Spray Dryer ANSYS Fluent CFD Simulation Tutorial

$220.00 Student Discount

- In this product, a spray dryer is simulated by ANSYS Fluent software.

- The geometry of this project has been designed using Desing Modeler software

- The mesh was created on this geometry using ANSYS Meshing software. The element number is 84047.

- We have used the Species Transport Model in this simulation.

- The hot airflow, is responsible for evaporating the moisture in the solution.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Project Description

In this product, a spray dryer is simulated by ANSYS Fluent software. The feed solution (slurry, paste, etc.) is first conveyed to the atomizer via a tank using a pump. The atomizer disperses the liquid solution as a spray or liquid droplets into the main dryer compartment.

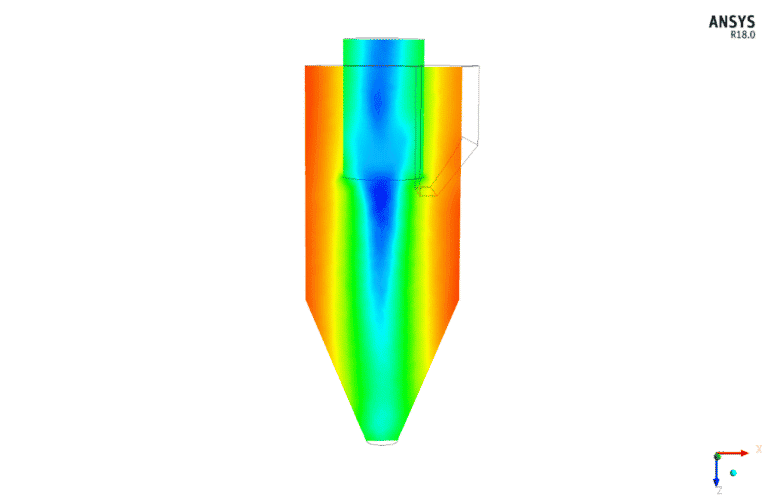

On the other hand, hot air, which rises from a burner or steam heater, blows into the chamber by a fan. At this point, the liquid phase of the spray contacts hot air so that the moisture within the droplets evaporates within a short time, leaving the powdered dry particles with the hot air out of the chamber.

We have used two types of continuous and discrete phases in the present problem. The hot airflow, responsible for evaporating the moisture in the solution, enters the spray dryer chamber as a continuous phase and flows into the chamber (Eulerian). The geometry of this project has been designed using Design Modeler software. The mesh was created on this geometry using ANSYS Meshing software.

The mesh type is unstructured, and the element number is 84047.

Spray Dryer Methodology

We have used the Species Transport Model in this simulation. It is assumed that the inlet’s hot and dry airflow has a very small amount of (about 0.009%) water vapor. Also, some moisture air comes into the inlet air with the feed solution. So the inlet air with the solution contains water vapor.

Therefore, in addition to receiving moisture from the feed solution, the inlet hot air flow also has the task of drying the humid air with the solution. In addition, there is a solution consisting of water and solid particles. Whose purpose is to separate the water droplets or the moisture from the particles.

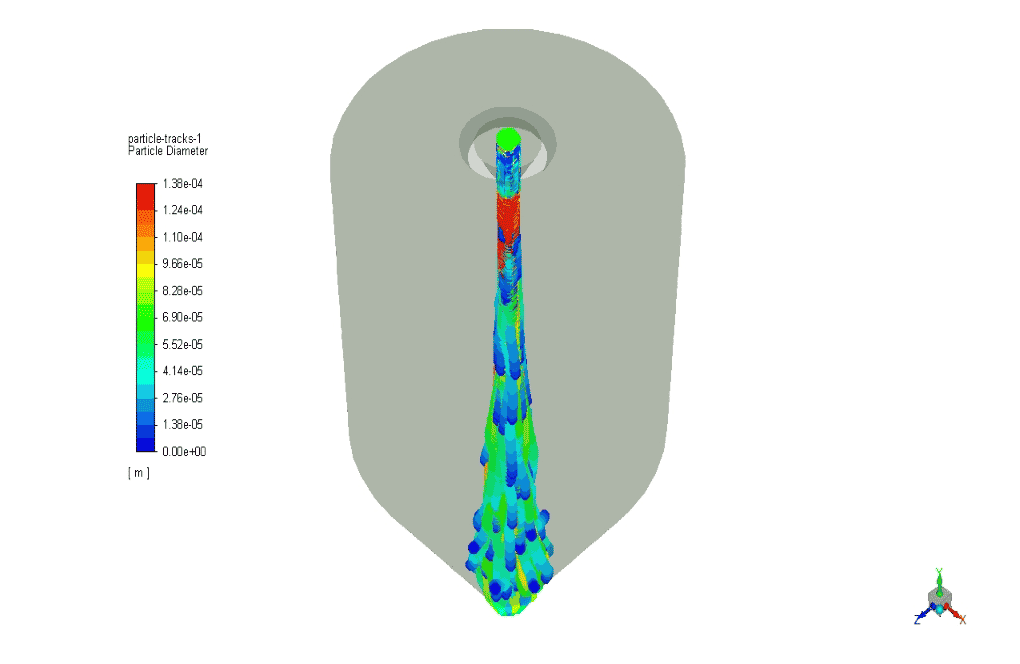

By choosing the Interaction With Continuous Phase, the behavior of the selective discrete phase flow (water droplets) interacts with the continuous flow (hot air).

Spray Dryer Conclusion

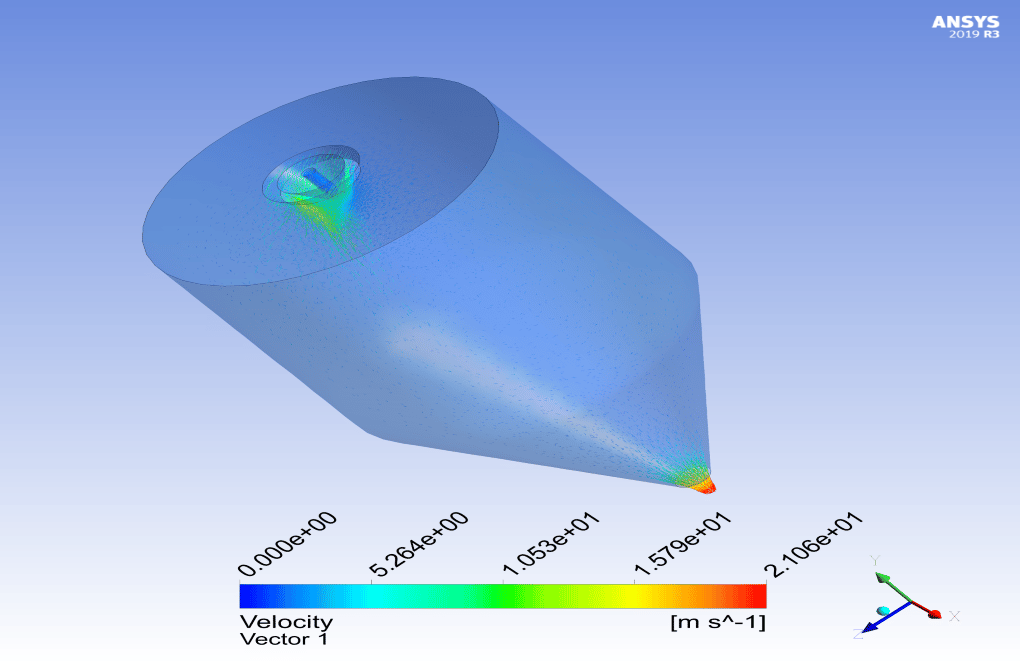

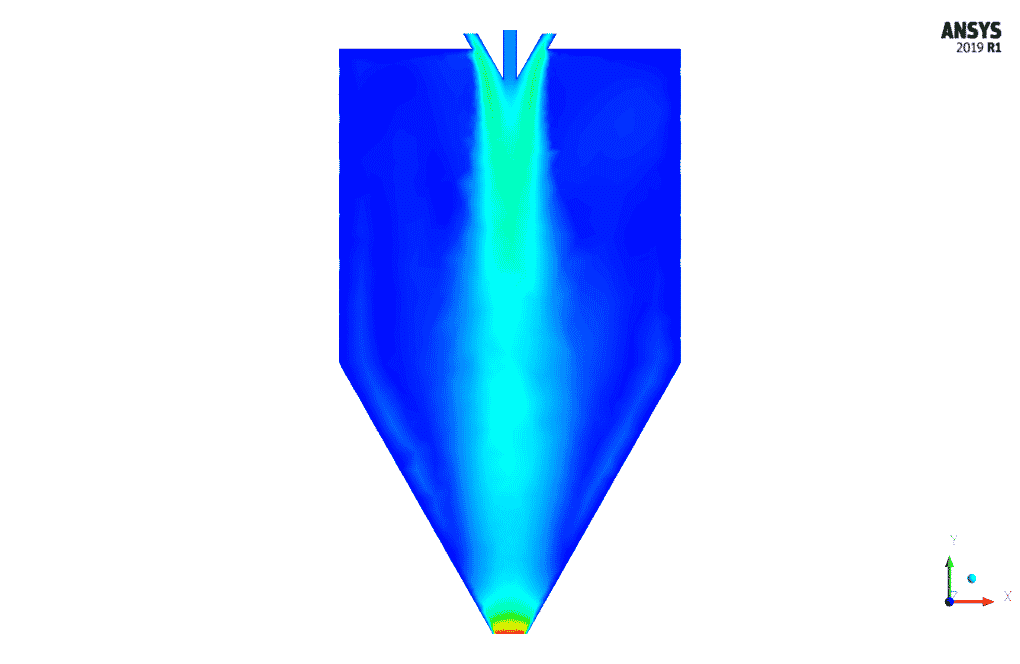

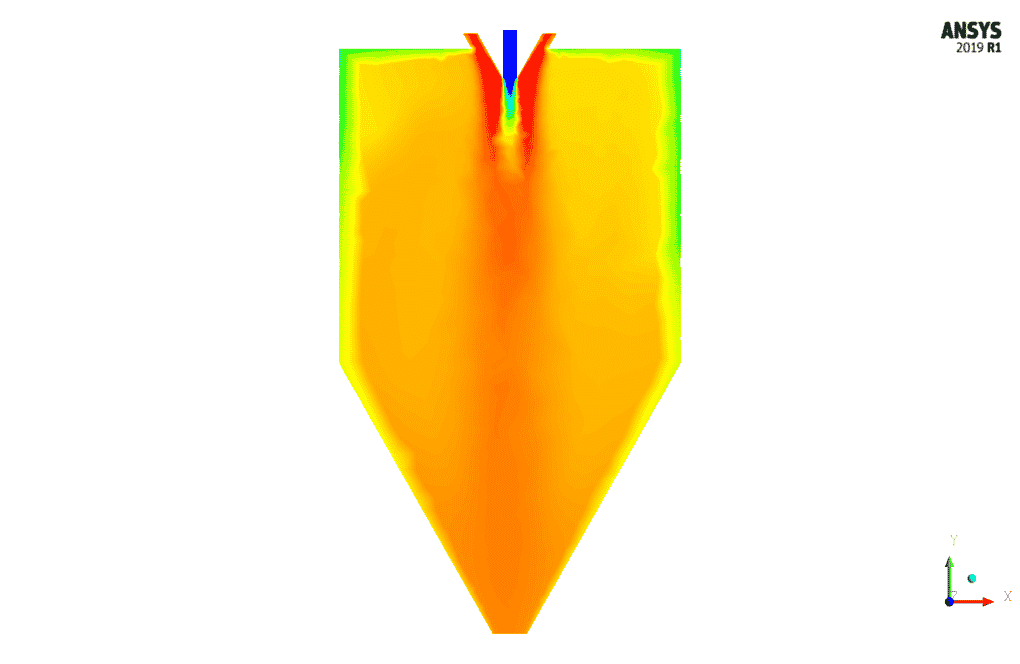

As can be seen in the pictures, the velocity, pressure, temperature, and particles injected into the domain are clear. Based on the spray dryers’ function, particles penetrate the domain at high speed. While a hot air stream enters from around. The behavior of the particles in the air and their penetration and breakup length are also discussed.

Combining these two phases, which enter the domain in Eulerian and Lagrangian, leaves the outlet uniformly at a temperature lower than the air inlet temperature.

Rylee Kilback –

It worked for me, great.

Nathen Keeling –

that was perfect

Irving Satterfield –

I’m interested in your spray dryer simulation. Can you tell me more about the methodology behind it?

MR CFD Support –

The methodology behind our spray dryer simulation involves several steps. First, we create a 3D model of the spray dryer. Then, we generate a mesh to discretize the model. After that, we set up the simulation by defining the boundary conditions and selecting the appropriate physical models. Finally, we solve the equations and analyze the results.

Maribel Barton –

What purpose does using the Species Transport Model serve in the Spray Dryer simulation?

MR CFD Support –

In the spray dryer simulation, the Species Transport Model is used to simulate the mixing and evaporation of multiple species. It helps track the concentration of each species, such as the water vapor and solid particles, allowing the model to accurately capture the drying process of the spray within the hot air flow.

Idella Schneider –

The tutorial was very enlightening. The step-by-step approach made understanding the complex interactions within the spray dryer much easier.

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear that you found the tutorial helpful and accessible. It’s great that the step-by-step approach worked well for you in understanding the complexities of spray drying simulation. Should you have any further questions or need more tutorials, feel free to reach out!

Maybell Jacobson –

Your product range is impressive. Keep up the good work!

MR CFD Support –

Thank you for your encouragement.

Madilyn Feil –

The description mentions that particles combine with hot air and leave the outlet at a uniform temperature. Is there a specific monitoring process to ensure that the temperature is uniform, or is this a predicted outcome based on the simulation parameters? It’s great to learn from a practical tutorial like this.

MR CFD Support –

The uniform temperature of particles and air mixture at the outlet is a predicted outcome based on the simulation parameters and models used, such as the Species Transport Model. Throughout the simulation, we can monitor the temperature at various points in the domain to track the temperature distribution. Generally, this is observed through post-processing tools provided in ANSYS Fluent, which allows us to visualize temperature contours and plots illustrating the mixture’s thermal uniformity as it exits the spray dryer.

Burnice Bahringer –

The Spray Dryer CFD Simulation product on your website is impressive! The detailed explanation and clear visuals are very helpful.

MR CFD Support –

Thank you for your kind words.

Maybell Effertz –

I never imagined the complexity behind something that might appear so simple. Seeing all those particles’ behavior with temperature changes clarified a lot for me!

MR CFD Support –

Thank you for your kind words. We are delighted to know that our Spray Dryer ANSYS Fluent CFD Simulation Tutorial provided you with a detailed understanding of the process and helped clarify the complex interactions taking place. It always makes us happy to hear feedback about how educational our simulations are.

Orpha Adams V –

This product description is really comprehensive! I learned a great deal about how spray dryers function and the complex simulations involved. Can this setup be adjusted for different substances apart from water, like different chemical compounds in the feed solution?

MR CFD Support –

Absolutely! The simulation setup described here is versatile and can certainly accommodate different feed solutions beyond water. By modifying the physical properties and behavior of the continuous and discrete phases in the simulation, various compounds with different evaporation points and chemical reactions to heat can be analyzed within the spray dryer environment.

Dr. Christ Funk I –

I enjoyed learning from the Spray Dryer ANSYS Fluent tutorial. The methodology was well explained and the simulation results were clear and detailed, making it easier to understand the spray dryer’s inner workings.

MR CFD Support –

Thank you for your positive feedback! We’re glad you found the tutorial informative and helpful for understanding the complexities of the spray dryer simulation. Your satisfaction with the tutorial motivates us to continue providing high-quality learning materials.

Lizeth Morar –

The explanation of the simulation is very informative. Are gravity effects included in the species transport model for this spray dryer simulation?

MR CFD Support –

Yes, the effects of gravity are indeed considered in the species transport model as it impacts the distribution and behavior of droplets within the drying chamber. Gravity would influence both the trajectory of droplets being sprayed and contribute to the natural convective flow of heated air within the chamber.

Krista Huel –

What a comprehensively designed simulation for a spray dryer. It’s truly fascinating to visualize particle behavior and heat interactions. Nice job outlining the inlet conditions and the species transport model usage. Can you tell me more about the validation process for the simulation results?

MR CFD Support –

Thank you for your interest in our simulation! For validation, we compare the simulation results with available experimental data or established theoretical models for spray dryers. Ensuring that parameters like the particle drying rate, exit moisture content, and temperature profiles match those of the reference cases establishes reliability in our simulation.

Melisa Yundt –

I’ve always been interested in the practical applications of these simulations. Can you give examples of products or industries that typically use spray dryers like the one in this simulation?

MR CFD Support –

Spray dryers are widely used across various industries for their ability to quickly and efficiently reduce the moisture content of a liquid feed to form dry powders. Some common applications include the production of milk powder in the dairy industry, instant coffee and tea in the food and beverage sector, pharmaceuticals where active ingredients need to be dried, and in the chemical industry for pigments, ceramics materials, or catalyst supports. The detailed understanding gained from simulations like this one can help optimize the drying process for specific product requirements.

Mrs. Lora Roberts –

Can these simulations be customized to fit my specific needs?

MR CFD Support –

Absolutely! We can customize our simulations to accommodate your specific needs. Please get in touch with us to discuss this further.

Abby Bednar –

Could you explain which specific Species Transport Model was used for the moisture air and the solid particles, and how it contributes to the drying process in the spray dryer simulation?

MR CFD Support –

In this simulation, the Species Transport Model was used to account for the mixing and interaction of multiple species within the spray dryer. The model allows for the simulation of the evaporation of moisture from the solid particles and the absorption of water vapor by the hot air. The primary species are the air, water vapor from the hot air, and the moisture-laden air mixed with the feed solution. The evaporation of moisture from the particles and subsequent drying are facilitated by the hot air’s ability to absorb water vapor, highlighting the significance of the hot air’s initial trace water vapor to the drying process and the overall efficiency of the dryer.

Ms. Ella O’Hara –

I really appreciate the comprehensive explanation of the spray dryer simulation process and the breakdown of the Eulerian-Lagrangian approach. It has given me a clear understanding of how moisture evaporation is handled and how the interaction between the hot air and spray is simulated to result in dry powdered particles!

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that our tutorial was informative and provided you with a clear understanding of the spray drying process specifics in ANSYS Fluent. If you have any further inquiries or need assistance with your simulation projects, feel free to reach out to us!

Adela Runolfsdottir –

I’m really impressed with how the droplet evaporation and particle creation are handled in the simulation. Great job on showing the detailed interaction between the two phases.

MR CFD Support –

Thank you for your kind words! We’re delighted to hear that our simulation’s detailed portrayal of droplet evaporation and particle formation met your expectations and provided clarity on the complex interplay between phases. Your satisfaction is our greatest motivation!