Abrasive Fluid Jet, CFD Simulation ANSYS Fluent Training

$80.00 Student Discount

In this project, an abrasive fluid Jet has been simulated by ANSYS Fluent software.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Abrasive Fluid Jet Description

The present simulation is about a fluid jet with abrasive particles via ANSYS Fluent. This process is used to cut hard materials such as metals, stones, composites, plastics, etc., and remove wire sheaths and pleats. The working mechanism of these systems is such that a beam of fluid moves at high speed towards the desired metal surfaces for cutting work.

Particles of an abrasive are injected into this path of the fluid to hit the surfaces with the fluid at high speed, and as a result, the cutting process takes place from the surfaces.

The most important advantage of this cutting method is that it does not need heating; because thermal cutting processes cause the desired material to melt or burn. In this project, a zone for fluid jet movement is designed; thus, the fluid jet with the abrasive material makes contact with a curved metal surface.

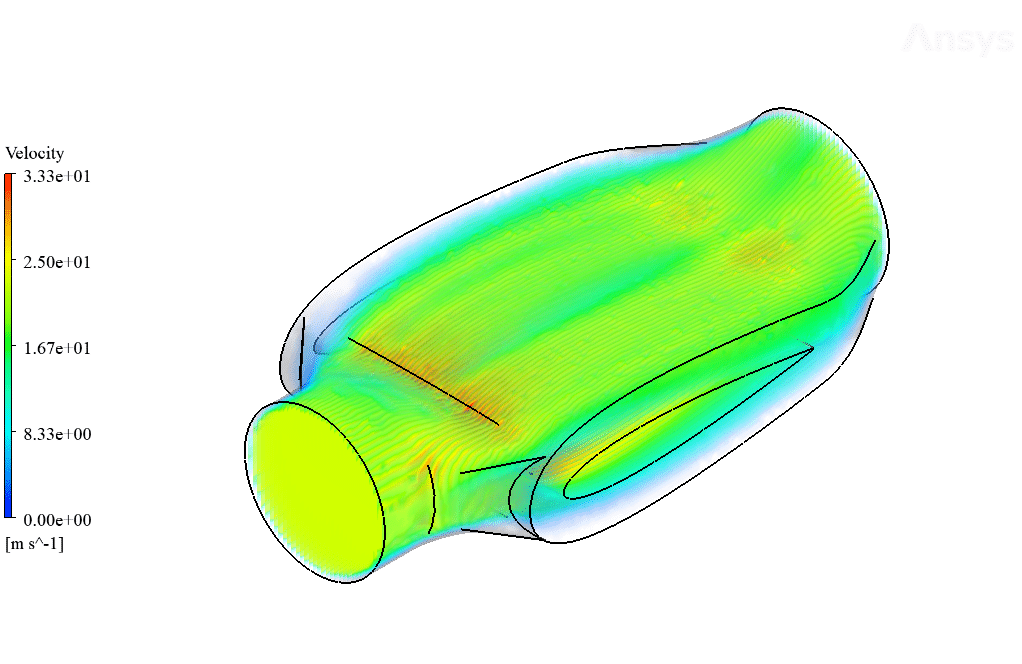

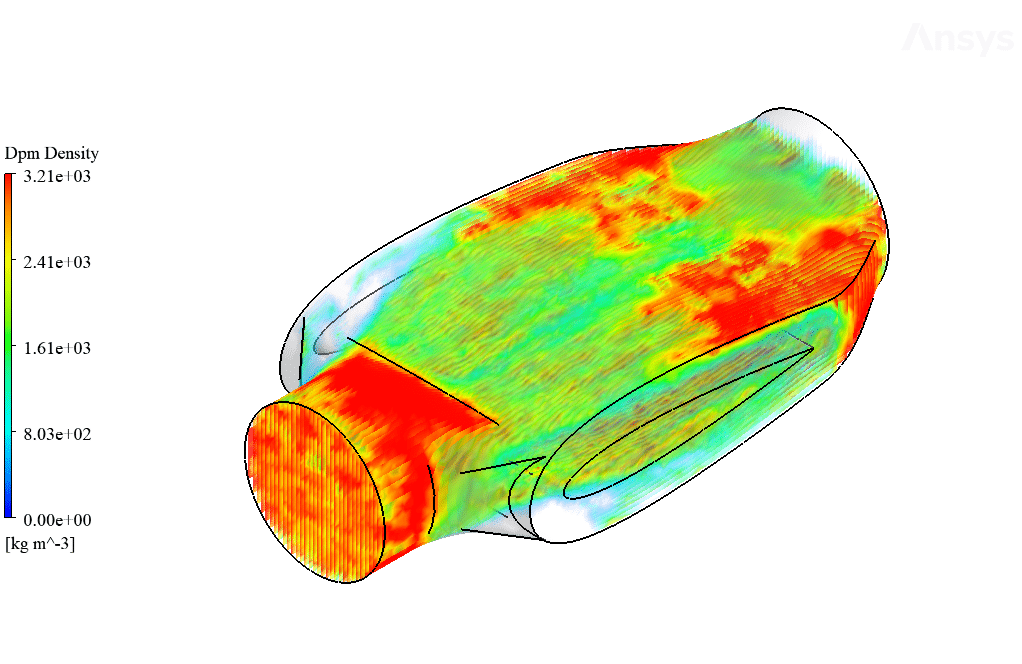

Oil has been used to create fluid jets, and sand particles have been used as abrasive particles. Oil enters the model as a continuous fluid at 23 m/s. The discrete phase model (DPM) is also used to define the motion of abrasive particles.

The discrete phase is used when discrete particles move in a continuous environment; in other words, the solution perspective changes from Eulerian to Lagrangian. Also, since abrasive particles cause abrasion on the desired surfaces, the erosion model must be activated.

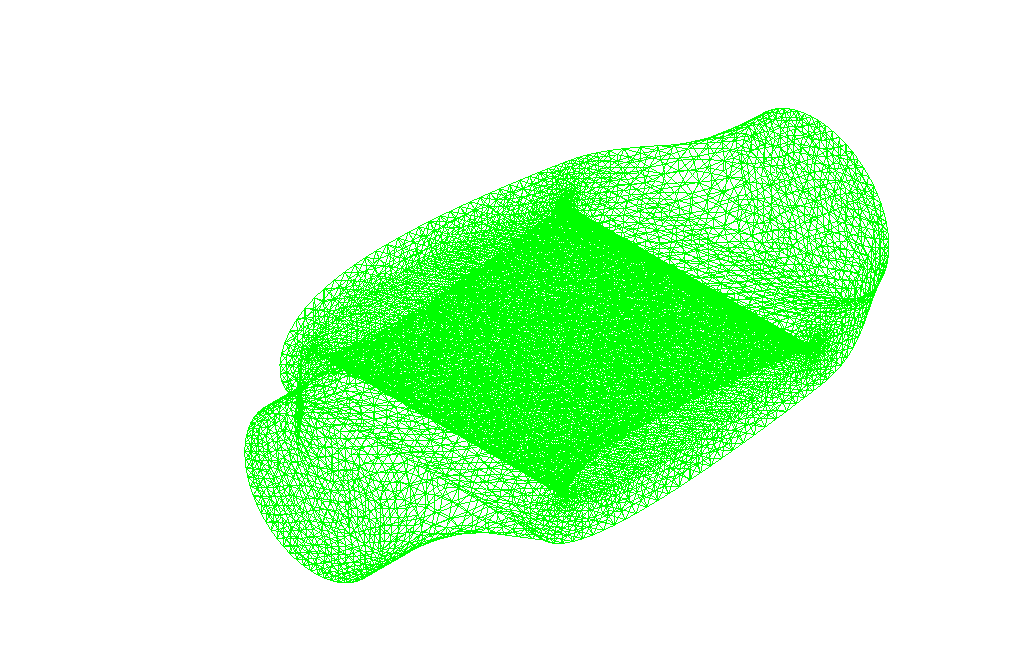

Geometry & Mesh

The present geometry is designed in a 3D model via Design Modeler. The computational zone is the space around a curved surface to which the fluid flows from a circular cross-section.

The mesh of the present model has been done via ANSYS Meshing. Mesh is done unstructured, and the number of production cells is equal to 924058.

Set-up & Solution

Assumptions used in this simulation:

- pressure-based solver is used.

- The present simulation is unsteady.

- The gravity is applied to the model, and the gravitational acceleration is defined as 9.81 m.s-2.

| Models | ||

| Viscous | k-epsilon | |

| k-epsilon model | realizable | |

| near-wall treatment | standard wall treatment | |

| Discrete Phase Model | On | |

| interaction with continuous phase | on | |

| physical model | erosion/accretion | |

| Injection | On | |

| injection type | surface | |

| injection surface | inlet | |

| diameter | 0.00015 | |

| mass flow rate | 0.046 kg.s-1 | |

| Boundary conditions | ||

| Inlet | Velocity Inlet | |

| velocity magnitude | 23 m.s-1 | |

| discrete phase BC type | escape | |

| Walls | Wall | |

| wall motion | stationary wall | |

| discrete phase model conditions | erosion/accretion | |

| erosion models | Generic, Finnie, Mclaury, Oka, DNV | |

| Outlet | Pressure Outlet | |

| gauge pressure | 0 pascal | |

| discrete phase BC type | escape | |

| Methods | ||

| Pressure-Velocity Coupling | SIMPLE | |

| pressure | second order | |

| momentum | second order upwind | |

| turbulent kinetic energy | second order upwind | |

| turbulent dissipation rate | second order upwind | |

| Initialization | ||

| Initialization methods | standard | |

| gauge pressure | 0 pascal | |

| velocity (x,y,z) | 23 m.s-1 | |

Abrasive Fluid Jet Results

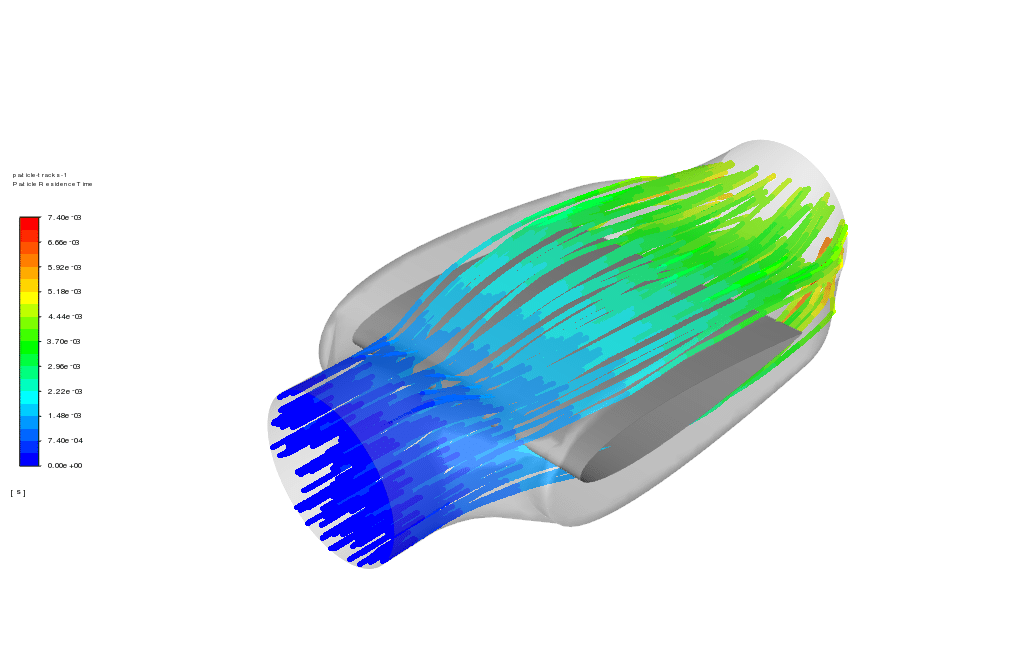

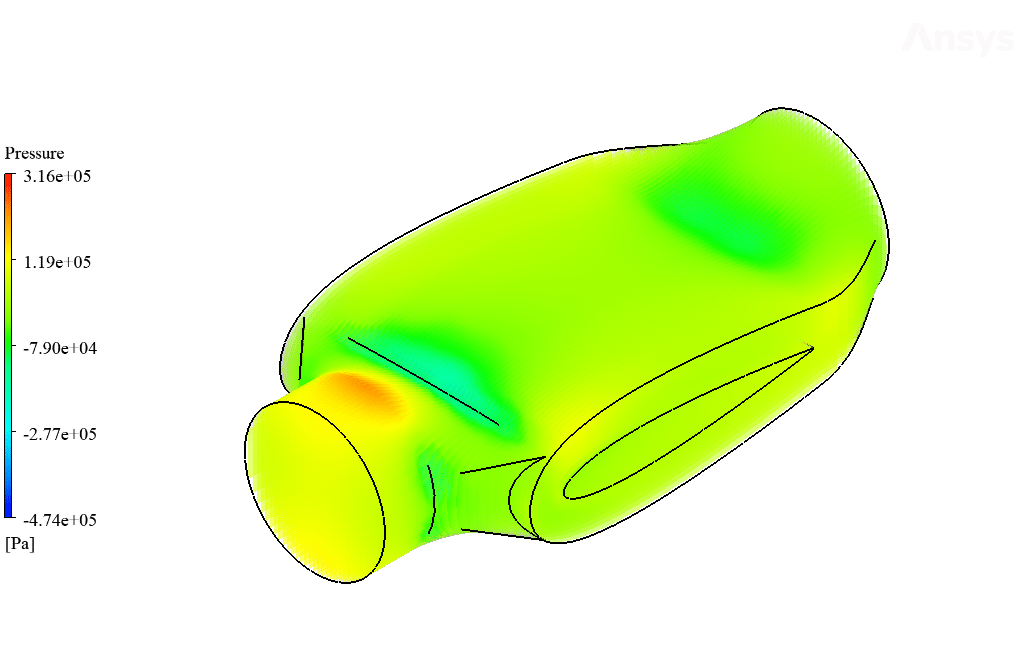

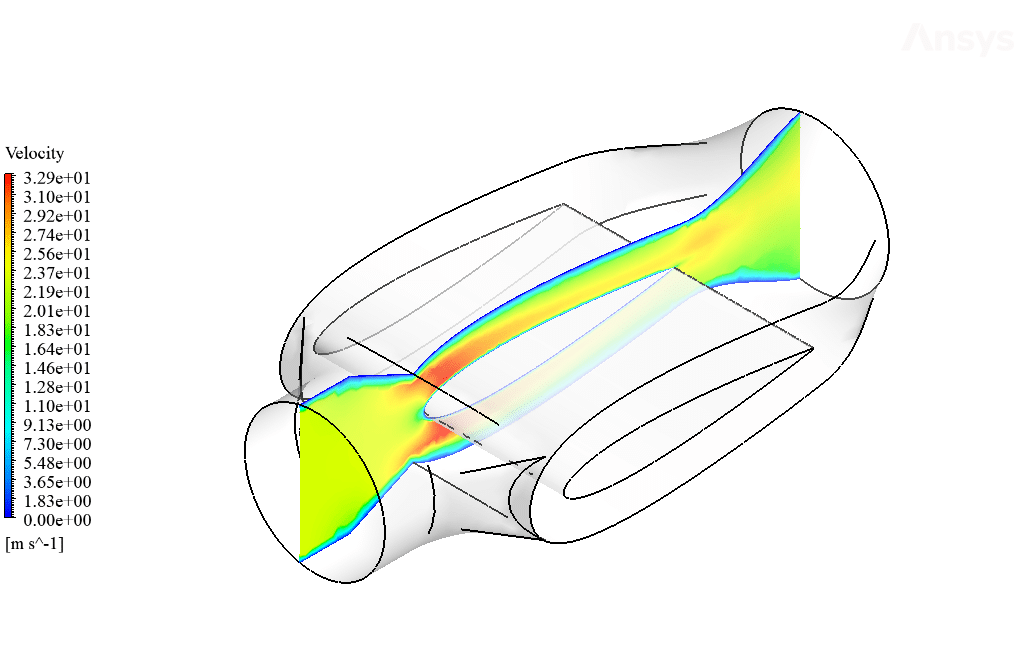

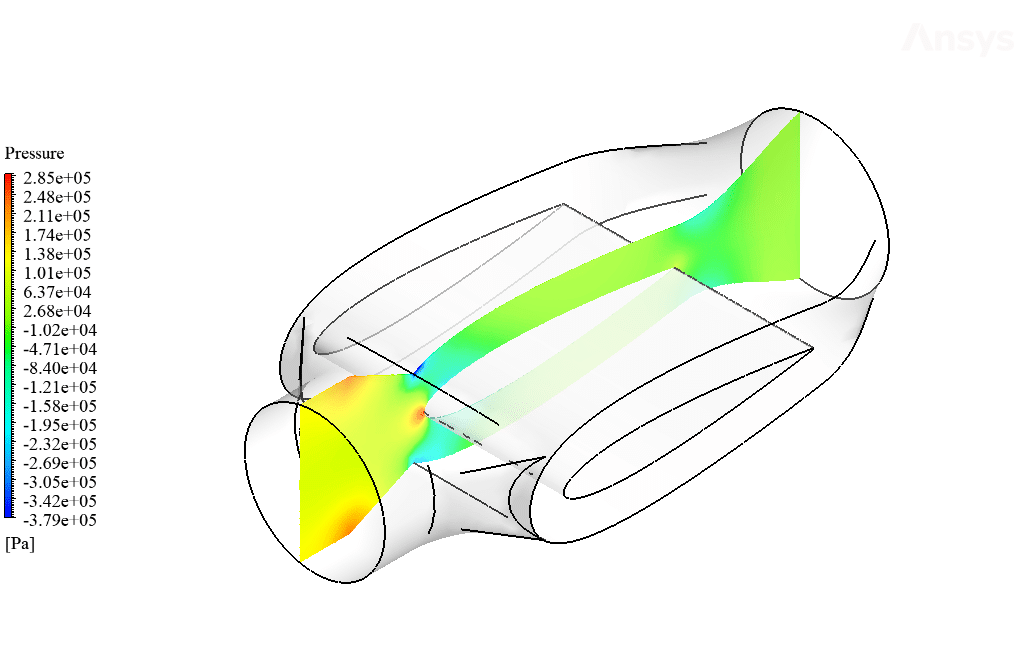

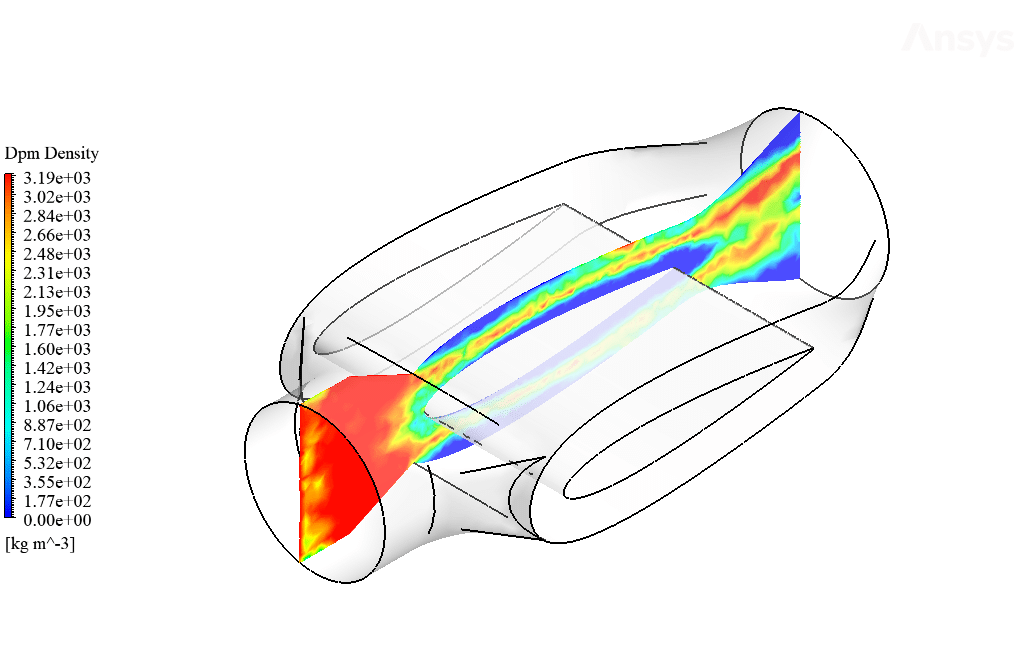

After calculation, 2D and 3D contours related to pressure, velocity, and DPM density are obtained. The particle tracking based on residence time is also obtained. The results show that the fluid flow becomes a jet of fluid as the cross-sectional area decreases and then, along with discrete sand particles, strikes the curved surfaces at high speed and pressure, thus causing an erosion process on the surfaces.

Unique Yost –

I just want to thank you for this incredibly detailed tutorial on abrasive fluid jet simulation using ANSYS Fluent. The steps mentioned were clear, and comprehensively covered every aspect of setting up and solving the simulation. Cheers to the team for such great work!

MR CFD Support –

We really appreciate you taking the time to leave such a positive review! We’re delighted to hear that you found the abrasive fluid jet simulation tutorial comprehensively detailed and helpful. It’s great to know the steps were clear and covered everything you needed. Thanks for your support, and we look forward to providing you with more valuable learning experiences!

Luna Howe DDS –

This simulation seems to cover all the necessary aspects very well. The details about how the different models and boundary conditions were set up really give confidence in the robustness of the simulation. I appreciate the inclusion of the erosion model to accurately predict the effects of the abrasive particles.

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear that you found the setup details for the simulation to be thorough and confidence-inspiring. Our goal is to provide users with comprehensive simulation scenarios that accurately reflect real-world physics, including the effects of erosion in abrasive processes. If you need further assistance or have any more questions regarding our simulations or products, please let us know. Your feedback is always welcome!

Mr. Merle Reynolds –

The training provides vivid and in-depth insights into CFD. Very impressed with the erosion model details and particle tracking visualization in the results!

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that the training exceeded your expectations and provided you with a clear understanding of the erosion model and particle dynamics. It’s wonderful to know that the visualizations helped in grasping the complex interactions within the simulation. If you have any further questions or need assistance with your CFD journey, please don’t hesitate to reach out!

Yasmine Erdman I –

I really appreciated the way you’ve explained the erosion model. Can you detail further how the erosion rates are actually calculated and predicted within the simulation?

MR CFD Support –

Certainly! The erosion rates within the simulation are calculated based on the impact dynamics between the abrasive particles and the target surfaces. By employing different mathematical erosion models such as Generic, Finnie, McLaury, Oka, and DNV, the influence of factors like the impact angle, velocity, and size of the abrasive particles on the erosion rates can be assessed. These parameters factor into the determination of stress distributions and ultimately predict areas of significant material wear. By integrating this data into ANSYS Fluent’s erosion model capabilities, quantitative predictions on the wear rate and areas likely to experience erosion can be achieved.

Mrs. Madaline Yost –

I found the intricate details of sand particle injection interesting. Can you explain further how the DPM takes the particle shape into account for erosion prediction?

MR CFD Support –

In this simulation, the Discrete Phase Model (DPM) is used to analyze the movement and impact of sand particles within the fluid flow. The DPM considers the particles’ properties such as size, density, and material but typically assumes a spherical shape for computations. For erosion prediction, the effect of particle impact on the surface is estimated using an erosion model, which uses the particle velocity, impact angle, size, and material properties. However, specific irregular shapes can also be approximated if necessary using custom functions or more advanced erosion models.

Dr. Helen Hyatt –

I was impressed with the simulated jet velocity and its ability to displace particles without thermal components. How does the variable density of the abrasive affect the cutting process in the simulation?

MR CFD Support –

In our simulation, the density of the abrasive can affect the kinetic energy of the particles and potential to cause erosion. Higher-density particles will carry more momentum at the same velocity compared to lower-density particles, potentially enhancing the cutting process due to increased impact force upon the material surface. We adjust the abrasives’ material properties within ANSYS Fluent to study these effects.

Nathaniel Friesen –

The product description was very informative! Using these materials I was able to understand the intricacies of setting up a CFD simulation involving an abrasive fluid jet. It’s clear that MR CFD took great care to cover every aspect from geometry creation to particle tracking. Excellent job ensuring users can learn about shear stress distributions due to abrasion as well.

MR CFD Support –

Thank you so much for your kind words! We’re thrilled to hear that our Abrasive Fluid Jet CFD Simulation ANSYS Fluent Training has been valuable to you and provided a deep understanding of the process. Your feedback is greatly appreciated, and we’re delighted to contribute to your learning experience. If you have any more questions or require further insights, please feel free to reach out to us!

Mrs. Katelynn Lind Sr. –

The process described sounds complex. Is a tutorial included with the learning product to help beginners understand setting up the DPM and erosion models for the abrasive fluid jet simulation in ANSYS Fluent?

MR CFD Support –

Yes, the learning product includes comprehensive tutorials and step-by-step instructions designed to guide both beginners and advanced users through the setup and analysis of DPM and erosion models for simulating the abrasive fluid jet in ANSYS Fluent. You will have all the necessary guidance to carry out the simulation on your own.

Dr. Walter Koelpin –

I am truly impressed with the detailed analysis and simulation results for the abrasive fluid jet process. The absence of heating in the cutting method and the use of both oil and sand particles to create an effective erosion process highlight the complexity and innovation of this simulation. Well done!

MR CFD Support –

Thank you for your kind words! It’s great to hear that our simulation on the abrasive fluid jet process impressed you. Providing detailed analyses and producing informative results for such complex procedures is what we strive for. Your feedback is much appreciated!

Prof. Blair Feest III –

Very informative training material! The detailed explanation of the injection type and models used in DPM was especially useful. Is there any chance that in future updates, we might see a comparison of erosion between different materials?

MR CFD Support –

Thank you for your positive feedback! We’re glad to hear that you found the training material on ‘Abrasive Fluid Jet’ simulation in ANSYS Fluent to be detailed and informative. Regarding your question about future updates, that is an excellent suggestion, and comparing the erosion effects on different materials could indeed add great value to the training. We will take this into consideration for future updates and try to include comparisons that can benefit users in material-specific simulations.

Dr. Nikko Kunze PhD –

This simulation has a very detailed setup! Can you explain how the erosion on the surfaces is measured or predicted in this CFD study?

MR CFD Support –

In the study, the erosion on surfaces is predicted by activating the erosion model within ANSYS Fluent. The simulation takes advantage of discrete phase modeling to track individual abrasive particles that cause erosion as they impact the surfaces. The erosion rates are computed by combining the particle impact velocity and impact angle with an empirical wear model, such as the Finnie, McLaury, or Oka models. Typical outputs of such an analysis would be the wear depth or material removal rate over time, which are visualized via contour outputs or perhaps even raw numerical data depending on the model specifics.