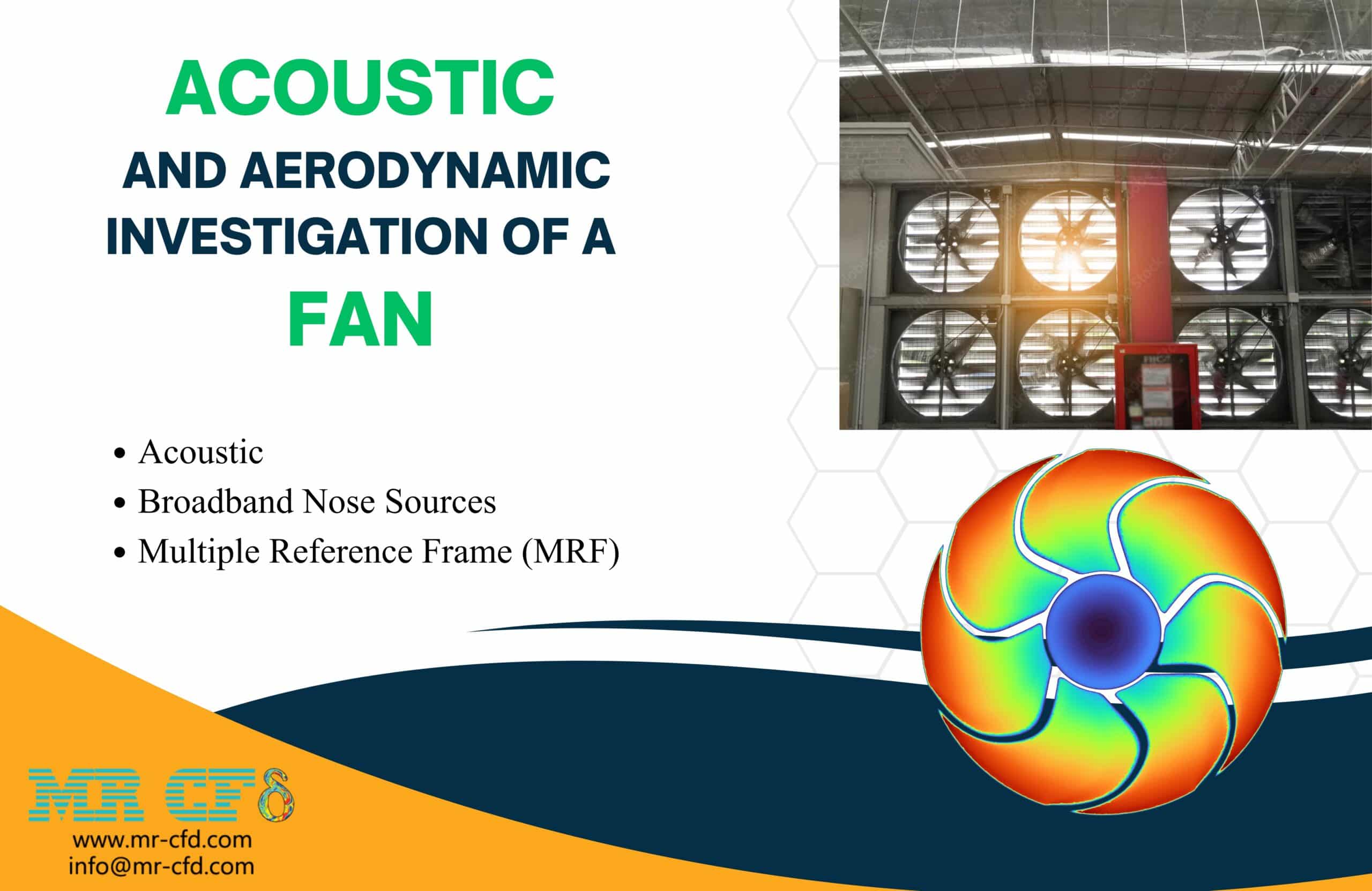

Acoustic and Aerodynamic Investigation of a Fan Using the MRF Technique in ANSYS Fluent

$120.00 $48.00 HPC

- The fan geometry, consisting of six blades and three zones, was created in DesignModeler and meshed with an unstructured tetrahedral grid of about 3 million elements.

- Broadband noise sources were applied in ANSYS Fluent to evaluate the acoustic performance and sound power level distribution.

- The Multiple Reference Frame (MRF) approach was used to model the rotating zone at 3000 RPM under steady-state conditions.

- Results show high-pressure and velocity regions near the blade tips, leading to stronger acoustic power levels along the fan casing.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

CFD Simulation of Acoustic and Aerodynamic of a Fan Using Frame Motion

Description

This project focuses on the acoustic analysis of a six-bladed fan using ANSYS software. The main objective is to study the airflow behavior and noise generation around the fan under specific operating conditions. The simulation aims to predict the broadband noise levels and better investigate the distribution of pressure and velocity fields to understand the fan’s aerodynamic and acoustic performance. The analysis helps identify key areas responsible for high noise generation and can be used to improve fan design for better efficiency and reduced noise levels.

Geometry and Mesh

The fan geometry was created in ANSYS DesignModeler and consists of three zones representing the flow domain and the fan structure. The fan model features six blades attached to a central hub within a cylindrical enclosure. The geometry was imported into ANSYS Meshing, where a non-conformal, unstructured mesh was generated. A fine tetrahedral mesh captured complex flow features around the blades, resulting in approximately 3 million elements. The mesh quality was carefully checked to ensure accurate flow and acoustic predictions while maintaining computational efficiency.

Model and Solver Settings

The simulation was performed in ANSYS Fluent using a pressure-based, steady-state solver. The turbulence effects were modeled using the standard k–ε turbulence model with standard wall functions to account for near-wall flow behavior. The fan rotation was modeled using the Multiple Reference Frame (MRF) approach at a rotational speed of 3000 RPM. Pressure inlet and pressure outlet boundary conditions were applied at the corresponding surfaces. The coupled algorithm achieved the pressure-velocity coupling, and hybrid initialization was employed to enhance solution convergence. The broadband noise model was used for acoustic analysis to estimate noise sources based on turbulent fluctuations.

Results

The results include contours of pressure, velocity, and acoustic power levels across the fan domain. As shown in the pressure contours, higher pressure regions appear near the leading edges of the blades. In contrast, lower pressure zones occur at the trailing edges, indicating the lift effect generated by rotation. The velocity contours reveal maximum airspeed near the blade tips, demonstrating strong tangential flow due to rotation. The acoustic power level plots indicate that the highest noise is concentrated around the blade tips and outer casing, where turbulent interactions and velocity gradients are most intense. Overall, the simulation successfully captures the aerodynamic and acoustic behavior of the fan under steady operating conditions.

You must be logged in to post a review.

Reviews

There are no reviews yet.