Air Bubble Injection in a shell and tube heat exchanger

$200.00 $80.00 HPC

- In this project, the heat transfer performance of a shell-and-tube heat exchanger with air bubble injection was simulated using ANSYS Fluent software. Three cases were studied: air injection into the shell, into the tube, and into both sides simultaneously.

- The geometry was created in SpaceClaim and meshed in ANSYS Meshing, initially generating about 12.6 million tetrahedral elements, later converted to a polyhedral mesh with approximately 2.43 million cells to reduce computational cost.

- The model was solved using a pressure-based steady solver with gravity effects included. A VOF multiphase model was applied to track air and water phases, while the realizable k-ε turbulence model with standard wall functions was used to capture flow behavior. The energy equation was enabled, and the SIMPLE algorithm with second-order upwind discretization ensured solution accuracy.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

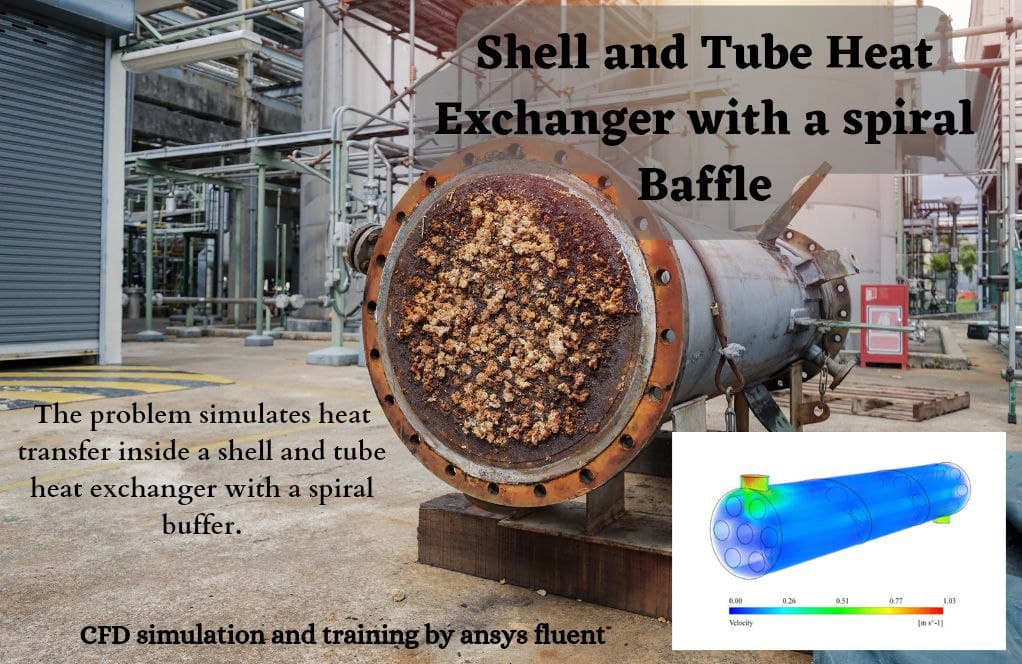

Air Bubble Injection in a shell and tube heat exchanger CFD Simulation by ANSYS Fluent

Description

In the air bubble project, heat transfer between the shell and tube in a heat exchanger is simulated, and the effect of air injection in the inlet of the shell and tube, as well as both, on the efficiency of the heat exchanger, is investigated.

Three cases were investigated in this project:

Case#1: air injected in the shell

Case#2: air injected in tube

Case#3: air injected in both shell and tube

The water flow rate of the shell is 4 LPM, the water flow rate of the tube is 1 LPM, and the air injection rate in all cases is 6 LPM.

Air has a thermal conductivity approximately 25 times lower than that of water, so in comparison with water, it can be considered an insulating material that reduces heat transfer. For this reason, we expect that air injection into the tube side would have a more significant adverse effect because the water flow rate in the tube is lower, and air can cover more heat transfer surfaces than air injection in the shell.

Geometry and Mesh

The geometry of the air bubble is drawn using SpaceClaim software. The length of the shell of the heat exchanger is 590cm, the Shell diameter is 110cm, the Number of baffles is three, and the Number of tubes is 18 with 5 cm diameters. Then the geometry of the air bubble is inserted into the ANSYS Meshing software, generating 12669457 tetrahedral elements. In addition, after importing the mesh into Fluent, we make the mesh polyhedral to reduce the computational cost so that the Number of meshes reaches 2,429,706.

Setup

The air bubble project is solved with a pressure-based and steady solver. Also, gravity is activated and its value is defined as 9.81 kg/s2. The gravity force is significant because of the difference in the high air and water densities. Two, water and air phases are defined, and each phase’s volume fraction at each cell is calculated with the VOF (volume of fluid) method. A k-e realizable model is used, and the standard wall function is selected for air bubble simulation. k-e is a very robust model in simulations that don’t have high swirl flow or separation. This model can be the best option (except when an exact boundary layer profile calculation is needed). The energy equation is activated too. The Semi-Implicit Method for Pressure Linked Equations (SIMPLE) algorithm is selected, and a second-order upwind discretization method is used for the momentum and energy equations.

Boundary condition

The boundary conditions of Inlet shell and tube for all cases of the air bubble are listed in the following table. Hot water flows in the tube and cold water flows in the shell.

| Case #1 | Case #2 | Case #3 | ||

| Inlet shell | Air flowrate | 6 LPM | 0 LPM | 6 LPM |

| Water flowrate | 4 LPM | 4 LPM | 4 LPM | |

| temperature | 23 C | 23 C | 23 C | |

| Inlet tube | Air flowrate | 0 LPM | 6 LPM | 6 LPM |

| Water flowrate | 1 LPM | 1 LPM | 1 LPM | |

| temperature | 50 C | 50 C | 50 C |

Results

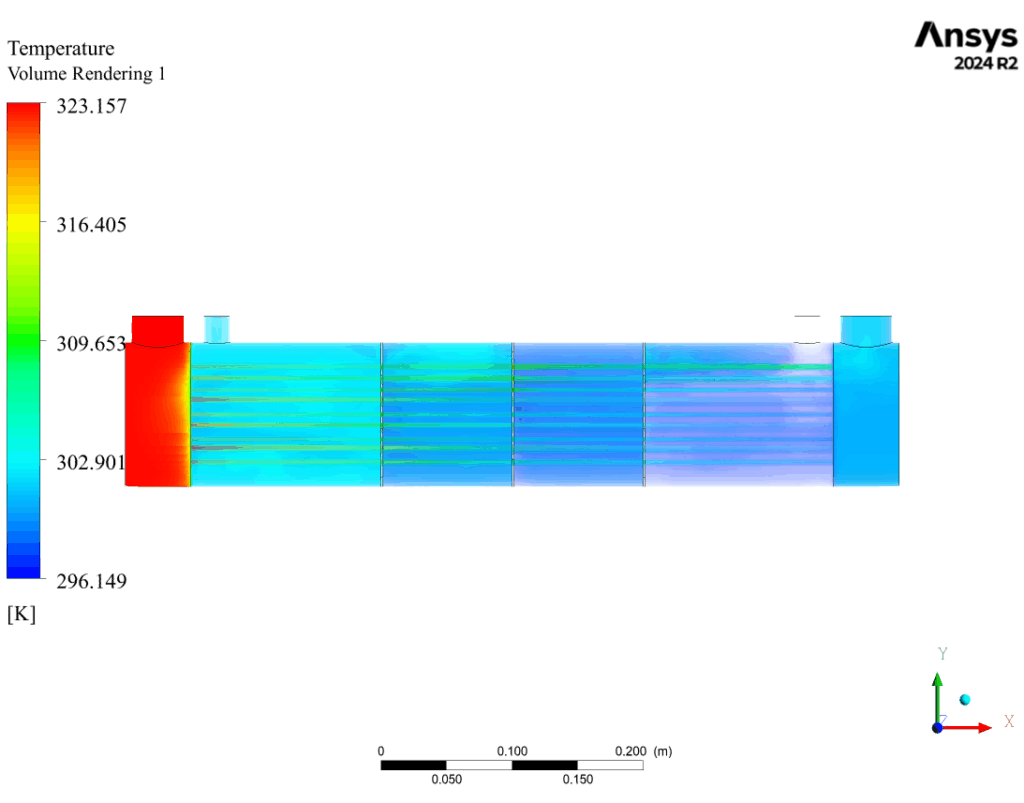

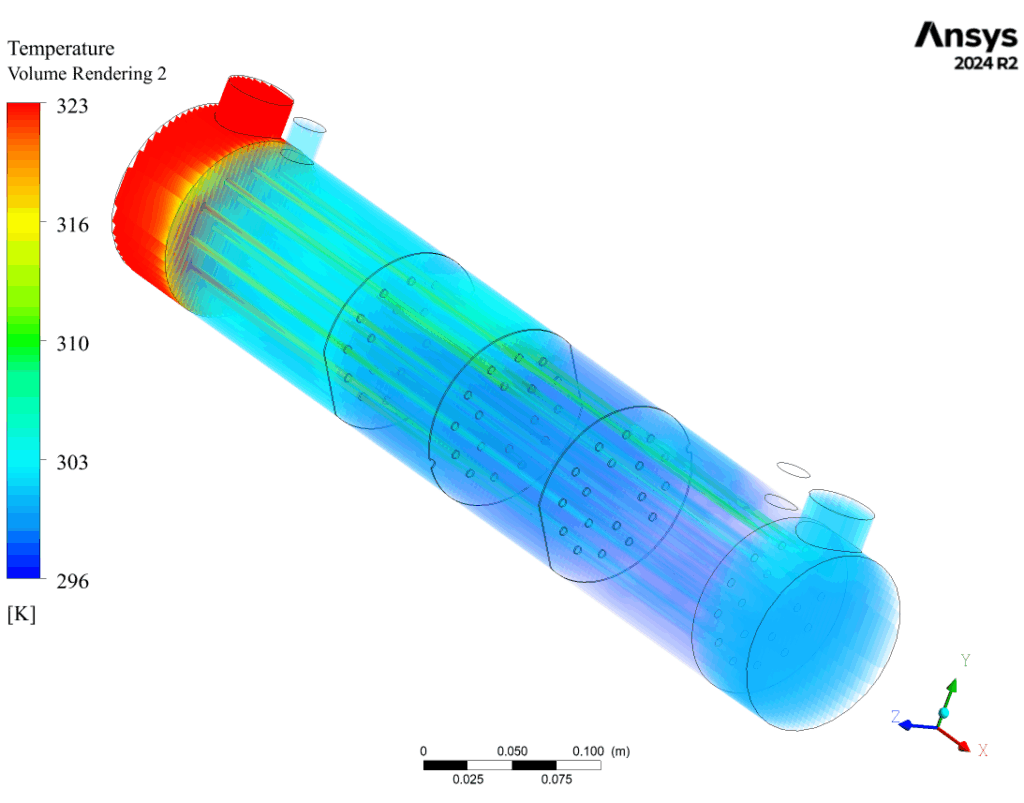

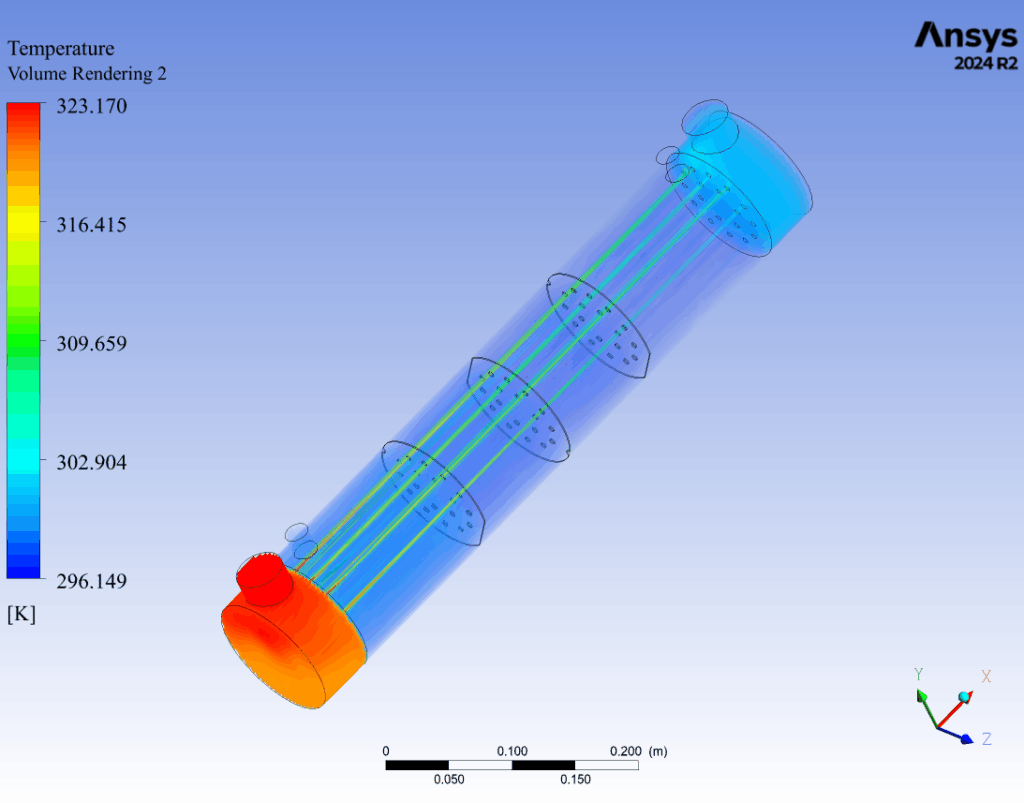

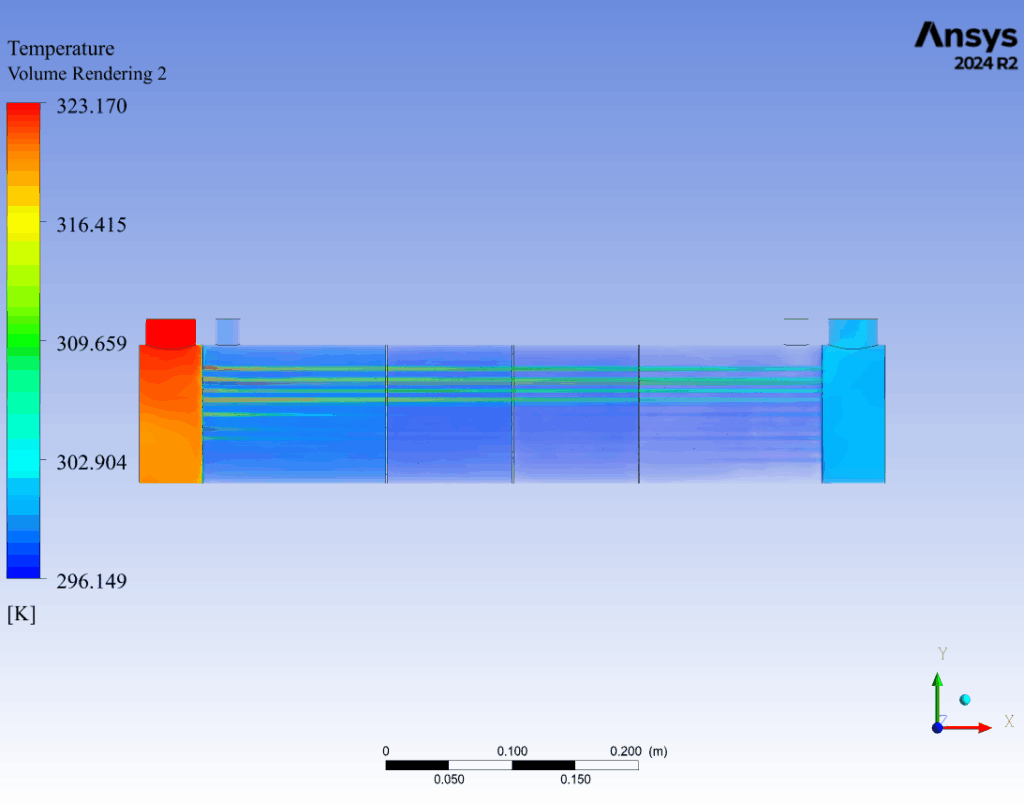

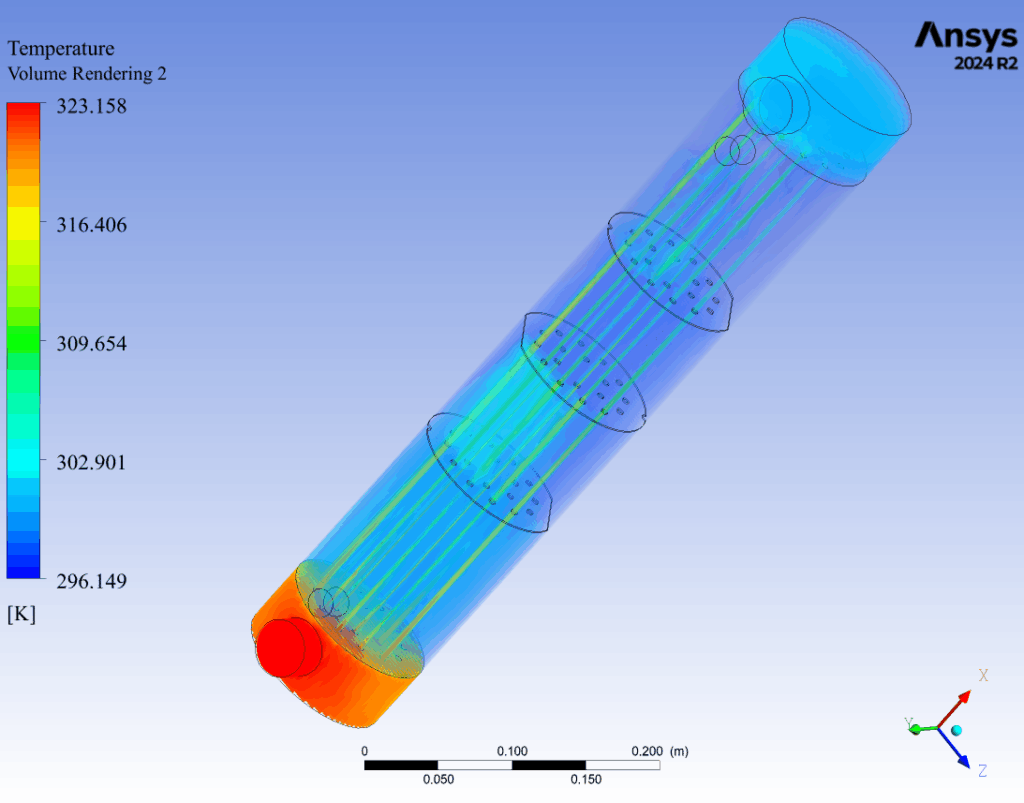

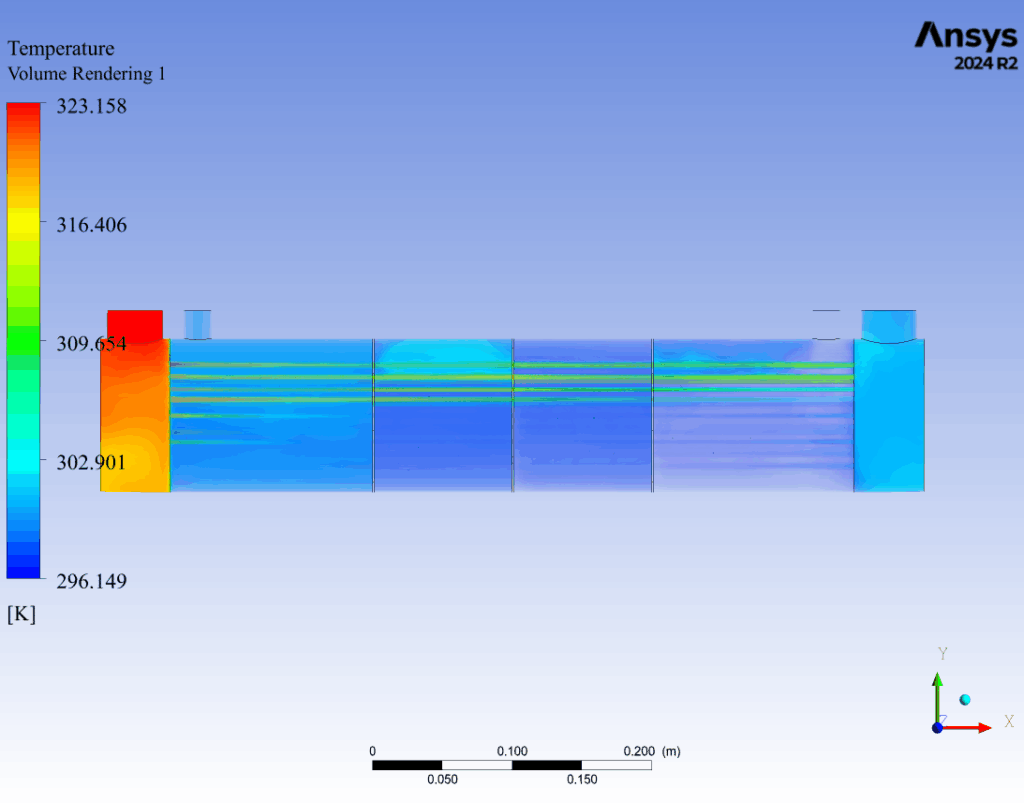

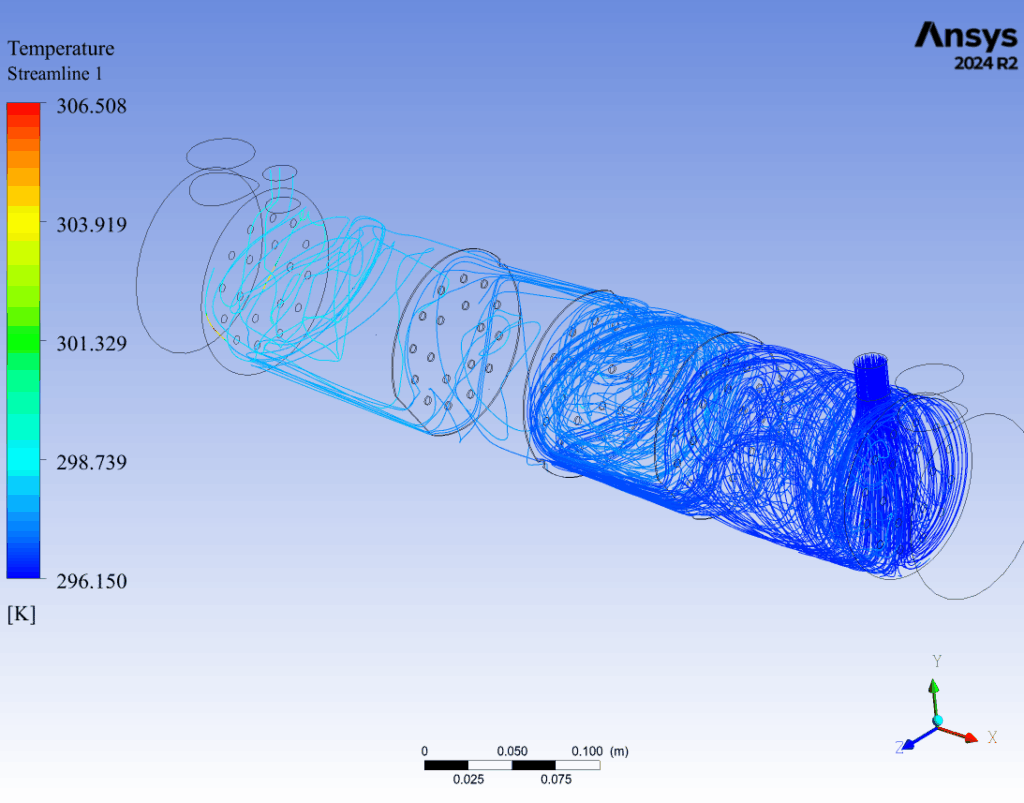

At first, let’s talk about temperature results. Inlet and outlet temperature values are presented at the end of the report, but in the following, we can see the rendering of temperature in 3 cases.

In case 1, the temperature change at the top of the shell, where the air exists, is faster. That’s because of the lower Cp of air than water; in this case, the temperature change of water in tubes is the same.

In cases 2 and 3, the temperature change in the upper tubes is lower because only air is flown in these tubes, and heat transfer is much lower.

Temperature of case 1:

Temperature of case 2:

Temperature of case 3:

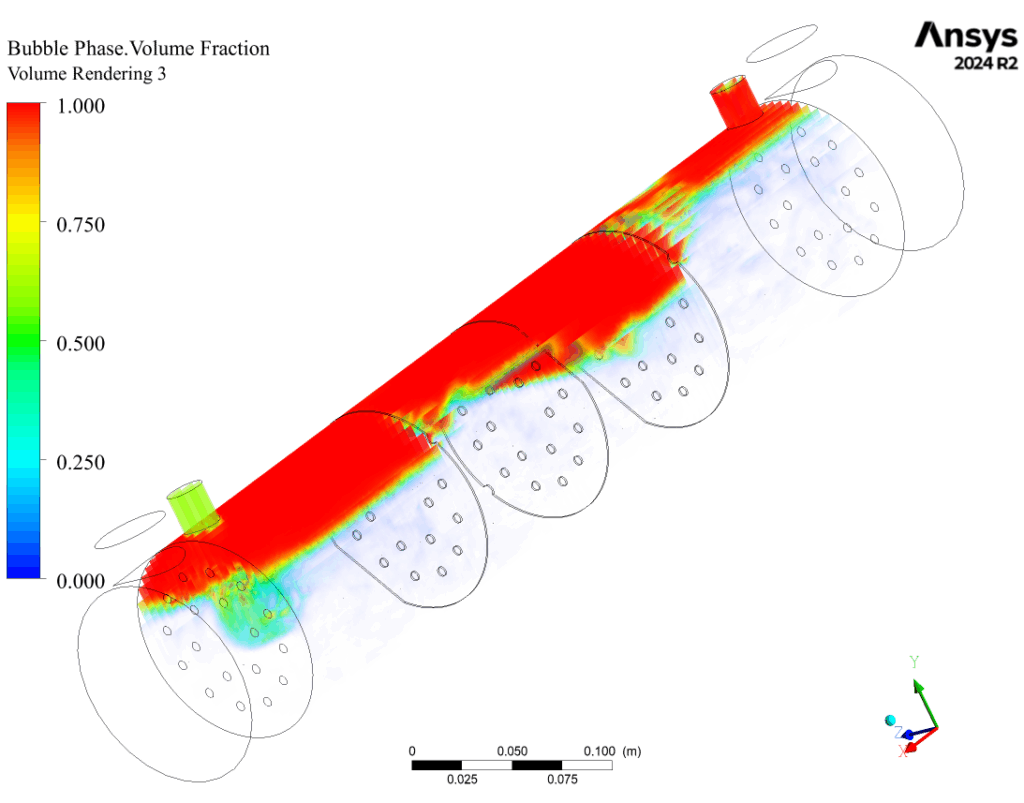

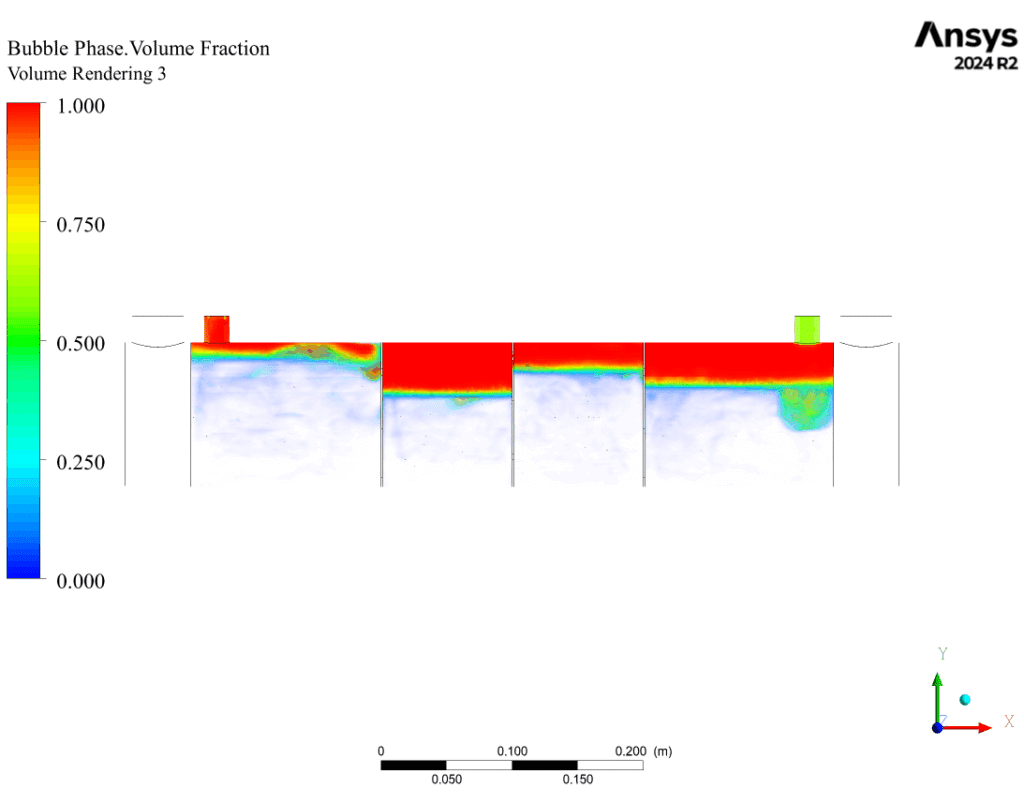

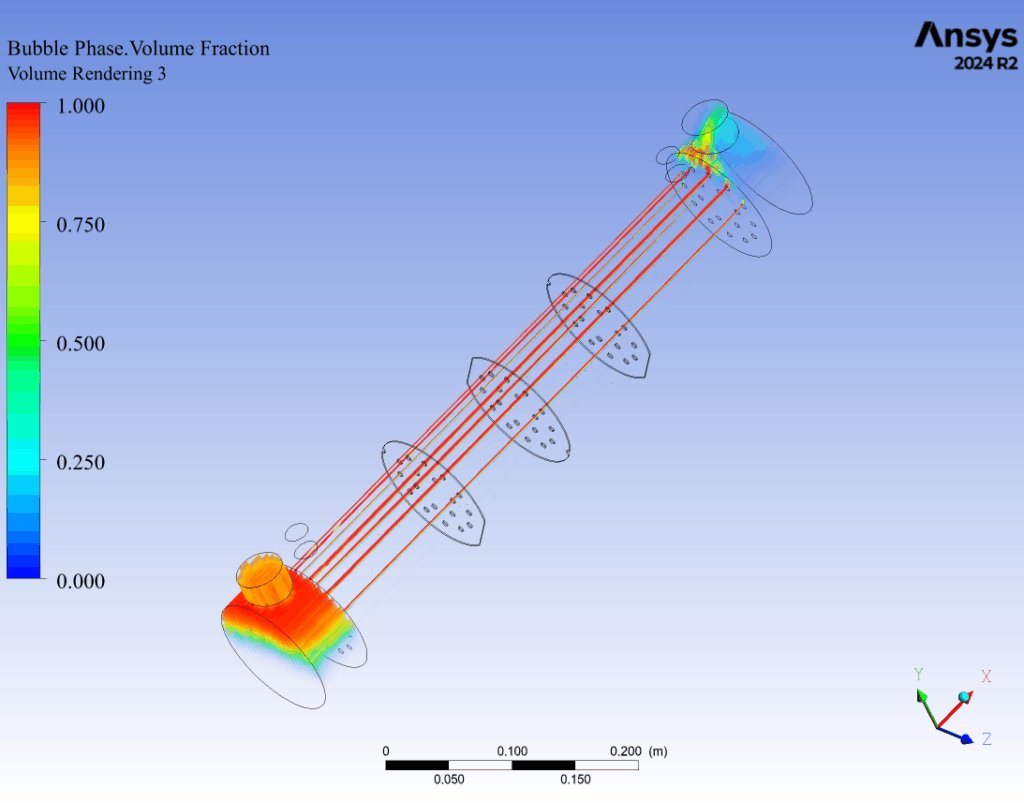

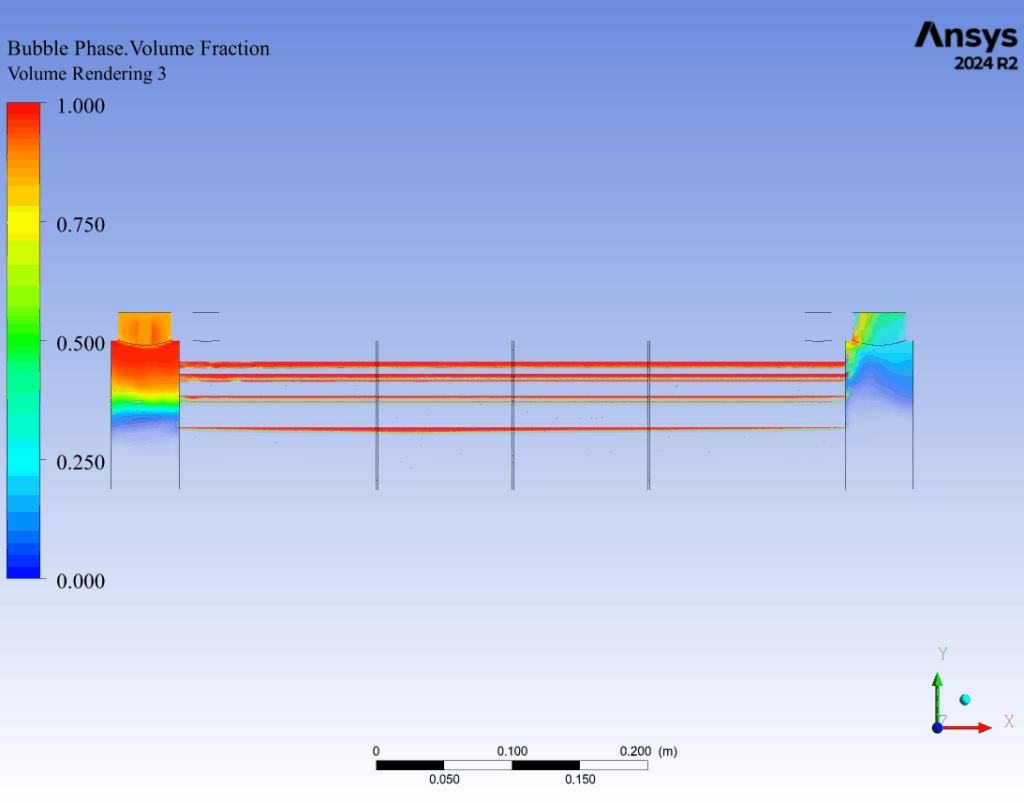

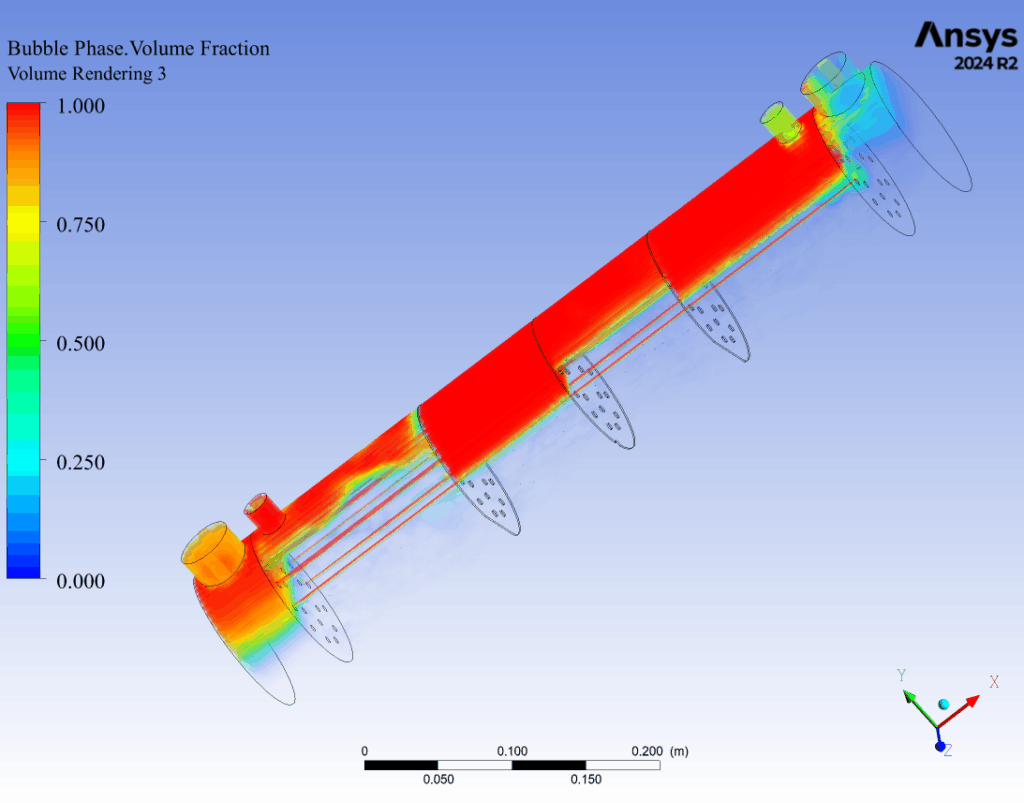

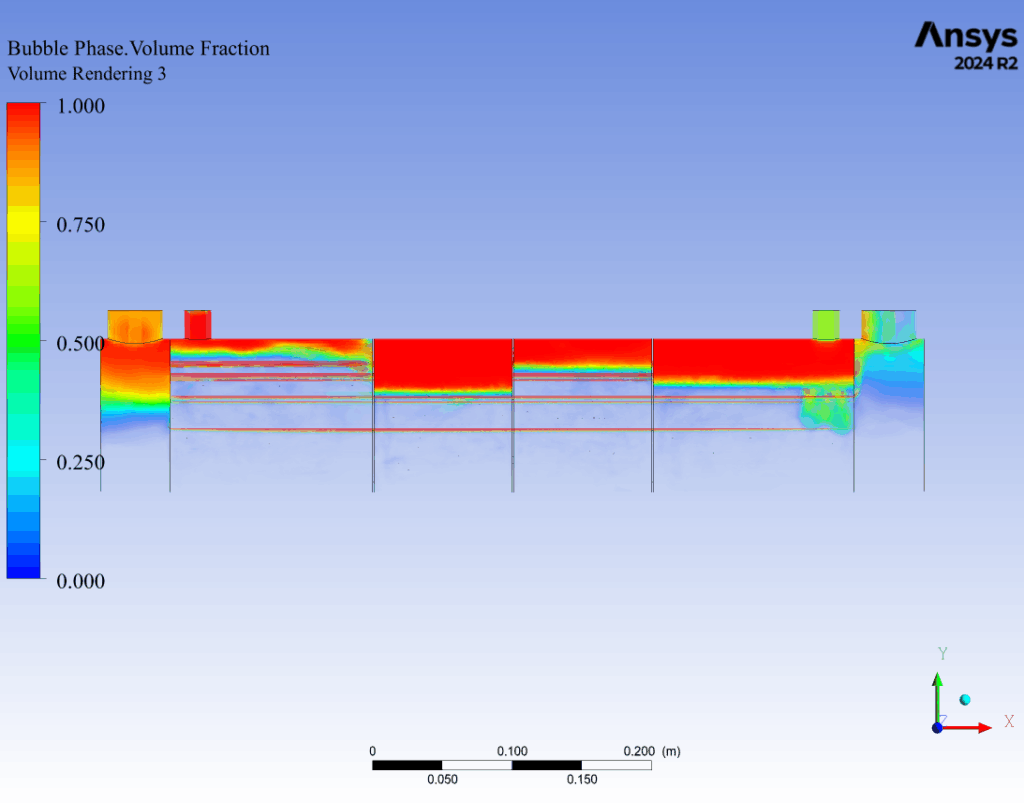

Volume fraction of air is presented in the following figures for each case. Because gravity is activated and there is a high difference between air and water density, we can see that the air bubbles move up and stay on the top of the water.

Volume fraction of air in case 1:

Volume fraction of air in case 2:

Volume fraction of air in case 3:

Streamline of shell case2:

The above figure shows the effect of baffles on the flow pattern in the air bubble project.

Summary results

| Total heat flux (W) | Tube flow | Shell flow | |||

| Inlet T (°C) | Outlet T (C) | Inlet T (°C) | Outlet T (C) | ||

| Air injection in the shell | 1508 | 50 | 28.2 | 23 | 27.2 |

| Air injection in the tube | 719 | 50 | 27.32 | 23 | 25.59 |

| Air injection in the shell and tube | 638 | 50 | 27.25 | 23 | 26.86 |

As discussed, air injection into the tube negatively influences heat transfer. Its reason is the very low air thermal conductivity, and the tube water flow rate is lower so, in this case, more heat transfer surfaces are covered with air. Also, in the third case, air injected from both the shell and the tube has the lowest heat transfer.

Now let’s talk about temperatures.

If we compare case 1 with case 2 of air bubble project, the heat transfer of case 2 is lower, but the temperature changes between the tube inlet and outlet in this case are higher because of the lower air Cp.

You must be logged in to post a review.

Reviews

There are no reviews yet.