Quadcopter Aerodynamic Analysis and CFD Simulation in ANSYS Fluent

$100.00 $40.00 HPC

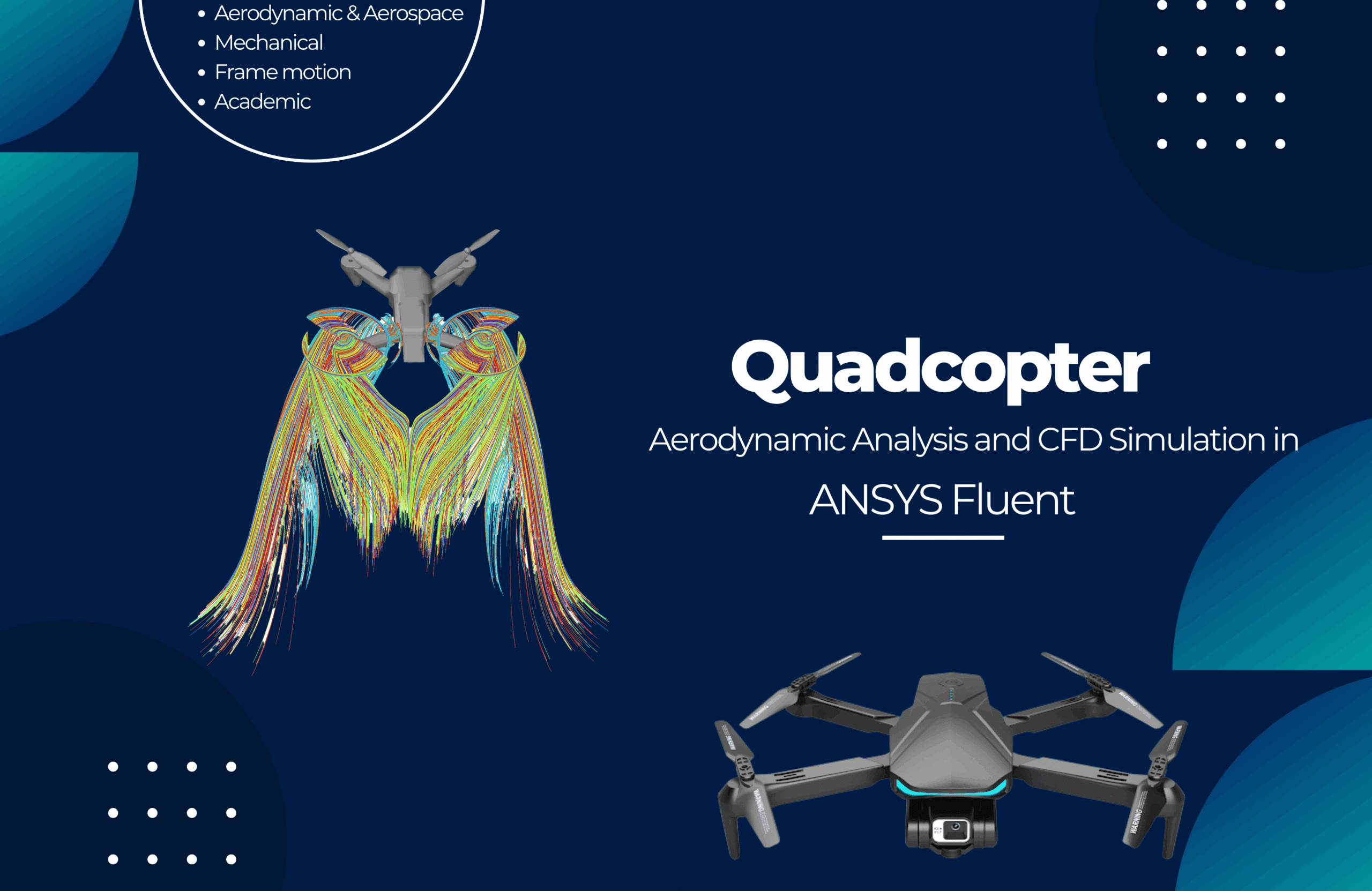

- In Quadcopter Aerodynamic Analysis, a numerical simulation was conducted to investigate the Dynamic Stability Derivatives of a quadcopter using ANSYS Fluent.

- A 3D symmetric geometry of the quadcopter was designed in SpaceClaim, capturing the essential aerodynamic features of the body and blades.

- The geometry was meshed using ANSYS Meshing, resulting in a high-quality grid with 3736312 elements.

- The simulation was performed in an unsteady (transient) framework to capture the time-dependent aerodynamic behavior.

- Mesh Motion techniques and User-Defined Functions (UDFs) were employed to define the rotational motion of the blades and the oscillatory motions of the quadcopter.

- This approach enabled the extraction of stability derivative data, providing insight into the dynamic response and control requirements of the quadcopter system.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Quadcopter Aerodynamic Analysis and CFD Simulation in ANSYS Fluent

Description

In Quadcopter Aerodynamic Analysis, a comprehensive simple simulation of a quadcopter was performed using ANSYS Fluent, a powerful computational fluid dynamics (CFD) software. The primary objective was to investigate the obtaining the drag, lift, and moment coefficients for the quadcopter’s blades.

The quadcopter geometry was designed using SpaceClaim, a 3D modeling software integrated with ANSYS. Leveraging the symmetry of the quadcopter, a 3D symmetric model was created, which significantly reduced the computational cost while maintaining the accuracy of the simulation. The designed geometry captured the essential features of the quadcopter, including the main body, rotors, and other relevant components.

Once the geometry was finalized, it was imported into ANSYS Meshing for discretization. The meshing process involved dividing the computational domain into smaller elements, creating a mesh that accurately represented the quadcopter’s geometry. Care was taken to ensure that the mesh quality was high, with appropriate refinement in regions of interest, such as near the rotors and the quadcopter body. Number of elements are 3736312.

you can also visit Quadcopter Acoustic, FSI and Dynamic Stability Derivatives Analyses.

Methodology

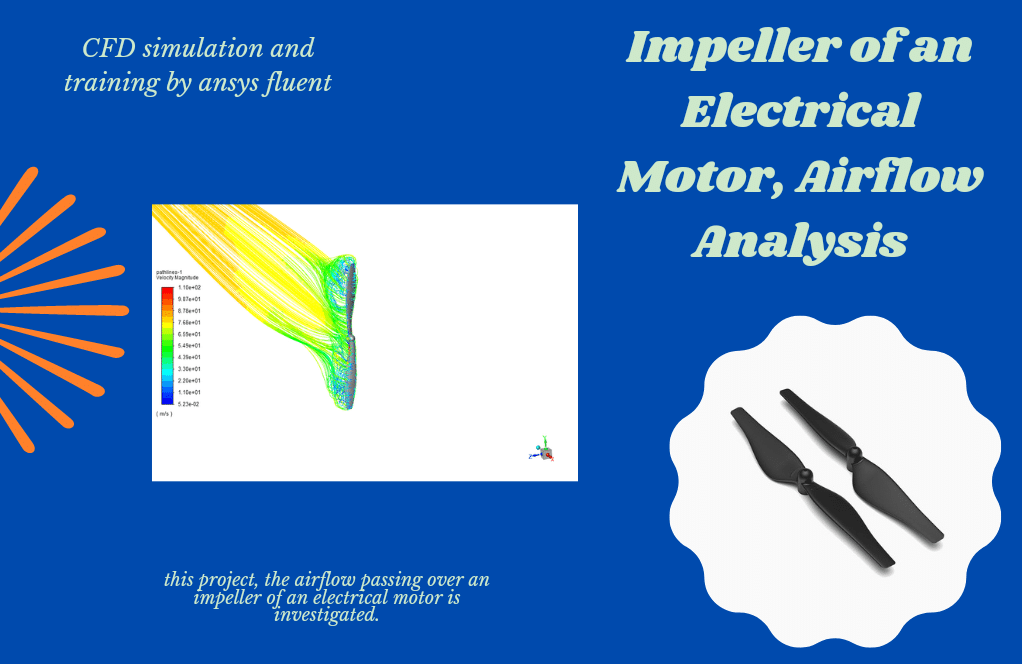

In Quadcopter Aerodynamic Analysis, we employ ANSYS Fluent software and leverage the applications of Computational Fluid Dynamics (CFD) to determine the surfaces that create lift and drag forces. In this simulation, to capture the rotational motion of the quadcopter blades with an angular velocity of 1200 RPM, we employed two frame motion zones. These zones allowed for accurate simulation of the blade dynamics and airflow characteristics around the quadcopter.

Results

In Quadcopter Aerodynamic Analysis we export the results. Both blades reach a steady after 600–800 iterations, showing convergence in the CFD simulation. Blade2 generates slightly higher lift (approx 4.45) compared to Blade1 (approx 4.3). This can be explained by the asymmetry in inflow conditions due to the quadcopter geometry: some blades experience interference from the body and neighboring arms, causing reduced effective angle of attack and weaker pressure difference across the blade surfaces.

Both blades converge to slightly negative drag coefficients (–0.07 to –0.08). This is a numerical artifact of thrust-producing propellers, where the force is aligned opposite to the freestream axis used in post-processing. In reality, this represents net thrust generation. Blade2 has a slightly more negative drag coefficient (more thrust contribution), which correlates with its higher lift.

Both blades have negative pitching moments, meaning the aerodynamic forces create a nose-down torque tendency. Blade1 has a more negative (Cm) than Blade2, indicating it is less aerodynamically balanced.

Strong suction (blue, low pressure) develops on the upper sides of blades. The blades closer to the body arms show weaker low-pressure regions, proving that arm interference reduces effective lift.

Tip regions show the highest velocities (85 m/s), which is expected due to rotational speed and induced vortex effects. Non-uniform velocity distribution across blades again reveals that some blades operate in cleaner air, while others suffer from flow blockage by the quadcopter body/arms.

The CFD results confirm that each blade on the quadcopter does not experience identical aerodynamic loads due to body-arm interference. Pressure and velocity contours visually prove flow disturbance. Graphs of (Cl, Cd, Cm) quantitatively show this imbalance: with Blade2 working slightly more efficiently than Blade1. This explains why real quadcopters require constant active stabilization by the flight controller.

You must be logged in to post a review.

Reviews

There are no reviews yet.