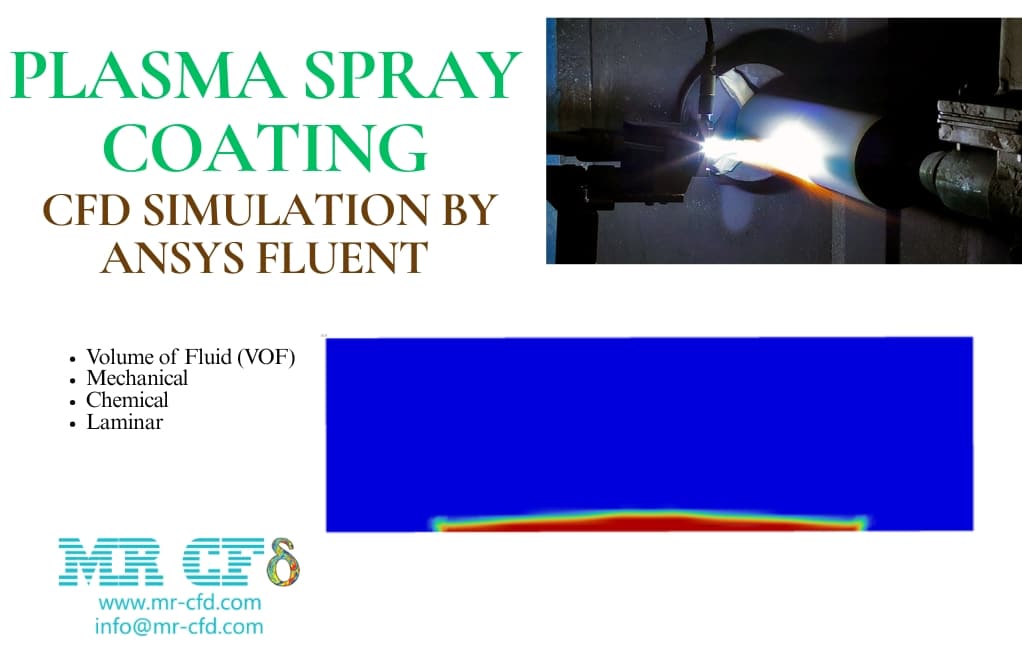

Plasma Spray Coating CFD Simulation by Ansys Fluent

$120.00 $48.00 HPC

- The project involves the numerical simulation of plasma spray coating using Ansys Fluent.

- Based on the paper, the study analyzes the impact and spread of Titanium Oxide on a surface.

- The 3D geometry is developed using the Design Modeler software.

- The meshing process utilizes ANSYS Meshing software, generating a structured mesh with 1,299,934 elements.

- The simulation utilizes a VOF multiphase model to capture the dynamics of droplet impact and spreading accurately.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Coating Simulation Using Ansys Fluent

Project Description

In this project, CFD modeling of plasma spray coating using Ansys Fluent is simulated. Regarding the paper entitled “Application and benchmark of SPH for modeling the impact in thermal spraying, “the volume fraction of Titanium Oxide on a wall has to illustrate the material appropriately spread, such as Figure 5 of the article.

Geometry and Mesh:

The geometry of the Plasma spray was drawn with Design Modeler software. As mentioned in the article, the computational domain extended 225 micrometers in the X direction, 225 micrometers in the Y direction, and 75 micrometers in the Z direction. Then, the geometry was imported to the Ansys Meshing software and generated 1299934 structure cells.

Methodology:

The plasma spray simulation solved transient and pressure-based. The Titanium oxide droplet has a 62-micrometer diameter and is moving with a velocity magnitude of 200 m/s. The VOF multiphase model is employed for the simulation.To simulate titanium, we create a cell region at (0, 0.04, 0 )coordination with a 0.031 mm radius and patch this region as titanium.

Results

As the contour below shows, the collision of the droplet with the wall results in its spread over the wall surface. The contour depicts the final state of the titanium oxide droplet. To understand the underlying process, an animation has been extracted and is attached to the report.

You must be logged in to post a review.

Reviews

There are no reviews yet.