Shell and Tube Heat Exchanger, Helical Fin, NanoFluid

$140.00 Student Discount

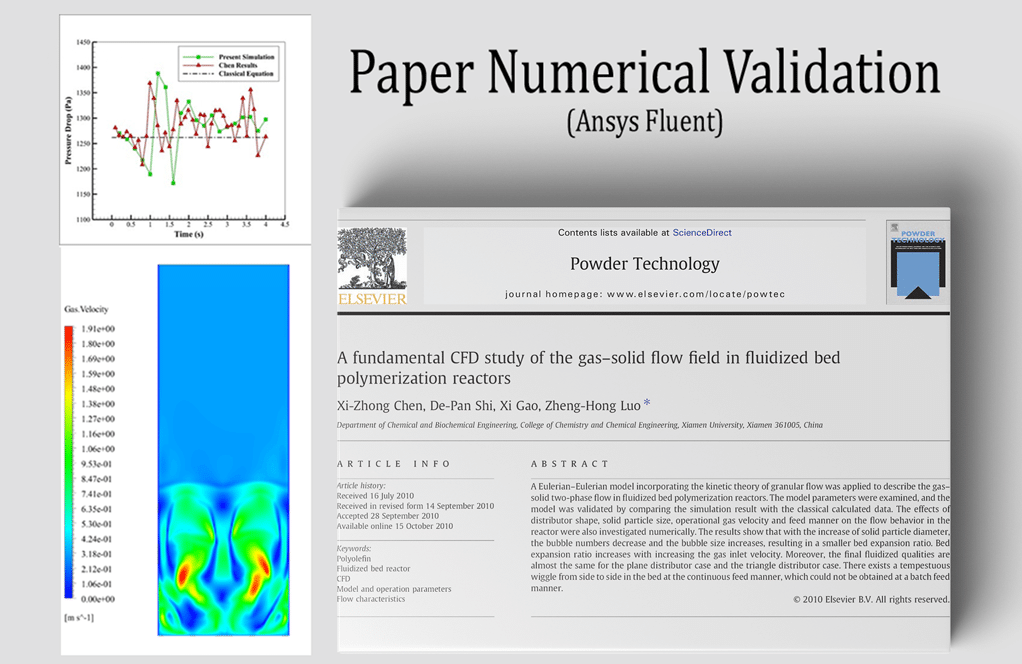

- In this project, we simulate a Shell & Tube Heat Exchanger with Helical Fin considering NanoFluid, by ANSYS Fluent software.

- The 3-D geometry of shell and tube heat exchanger considering a helical tape is designed and meshed by Design modeler and ANSYS Meshing software, respectively.

- The nano-fluid is modeled by applying multiphase flow (Mixture method).

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Shell and Tube Heat Exchanger, Helical Fin, Mixture NanoFluid, ANSYS Fluent CFD Simulation Training

This simulation is about a shell and tube heat exchanger with helical fins via ANSYS Fluent software.

Heat exchangers are mechanical devices that transfer heat between hot and cold sections. Heat exchangers have many applications in industry and are made in different types. One of the industry’s most common and widely used types is shell and tube, heat exchangers.

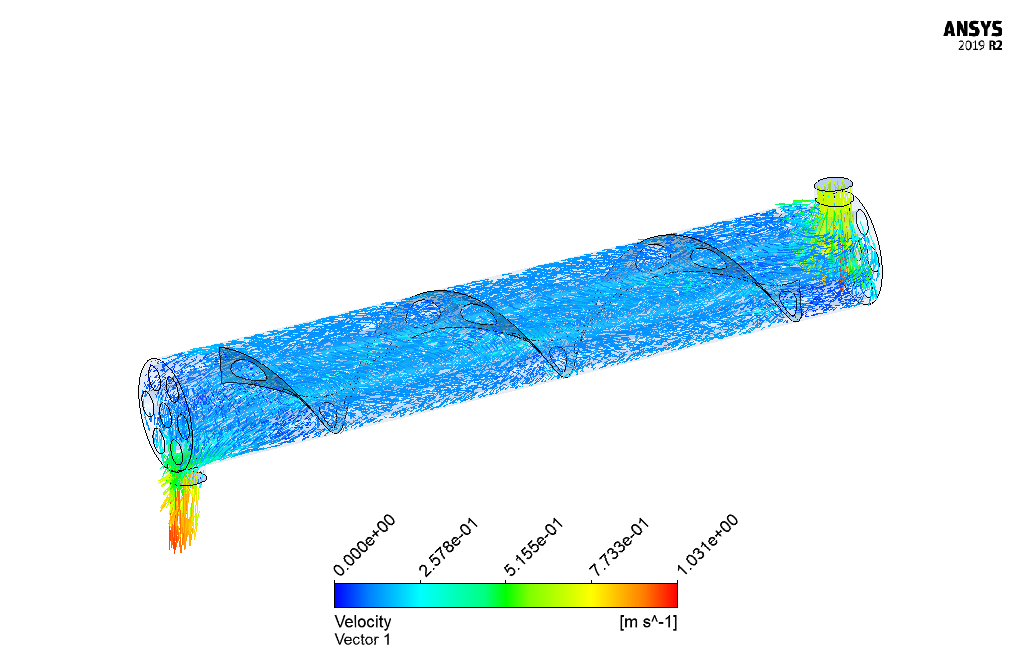

One of the two cold or hot flows passes through the heat exchanger’s tubes, and the other flow passes through the shell. Now, if helical fins are used inside the heat exchanger’s shell, it will prolong the movement of the fluid inside the shell and increase the chance of contact with the surface of the tubes.

As a result, the heat transfer rate inside the heat exchanger is enhanced. In this project, the heat transfer inside the heat exchanger is investigated. Inside the heat exchanger, Al2O3-water nanofluid is used instead of pure fluid.

The geometry of the present model is drawn by Design Modeler software. The model is then meshed by ANSYS Meshing software. The model mesh is unstructured.

Shell and Tube Methodology

In this simulation, nanofluid is used inside the heat exchanger. Two methods can be used to define nanofluids. In the first method, a multiphase model is defined, consisting of an initial fluid and mixed nanoparticles inside it.

This method has a relatively high computational cost. In the second method, formulas and relations related to the thermophysical properties of nanofluids are used.

This means that we have the density, specific heat capacity, thermal conductivity, and viscosity of the base fluid and nanoparticles. According to the formula, we can obtain the values of these parameters for the nanofluid.

Shell and Tube Conclusion

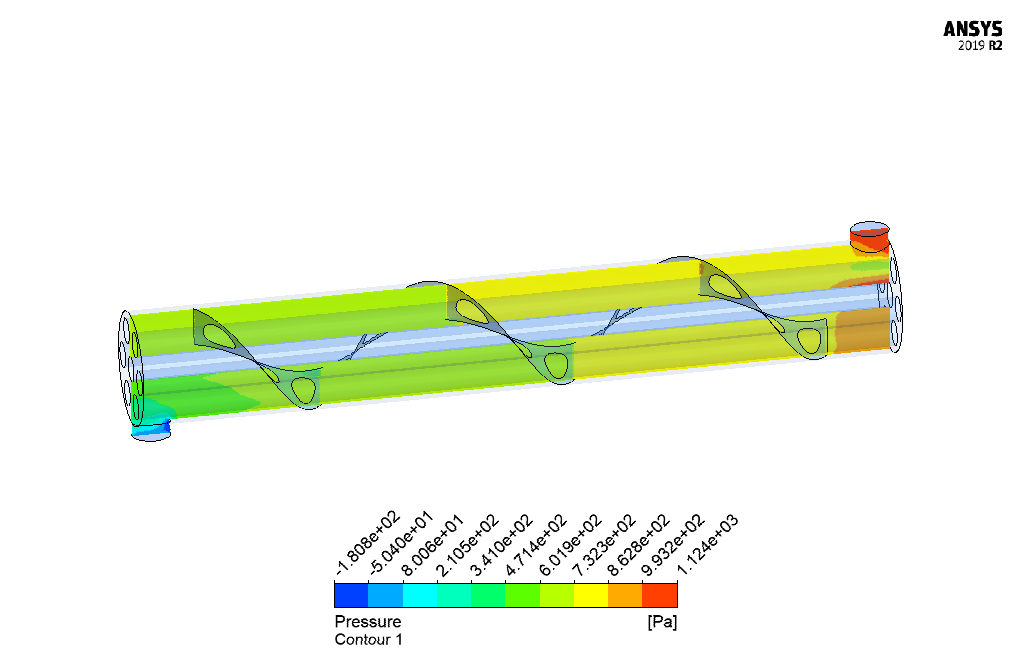

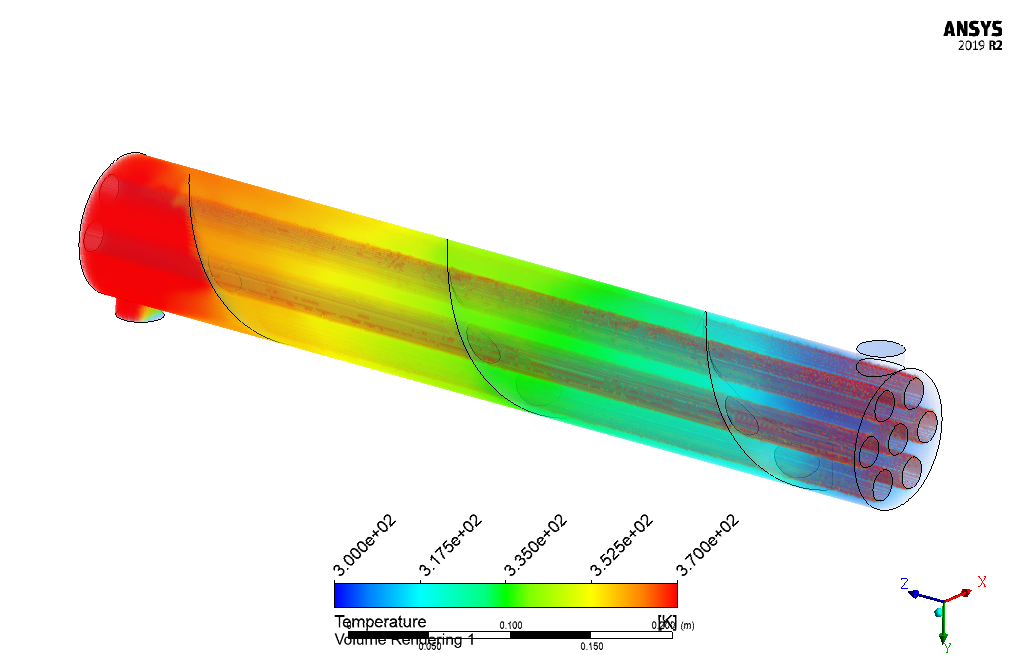

After simulation, the contours of temperature, velocity, and pressure are obtained. The results show that using nanofluids instead of fluid and applying helical fins inside the shell’s flow path helps to enhance heat transfer.

The temperature contour correctly shows the heat transfer in the shell section of the heat exchanger.

Dr. Donavon Harber DDS –

The detail in your simulations is outstanding. Great job!

Precious Crist –

Why did you choose these specific software tools for your simulations?

MR CFD Support –

Design Modeler and ANSYS Meshing offer advanced capabilities and are reliable tools for creating high-quality models and precise meshes, which are essential for accurate CFD simulations.

Corrine Anderson –

How can this simulation help in optimizing the design of shell and tube heat exchangers?

MR CFD Support –

This simulation can provide valuable insights into the heat transfer process in shell and tube heat exchangers, which can be used to optimize their design and improve their performance.

Kip Bailey –

Can this simulation model the effect of different operating conditions on the performance of the heat exchanger?

MR CFD Support –

Yes, we can create a custom simulation to model the effect of different operating conditions such as fluid velocities, temperatures, and properties.

Jadyn Cole PhD –

I’m extremely impressed with how the use of helical fins in the heat exchanger and the utilization of Al2O3-water nanofluid bolstered the heat transfer. The training made the complex concepts really accessible.

MR CFD Support –

Thank you for your positive feedback! We are thrilled to hear that the training was helpful and that the concepts presented were made clear and easy to understand. It’s great to know that the benefits of using helical fins and nanofluids were effectively communicated. We appreciate your review and are here if you have any further questions or need additional information.

Dr. Creola Lehner I –

I am thoroughly impressed with how the simulation enhances understanding of heat transfer in a shell and tube heat exchanger. The practical utility of helical fins combined with nanofluid technology within ANSYS Fluent is well-demonstrated.

MR CFD Support –

Thank you for your review! We’re glad to hear that you found the simulation insightful and practical. It’s great to know that the training provided clear demonstration of the impact of helical fins and nanofluid on heat transfer efficiency in shell and tube heat exchangers.

Gregorio Oberbrunner –

Your detailed simulation was quite instructional! I was particularly amazed by how the helical fins and Al2O3-water nanofluid enhanced heat transfer. You managed to illustrate the contributory effects of the fins and nanofluids elegantly in the temperature contours. Excellent work on the meshing as well – it sets a solid foundation for accurate simulation results. Kudos to the team behind this thoughtful project execution.

MR CFD Support –

Thank you for your encouraging feedback! We’re thrilled to learn that our simulation on a shell and tube heat exchanger with helical fins using Al2O3-water nanofluid could clearly demonstrate the enhanced heat transfer effects. Our team takes great care in creating detailed models and simulations to provide clear, informative results. We appreciate your compliments on our meshing and project execution – it’s always great to hear when our hard work resonates with our audience. If you need further information or assistance about our simulations or any other products, please reach out. Your success is our goal!

Dr. Kristopher Herzog –

This training on the simulation of a shell and tube heat exchanger with helical fins sounds fantastic. The inclusion of nanofluid for heat transfer optimization is a cutting-edge approach, and the thorough analysis using ANSYS Fluent clearly demonstrates the benefits of such techniques. Great job providing a detailed insight into the simulation process and final outcomes!

MR CFD Support –

We’re delighted to hear that you appreciate the Shell and Tube Heat Exchanger, Helical Fin, NanoFluid CFD Simulation Training. It’s wonderful to know that our efforts to use innovative approaches like nanofluid in a well-established system are recognized. Your satisfaction with the detailed analysis and results is very encouraging. Thank you so much for your positive feedback!

Mr. Buster Hermiston –

The course content sounds good and thorough. I especially find the utilization of helical fins and nanofluids promising for enhanced heat transfer. Did the tutorial also talk about the maintenance challenges and how the helical fins might affect the cleaning process of the heat exchanger?

MR CFD Support –

The focus of this tutorial is primarily on the simulation and the effects of helical fins and nanofluids on heat transfer efficiency. It covers the setup and results of the simulation rather than maintenance aspects. Routine maintenance and cleaning procedures for complex geometries like helical fins would be typically found in operational manuals or discussed in courses detailing the heat exchanger’s mechanical and maintenance aspects.

Dr. Marcos Goyette MD –

This CFD training content was outstanding! I learned so much about the application of nanofluid and helical fins to improve heat exchangers’ efficiency. The mix of animation, clear explanations, and practical examples truly made the concept easier to understand.

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that our simulation training on shell and tube heat exchangers enriched with helical fins and nanofluid provided you with a comprehensible and engaging learning experience. Your enjoyment and understanding are our top priorities, and reviews like yours make all our efforts worthwhile!

Ansel Harris –

I’m amazed by the efficiency improvements using helical fins and nanofluid in a shell and tube exchanger. Could this method be scaled up for industrial applications?

MR CFD Support –

Thank you for your positive feedback! Indeed, the use of helical fins and nanofluids can significantly improve heat transfer, making this method highly scalable for industrial applications. These improvements can aid in better thermal management, efficiency, and possibly even reduced overall size of heat exchangers for given tasks in various industries.

Nikki Little IV –

The training course for the Shell and Tube Heat Exchanger with Helical Fin sounds promising. Great resource for understanding enhanced heat transfer mechanisms with nanofluids!

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that you found the Shell and Tube Heat Exchanger with Helical Fin training useful, and we hope it will prove beneficial for your continued learning and applications in the field of heat transfer and fluid dynamics.

Eldora Kuhn –

The approach to optimizing heat transfer in this simulation is fascinating. The inclusion of helical fins and a nanofluid seems like an innovative solution. I’d love to see how the temperature gradient looked across the heat exchanger in more detail.

MR CFD Support –

Thank you for your appreciation! It is indeed thrilling to see the positive impact of helical fins and nanofluids in enhancing heat transfer efficiency. We’re glad to know you’re interested in the details. If you need more specific visualizations or technical details, do not hesitate to get in touch with us, and we’d be happy to assist further. Your curiosity is what drives us to keep improving our simulations!

Zander O’Keefe III –

I found the concept of using nanoparticle-enhanced fluids fascinating! The application of nano-fluids and helical fins seems to greatly improve heat transfer efficiency inside the heat exchanger.

MR CFD Support –

We’re thrilled to hear that you appreciate the innovative approach! Enhancing heat transfer with nano-fluids and helical fins indeed represents a significant step forward in heat exchanger technology. Thank you for your positive feedback, and we’re glad that our product was able to provide you with valuable insights!

Prof. Westley Frami V –

How do you model the heat transfer process in this simulation?

MR CFD Support –

We use the energy equation in ANSYS Fluent to simulate the heat transfer process between the hot and cold fluids in the heat exchanger.

Madaline Hermann –

I just finished the ‘Shell and Tube Heat Exchanger, Helical Fin, NanoFluid’ training and am impressed with the detailed modeling process. The use of helical fins and Al2O3-water nanofluid showcased significant heat transfer efficiency improvements. Great work!

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear that our simulation training helped you understand complex heat transfer dynamics within shell and tube heat exchangers using nanofluids and helical fins. Your feedback is greatly appreciated!

Emely Lueilwitz –

The project on shell and tube heat exchangers with helical fins sounds impressive. I’m especially interested in the use of nano fluids for increased heat transfer efficiency. Great application of innovative materials and design to practical engineering solutions.

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that you found the application of nano fluids and the design of helical fins in shell and tube heat exchangers impressive. Such innovative approaches in the field of CFD simulation are part of our continuous efforts to provide useful and practical training for enhancing engineering solutions.