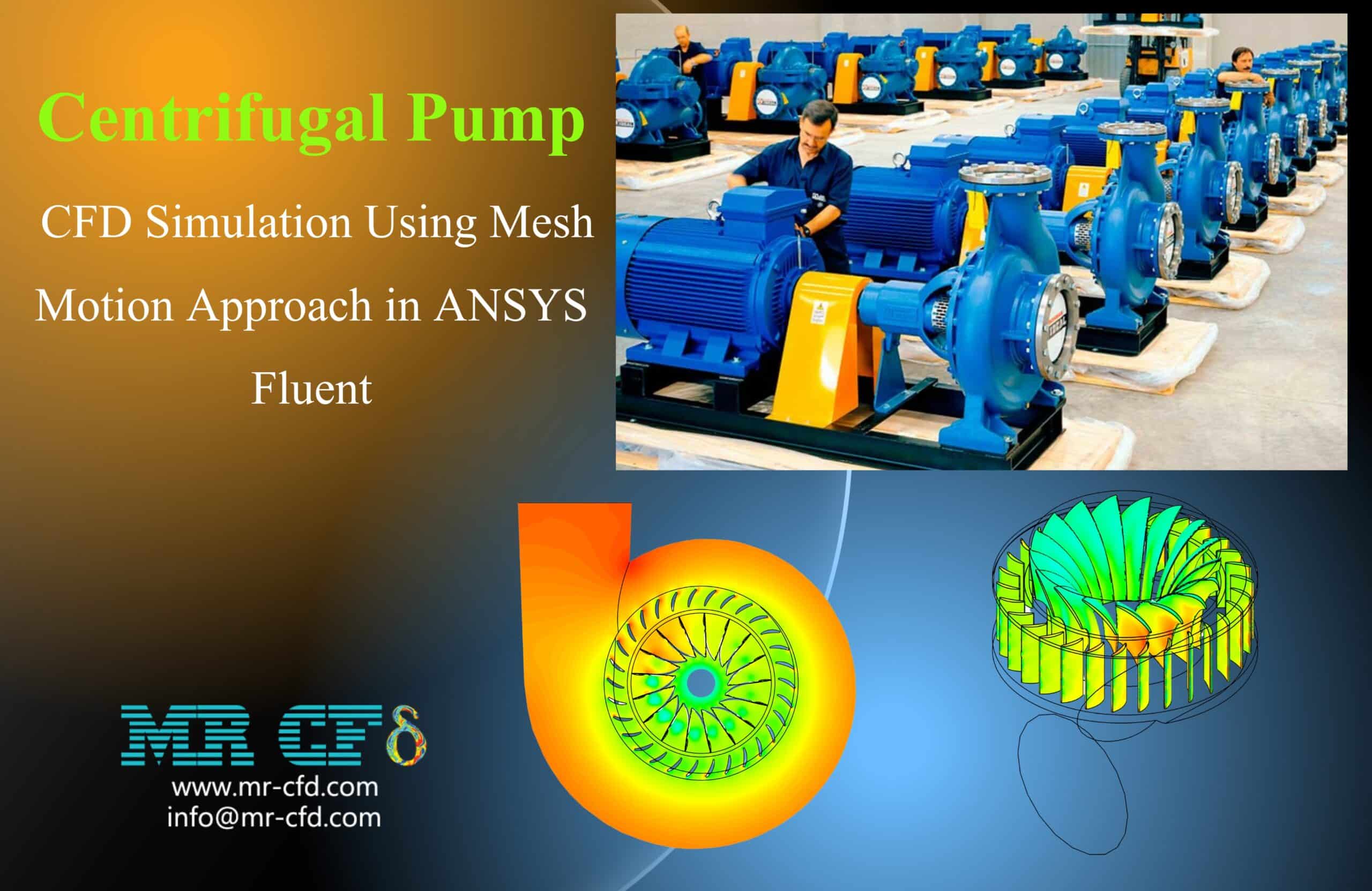

Centrifugal Pump (3D) CFD Simulation Using Mesh Motion Approach in ANSYS Fluent

$120.00 $48.00 HPC

- This project presents a CFD simulation of a centrifugal pump performed in ANSYS Fluent using the mesh motion approach.

- The geometry was modeled in SpaceClaim/DesignModeler and discretized into a high-quality tetrahedral mesh (About 2M elements).

- A pressure-based transient solver with the k–ω SST turbulence model was applied, with water as the working fluid.

- Results show a clear pressure rise from impeller inlet to outlet, confirming efficient energy transfer by the pump.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

CFD Simulation of a (3D) Centrifugal Pump Using Mesh Motion in ANSYS Fluent

Description

In this study, a centrifugal pump was simulated using ANSYS Fluent 2024 R2 with the mesh motion (moving mesh) approach. The goal was to evaluate the flow behavior, pressure distribution, and energy transfer from the impeller to the fluid under transient operating conditions. The pump geometry used in this project was based on a design similar to the centrifugal pump simulation using the MRF approach. Unlike the steady MRF (Multiple Reference Frame) method, here a mesh motion strategy was adopted to capture the unsteady rotor–stator interaction, which leads to more accurate representation of transient flow effects inside the pump.

Geometry and Mesh

The computational geometry of the pump was created using ANSYS SpaceClaim and DesignModeler. It consisted of two main zones:

- A rotating zone (impeller), where mesh motion was applied.

- A stationary zone (casing/volute), which housed the flow channel and outlet.

The domain was discretized in ANSYS Meshing using a non-conformal interface between the two zones to allow relative rotation. The final grid contained approximately 2 million tetrahedral elements. Figure 4 shows the generated mesh, where the casing, inlet, and impeller regions are clearly resolved to ensure sufficient accuracy for transient CFD analysis.

Models and Solver Settings

The simulation was carried out in ANSYS Fluent using the following setup:

- Solver Type: Pressure-based, transient solver.

- Turbulence Model: k–ω SST model, chosen for its robustness in handling rotating machinery and near-wall flow prediction.

- Working Fluid: Incompressible water.

- Rotational Speed: Impeller operated at 1500 RPM with mesh motion enabled.

- Boundary Conditions:

- Inlet: Velocity inlet of 140 m/s.

- Outlet: Pressure outlet.

- Coupling Scheme: Pressure–velocity coupling handled by the Coupled algorithm for enhanced convergence in transient flow.

This setup ensured the capture of time-dependent fluid–structure interactions inside the rotating domain and realistic flow development through the casing.

Results

The CFD results provided valuable insight into the pressure and velocity fields of the centrifugal pump. Pressure contours (Figures 1–3) indicate a clear pressure rise from the eye of the impeller to the casing outlet, demonstrating the energy imparted by the rotating blades to the fluid. High-pressure regions appear near the impeller exit, while low pressure occurs at the inlet region, consistent with expected pump operation.

The transient effects of the rotating impeller were also visible in the form of unsteady pressure fluctuations and localized vortices within the casing. Compared to a steady MRF approach, the mesh motion method allowed for capturing directional flow development and secondary circulation more realistically.

Overall, the simulation confirmed the pump’s ability to effectively accelerate the fluid and increase the pressure head, validating the moving mesh approach as a suitable method for studying unsteady pump behavior.

You must be logged in to post a review.

Reviews

There are no reviews yet.