Fluidized Bed Polymerization Reactor, Paper Numerical Validation, ANSYS Fluent Training

$280.00 Student Discount

- The problem numerically simulates Fluidized Bed Polymerization Reactor using ANSYS Fluent software.

- We design the 2-D model by the Design Modeler software.

- We Mesh the model by ANSYS Meshing software, and the element number equals 938174.

- We perform this simulation as unsteady (Transient).

- We perform the simulation according to a Reference Article and validate the results.

- We use the Eulerian Multi-Phase model to define the suspension of solid particles within a fluid flow like a fluidized bed.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Description

This simulation is about a fluidized bed polymerization reactor via ANSYS Fluent software. We perform this CFD project and investigate it by CFD analysis. A reactor is a device for performing chemical reactions (conversion, composition, decomposition, etc.) using catalysts and, as a result, the conversion of raw materials into desired products.

Due to the economic aspects of the production of reactors, it is necessary to design reactors with higher efficiency but lower cost and lower energy consumption; therefore, in the design of reactors, parameters such as volume, temperature, pressure, particle concentration, particle residence time, heat transfer coefficient, and reaction rate are important.

Chemical reactors have different classifications, including continuous and discontinuous reactors, homogeneous and heterogeneous, pipe and tank reactors, and fixed bed and fluidized bed reactors. In fixed bed reactors, the solids are stationary inside the reactor as a catalyst, and the reactants pass through these materials, reacting and leaving the reactor. In these fluidized bed reactors, the solids are reactants or catalysts suspended in the flow under pressure.

The fluidized bed-type reactor has advantages such as a high heat transfer rate and high mass transfer rate, lower heat transfer surface, uniform temperature distribution, proper temperature control, and complete and rapid mixing of reactors and catalysts.

The main advantage of the fluidized bed type reactor compared to the fixed bed type is the ability to control the temperature and prevent the formation of hot spots, which is necessary for any reaction. Fluidized bed reactors have many industrial applications, including petrochemical, chemical, electricity generation, incinerator, etc. This problem will simulate a two-phase flow inside a fluidized bed reactor with simple geometry.

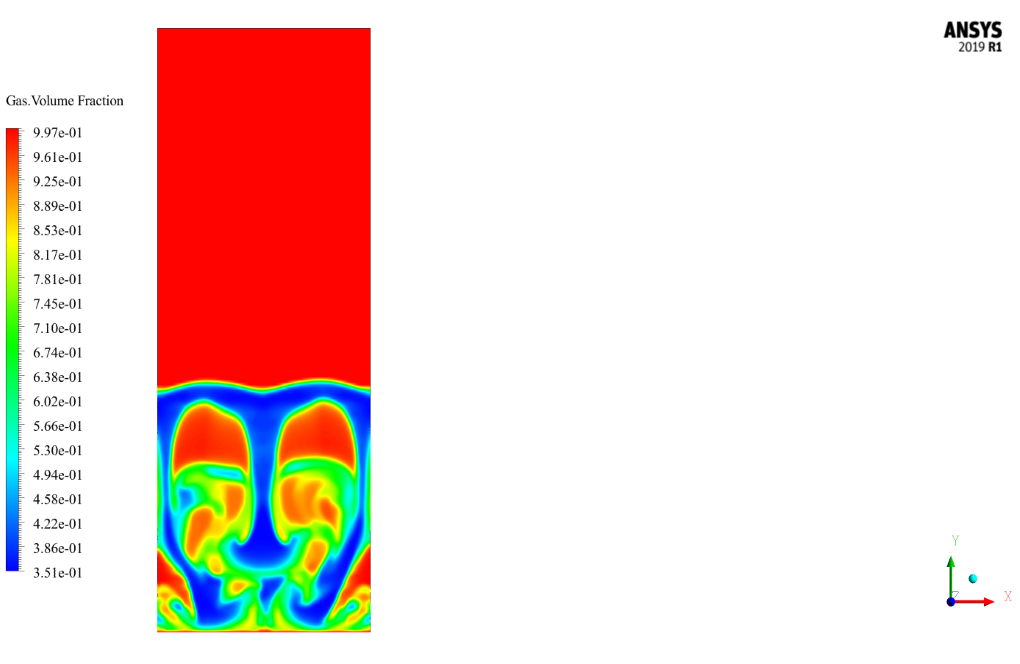

The results are compared and validated with a paper called “A fundamental CFD study of the gas-solid flow field in fluidized bed polymerization reactors.” The simulation process is such that in the initial state inside the chamber, the solid suspended particles are only up to a height of 20 cm from the chamber bottom with a volume fraction of 0.63 inside the gas flow. The operating pressure of the system is defined as 1400000 pa.

The gas flow enters vertically and upwards at a speed of 0.3 m/s, while no solid particles enter the reactor. The present study investigates the behavior of suspended solid particles in the gas flow over time and the pressure drop generated from the reactor inlet to the outlet. The geometry of the present model is drawn by Design Modeler software. The model is then meshed by ANSYS Meshing software. The model mesh is unstructured, and 938174 cells have been created.

Fluidized Bed Method

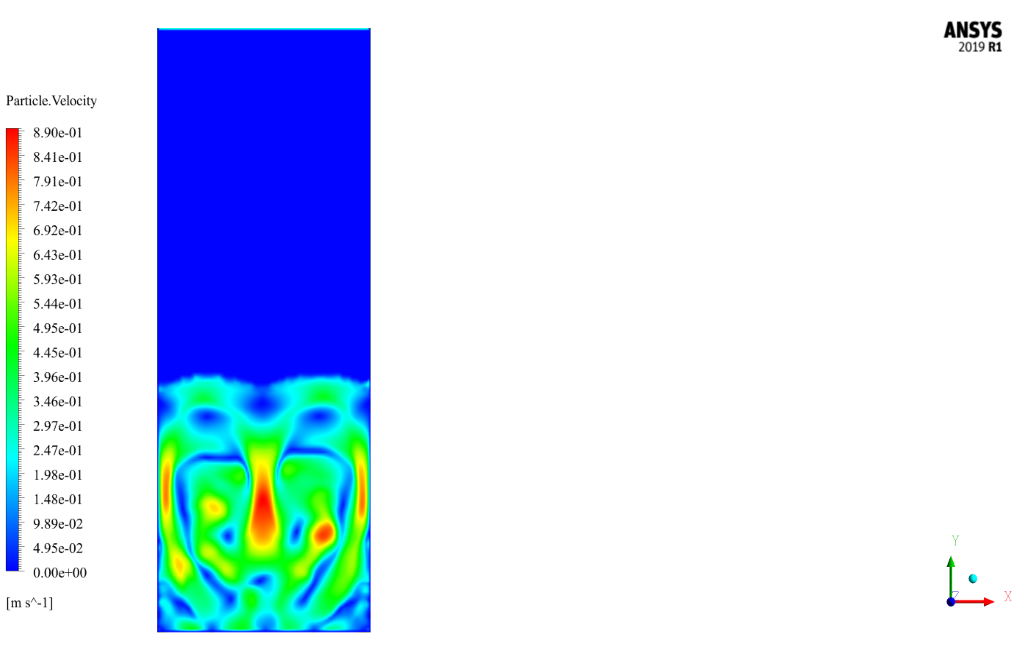

Since the performance of reactors is inherently based on the mixing of flows and particles as reactants and catalysts in the chemical reaction process, a multi-phase model has been used to define the fluid flow within the model.

Also, considering the present model is related to simulating the suspension of solid particles within a fluid flow like a fluidized bed model, choosing the Eulerian multi-phase flow model is the most appropriate option.

Therefore, the model includes a gas flow defined as the primary phase and suspended solids defined as the secondary phase. The present model is unsteady; because the model’s nature is such, the behavior of the particles in the model changes over time. The simulation process was performed for 4 s with a time step of 0.001 s.

Fluidized Bed Conclusion

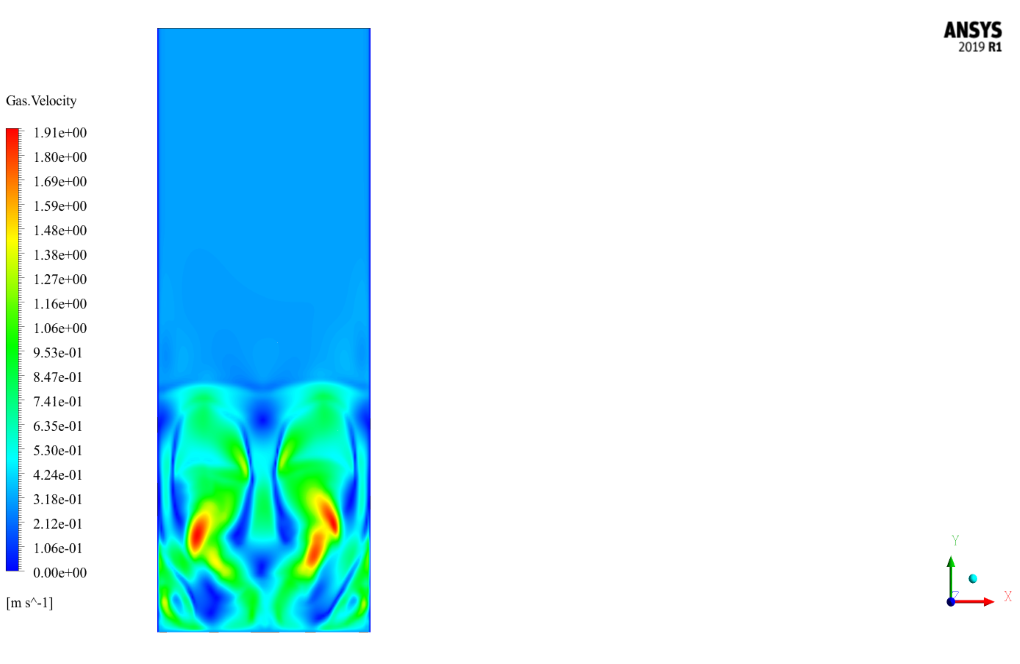

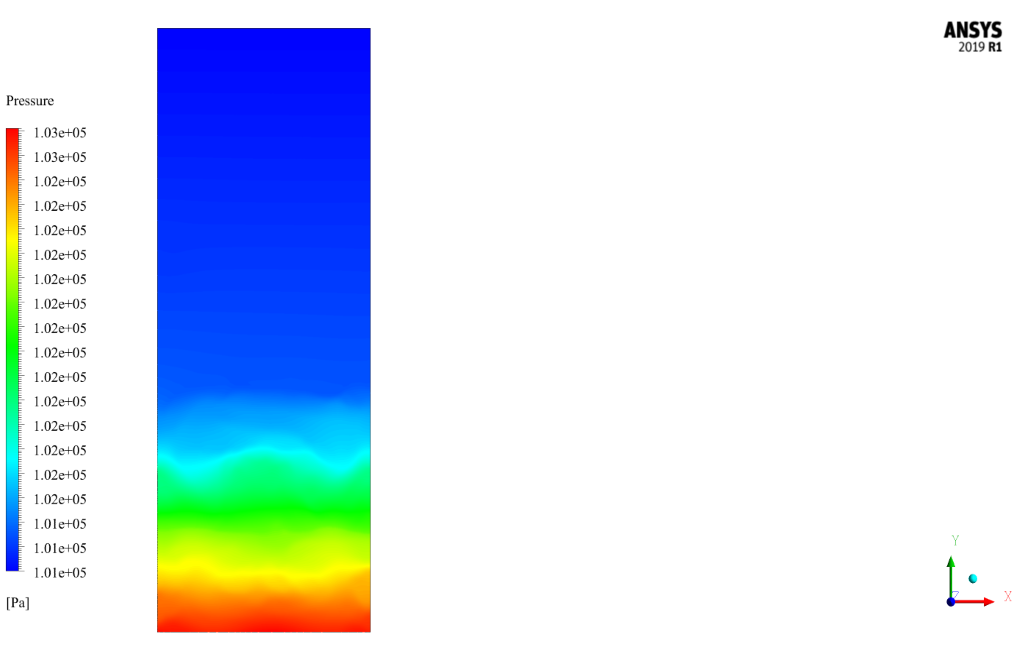

After simulation, two-dimensional contours related to the mixture pressure, gas flow velocity and suspended solids, and volume fraction of the gas flow and solid suspended particles from zero to four seconds are obtained.

Also, the pressure value at the inlet and outlet is obtained. Therefore, the pressure drop in the model has been obtained at different times because the pressure drop is equal to the static pressure difference between the inlet.

So the pressure drop is presented as a function of time. The pressure drop at different times (every 0.2 seconds) was obtained using facet average and compared with the results in the article.

The diagram in Figure 6 of the article has been used to validate the present numerical simulation results. This plot shows the pressure drop within the model over 4 seconds. A comparison of the present numerical simulation results with the results of the numerical work of the article is presented.

Dr. Sanford Stroman –

How does the unsteady nature of the simulation affect the accuracy of pressure drop measurements over time?

MR CFD Support –

The unsteady nature of the simulation reflects the dynamics and fluctuations of the pressure values as the particles and gas interact over time. It is of paramount importance to accurately resolve the temporal changes to provide precise measurements of pressure drops. Smaller time step sizes and careful numerical methods ensure the simulation captures transient effects accurately, which influences the precision of pressure drop calculations at any given timeframe within the model.

Annabell Wintheiser –

The training was of spectacular quality! Comparing your simulation results with those in the referenced academic paper added so much credibility and showed practical examples of how we can use CFD for real industrial applications. Thank you for explaining everything so clearly, including reactor design aspects, operational parameters, and the advantages of fluidized bed reactors. Understanding pressure drop and particle behavior over time has been invaluable for my research in chemical engineering applications.

MR CFD Support –

Thank you for your kind words! We are delighted to hear how beneficial you found the training to be, especially in connecting theoretical understanding with practical industrial scenarios. It is our aim to deliver comprehensive learning experiences that add meta value to your work. Should you have any further questions or require additional resources, please do not hesitate to reach out. We wish you all the best in your future research and engineering endeavors!

Arjun McGlynn –

This simulation is a great tool for optimizing the design and operation of fluidized bed reactors.

Gonzalo Block –

I am thoroughly impressed by how the Fluidized Bed Polymerization Reactor simulation mirrors real-world reactor functionality. It seems comprehensive in scope, covering crucial parameters like temperature control, which are essential for preventing the formation of hot spots. Excellent work on this realistic and detailed training module.

MR CFD Support –

Thank you for your positive feedback on our Fluidized Bed Polymerization Reactor simulation training. We strive to provide precise and practical simulations that help understand complex chemical processes. We’re thrilled to know that you have found it comprehensive and reflective of real-world functionality. Your insights on the importance of temperature control signify that our efforts to simulate such critical aspects are being recognized. Thanks again for your kind words!

Mrs. Berniece Wisozk Sr. –

The ability to customize this simulation for specific designs is a game-changer!

Stephen Roberts –

I’m thrilled with the comprehensive explanation of the fluidized bed polymerization reactor. Have you noticed any significant discrepancies between your simulation results and the validation paper? If so, how did you address them?

MR CFD Support –

Thank you for acknowledging our efforts. We strive for precision and ensure that our simulations are as accurate as possible. Using the provided information, we delicately compared our results with the paper and made adjustments as necessary. We did observe minimal discrepancies due to model assumptions, boundary conditions, or meshing differences, which were all addressed by refining the mesh, tweaking the model parameters, and validating several benchmarks to hone the accuracy. Ensuring that our results are consistently reliable and on par with peer-reviewed standards is of utmost priority.

Randal Reilly –

The simulation sounds complex. Was it a straight-forward process to replicate the gas-solid flow field as described in the referenced paper?

MR CFD Support –

Yes, the process was quite involved, but leveraging the capabilities of ANSYS Fluent, we were able to accurately replicate the gas-solid flow field in our simulation as highlighted in the paper. Careful consideration was given to all setup parameters to ensure they were consistent with the paper’s methodology.

Michelle Adams –

The detailed approach used in the simulation for replicating the fluidized bed polymerization reactor’s behavior was fascinating. Especially impressive was how the study aligned the results with those presented in the referenced paper for validation purposes. The focus on parameters such as pressure drop and particle suspension dynamics provided insightful observations beneficial for both academic research and industrial applications. Keep up the notable work!

MR CFD Support –

Thank you for your kind words and positive feedback on our Fluidized Bed Polymerization Reactor simulation training. We are thrilled to hear that the detailed methodology and validation process met your expectations and provided valuable insight for your needs. We look forward to continuing to provide high-quality simulations and services.

Miss Kaylee Kohler –

Fantastic resource for understanding complex reactor simulations! The detail about how particle dynamics are analyzed over time really helps comprehend the fluidized bed process. By any chance, could you offer more courses or materials specifically on multi-phase flow modeling?

MR CFD Support –

Thank you for your kind words! We’re glad to hear that the material was informative and helpful to you. Regarding multi-phase flow modeling, we certainly can offer more specialized courses and materials that delve deeper into this subject. Our team is continuously developing new content, so stay tuned for future releases that will cover multi-phase flow modeling in greater depth.

Lawson Keeling –

This product sounds intriguing! Is this reactor simulation also helpful for undergraduate students who are trying to understand fluidized beds, or is it more targeted toward professionals?

MR CFD Support –

Yes, undoubtedly this reactor simulation is a fantastic teaching tool for both undergraduate students and professionals. For students, it offers a practical insight into fluidized bed dynamics in polymerization processes. The numerical validation aspect can also improve their understanding of applying CFD to real-world chemical engineering problems. For professionals, it adds value by providing a case study which can be used to understand complex fluid-particle interactions in reactor design and operation.

Antonetta McKenzie –

The training was fantastic! The step-by-step approach helped me understand fluidized bed reactors thoroughly, especially the multi-phase modeling. Great job on demonstrating the practical applications in industries like petrochemical and electricity!

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that our fluidized bed reactors training with a focus on multi-phase modeling was effective and provided valuable insights into its industrial applications. Your satisfaction with the learning experience is important to us, and we look forward to bringing you more quality simulations and training materials!

Ms. Antoinette Homenick PhD –

This simulation is a testament to the power of computational fluid dynamics!

Bella Kunde II –

Was settling time taken into consideration? The simulation needed time for the fluidized particles to stabilize before measurements.

MR CFD Support –

Thank you for your positive feedback! To ensure accurate results, a sufficient settling period was indeed factored into the simulation to allow the solid particles within the reactor to reach a stable state before the recording of data commenced.

Charles Nitzsche –

The ANSYS Fluent training on the fluidized bed polymerization reactor has been an incredibly rich learning resource. It not only explained complex concepts in an accessible way but also included numerical validation against scholarly work, which really bolsters credibility and understanding. Superb!

MR CFD Support –

Thank you for your kind words! We are thrilled to hear that you found the training to be insightful and credible. Our goal is to provide clear and practical learning materials that are backed by solid validation. We’re glad that this came through in our fluidized bed polymerization reactor simulation training using ANSYS Fluent. If you have any further questions or need more assistance, feel free to reach out.

Miss Alana Crona –

The fluidized bed reactor training was very detailed, and the comparison with the validation paper provided a great understanding of the real-world application. The focus on the pressure drop and particle behavior over time offered great insights into the dynamics within the reactor.

MR CFD Support –

Thank you for your positive feedback! We’re glad that the training material was able to provide you with a thorough understanding and valuable insights. If there’s anything more we can assist with regarding our simulations or any additional information you would like to know, please feel free to reach out.