research aimed to determine the optimum concentration of nanoparticles for enhanced heat transfer utilizing TiO2 nanoparticles in water.

Using ANSYS Fluent, this project replicates the mixing of water and nanofluid in a laboratory chamber. Inspired by the research published in “Optimal Concentration of Nanofluids to Increase Heat Transfer under Natural Convection Cavity Flow with TiO2 – Water,” There is a comparison between the findings in the study and those of the quasi-simulation.

MR CFD provides instruction in using ANSYS Fluent for computational fluid dynamics (CFD) simulations of radiator thermal performance with fans. This service trains academics and engineers to model the radiator, fans, and surrounding environment for CFD simulations of radiator thermal performance with fans. Mesh creation, boundary conditions, and solver configuration are only some CFD simulation fundamentals covered in the course. Practical exercises with ANSYS Fluent software are also a part of the curriculum, covering topics such as simulation setup and execution, post-processing, and result interpretation. CFD simulations of radiator thermal performance with fans can also be validated against experimental data using MR CFD’s paper numerical validation service. To ensure the quality and reliability of the CFD simulations, this service will evaluate the numerical simulations of radiator thermal performance with fans by comparing the simulation results with published experimental data. The service provides a full report on the validation outcomes, including comparing the simulated and experimental data and suggestions for enhancing the simulation’s accuracy. MR CFD’s radiator thermal performance with fans CFD simulation training and paper numerical validation service is invaluable regarding heat transfer and CFD simulation.

The issue involves modeling the passage of air and heat from a radiator. For this simulation, we used ANSYS Fluent and the article “CFD Study on Thermal Performance of Radiators in a Power Transformer: Effect of Blowing Direction and Offset of Fans” as a guide.

The actual CFD simulation results are compared and validated with those from the current study. This radiator has three horizontally-mounted fans to distribute airflow. Multiple rows of fins and aluminum plates improve the radiator’s ability to dissipate heat.

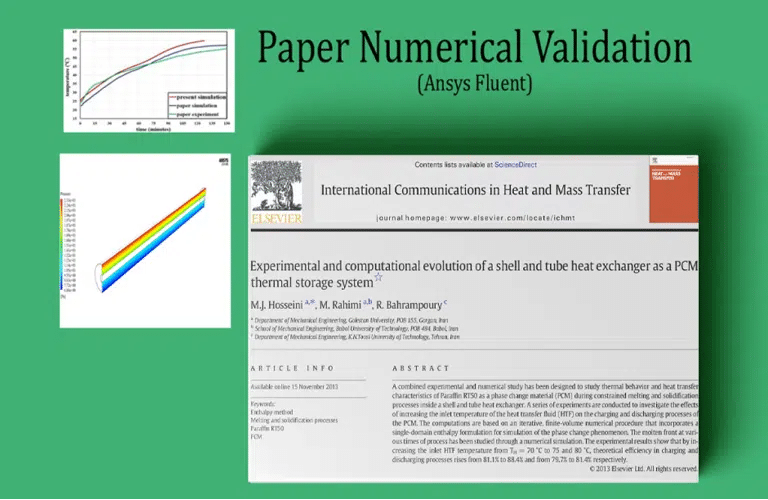

For those interested in learning how to use ANSYS Fluent for CFD simulations of shell and tube heat exchangers, including phase change materials (PCM), MR CFD provides training services. This service aims to train researchers and engineers to model shell-and-tube heat exchangers, PCM, and their environments to run CFD simulations of these systems. Mesh creation, boundary conditions, and solver configuration are only some CFD simulation fundamentals covered in the course. Practical exercises with ANSYS Fluent software are also a part of the curriculum, covering topics such as simulation setup and execution, post-processing, and result interpretation.

Regarding heat transfer and CFD simulation, MR CFD’s shell and tube heat exchanger with PCM CFD simulation training and paper numerical validation service are both excellent options. We can model the solidification and melting of a phase change material inside a shell and tube heat exchanger using ANSYS Fluent.

Based on the research paper, “Experimental and computational evolution of a shell and tube heat exchanger as a PCM thermal storage system,” numerical simulations were run and compared to the report’s findings to ensure accuracy. The article’s findings are grounded in both experimentation and computational modeling. Phase transition materials typically contain organic molecules to store vast amounts of thermal energy in a latent form. These materials can store thermal energy by going through a phase change (from solid to liquid or vice versa), during which they either absorb heat from their surroundings (causing cooling) or release heat (causing warming) depending on the direction of the phase change.

A numerical investigation of the effect of surface wettability on the boiling curve

MR CFD provides instructions on how to use ANSYS Fluent for CFD simulations of the impact of surface wettability on pool boiling. To better understand how surface wettability affects pool boiling, scientists and engineers can take advantage of this service, which teaches them how to model the boiling surface, fluid characteristics, and surrounding environment to do CFD simulations. Mesh creation, boundary conditions, and solver configuration are only some CFD simulation fundamentals covered in the course. Practical exercises with ANSYS Fluent software are also a part of the curriculum, covering topics such as simulation setup and execution, post-processing, and result interpretation.

Regarding CFD simulations of surface wettability impacts on pool boiling, MR CFD provides a paper numerical validation service. To ensure the quality and reliability of the CFD simulations, this service will evaluate the numerical simulations of surface wettability impacts on pool boiling by comparing the simulation findings with published experimental data. The service provides a full report on the validation outcomes, including comparing the simulated and experimental data and suggestions for enhancing the simulation’s accuracy.

Regarding heat transfer and CFD simulation, MR CFD’s surface wettability influence on pool boiling CFD simulation training and paper numerical validation service are invaluable assets. In this scenario, the nucleate boiling inside a vertical channel is simulated by ANSYS Fluent. The publication “A numerical investigation of the effect of surface wettability on the boiling curve” inspires the simulation. Its findings are compared to those in the paper and confirmed to be accurate. The influence of surface wettability on the boiling curve in a swimming pool is investigated.

Numerical investigation of air gap membrane distillation (AGMD): Seeking optimal performance

MR CFD provides instructions on how to use ANSYS Fluent for Air Gap Membrane Distillation (AGMD) CFD simulations. This service aims to equip scientists and engineers with the know-how to model the AGMD system, fluid characteristics, and surrounding environment to do CFD simulations of AGMD. Mesh creation, boundary conditions, and solver configuration are only some CFD simulation fundamentals covered in the course. Practical exercises with ANSYS Fluent software are also a part of the curriculum, covering topics such as simulation setup and execution, post-processing, and result interpretation.

Regarding CFD simulations of AGMD, MR CFD also provides a paper numerical validation service. To assure the correctness and reliability of the CFD simulations, this service is meant to validate the numerical simulations of AGMD by comparing the simulation results with published experimental data. The service provides a full report on the validation outcomes, including comparing the simulated and experimental data and suggestions for enhancing the simulation’s accuracy.

MR CFD’s AGMD CFD simulation training and paper numerical validation service are excellent options for membrane distillation and CFD simulation. ANSYS Fluent is used to model the air gap membrane distillation (AGMD) in this scenario. These results are based on a simulation run using data from the article “Numerical investigation of air gap membrane distillation (AGMD): Seeking optimal performance.”

Its findings are compared to those in the paper and confirmed to be accurate. There are four distinct sections within the chamber of these membrane distillation systems: one for the flow of salty water (the system’s feed water), one for the flow of freshwater (the distillate), one for an air gap, and one for the membranes or filters themselves.

It is set up in the path of hot water and ventilation. These membrane distillation systems are designed so that hot salt water flows into the chamber from one side while cold water flows in from the other. Over time, these vapors will come into contact with the space’s cold surface, causing them to lose heat and condense into water.

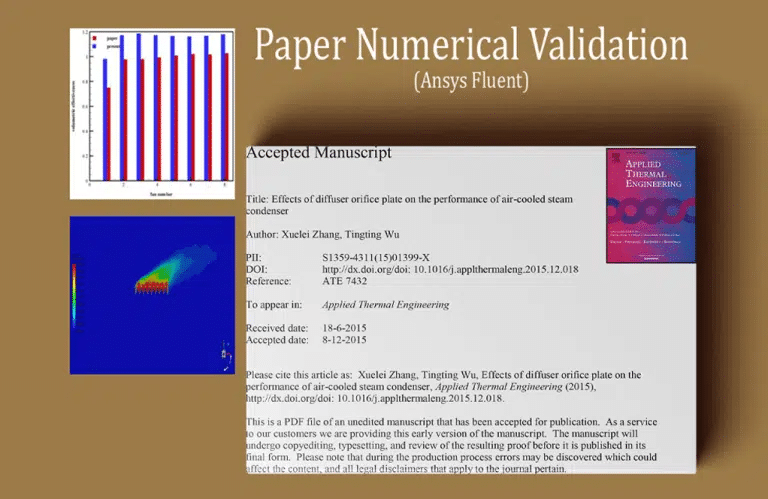

Effects of a diffuser orifice plate on the performance of the air-cooled steam condenser

This project simulates the ACSC system in a 600 MW power plant based on the article “Effects of a diffuser orifice plate on the performance of air-cooled steam condenser.” The current numerical CFD simulation work results are compared and validated with the reference paper by ANSYS Fluent software. The primary purpose of designing and using these systems in power plants is to prevent energy waste; In this way, these systems condense the hot steam from the turbine and transfer the water from the distillation process to the pump section of the steam turbine. The power plant studied in the present work consists of 7 rows of ACSC systems. The fourth row is studied in this CFD simulation. Each row of ACSC systems consists of eight fans, each located under two diagonally porous plates. The operation of these systems is such that the hot and low-pressure steam of the turbine outlet passes through each of the pipes and then is transferred to the interior space of the diagonal plates installed on both sides of that pipe.

Heat Transfer Engineering MR CFD Projects

There are several MR CFD simulation projects in Heat Transfer engineering. Following are some examples of CFD simulation projects:

Humidification Dehumidification (HDH) CFD Simulation

This Computational Fluid Dynamics (CFD) project uses the ANSYS Fluent software to study a humidification dehumidification (HDH) system. The HDH system is a model for other methods of desalinating water. The humidification and dehumidification processes provide the foundation for this method’s underlying mechanism. The evaporator, also known as the humidifier, is located on one side of the system, while the condenser, also known as the dehumidifier, is on the opposite side.

The condenser, also known as a dehumidifier, has spiral tubes into which the cold water flows. After then, it absorbs the heat from the steam within the shell. The transfer of heat will continue until the steam cools down enough to condense; as a result, the water that is contained within the tube will get warmer. This heated water is then sprayed onto the filter plates of the evaporator, which are located inside the humidifier (also known as an evaporator).

These droplets combine with the dry air expelled from the condenser to create wet steam, also known as humidified air. The final product, the steam, is free of impurities since they are left behind in the evaporator. After being warmed up by a heater, the pure steam passes through the condenser.

As was indicated earlier, the interior of the condenser shell is now in contact with the pipes that carry the cold feed water. It may proceed via the humidification or distillation processes, separating pure water from steam. This system has a two-part mechanism, which may be broken down into the categories of humidification and dehumidification. As a result, two different simulations have been carried out for this issue. The first simulation looked at how humidification affected things.

The chamber is filled with dry air that rises from the bottom to the top. While this happens, little droplets of hot salt water are sprayed through several openings within the chamber after collisions with the airflow. The droplets within the chamber’s membrane portion ultimately produce humid air.

This steam is clean and contains no salt in any form. The process of dehumidification was analyzed in the second simulation. The chamber now receives the flow of moist air made in the phase before this one. The cooling water circulation is thought to be carried out inside the chamber by spiral tubes. Condensation and the creation of freshwater are both caused when hot steam comes into contact with the cold surface of the spiral tube.

CFD Simulation Training Packages

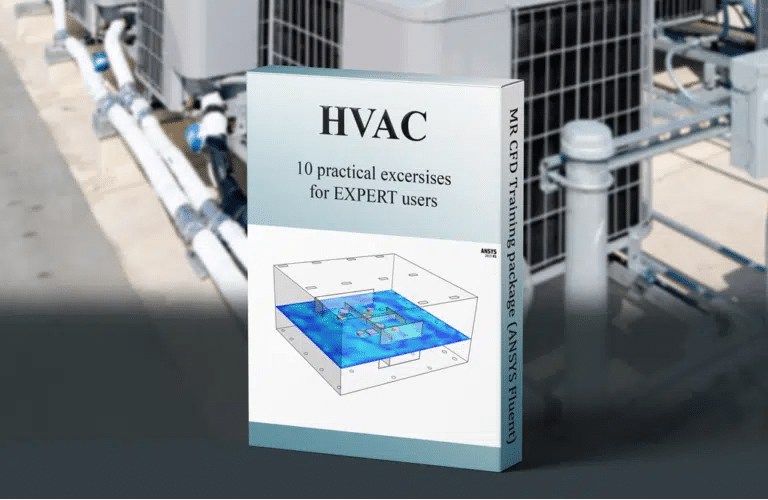

HVAC

As one of its products in the industry of heat transfer engineering, MR CFD provides a four-tiered HVAC CFD Simulation Training Package that caters to beginners, intermediates, advanced, and expert-level users, respectively. This training package will equip engineers and researchers with the knowledge required to undertake computational fluid dynamics (CFD) simulations of HVAC systems. These simulations include modeling of the system, fluid properties, and the environment in which the system is located.

The HVAC CFD Simulation Training Package is only one of the many products and services that MR CFD provides in heat transfer engineering. MR CFD also provides numerical simulations, paper numerical validation, and consultancy services in addition to the HVAC CFD Simulation Training Package. These goods and services are intended to assist customers in optimizing their heat transfer procedures, which in turn helps them to enhance efficiency and cut expenses.

MR CFD is a reliable provider of high-quality goods and services in heat transfer engineering, and the HVAC CFD Simulation Training Package is a valuable resource for those working in the field of HVAC systems. The HVAC CFD Simulation Training Package is also a valuable resource for HVAC systems workers.

Solar Air Conditioning

This training package comprises nine different CFD simulation tasks that may be completed using ANSYS Fluent. These projects are centered on solar air cooling and occur in various settings. This program comes highly recommended by MR-CFD for anyone interested in Renewable Energy Engineering, in particular Solar Energy analysis. Using this program, you will become familiar with various project descriptions and designs and the process of simulating those projects while considering the results of various connected studies.

First, we will begin the training program with a straightforward assignment focusing on solar radiation’s impact on a home’s heating, ventilation, and air conditioning system. Afterward, we will conduct an investigation into the radiation at various times during the course of a single day. After that, we evaluate the influence of more detailed effective structures like shadings, diverse facade designs, and balconies on a house’s heating, ventilation, and air conditioning system using CFD modeling. After that, we simulate the effect radiation has on buildings such as offices, mosques, and petroleum tanks. In conclusion, we will look into a detailed CFD analysis of the Urban Heating Island, also known as the UHI.

Study this fantastic and valuable training package. You can say that you are an expert in modeling and evaluating any CFD simulation connected to solar radiation and its applications. For example, you can declare that you are an expert in the solar ray tracing model. After that, you’ll be prepared to work as a CFD engineer in one of the associated fields.

- Façade Design Effect on Passive Ventilation Considering Solar Radiation

- Solar Shading Double Glazing façade, Balcony

- Solar Radiation effect at different hours and in various structures (houses, offices, …)

- Urban Heating Island (UHI)

Solar Still Desalination

This training package includes five CFD tasks that require the use of the ANSYS Fluent software and are all relevant to the CFD simulation of solar still desalination. MR-CFD recommends this program to everyone ted in Renewable Energy Engineering. Specifically, You will be given an overview of various project descriptions and designs and instruction on how to simulate those projects while considering a wide variety of studies associated numerically.

The first thing we perform when we begin the training package is a paper validation on a Single Slope Solar Still to verify the CFD approach we have been employing with the Mixture Multiphase Model. Then, using the VOF multiphase model, we will examine double-slope solar still desalination. Last, we conclude by simulating step solar still using sun ray tracking and the Species Transport model.

Nearly every one of these simulations for solar still analysis requires a UDF to impose Surface Evaporation as the primary mechanism that must be used to determine the mass transfer rate. Suppose you study this tremendous and practical training program. In that case, you can say that you are a specialist in modeling and evaluating every CFD simulation relevant to every sort of solar still desalination and its applications. After that, you’ll be prepared to work as a CFD engineer in one of the associated fields.

- Paper Validation

- Step, Single Slope, and Double Slope Solar Still Desalination

- Clean Water & Renewable Energy

- Surface Evaporation UDF

- VOF Multiphase & Species Transport

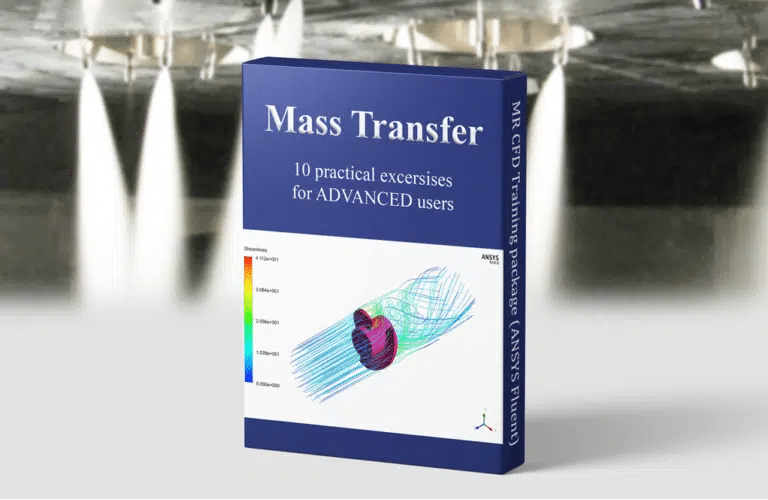

Mass Transfer

In heat transfer engineering, one of the items that MR CFD has available for purchase is the Mass Transfer CFD Simulation Training Package for Beginner and Advanced researchers. This package is intended to equip researchers and engineers with the knowledge required to carry out computational fluid dynamics (CFD) simulations of mass transfer processes. This knowledge will include modeling the system, fluid properties, and the environment in which the system is located.

In heat transfer engineering, MR CFD provides a wide variety of products and services in addition to the Mass Transfer CFD Simulation Training Package. These products and services include numerical simulations, paper numerical validation, and consultancy services. These goods and services are intended to assist customers in optimizing their heat transfer procedures, which in turn helps them to enhance efficiency and cut expenses.

MR CFD is a reliable, high-quality goods and services provider in heat transfer engineering and mass transfer processes. The Mass Transfer CFD Simulation Training Package is a significant resource for individuals who work in these areas, and it is offered as part of the company Mass Transfer CFD Simulation Training Package.

Heat Transfer Industrial Companies

Many companies specialize in heat transfer in various industries, including:

Alfa Laval: Alfa Laval is a worldwide business focusing on three core competencies: fluid handling, heat transfer, and separation. They serve food, beverage, pharmaceutical, and power sectors with heat transfer equipment.

GE Power: GE Power is a division of General Electric that manufactures and sells gas turbines, steam turbines, and heat recovery steam generators, all used to produce electrical power.

Siemens Energy: Siemens Energy is a global leader in power generation, including gas turbines, steam turbines, and heat recovery steam generators, among other products and services.

Thermax Limited: Boilers, chillers, and heat exchangers are only some of the energy and environmental solutions offered by the Indian firm Thermax Limited.

SPX Corporation: Heat exchangers, cooling towers, and filtration systems are just a few products SPX Corporation exports worldwide.

Johnson Controls: Johnson Controls is a global leader in designing, manufacturing, and supporting thermal comfort and energy management solutions for commercial and residential buildings.

Danfoss: Danfoss is a multinational corporation that manufactures and sells heat exchangers, compressors, and valves, among other HVACR components.

Trane Technologies: Trane Technologies manufactures HVAC (heating, ventilation, and air conditioning) and refrigeration (refrigeration) systems for commercial and residential buildings and factories.

Emerson Electric: Products and services from Emerson Electric include heat exchangers, compressors, and controls for use in HVAC and other industrial automation applications.

Mitsubishi Electric Corporation: Mitsubishi Electric Corporation is a multinational conglomerate specializing in power generation, HVAC, and automation, among other business areas. They offer various mechanical devices, including gas turbines, steam turbines, and heat pumps.

MR CFD Industrial Experience in the Heat Transfer Field

Following are some examples of Heat Transfer industrial projects recently simulated and analyzed by MR CFD in cooperation with related companies.

ICU Ventilation Design Improvement

This project aims to build an intensive care unit considering thermal comfort conditions, specifically PMV and PPD. In addition to this, it is critical to take measures to stop the spread of infectious diseases. Within the scope of the experiment, there is one patient, referred to only as patient #1, who is afflicted with a respiratory condition. This raises the possibility of an infection.

- The geometry is designed in Design Modeler & meshed in ANSYS Meshing software.

- One of the patients is suffering from respiratory disease. It is one of our goals to prevent it from dispersion.

- The one-way discrete Phase Model (DPM) is used to model aerosols.

- Our other concern in this project is good thermal comfort, controlled by PPD & PMV factors.

Improvements to the Greenhouse’s Ventilation and Architecture

A structure made of glass or plastic that divides a portion of a field from the surrounding environment is called a greenhouse. It protects plants against harsh weather conditions and other things that can harm their growth, such as animals and insects. For instance, it can shield plants from the damaging effects of excessively cold or hot seasons. Therefore, while constructing a greenhouse environment, the goal is to give a safe and perfect situation for sensitive plants to grow gradually, which may be tricky and challenging to govern depending on the constraints and facilities!

In this project, we aim to create a greenhouse that can fit into a 5-meter by 10-meter rectangular field and provide normal environmental conditions during the summer. These characteristics include an acceptable temperature range (294–298 degrees Kelvin), high humidity (25–30 percent mass fraction of water), and a low ammonia fraction (less than 15 parts per million). On the other hand, due to the numerous constraints imposed by the customer, including dense vegetation and incredibly delicate plants, we were forced to execute six rows of longitudinal carriers at two different heights.

The two industrial fans in the greenhouse could not meet the customer’s demand, each with a mass flow rate of 0.5 kilograms per second. Therefore, our team has accomplished the aim of supplying ideal conditions utilizing numerical methods (CFD simulation) via ANSYS Fluent software. The project is carried out in three stages, each of which will be discussed in greater depth below.

- In this project, an industrial Greenhouse has been numerically simulated by ANSYS Fluent.

- We are studying relative humidity, airflow velocity, and thermal condition.

- Removing Ammonia as a pollutant.

- Greenhouse design improvement.

- HVAC analysis.

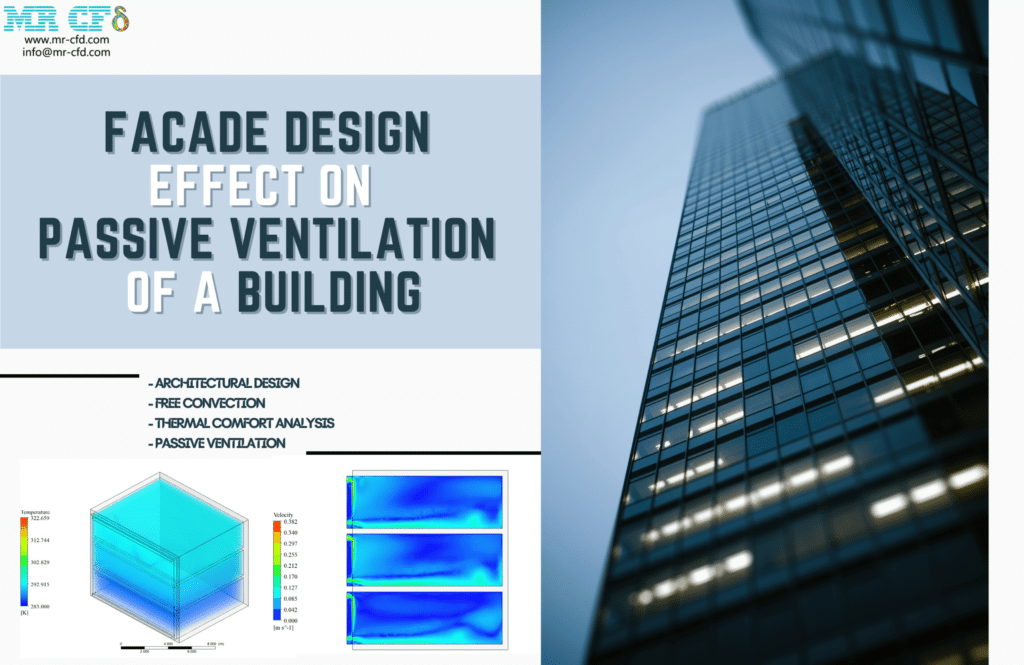

The Influence of Building Facade Design on the Use of Passive Ventilation

It is one of the most critical aspects of the overall Design of the building in terms of energy efficiency, even though it lends the structure its distinctive appearance. The shape and size of a building’s facade can take on various forms, resulting in different levels of thermal comfort and energy consumption. It is one of those components of the structure that enables the engineers to have the flexibility to provide some of the required energy by employing passive ventilation systems.

A three-story apartment in Sydney, the state capital of New South Wales, is modeled and simulated in this project. Sydney is located in Australia. In this study, numerous facade conditions are investigated to determine which ones lead to the greatest possible outcome, which takes into account natural ventilation, optimal temperature conditions, and air change per hour (ACH).

- In this project, the effects of façade design on passive ventilation of a building are numerically investigated by ANSYS Fluent.

- We study thermal conditions from the energy aspect and ventilation (ACH).

- Façade design as a passive ventilation system

- Solar ray tracing effect on heat transfer

Ventilation of the Generator Room

Ansys Fluent is the software that will be used to simulate the heating, ventilation, and air conditioning (HVAC) of a generator room for this project. After finishing the simulations, in which a generator room is first simulated without a fan, it is noted that the room temperature with 32 generators is relatively high. This is because the generators generate much heat. The temperature has been significantly reduced because 32 fans totaling 11,000 CFM have been utilized. However, to enhance ventilation and temperature and achieve the appropriate level of thermal comfort between generator rows, 32 fans with a total of 36,500 CFM have been added.

In various business settings, generators represent one of the most common and critical forms of electrical generation. When more than one generator operates nearby, the ambient temperature might become uncomfortably warm. Because of the intense heat, operators cannot access the generators during the summer months. Therefore, to address this issue, we installed several fans within the generator to lower the ambient temperature to a comfortable level for the operators.

Diesel generators are usually manufactured and distributed in various sizes to accommodate their respective uses. The apparent power establishes these dimensions as the basis for the determination. The CAT C175-20 generator, which has a power of 4000 kW, is being utilized for this project.

A high-speed centrifugal blower and an industrial suction fan are utilized when dealing with contaminated, unclean, and impure air. Additionally, this industrial fan is utilized in locations characterized by high temperatures. A TPI Commercial Belt Drive Drum Fan model, CPB 42-B, with a capacity of 13,500 CFM, and an AEROVENT type fan with a capacity of 11,000 CFM, have been used to construct this project.

Industrial Furnace

The simulation of an industrial furnace has been carried out as part of this project. The simulation results have been analyzed with the help of the ANSYS Fluent program. This CFD project is carried out, and a CFD investigation is carried out. In this endeavor, the Ansys Fluent software was used to perform a numerical simulation of an industrial furnace. Methane fuel is burned in the Furnace being replicated for this project. This aims to heat the methane within the pipes so that it may be transferred more quickly and with less effort.

When the findings are examined, it is clear that there has been a rise in temperature at the pipe’s output in comparison to the temperature at the pipe’s entrance. Combustion occurs once the fuel is introduced into the Furnace, which combines it with the present air. The floor of the Furnace contains six burners that have been installed there.

When the flame enters the radiating area of the Furnace, it strikes the pipes and causes the liquid contained within the pipe, methane, to heat up. Burnt gases come out of the chimney when combustion gases are expelled. In the oil, gas, and petrochemical sectors, furnaces supply heat for various activities requiring temperatures higher than 400 degrees Celsius.

In this endeavor, the ANSYS Fluent software was used to perform a numerical simulation of an industrial furnace. Methane fuel is burned in the Furnace being replicated for this project. This aims to heat the methane within the pipes so that it may be transferred more quickly and with less effort. When the findings are examined, it is clear that there has been a rise in temperature at the pipe’s output in comparison to the temperature at the pipe’s entrance.

- The problem numerically simulates Furnace using ANSYS Fluent software.

- We design the 3-D model with the Design Modeler software.

- We Mesh the model with ANSYS Meshing software, and the element number equals 7800000.

- We use the Species Transport model to define the combustion reaction between methane and air.

Urban Heat Island (UHI)

The investigation of urban heat islands, often known as UHIs, is one of the academic community’s most widely pursued research topics. We make use of CFD analysis in our investigations into these topics. On the North Island of New Zealand is where you’ll find the sprawling metropolis of Auckland—the urban area with the highest population in the country and the fifth largest city in Oceania overall.

To the east is the Hauraki Gulf, to the southeast are the Hanau Ranges, to the southwest is Manuka Harbor, and to the west are the Waitakere Ranges. Auckland is located in New Zealand. The slopes of the neighboring hills are blanketed in tropical forest, and there are 53 active volcanoes scattered across the terrain. The climate of Auckland is classified as oceanic. The National Institute of Water and Atmospheric Research (NIWA) identifies the climate there as subtropical. This city has summers that are warm and muggy and winters that are mild but humid.

Occasional instances of air pollution caused by emissions of fine particles can be found in Auckland. There are also sporadic instances of carbon monoxide levels that exceed the recommended thresholds. Even though marine winds typically do a pretty good job of dispersing pollution in a relatively short time, smog can occasionally form, particularly on still winter days. As a result of the location of the mean high-pressure band in the New Zealand sector of the Southern Hemisphere, nearly 30 degrees South, the winds that blow over the country are predominantly westerly.

However, daily, there is a large amount of fluctuation in how the pressure is distributed. Sometimes extremely powerful anticyclones will form in the southern part of the country, while depressions will form in the northern part. They are responsible for reversing the typical weather pattern, which results in an easterly flow. These stumbling blocks may linger for a while. They break in the more typical westerly winds connected with advancing meteorological systems toward the east.

This simulation aims to investigate ocean breezes’ influence on the traffic patterns on urban highways in the city of Auckland. As a result, the urban plan of the Auckland University of Technology (UHI) will serve as the focus of our investigation into this matter.

- In this project, an Urban Heat Island (UHI) has been numerically simulated by ANSYS Fluent.

- Investigating Wind and Thermal Comfort, Considering Solar Radiation.

- Renovation Suggestion for Local Improvement.

- Urban Planning.

MR CFD conducted numerous outsourced CFD simulation projects for industrial companies and research in Heat Transfer Engineering applications. With several years of experience simulating various problems in various CFD fields using ANSYS Fluent software, the MR CFD is ready to offer extensive CFD Simulation, Training, and Consultation services.

You may find the Learning Products in the Heat Transfer Engineering CFD simulation category in Training Shop. You can also benefit from Heat Transfer Engineering Training Packages appropriate for Beginner, Intermediate, and Advanced users of ANSYS Fluent. Also, MR CFD is presenting the most comprehensive Heat Transfer Engineering Training Course for all ANSYS Fluent users from Beginner to Experts.

Our services are not limited to the mentioned subjects. The MR CFD is ready to undertake different and challenging projects in the Heat Transfer Engineering modeling field ordered by our customers. We even carry out CFD simulations for any abstract or concept Design you have to turn them into reality and even help you reach the best strategy for what you may have imagined. You can benefit from MR CFD expert Consultation for free and then Outsource your Industrial and Academic CFD project to be simulated and trained.

By outsourcing your project to MR CFD as a CFD simulation consultant, you will not only receive the related project’s resource files (Geometry, Mesh, Case & Data, …), but also you will be provided with an extensive tutorial video demonstrating how you can create the geometry, mesh, and define the needed settings(pre-processing, processing, and post-processing) in the ANSYS Fluent software. Additionally, post-technical support is available to clarify issues and ambiguities.