Chevron Plate Heat Exchanger, ANSYS Fluent CFD Simulation Training

$80.00 Student Discount

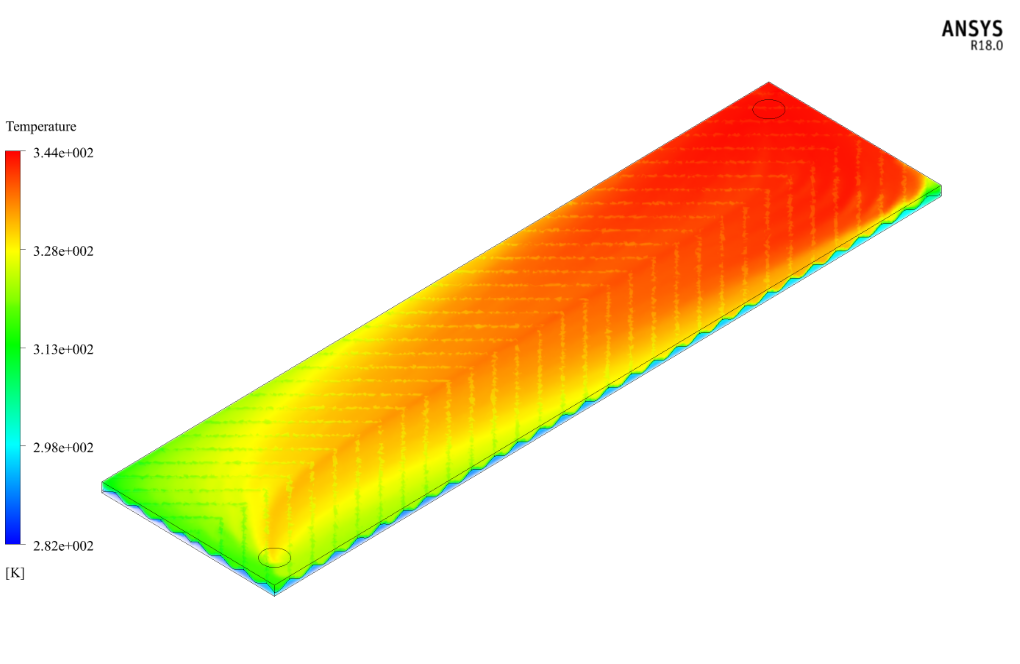

- The problem numerically simulates Chevron Plate Heat Exchanger using ANSYS Fluent software.

- We design the 3-D model by the Design Modeler software.

- We Mesh the model by ANSYS Meshing software, and the element number equals 638892.

- The Energy equation is activated to consider heat transfer in the heat exchanger.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Description

The present problem deals with the simulation of a plate heat exchanger called CHEVRON by ANSYS Fluent software. We perform this CFD project and investigate it by CFD analysis.

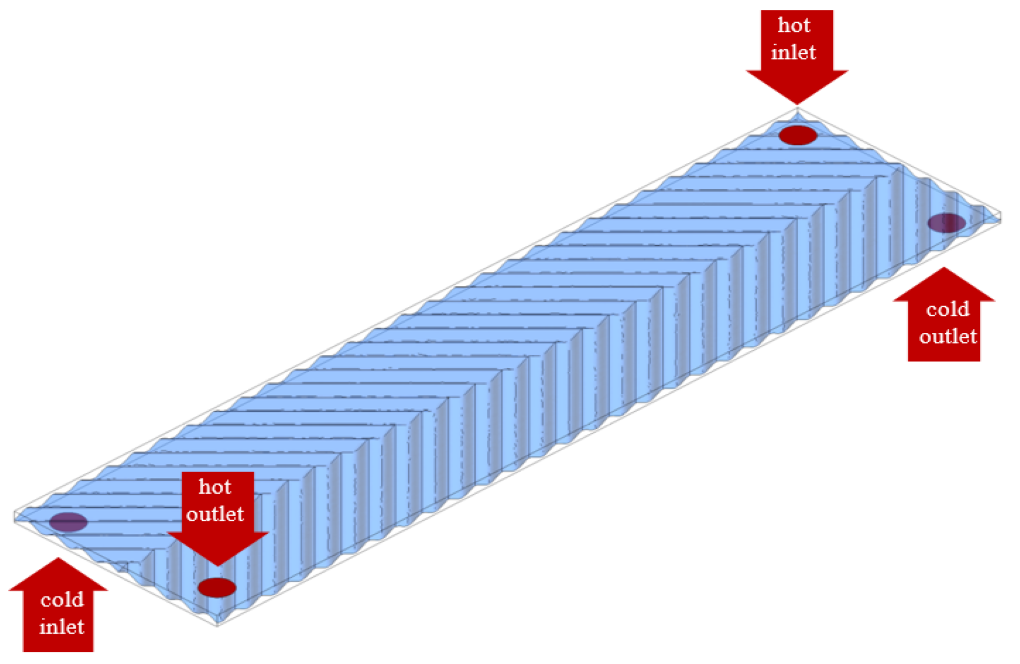

In this model, water acts as both hot and cold fluid flow in a heat exchanger. The plates between the two flows and all the heat exchanger walls are aluminum, which is responsible for the heat transfer between the cold water and the hot water flow. This project investigates the heat transfer between two hot and cold fluids through a chevron plate heat exchanger.

The 3-D geometry of the present model is designed by Design Modeler software. Since the model is related to the plate heat exchanger, it consists of two main parts: the hot water flow zone and the cold water flow zone. The separator plates (chevron) determine the boundary between these two flows.

The unstructured mesh of the present model is carried out by ANSYS Meshing software. The element number is equal to 638892.

Chevron Methodology

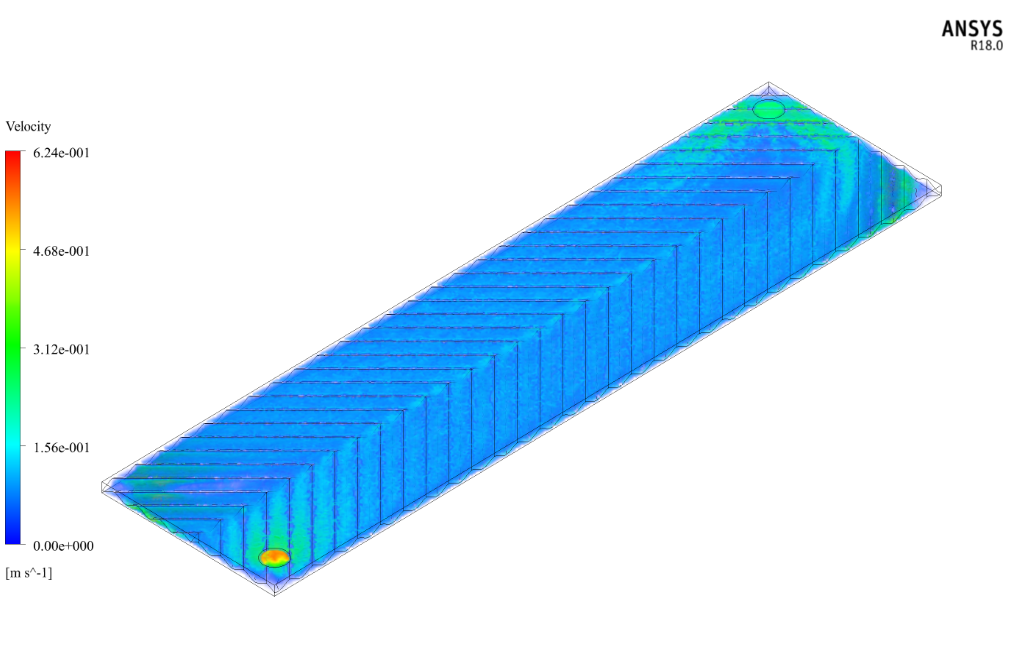

The hot and cold velocities are equal to 0.25m/c, while the temperature equals 283.15k and 343.15k for cold and hot water, respectively. Standard K-e model applying a Steady-State solver is used for this CFD simulation

Chevron Conclusion

Chevron heat exchangers are more efficient than other plate heat exchangers because of the turbulent flow on both sides, which leads to a better heat transfer performance considering the shape of chevron plates, including grooves.

The particular configuration of the chevron plates increases the contact surface compared to standard plates, which directly leads to a higher heat transfer rate between cold and hot fluids.

After resolving the flow, the cold output temperature is computed as equal to 300.8757 k, and the hot output temperature is computed as equal to 325.714 k. Therefore, the temperature difference between the cold inlet and outlet is 17.72 degrees, and for hot water, this value is equal to -17.436 k.

Also, the total heat transfer rate on the plate is computed as equal to 1440.7727 W.

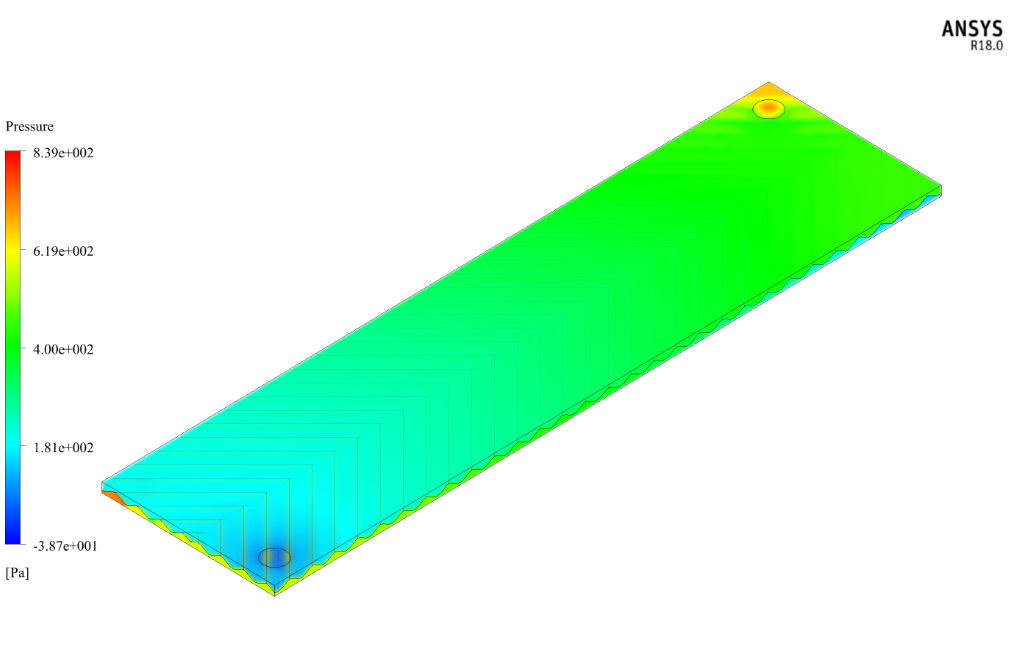

The average Nusselt number (Nu=((q’*d)/k(Tb-TW))) is computed equal to 593.432. Also, the pressure drop is about 610pa to 690pa on cold and hot sides, respectively. Finally, by using the formula below, the heat load in this project is computed as equal to 9,980.04 J/s. (Q.=M.C)

Cloyd Hills –

It was good, and it got me started. Thank you.

Roderick Boehm –

How do you generally handle a high-quality mesh of these kinds of complex geometries? I usually challenge to it

MR CFD Support –

The simulation uses ANSYS Meshing software to generate a high-quality mesh for the complex geometry of the chevron plates. The software allows us to refine the mesh in areas of interest, ensuring that we accurately capture the thermal and fluid flow phenomena.

Mrs. Lempi Murray –

What are the benefits of using a chevron plate heat exchanger over a flat plate design?

MR CFD Support –

Chevron plate heat exchangers have corrugated plates that create a swirling flow, which enhances heat transfer and reduces fouling. This can result in higher efficiency and longer operational life compared to flat plate designs.

Wilma Gibson –

I’m looking for a simulation of a double pipe heat exchanger. Can you help with that?

MR CFD Support –

Absolutely! We can certainly help with simulations of double pipe heat exchangers. Please provide more details about your requirements, and we’ll do our best to accommodate your request.

Brandy Little –

How is the effectiveness of the heat exchanger calculated in the simulation?

MR CFD Support –

The effectiveness of the heat exchanger is calculated as the ratio of the actual heat transfer to the maximum possible heat transfer. This is determined using the temperatures and flow rates of the hot and cold fluids.

Augustine Boyer Sr. –

Fantastic results! The temperature differential and efficiency of the chevron plate design truly highlight the benefits of using such a configuration in heat exchangers. Being able to see the outcome of the simulation and the detailed explanation make it a valuable learning experience. The average Nusselt number and the heat transfer calculation really put into perspective the effectiveness of this design!

MR CFD Support –

Thank you for your kind words! We are thrilled to hear that our training product on Chevron Plate Heat Exchanger CFD simulation was effective and informative. Knowing that you’ve gained insights into the benefits of the chevron plate design and understood the calculation of the Nusselt number and heat transfer confirms that our learning materials are on the right track. We appreciate you taking the time to review our product, and we look forward to providing you with more valuable learning experiences in the future.

Elmo Veum –

excellent

Salma Zulauf DDS –

I am delighted with the results of this training on simulating a Chevron plate heat exchanger! It’s fascinating to see how the chevron design’s turbulence enhances heat transfer efficiency. Before I attempt a similar analysis, could you provide insights into how the flow turbulence is ensured and stabilized across the plates within the simulation setup?

MR CFD Support –

We’re thrilled to hear that you appreciate the training content on the Chevron plate heat exchanger simulation. The turbulence is ensured by the specific design of the chevron plates that naturally induces turbulent flow. This is represented in the simulation setup by utilizing the Standard k-epsilon (k-ε) turbulence model. Additionally, to ensure stabilized turbulent flow in the simulation, we carefully set the boundary conditions and refine the mesh where high gradients are expected, facilitating accurate capture of the fluid’s turbulent behavior. The velocity inlet conditions are the same for both hot and cold water to maintain consistency in flow across the plates. Good practice in setting a reasonable convergence criterion also contributes to a stable solution. We recommend reviewing experimentally verified Reynolds numbers for your application to initially validate your setup.

Prof. Santino Daugherty –

I’m very impressed with the detailed analysis of the Chevron plate heat exchanger simulation. The data on temperature changes and heat transfer rates is particularly informative. Great job!

MR CFD Support –

Thank you for your positive feedback! We’re glad you found the analysis informative and helpful. If you have any more questions or need further assistance, feel free to reach out.

Vivien Macejkovic –

I’ve been truly impressed by the level of detail in the CFD project on the Chevy Plate Heat Exchanger. The clear explanation of temperatures, flow velocities, and the efficiency metric like the Nusselt number provided a comprehensive understanding of the system’s performance. Well done, MR CFD Company!

MR CFD Support –

Thank you so much for your kind words! We’re thrilled to hear that you found the project details and explanations helpful and comprehensive. Our goal is to provide valuable insight into the complexities of CFD simulations, and your feedback lets us know we’re on the right track. We appreciate your support!

Eldon Murphy Sr. –

The tutorial sounds thorough but I’m curious how the simulation deals with pressure losses in the chevron plate heat exchanger. Can you tell, if the results provided include the details on how different pressure drops affect overall efficiency?

MR CFD Support –

In this simulation of the CHEVRON plate heat exchanger using ANSYS Fluent, pressure drop is indeed considered. By providing the mentioned pressure drop values for both cold and hot sides, the simulation takes into account the effect of pressure losses on the system. It looks into how these losses impact thermal efficiency and ensures developers understand the implications for heat exchanger performance.

Anya Kerluke V –

I just completed the Chevron Plate Heat Exchanger training, and it was a great experience! The detailed methodological approach helped me understand the setup, and the simulation results were enlightening. I’ve gained a deeper appreciation for the chevron plate design’s efficiency and its effect on heat transfer performance.

MR CFD Support –

Thank you for the wonderful feedback! It’s fantastic to hear that our Chevron Plate Heat Exchanger training provided you with insightful knowledge and a better understanding of the chevron plate design. We’re thrilled that you found the training enriching and helpful. If you have any more questions or need further assistance, feel free to reach out. Good luck with your future simulations!