Battery Pack 1P6S, Paper Numerical Validation, ANSYS Fluent

$240.00 $96.00 HPC

- This product numerically simulates a Battery Pack using ANSYS Fluent software.

- We design the 3-D model with the Design Modeler software.

- We mesh the model with ANSYS Meshing software.

- The battery pack is constructed of six batteries stacked in Series, called 1P6S.

- We use the Battery Model to define the discharge process of a battery.

- We use the Multi-Scale Multi-Domain (MSMD) solution method and the NTGK electrochemistry model.

- The present CFD work is Validated with a reference Article.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Description

In this project, we perform the CFD simulation of a “Battery Pack” in ANSYS Fluent software.

We present this CFD product based on the simulation of a reference article, “Thermal analysis of phase change material encapsulated Li-ion battery pack using multi-scale multi-dimensional framework.” So, we compare the results of the present work with the reference article to validate the paper.

According to the reference paper, we implement paper validation in Three steps. In other words, we analyze the performance of the battery system in 3 different cases:

- 1st part: a single battery

- 2nd part: a single battery with PCM cover

- 3rd part: a battery pack

The present product is related to the Third case of the battery system simulation: “a Battery Pack in Serial connection”.

So, we analyze a battery pack, represented as “1P6S”. This battery pack, involving 6 pouch-type Li-ion batteries, is configured in a serial arrangement.

Methodology

First, we model the computational domain geometry using “Design Modeler” software. So, we design 6 vertical pouch batteries as a battery pack with a real connection. Each battery cell consists of an active cell with positive and negative tabs, which are connected by busbars through the non-identical tabs.

Next, we mesh the model using “Ansys Meshing” software, and 357,535 elements are generated.

Finally, we simulate the present battery system using the “Battery Model” in Ansys Fluent software.

So, we use the Multi-Scale Multi-Domain (MSMD) solution method. The MSMD is a comprehensive method for modeling lithium-ion batteries, because it involves a multi-scale and multi-physical nature.

Then, we use the NTGK (Newman, Tiedemann, Gu, and Kim) electrochemistry sub-model. The NTGK model is a semi-empirical method for electrochemical computations.

We intend to analyze the battery discharge process at a 5 C-rate. The C-rate is the charging/discharging current to the battery’s nominal capacity. We set up battery modeling information according to the reference article, including materials, boundary conditions, battery parameters, etc.

Since the charging/discharging process in the battery system occurs over time, we run the calculation in an unsteady state (transient).

Conclusion

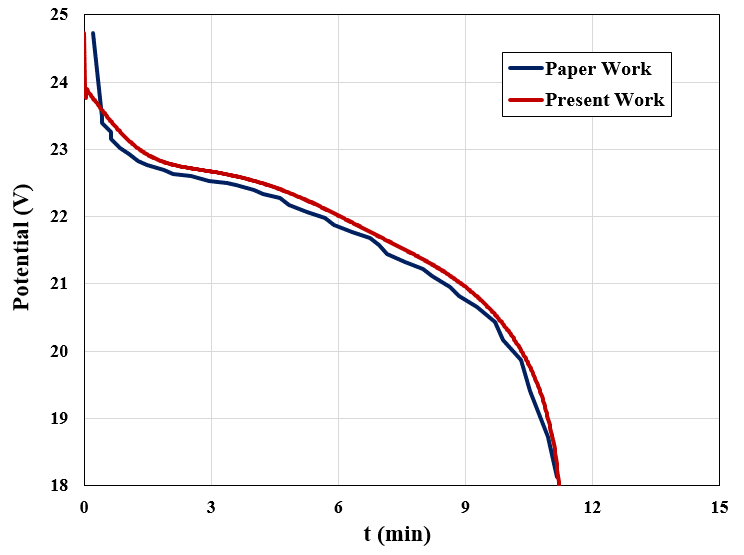

For the post-processing, we analyze the present battery system for approximately 13 min.

We obtain contours of the temperature distribution and the potential field distribution at the last time.

The results show that when the battery pack is discharging, its overall voltage decreases. On the other hand, considerable heat is generated due to the electrochemical operation of the battery pack, and as a result, the surface temperature of individual batteries increases.

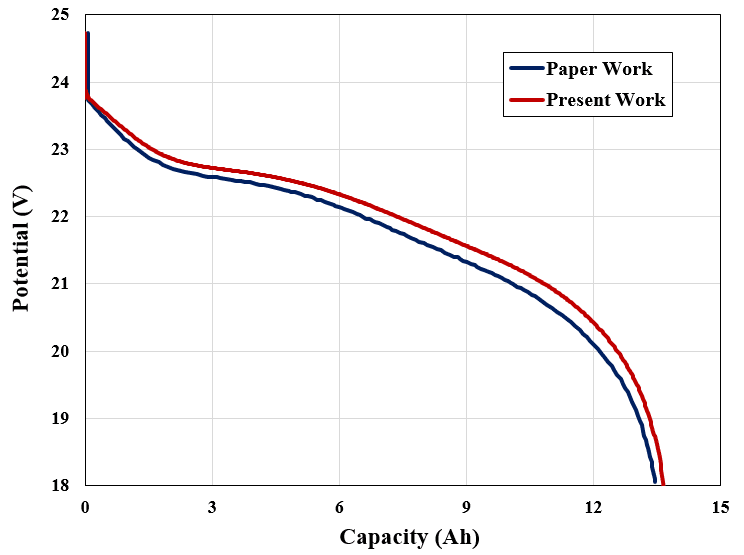

Finally, we compare the present results with the paper to achieve paper validation. Therefore, we present the battery pack voltage over time and the battery pack voltage with respect to capacity.

You must be logged in to post a review.

Reviews

There are no reviews yet.