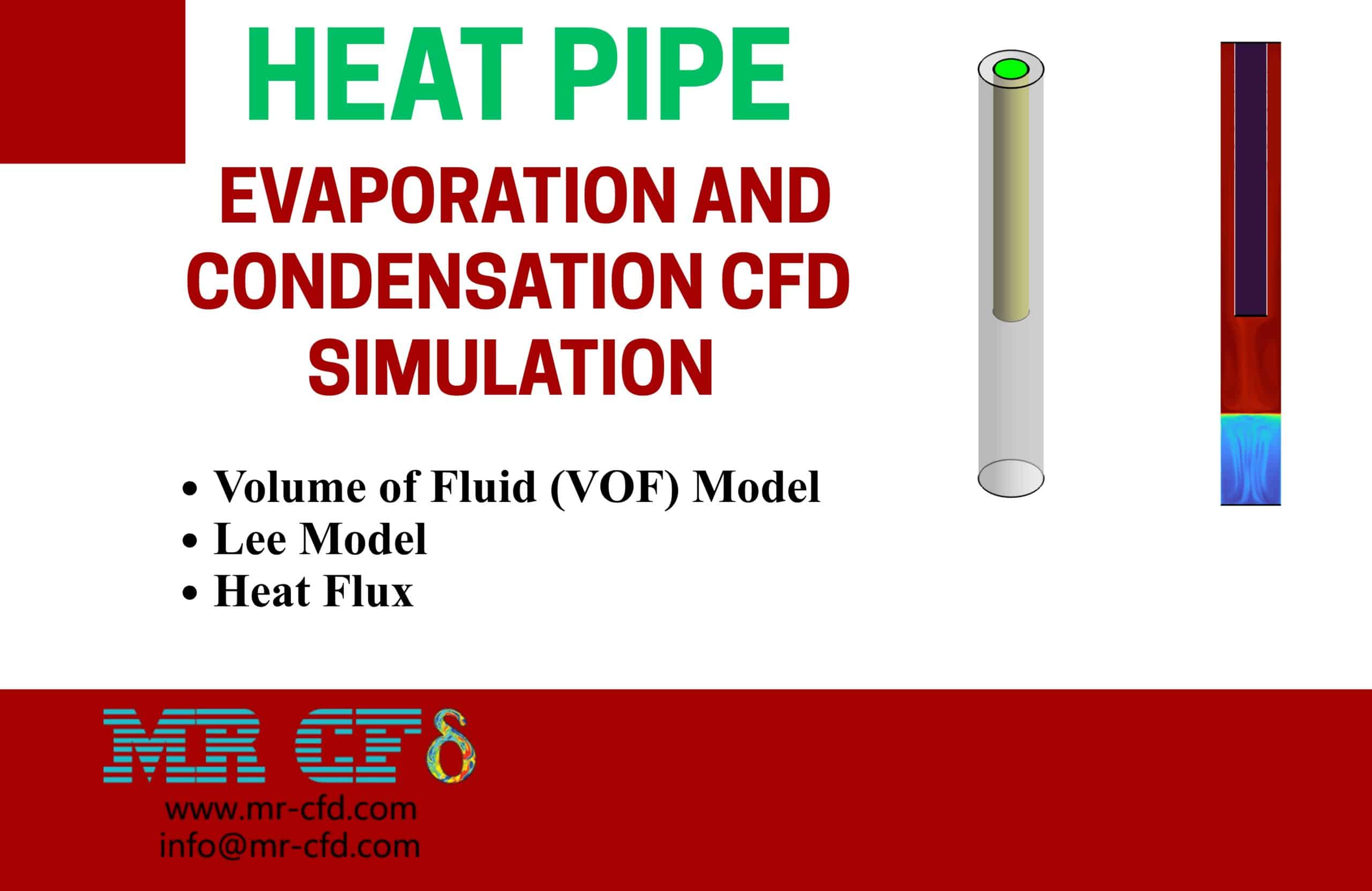

Heat Pipe Evaporation and Condensation CFD Simulation Using ANSYS Fluent

$120.00 $48.00 HPC

- This transient 3D simulation models evaporation and condensation of water in a thermosyphon heat pipe using the VOF and k‑ε models.

- The domain, meshed with 3,900,000 elements, includes heated and cooled sections defined by heat‑flux and temperature boundaries.

- At t = 1.655 s, liquid accumulates in the evaporator, vapor rises to the condenser, and condensation occurs at cooler surfaces.

- Contours of mass transfer, liquid fraction, temperature, and velocity confirm stable phase circulation and efficient heat transport.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

CFD Simulation of Heat Pipe Evaporation and Condensation Using Volume of Fluid (VOF)

Description

This project uses ANSYS Fluent software to present a transient numerical simulation of evaporation and condensation phenomena in a heat pipe. The study aims to analyze the complex three-phase flow behavior within a thermosyphon heat pipe system under operating thermal conditions. Heat input at the evaporator region leads to vapor formation. In contrast, heat removal at the condenser promotes condensation, creating a continuous phase change cycle that enables efficient thermal transport within the device. The simulation captures the transient evolution of vapor generation, condensate return, and fluid circulation inside the heat pipe.

Geometry and Mesh

The three-dimensional geometry of the thermosyphon heat pipe was created using the ANSYS DesignModeler. Then, the geometry is inserted into the ANSYS Meshing software. The model includes three primary sections: the evaporator at the bottom (heat input zone), the adiabatic middle section (insulated zone), and the condenser at the top (cooling zone). The domain was discretized using an unstructured mesh of approximately 3,900,000 elements, providing adequate resolution for accurate transient multiphase predictions. The overall mesh distribution ensures smooth fluid flow and reliable representation of phase boundaries without excessive computational cost.

Model and Solver Settings

A three-phase Volume of Fluid (VOF) model was adopted to simulate the interaction among liquid water, vapor water, and air as the non-condensable phase. The standard k–ε turbulence model with standard wall functions accounted for turbulent effects in vapor and liquid regions. The evaporation–condensation mechanism in ANSYS Fluent was employed to handle phase change based on local pressure and temperature fields. The heat flux boundary condition was applied at the evaporator wall to provide the required energy input, while the condenser wall was maintained at a fixed temperature to facilitate condensation. The remaining walls were treated as adiabatic surfaces, ensuring that all heat transfer occurs only between the active evaporator and condenser regions. The simulation was run under transient conditions to capture the dynamic evolution of vapor and liquid distribution over time.

Results

At the transient time of 1.655 s, the contours illustrate the dynamic evaporation and condensation processes occurring inside the thermosyphon heat pipe. The liquid volume fraction contour shows that the working fluid, is mostly concentrated at the lower evaporator region, where the volume fraction approaches unity, while the upper zones exhibit very low liquid content, indicating vapor formation and motion toward the condenser. The mass transfer rate contour confirms this behavior, with positive values in the evaporator zone showing active vapor generation as liquid absorbs heat from the wall heat flux; near the condenser, the mass transfer decreases, reflecting ongoing condensation on the cooled surfaces. The temperature contour exhibits a clear gradient along the length of the pipe, with the evaporator sustaining higher temperatures of about 323 K and the condenser maintained near 283 K, which drives continuous phase change and circulation. Meanwhile, the velocity magnitude contour reveals enhanced flow near the interface regions, where vapor formation induces upward motion within the pipe core and slower, downward motion of condensate near the walls. Overall, these transient results demonstrate a well‑developed two‑way flow loop characteristic of effective thermosyphon performance, with strong evaporation at the heated section and condensation at the cooled region, ensuring efficient heat transfer through phase change.

You must be logged in to post a review.

Reviews

There are no reviews yet.