Boiling Phenomenon and Bubble Formation CFD Tutorial

$200.00 Student Discount

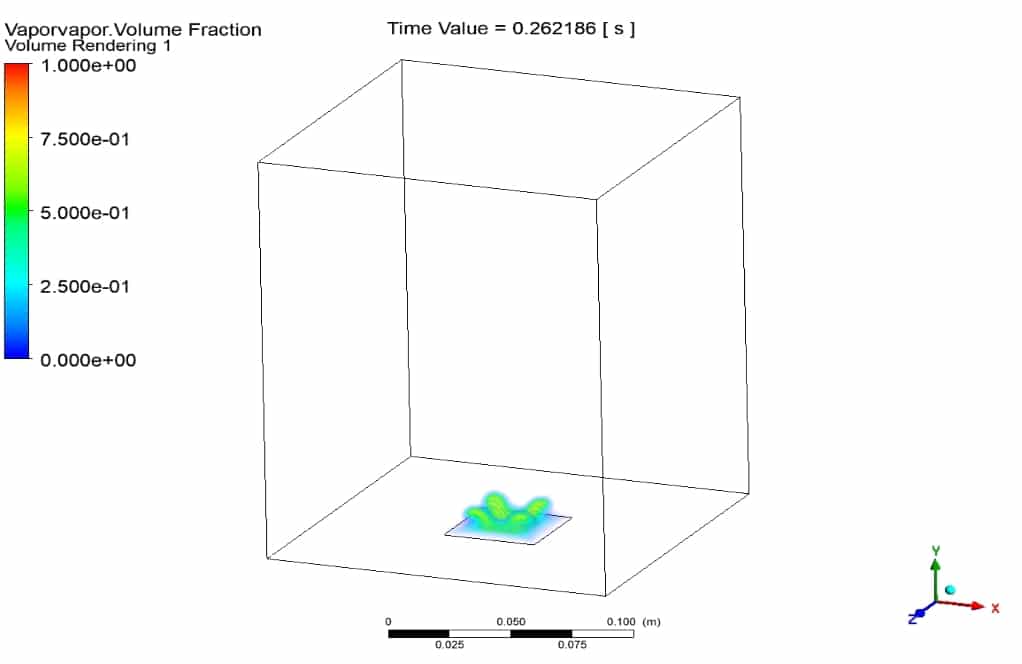

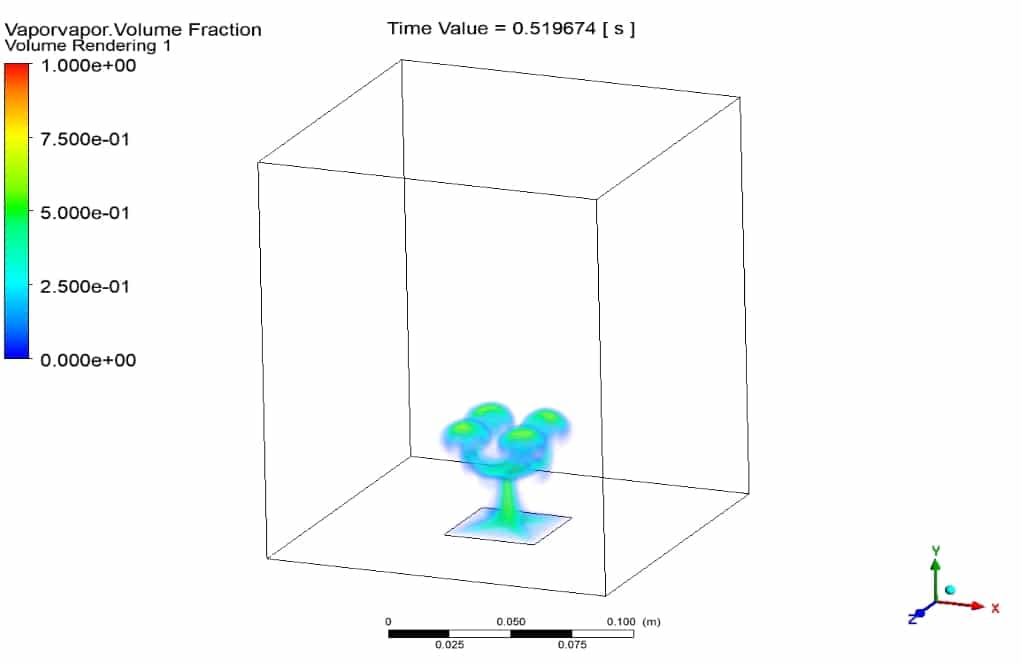

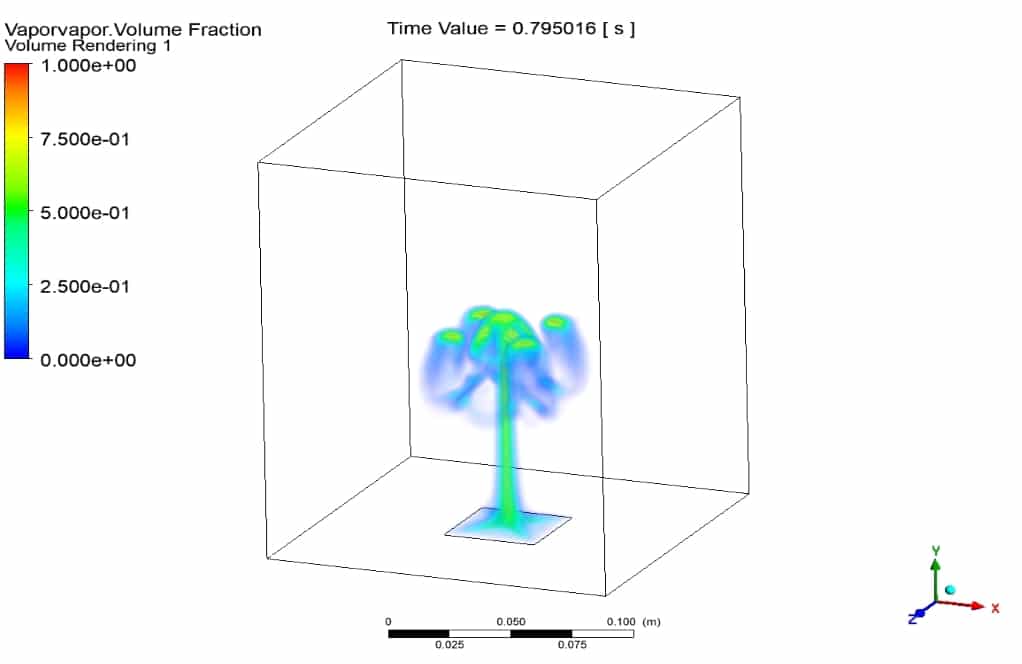

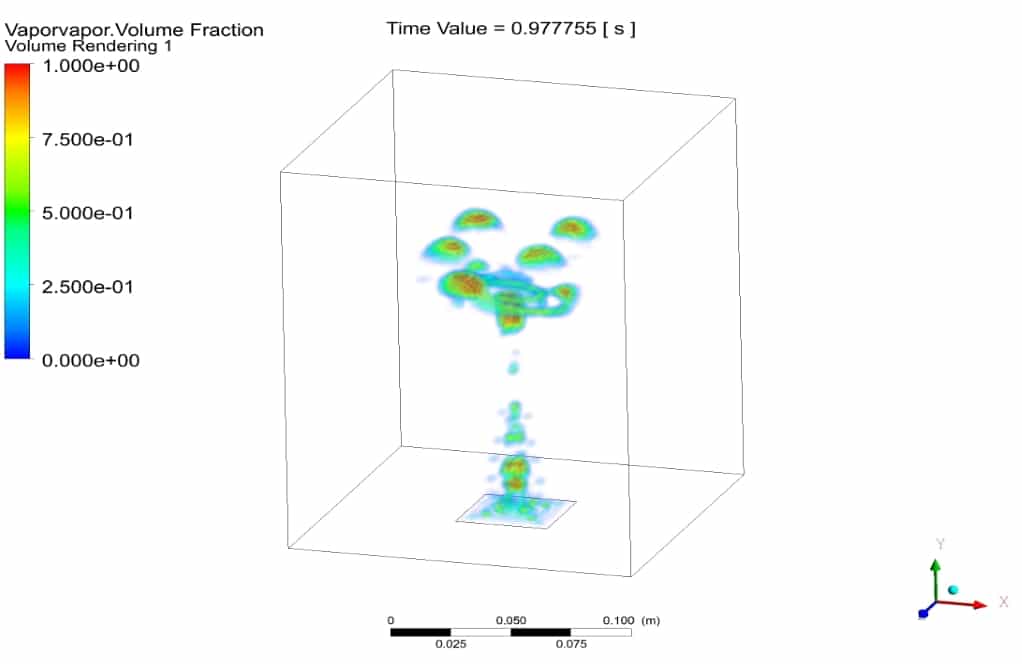

In this project, Boiling Phenomenon to investigate three-volume fraction discretization methods has been simulated and the results of this simulation have been investigated.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Boiling Phenomenon and Bubble Formation, Ansys Fluent CFD Simulation Training

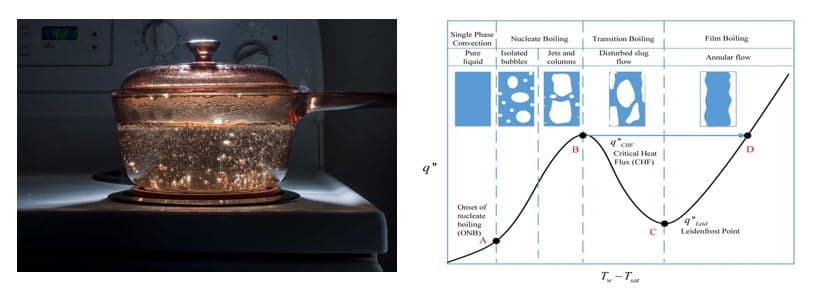

Boiling is the fast evaporation of a liquid when heated to its boiling point. The temperature at which the liquid’s vapor pressure equals the pressure exerted on the liquid by the surrounding environment. Boiling may be classified into two types: nucleate boiling, in which tiny bubbles of vapor develop at distinct places, and critical heat flux boiling, in which the boiling surface is heated above a specific critical temperature and a film of vapor forms on the surface. Transition boiling is an unstable intermediate form of boiling that has components of both forms. The boiling point of water is 100 °C or 212 °F; however, it is lower at higher altitudes due to reduced air pressure. Boiling Phenomenon and Bubble Formation CFD simulation by ANSYS Fluent is carried out in this product.

Project Description

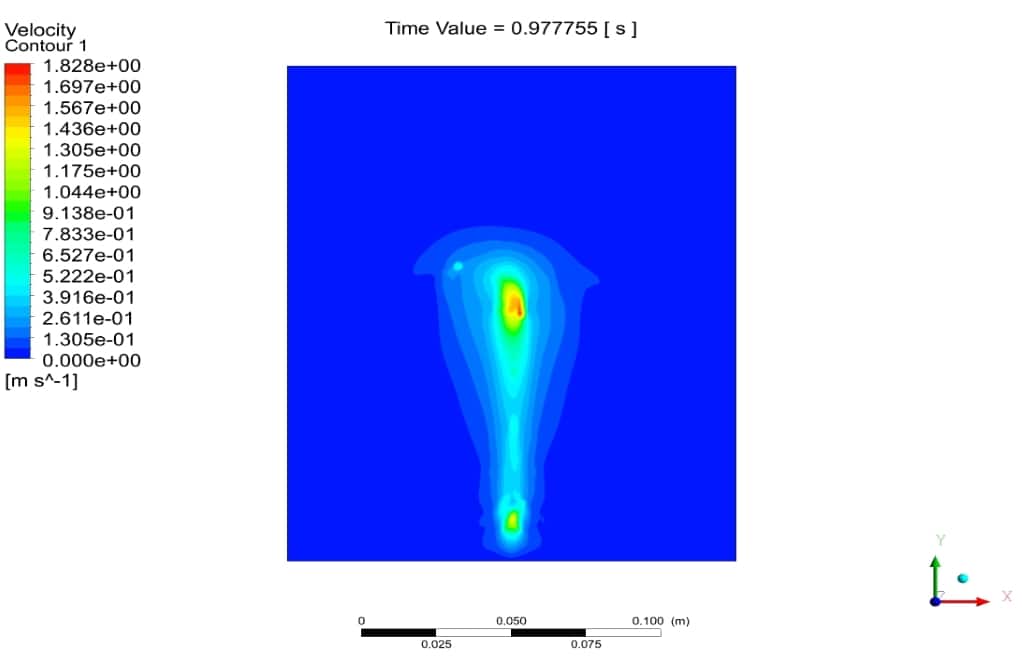

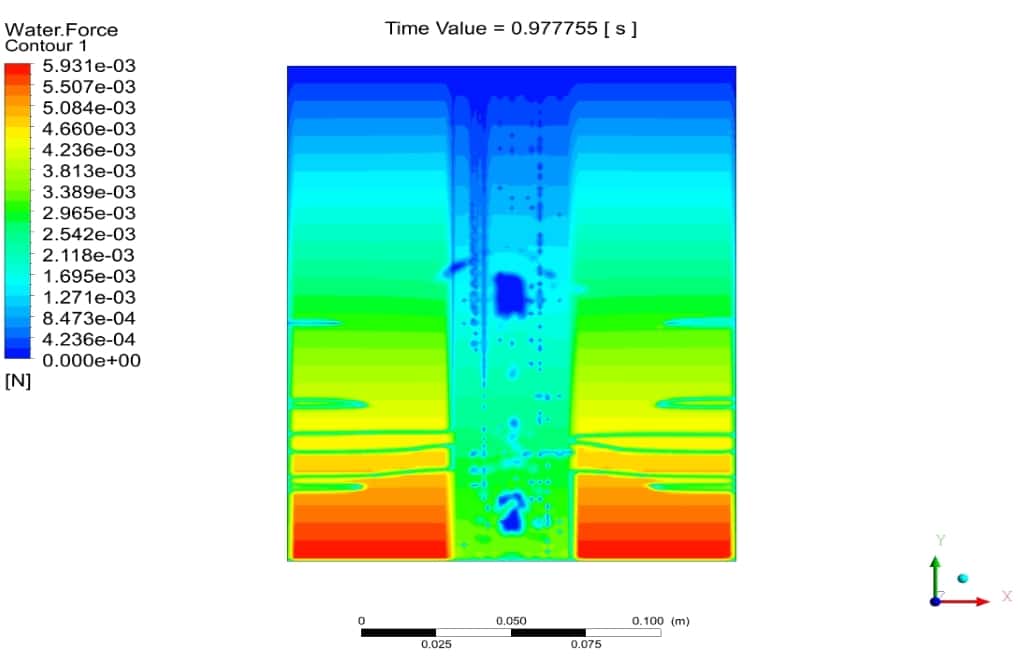

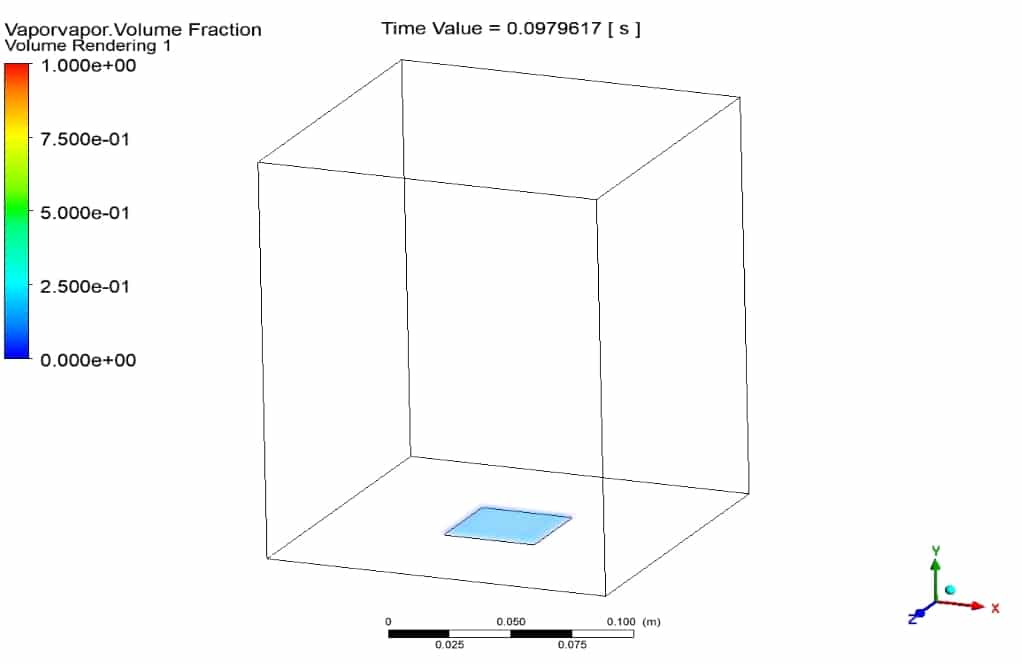

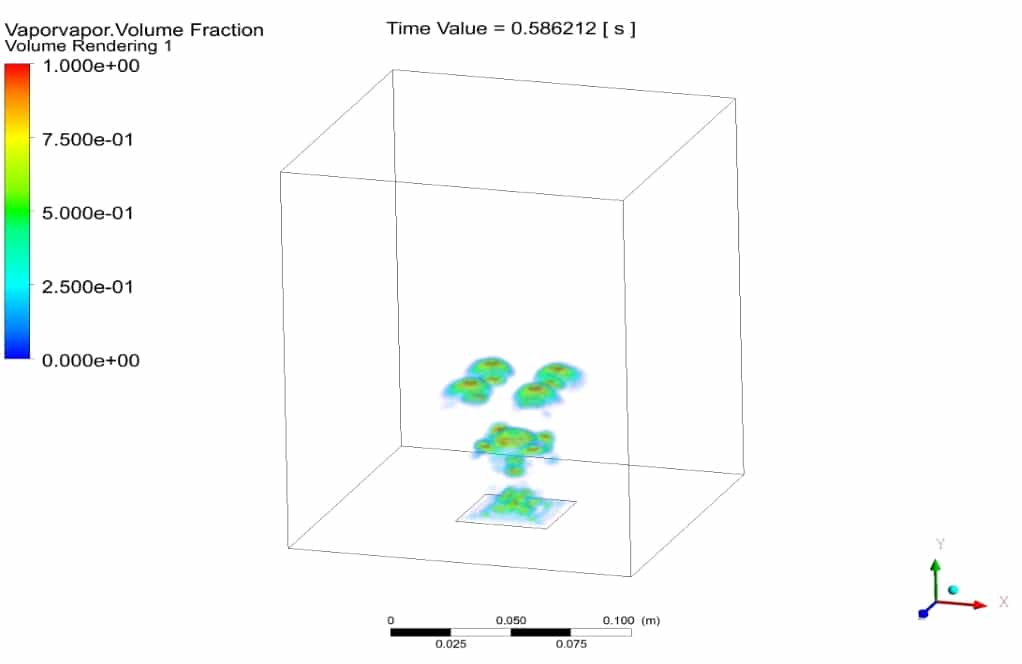

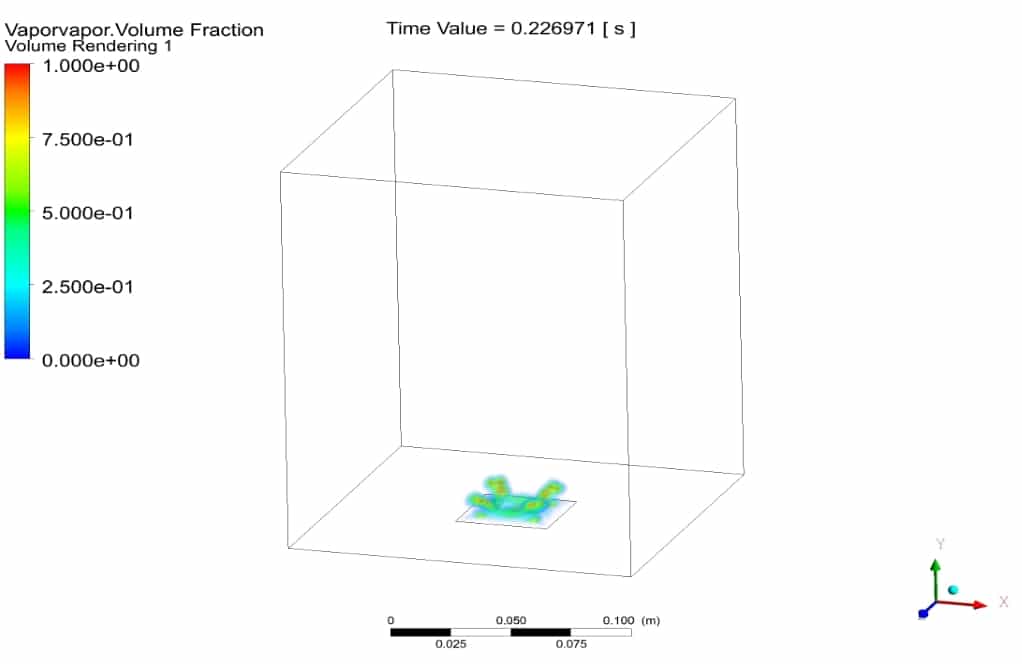

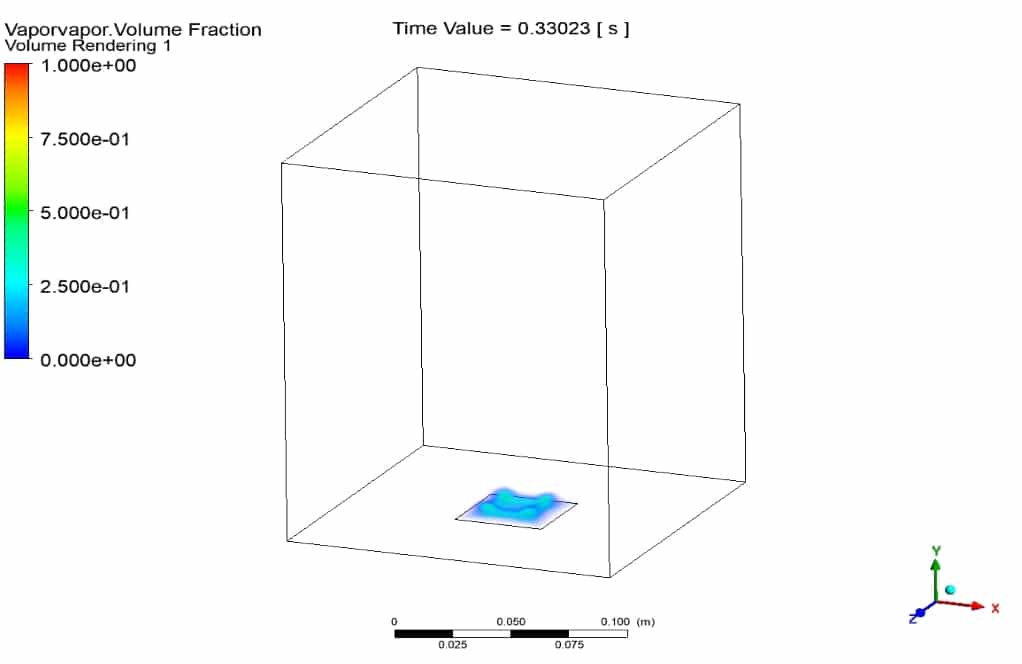

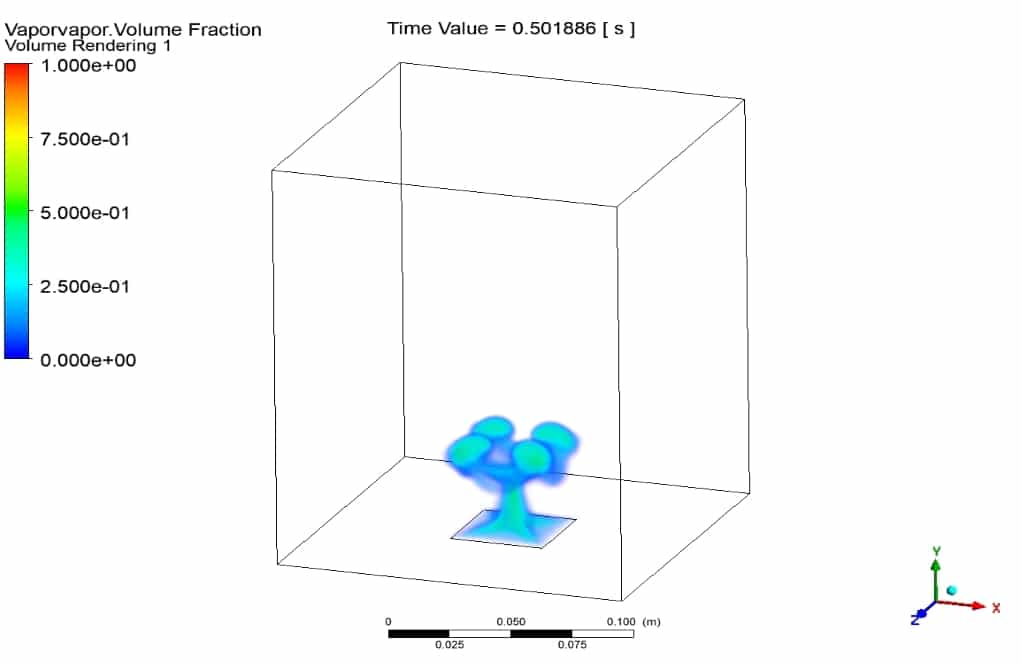

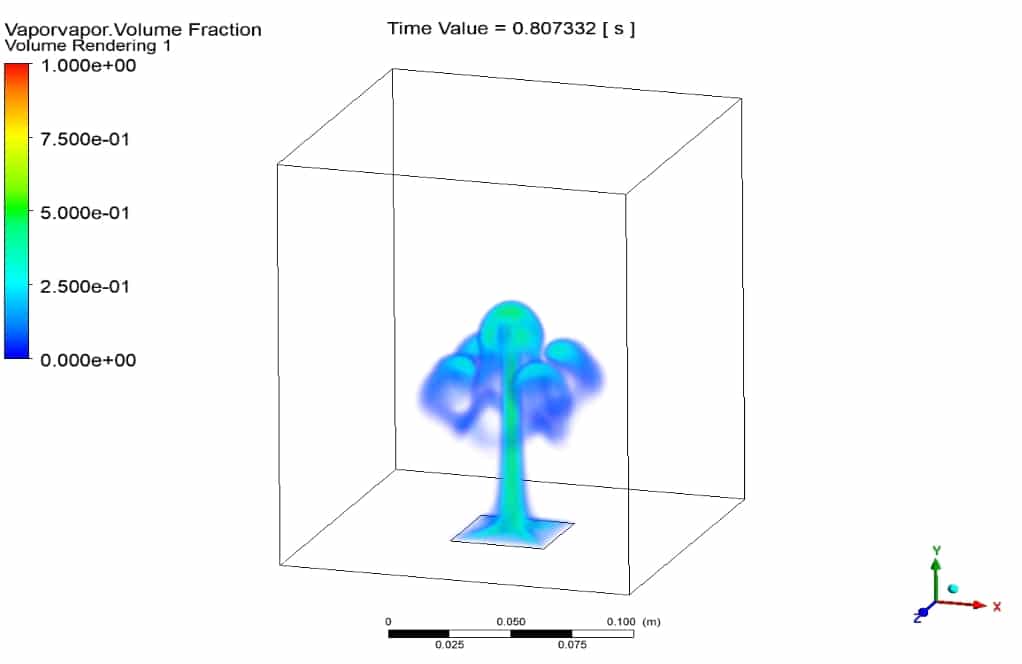

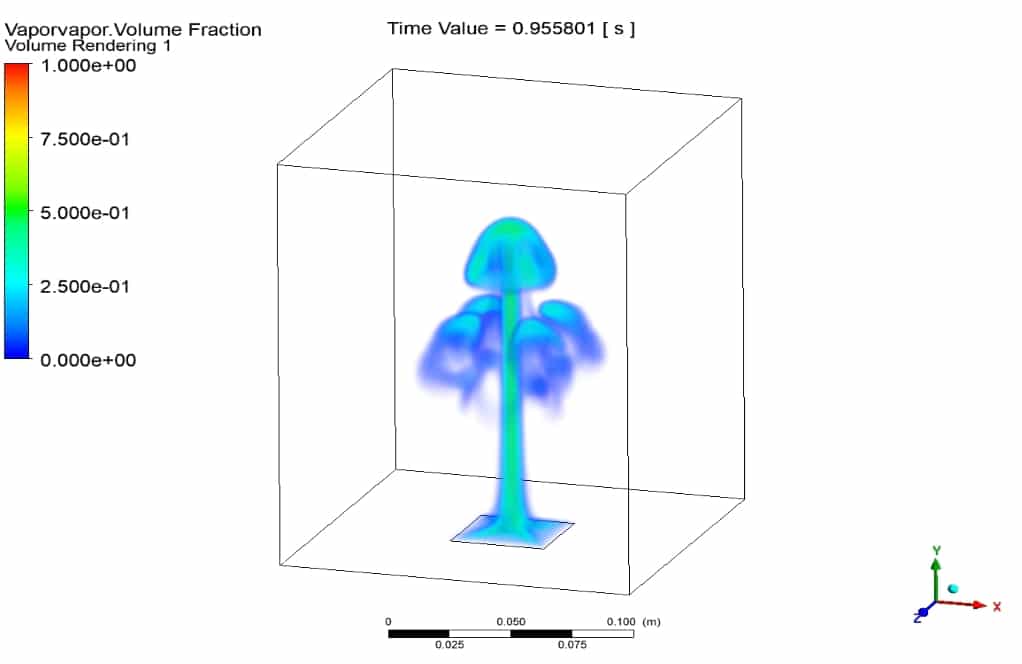

In this simulation, the difference between HRIC-compressive-Geo-reconstruct models and their effect on the output results were discussed by changing the volume fraction discretization. The computational domain is a 15 x 15 cm cube with a 2 x 2 cm heated surface. The change in volume fraction discretization showed no significant change in surface temperature and heat transfer coefficient. Only the Geo-Reconstruct model visually models a more realistic simulation with a higher computational cost.

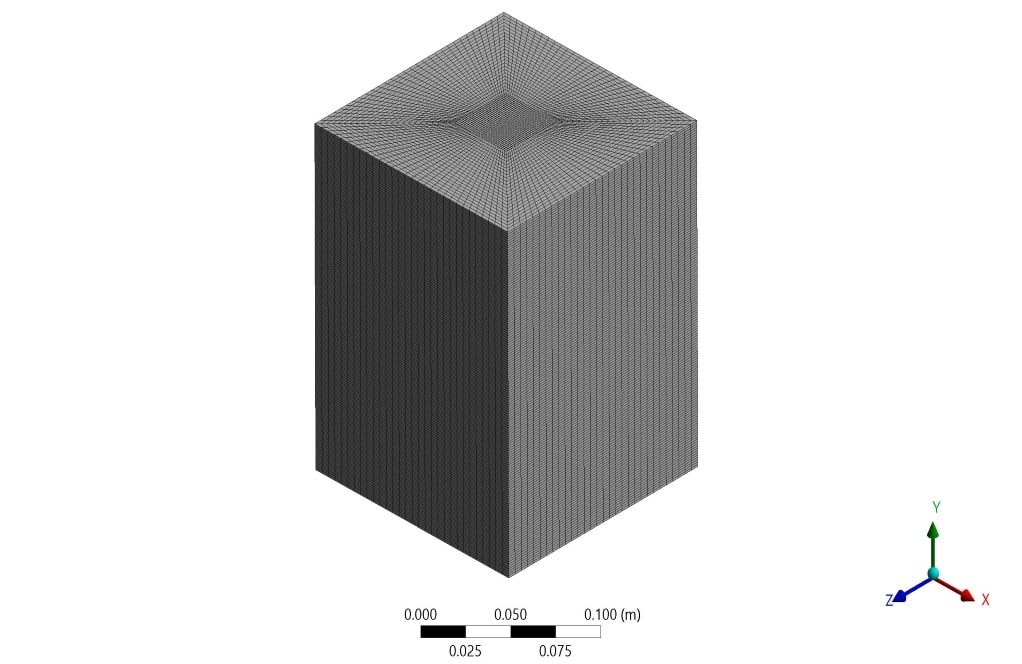

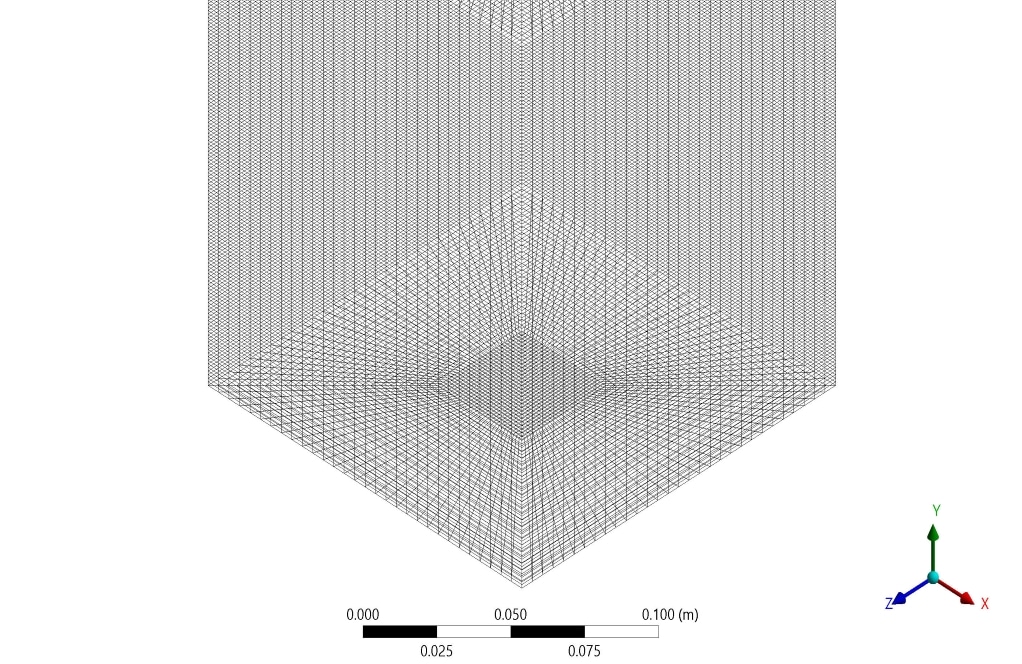

Geometry & Mesh

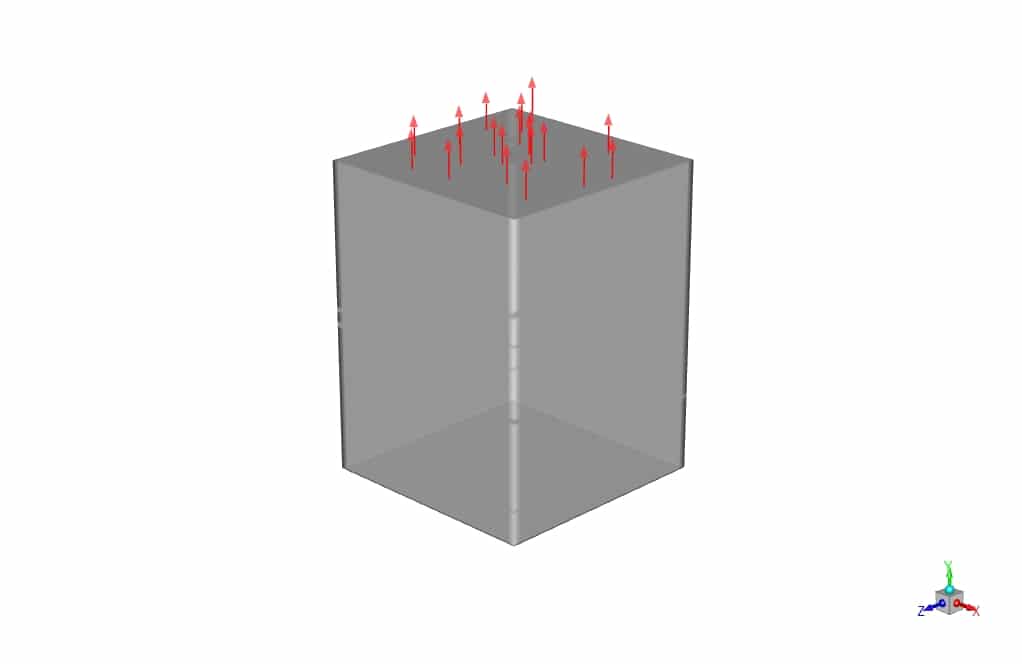

The computational domain was designed using Design Modeler software. The computational domain includes a 15 x 15 cube with a 2 x 2 cm heating surface.

Ansys Meshing software was used for grid generation, and the type of problem elements was structured. Also, the total number of elements was about 570000.

CFD Simulation Solver Setting

In this simulation, the following hypotheses are established:

- A pressure solver was used.

- The problem was solved transient

- An explicit VOF multiphase model was activated.

- Gravitational and capillary effects were considered.

Also, the table below shows the characteristics and values of boundary conditions, along with the models and hypotheses.

| Material Properties | |||

| Water | |||

| Amount | Fluid properties | ||

| 998.2 | Density (kg/m3) | ||

| Water vapor | |||

| Amount | Fluid properties | ||

| 0.5542 | Density (kg/m3) | ||

| Multiphase | |||

| Homogeneous model | VOF (volume of fluid) | ||

| Number of Eulerian phases | 2 (water-water vapor) | ||

| Interface modeling | sharp | ||

| Formulation | Explicit | ||

| Phase interaction | |||

| Evaporation & Condensation | Lee model | ||

| From phase Frequency (1/s) | 10 | ||

| Fluid type | Surface tension coefficient (N/m) | ||

| Water-vapor | 0.06 | ||

| Boundary Condition | |||

| Type | Heat flux (W/m^2) | ||

| Hot wall | 10000 | ||

| Cell zone condition | |||

| Fluid | mixture | ||

| Turbulence models | |||

| K- | viscous model | ||

| Realizable | K- model | ||

| Standard wall function | Wall function | ||

| Solution methods | |||

| Coupled | pressure velocity coupling | ||

| Modified body force weighted | pressure | spatial discretization | |

| First-order upwind | momentum | ||

| First-order upwind | turbulent kinetic energy | ||

| First-order upwind | turbulent dissipation rate | ||

| Volume fraction | Geo-reconstruct

Compressive Modified HRIC |

||

| Initialization (Standard) | |||

| 0 (Pa)

|

gauge pressure | ||

| 373.15 K | Temperature | ||

| 1 | Water volume fraction | ||

Boiling Phenomenon and Bubble Formation Results

The table below clarifies that the average surface temperature at the input of the problem and the heat transfer coefficient in these three discretization models do not change much. In the simulation with high computational cost, it is suggested that the discretization methods of compressive and modified HRIC Be have a lower computational cost. But for near-reality simulation, it is better to use the Geo-reconstruct model, which has a higher computational cost.

| Discretization method | Surface temperature (K) | Heat transfer coefficient (W/m^2.K) |

| compressive | 385.835 | 102.398 |

| Modified HRIC | 385.688 | 102.547 |

| Geo-reconstruct | 387.96463 | 101.76327 |

The grid elements need to be finer near the hot surface to increase the simulation accuracy. The distance of the first cell is essential in boiling studies, but this is very effective in increasing the computational costs in 3D simulations.

Hermina Rohan –

This tutorial sounds comprehensive. Could you please detail if the capillary effects are also accounted for in multiphase interaction in addition to the gravitational effects mentioned?

MR CFD Support –

In the given simulation setup for the Boiling Phenomenon and Bubble Formation, both gravitational and capillary effects are taken into account. Capillary forces play a crucial role in the formation and movement of bubbles during the boiling process, especially at the microscopic level.

Dawson Goldner –

The Geo-reconstruct model is mentioned to produce the most realistic simulation. Can you describe what makes it more realistic compared to the other models?

MR CFD Support –

The Geo-reconstruct model provides a more realistic simulation by better capturing the interface between the boiling liquid and the vapor phase. It accurately tracks the interface while ensuring mass conservation. The model is capable of reproducing complex interface dynamics, including surface tension effects and bubble formation, which leads to a more physically accurate representation of the boiling process. While it has a higher computational cost, the trade-off is a more detailed and representative simulation of the boiling phenomenon.

Mrs. Anjali Metz –

I was fascinated by this product! The level of detail in the model settings is impressive. Being able to compare the different volume fraction discretization models and their outcomes is extremely helpful for understanding complex boiling phenomena in CFD simulations. Hats off to the MR CFD team for creating such a thorough and informative tutorial!

MR CFD Support –

Thank you so much for your kind words and positive feedback! We’re delighted to hear that our tutorial on boiling phenomena and bubble formation has been helpful to you. Our goal is always to provide comprehensive and detailed learning materials that aid in understanding complex simulations. Your appreciation truly means a lot to us. If you need any further assistance or are interested in other CFD topics, please don’t hesitate to reach out!

Mr. Leonel Beier IV –

This simulation sounds fascinating! Could you tell me more about how the Lee model for phase interaction influences the results in terms of evaporation and condensation?

MR CFD Support –

Certainly, in the simulation, the Lee model is used for phase interaction, specifically to capture the evaporation and condensation processes during boiling. The Lee model defines a frequency at which phase change happens and also factors in surface tension between the water and vapor phases, enhancing the prediction of the bubble formation and collapse. It directly influences the accuracy of capturing the transition between liquid and vapor, affecting the dynamics of boiling and condensation in the simulation.

Carmel Kreiger IV –

The tutorial mentions that the grid elements near the hot surface should be finer – could you clarify the ideal distance of the first cell from the hot surface for accurate simulations?

MR CFD Support –

The ideal distance of the first cell from the hot surface for achieving accurate simulation results in boiling studies depends on several factors and can vary. However, a balance must be struck between improving simulation accuracy and computational cost. The specific values for cell distance in this tutorial are not provided, but typically, it would be a fraction of a millimeter, ensuring that the thermal boundary layer is well-resolved without excessively increasing computational resources. Adjustments may be required based on preliminary simulation results and available computational capacity.

Lester Marks Jr. –

Very impressed with the detailed analysis of different volume fraction discretization methods in this CFD tutorial on boiling. The comparative results provide clear guidance on selecting an appropriate method based on computational cost and accuracy for similar studies in the future.

MR CFD Support –

Thank you for your positive feedback! We are pleased to know that the tutorial provided clear and helpful insights into the boiling simulation process and helped you understand the importance of choosing the right discretization method. Your recognition truly motivates us to continue offering high-quality learning products.

Mckenna Bradtke –

This tutorial seems very detailed. Can you tell me if there is an included section that helps to understand how to interpret the bubble dynamics in terms of nucleate boiling?

MR CFD Support –

The tutorial provides an in-depth analysis of the boiling phenomenon and bubble formation and includes a comparison of different volume fraction discretization methods to study their effects on the simulation results. While we explore material properties and boundary conditions extensively, the tutorial also highlights how different discretization models—compressive, modified HRIC, and Geo-reconstruct—can impact the realism and computational cost of the simulation. Although not explicitly stated, it is implied that an understanding of bubble dynamics in relation to nucleate boiling can be gained through analyzing the pressure, temperature, and volume fraction results provided by the tutorial, particularly focusing on the Geo-reconstruct model due to its more realistic depiction of simulation elements. If additional insights on the interpretation of bubble dynamics regarding nucleate boiling are needed, we suggest revisiting the results section or the formulations employed for phase interactions.

Ernest Maggio –

I followed the tutorial and must say it is excellent. One thing though, could the use of different discretization methods impact the formation and behavior of bubbles in any significant way, beyond just visualization differences? Could you elaborate more on this aspect, please?

MR CFD Support –

The choice of discretization methods mainly affects the accuracy of interface capturing between phases in multiphase flow simulations such as boiling. While visual differences are the immediate indicators of these effects, the formation and behavior of bubbles are indeed influenced at a more numerical level. Methods like Geo-reconstruct will tend to provide a more precise simulation of the surface tension effects and bubble interface dynamics compared to compressive or HRIC, thus better capturing the physics of bubble formation and detachment. However, it should be noted that increases in numerical accuracy usually demand higher computational resources. If you seek more detailed insights into bubble dynamics, a finer mesh or more advanced models could be advisable.

Susie Boehm –

I noticed the simulation accounts for both gravitational and capillary effects which are essential for bubble formation. But does the simulation also take into account wall adhesion properties, and if so, how are they modeled for the water-vapor interaction at the heated surface?

MR CFD Support –

In the context of CFD simulation for boiling and bubble formation, wall adhesion properties are typically accounted for by defining a contact angle at the wall-fluid interface as a part of the surface tension modeling. These properties influence the shape and detachment of the bubbles formed during boiling. In the simulation using ANSYS Fluent, wall adhesion can be defined through boundary conditions (such as specifying contact angles) and accurate representation of surface tension forces. However, as for the specific handling of this parameter in our project description, it’s either implicitly considered within the surface tension coefficient or not directly addressed. For a comprehensive answer, reviewing detailed documentation or support input for ANSYS Fluent may provide more insights.

Walter Botsford –

The tutorial was incredibly helpful in understanding the boiling process and VOF modeling. Especially, the comparison between compressive, modified HRIC, and Geo-reconstruct methods was insightful.

MR CFD Support –

Thank you for your positive feedback! We are glad the tutorial provided you with a clear understanding of the boiling phenomenon and the useful insights on various VOF modeling strategies. If you have any more questions or need further clarity, feel free to reach out!

Quinton Medhurst III –

Very clear explanation of the physics and setup! Can you clarify which physical factors are responsible for the boiling point’s variations at different altitudes?

MR CFD Support –

Thank you for your kind words! Sure, the boiling point of a liquid varies with the surrounding pressure. At higher altitudes where atmospheric pressure is lower compared to sea level, the vapor pressure required for a liquid to begin boiling is reached at lower temperatures. This is why the boiling point of water is lower on a mountain than it is at sea level.

Alan Kessler –

This tutorial seems comprehensive, could you elaborate on how the gravitational and capillary effects were incorporated into the simulation, especially considering the impact on bubble behavior?

MR CFD Support –

In this simulation, gravitational effects were taken into account to simulate the buoyant rise of the bubbles created during the boiling process. This is done through specifying a gravitational acceleration in the body forces section. Capillary effects, which are crucial for accurate simulation of the surface tension at the liquid-gas interface, were integrated via the surface tension coefficient within the multiphase VOF model. Correctly accounting for these effects helps ensure that the bubble morphology and detachment are realistically represented.

Cary Hammes –

I would like to understand the impact of gravitational and capillary effects on the simulation. Can you elaborate on how these were factored in?

MR CFD Support –

Gravitational and capillary effects play vital roles in boiling simulations as they influence bubble formation and rise. Gravity impacts the buoyancy and movement of the bubbles when they form, while capillary effects determine the shape of the bubbles due to surface tension. In the ANSYS Fluent simulation, gravity was taken into account by specifying it as an operating condition, affecting the fluid buoyancy. The capillary effects were considered by defining the surface tension coefficient in the phase interaction settings. By accurately setting these parameters, the simulation can replicate the boiling behavior seen in real-world scenarios.

Fritz Kessler –

I’m impressed by the level of detail in this CFD tutorial on boiling and bubble formation! Can you comment on how user-friendly the tutorial is for beginners in CFD?

MR CFD Support –

Thank you for the kind words! We strive to make our tutorials accessible to a wide range of learners. The tutorial you mentioned is designed with step-by-step guidance and assumes the user has basic knowledge of CFD principles. For complete beginners, we provide fundamental background knowledge to help them get started before tackling specific phenomena like boiling and bubble formation.

Kristopher Sanford –

The detailed results show changes in the heat transfer coefficient due to different discretization methods. Are the differences here significant enough to influence which method we select for subsequent simulations?

MR CFD Support –

The differences in the heat transfer coefficient among the compressive, modified HRIC, and Geo-reconstruct discretization methods are relatively small. Thus, the slight variations should not play a major role in selecting which method to use for most simulation scenarios. For more cost-effective simulations with lower computational expense, compressive and modified HRIC methods are adequate. However, when closer to reality representation is crucial, Geo-reconstruct is the better choice despite higher computational costs.

Gus Boyle –

I appreciate the detailed explanation given for the CFD simulation training on the Boiling Phenomenon and Bubble Formation. The comparison of the HRIC-compressive-Geo-reconstruct models was enlightening. Could you please elaborate on how the different discretization methods specifically influence the accuracy and realism of the simulation?

MR CFD Support –

Using different discretization methods, like the Geo-reconstruct model, provides a more precise capture of the interface between the phases, resulting in a more realistic representation of bubble formation and behavior. However, the trade-off is a higher computational cost due to the finer mesh required for such accuracy. The other models, like compressive and modified HRIC, may offer almost similar numerical outputs concerning average surface temperature and heat transfer coefficient, but they achieve this with a less detailed interface representation, which is computationally more economical. Balancing accuracy and computational resources is key to choosing the appropriate discretization method for a specific simulation.

Prof. Mariana Gusikowski Sr. –

I appreciate the intricacies of surface conditions requiring finer grid elements and the trade-off with higher computational costs. Did you have to adjust the initial estimated runtime before factoring in the necessary fineness in grid density near the heated surface, and how did this influence your overall project timeline?

MR CFD Support –

I am glad that you are considering these technical factors about your simulation accuracy and computational costs. The assessment of runtime was certainly adjusted—for CFD simulations, especially those involving boiling and multiphase flows, sensitivity to grid-scale effects is crucial. By refining the grid near the heated surface, I ensured the local physics were captured more accurately. This does result in lengthier computational times, so overall project timelines need to account for the increased simulation duration. Timelines are often extended to allow for the more detailed analysis required for capturing the fine scale phenomena near the heated surface without compromising the accuracy necessary for credible simulation outcomes.

Malika Flatley –

This tutorial is a fantastic resource for understanding the nuances of different discretization models in boiling simulations. The detailed explanation of the geometry setup, boundary conditions, and solver settings helped me grasp the complexity of multiphase simulations. Watching the formation of bubbles on the Heated wall surface was particularly insightful!

MR CFD Support –

We’re thrilled to hear that the tutorial was helpful and educational for you! At MR CFD, we strive to provide clear and detailed explanations to ensure a deep understanding of complex CFD phenomena. Thank you for recognizing the careful setup and attention to detail in the bubble formation simulation.