DPM-Drag Macro, UDF, Drag between Particles and Fluid CFD Simulation

$140.00 Student Discount

- The problem numerically simulates the particle spraying in continuous fluid ANSYS Fluent software.

- We design the 3-D model with the Design Modeler software.

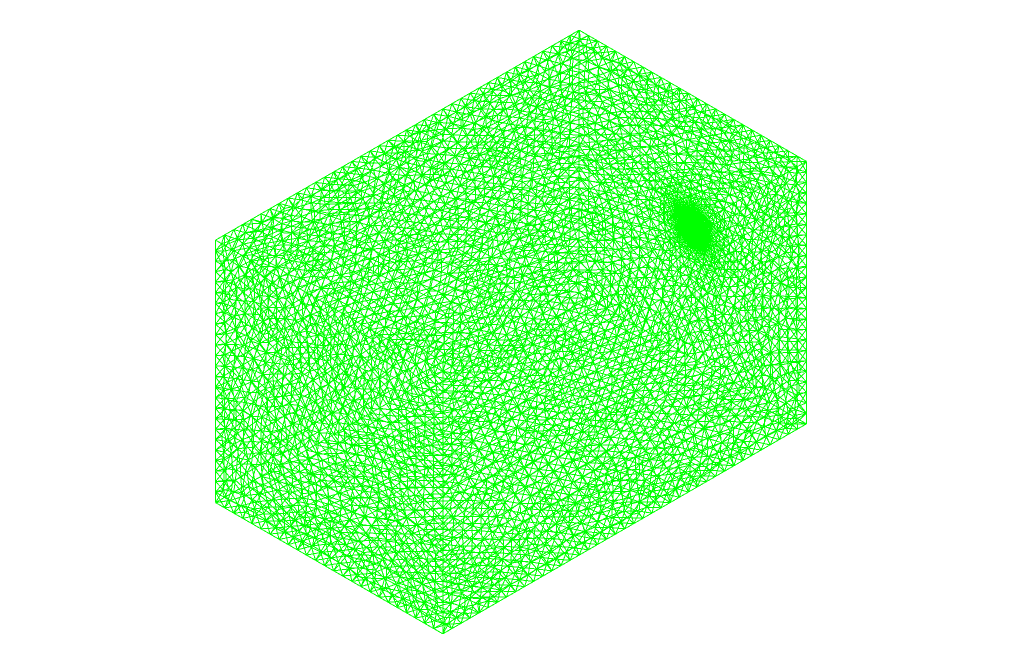

- We mesh the model with ANSYS Meshing software, and the element number equals 127,100.

- We performed the simulation in Transient (unsteady-state).

- We use the Discrete Phase Model (DPM) to define particle spraying.

- We use the User-Defined Function (UDF) to define a drag between particles and fluid.

- We use the DPM-DRAG Macro for UDF.

- We compare different Drga Laws, including Spherical, Stokes Cunningham, Non-spherical, and High-Mach.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Description

In this project, we performed a numerical simulation using ANSYS Fluent software’s User-Defined Function (UDF). For this CFD product, we used DPM-Drag-Macro to write UDF programming.

This product is the 2nd chapter of the User-Defined Function (UDF) Training Course.

We considered a simple chamber that is a place for spraying discrete particles. So, we defined an inlet for spraying discrete particles. When discrete particles are sprayed in a continuous fluid, a drag force is created between the discrete particles and the continuous fluid.Hence, we need to define a relation to define the drag force between discrete particles and continuous fluid.

First, we modeled the geometry in 3D with Design Modeler software. Then, we meshed the model with ANSYS Meshing software. Meshing is unstructured, and 127,100 cells are created. Finally, we numerically simulated the current model based on the CFD method by ANSYS Fluent software.

Methodology (UDF)

In this project, we defined a Discrete Phase Model (DPM) so that discrete particle spraying occurs. To define the discrete phase, we need to define an Injection to model the spray process. When the injection is defined, the drag force is applied between the particles and the fluid. So, we need to define a particular relation for drag force. A Drag Law is then used to calculate the drag force. Different drag laws include Spherical, Stokes-Cunningham, Non-Spherical, and High-Mach-Number.

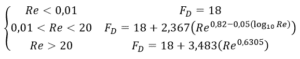

In addition, we can define a method to calculate the drag force by defining the User-Defined function (UDF). We need to use the DPM-DRAG Macro (DEFINE_DPM_DRAG macro) for this UDF. The drag force relations we use are defined as follows. According to these relations, the drag force depends on the Reynolds number.

Conclusion (UDF)

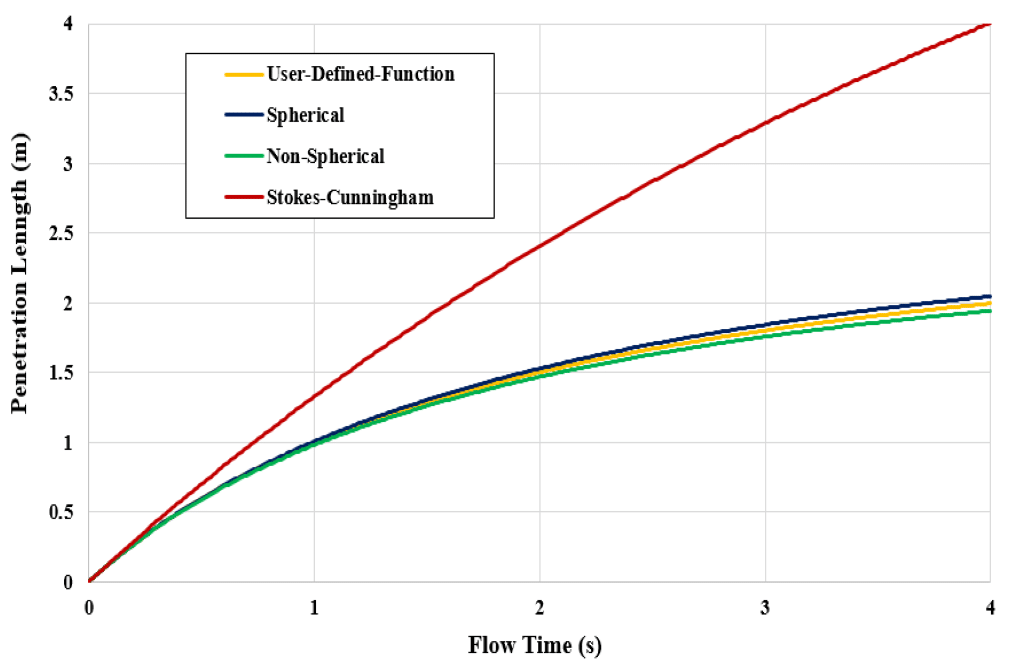

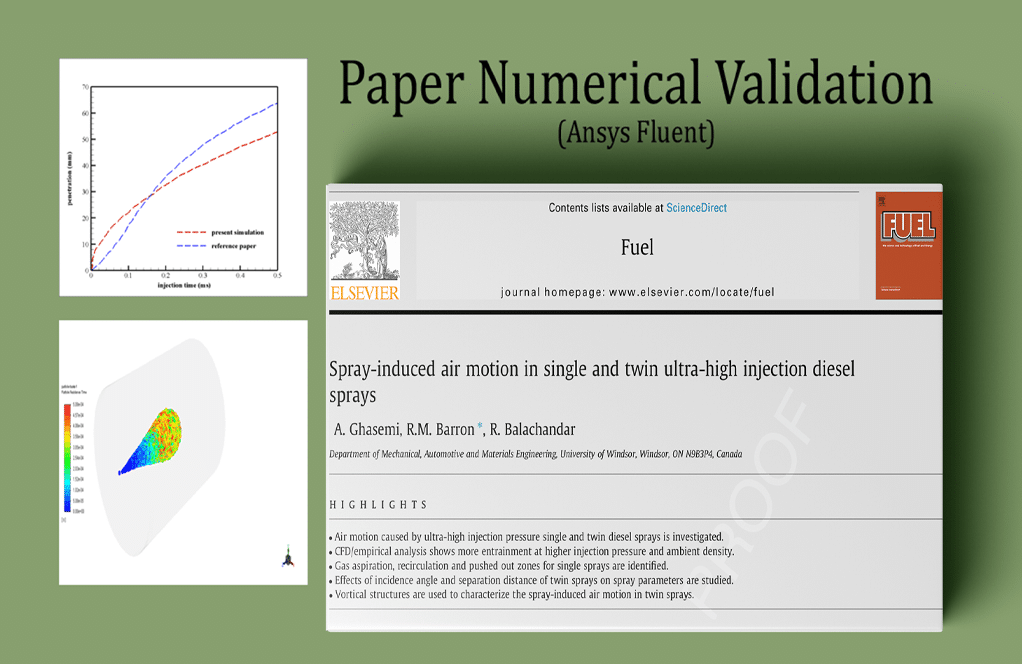

After completing the calculation, we will review the results. First, we performed simulations with different drag laws to compare the results with each other. We performed the same simulation for spherical, non-spherical, and stokes-cunningham models. Then, we performed the same simulation using the UDF.

Finally, we compared the results of different methods in a plot. We evaluated the Penetration Length parameter to determine the effectiveness of each drag force calculation model.

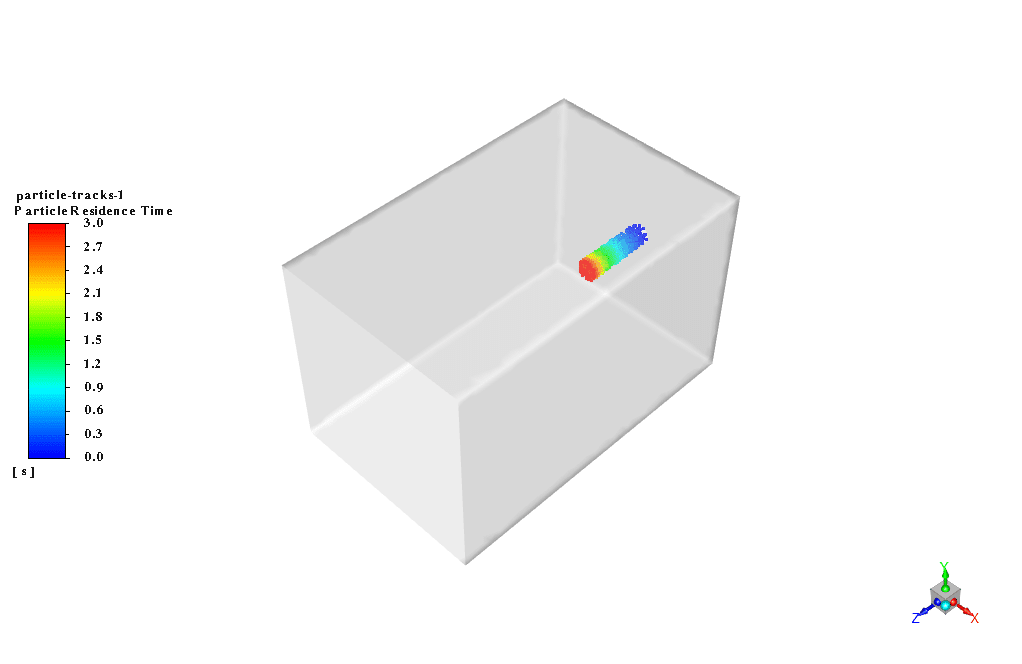

Penetration length shows how far the discrete particles spread in the fluid. So, the drag force can be effective in decreasing or increasing the penetration of particles.

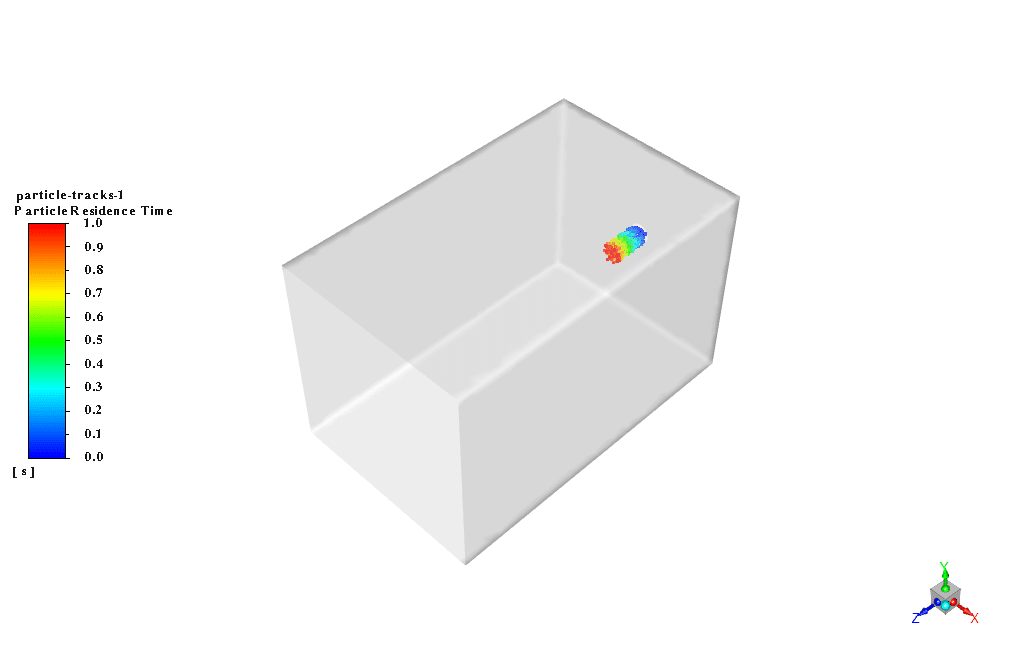

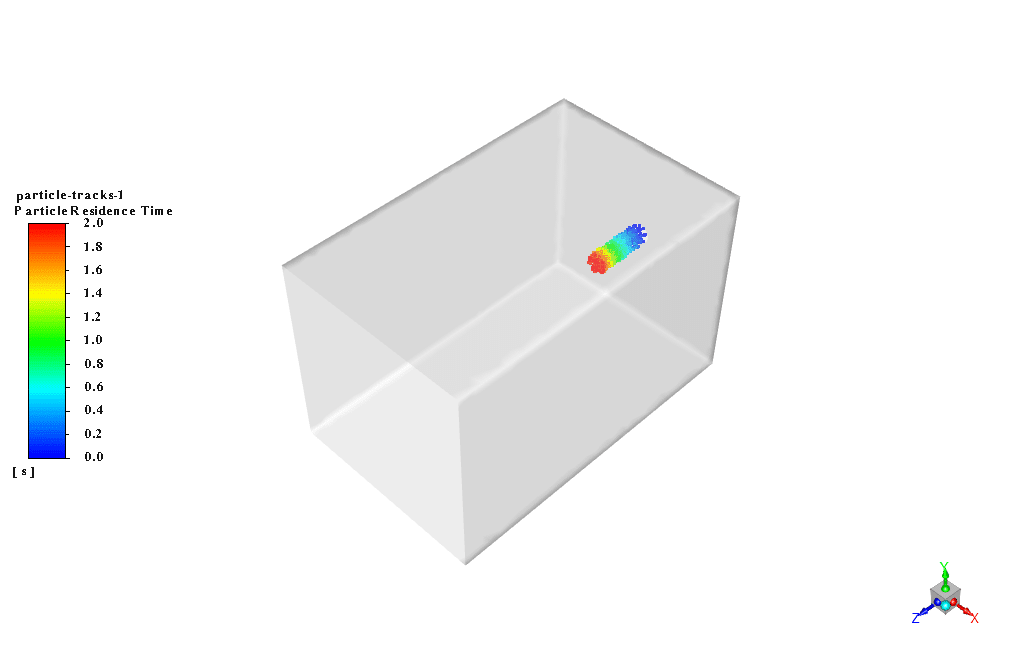

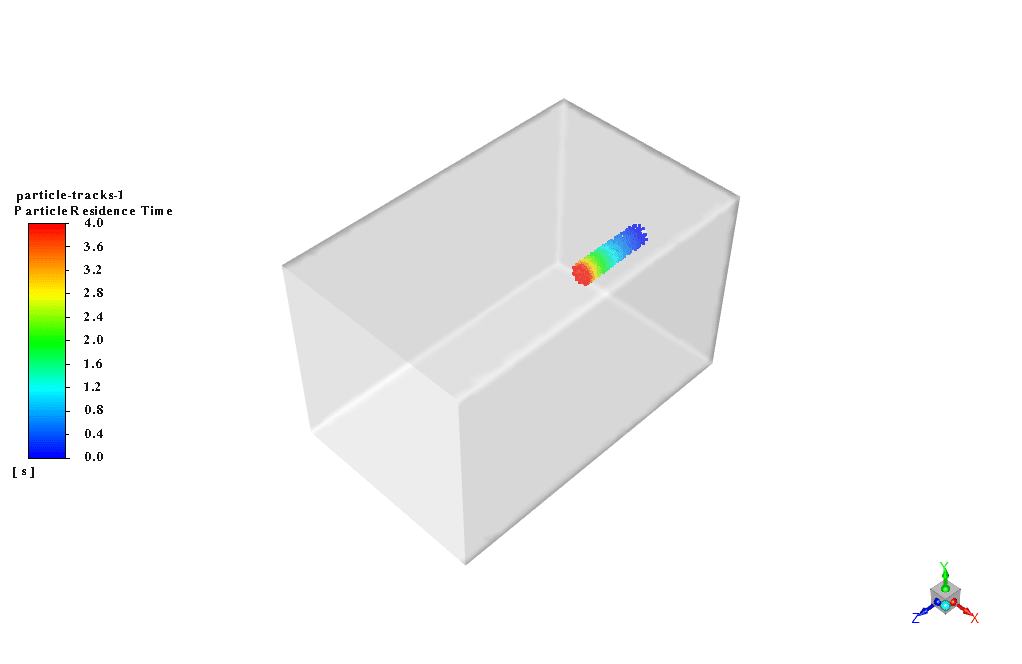

In the next step, we only consider the simulation using UDF. We obtained Particle Tracking since we used the discrete phase model in this simulation. Particle tracking is used to check the trajectory of particles.

We performed the modeling in an unsteady (Transient) state for 4 seconds. So, we obtained the particle tracking at different times to obtain the movement path of the particles in the fluid.

Reviews

Related products

-

Diesel Spray Ultra-High Injection, Paper Numerical Validation, ANSYS Fluent Tutorial

Rated 4.56 out of 5$200.00 Student Discount

Dr. Emiliano Bednar –

The information on different drag laws is fascinating! Which one proved to be most similar to the UDF results for the penetration length measurement?

MR CFD Support –

The comparison showed that the discretion of the user-defined function (UDF) allowed for more accurate prediction of particle behavior and thus, when properly calibrated, UDF results were observed to most closely simulate the actual penetration length of the particles in comparison to the predefined drag laws.

Jaiden Kirlin –

Does the provided UDF dynamically adjust with various injection conditions, or is it specific to certain particle types and fluid properties?

MR CFD Support –

The UDF defined using the DPM-DRAG Macro in this simulation is designed to calculate the drag force between the particles and the fluid based on the Reynolds number. Although it is typically applicable to different injections and fluids because of its standard based on the Reynolds number, its accuracy might depend on specific properties of the particles and the fluid. To adapt it dynamically to a wide range of conditions, the UDF might require modifications to take into account other pertinent factors like particle shape, fluid viscosity, flow regime, etc.

Viva Donnelly –

Is it possible to apply this UDF for different particle sizes or is it specific to the size used in the study?

MR CFD Support –

Yes, it is possible to apply the UDF for different particle sizes. The UDF defined for the drag force calculation is generally based on the properties such as the Reynolds number, which are applicable to a range of particle sizes. However, adjustments to certain parameters within the UDF might be necessary to accurately represent the forces acting on particles of different sizes.

Josiane Nader –

I’m excited to learn about discrete particle injections. Does the course help in understanding how the Penetration Length of the particles can be manipulated for different applications?

MR CFD Support –

Absolutely! In the User-Defined Function (UDF) course, you will learn how different drag laws affect the penetration length of particles and how to use UDF to simulate and control particle behavior for specific applications. You will understand how variables such as drag force contribute to the spread of particles in fluid, preparing you to tailor the penetration length for your particular needs.

Mr. Jessy Schmidt –

Is the penetration length significantly different when applying UDF compared to pre-defined drag laws?

MR CFD Support –

When using UDF, the penetration length may display notable differences compared to using predefined drag laws due to the tailored drag relation accommodated by the UDF, which accounts for specific case parameters that are not captured by the default drag models in ANSYS Fluent.

Rudy Schinner –

Is the training sufficient enough to help me create my own UDFs for different applications, or is it extremely tailored to this specific case of drag force between particles and fluid?

MR CFD Support –

The UDF training presented in the 2nd chapter of the User-Defined Function (UDF) Training Course is designed to give you a fundamental understanding of how to implement UDFs in ANSYS Fluent for drag force calculations between discrete particles and fluid. A general fight on how to use UDFs effectively in different scenarios typically outlines the required steps for custom UDF creation, focuses on applying them to a range of applications, and implies that you should be able to utilize the concepts learned to create your own UDFs for various cases.

Anna Stehr –

Is the drag force relation included in the UDF based on any specific drag law out of those you have mentioned (spherical, non-spherical, Stokes-Cunningham, and high-Mach-number) or is it a custom relation? Also, can you briefly explain the impact of different drag laws on the penetration length of the discrete particles?

MR CFD Support –

In this project, the drag force relation included in the UDF is a custom relation that is defined using the DEFINE_DPM_DRAG macro from ANSYS Fluent. This custom relation considers the drag force dependency on the particle’s Reynolds number.

Different drag laws have a significant impact on the penetration length of discrete particles within the fluid. For instance, the Spherical drag law typically assumes particles are spherical, which affects the resistance they face when moving through the fluid. The Stokes-Cunningham law is used for very small particles and includes corrections for rarefied flows. Non-Spherical takes into account the shape of particles, and the High-Mach-Number drag law is for particles with high velocity relative to the sound speed in the fluid. Each drag law will calculate a different drag force value, which will either increase or decrease the penetration length of the particles, affecting the spread and distribution within the continuous fluid.

Miss Wilma Haley –

The concept of UDF is fascinating! Is expertise in coding required to effectively use the DPM-Drag-Macro for UDF in ANSYS Fluent?

MR CFD Support –

Using the DPM-Drag-Macro for UDF does require some proficiency in programming, specifically in C programming language as used by ANSYS Fluent for writing User-Defined Functions. However, it is designed in a way that users with basic to intermediate coding skills and understanding of the simulation’s physical principles can create the necessary custom functions for their simulations.

Prof. Loraine Carter –

This review was so informative! Your careful explanation of the Discrete Phase Model and how the UDF and DPM-DRAG Macro manipulates the drag force based on the Reynolds number really made the process clear. The systematic approach to evaluating different drag laws and the use of Penetration Length as an assessment criterion was insightful. It’s impressive to read about the competency of MR CFD Company’s training course in guiding through such complex CFD simulations using ANSYS Fluent.

MR CFD Support –

Thank you for your positive feedback! We’re glad to hear that our training course on User-Defined Functions (UDF) in ANSYS Fluent has been helpful to you. It is our goal to provide comprehensive materials that make complex simulations understandable and attainable. We appreciate you taking the time to review our product and are pleased to know you found it insightful. Keep exploring and learning with our courses!

Carmelo Heller –

I’m impressed with the detail put into the DPM-Drag Macro UDF CFD simulation. Can you tell which method between the spherical, non-spherical, and Stokes-Cunningham models for the UDF provided the best results in terms of penetration length?

MR CFD Support –

Thank you for your compliments on our comprehensive DPM-Drag Macro UDF CFD simulation. In our study and comparisons, using the UDF allowed for the most accurate determination of the discrete particles’ behavior, thus providing a more accurate result for the penetration length than the standard models.

Ford Balistreri –

Fantastic product! I’ve learned so much about implementing UDFs for enhancing drag force calculations between particles and fluid in CFD simulations. Your detailed methodology for using DPM and various drag laws was especially insightful.

MR CFD Support –

Thank you for your positive feedback! We are thrilled that you found our training course on DPM Drag Macro and UDF implementation helpful and informative. It’s great to hear that the detailed methodologies provided clarity and enhanced your understanding of drag force calculations in CFD. If you have any more questions or need further assistance with similar simulations, feel free to reach out!

Delores Kirlin –

Can we modify the UDF to cater for different particle densities or is it fixed within the code? I’m looking to simulate a range of particles with varying densities.

MR CFD Support –

The UDF can be adjusted to accommodate different particle densities. In the DEFINE_DPM_DRAG macro, you have the flexibility to implement customized relations for the drag force that can include varying particle properties, such as density. If you require specific changes for different particle densities in your simulations, the UDF code will need to be modified accordingly.

Leonie Bergnaum –

Could you possibly clarify how the UDF influences the results compared to the standard drag models provided by ANSYS Fluent, especially regarding penetration length of the particles?

MR CFD Support –

Admin: Certainly! The UDF allows for a customized drag relation that can more accurately represent specific conditions not covered by the standard drag models in ANSYS Fluent. By tailoring the drag force calculation through the UDF, one can better predict the interaction between the fluid and the particles, which directly affects the penetration length—the distance particles travel in the fluid. This personalized calculation can lead to either increased or reduced particle penetration, providing insights that can improve the design or efficiency of the spraying process.

Rozella Wisoky –

The explanation of DPM-Drag Macro is thorough, but can you provide some insight into how the Penetration Length is calculated and its relationship with the drag force in simple terms?

MR CFD Support –

The Penetration Length is a measurement of how far the discrete particles travel within the fluid before coming to rest or exiting the simulation domain. The stronger the drag force applied on the particles by the fluid, the quicker the particles lose momentum, leading to a shorter Penetration Length. Vice versa, a weaker drag force would allow the particles to traverse a greater distance, resulting in a longer Penetration Length. In the provided simulations, various drag force models are tested to observe their effect on the Penetration Length of the sprayed particles.

Forest Crona DDS –

What do the different drag laws (spherical, non-spherical, stokes-cunningham) represent in the simulation, and why is it necessary to compare them?

MR CFD Support –

The different drag laws represent alternative models to calculate the drag force experienced by particles in a fluid flow. Each drag law accounts for different particle shapes and flow conditions. For instance, the Spherical drag law is ideal for particles that are nearly perfect spheres, while the Non-Spherical law applies to particles that deviate from a spherical shape. The Stokes-Cunningham law includes corrections for very small particles where slip flow regimes occur. Comparing them is necessary to determine which model accurately predicts the behavior of the discrete phase in the simulation since this can significantly impact predictive accuracy, particularly regarding particle penetration and dispersion.

Prof. Peter Treutel DDS –

This UDF course sounds very technical. Does the product include examples applicable to other simulations beyond spraying particles in a chamber?

MR CFD Support –

Absolutely! While the UDF course focuses on the specific example of drag force between particles and fluid in a spraying chamber, the techniques and coding strategies you’ll lpub8 disparate applications. The skills you acquire in writing UDFs and applying them to control the simulation’s physics extend to a variety of other CFD challenges, providing valuable tools for customizing and enhancing your own simulation projects.

Rowan Yost –

I’m curious about the UDF code used in this simulation. Could you provide more details about the UDF implementation?

MR CFD Support –

Certainly! In this simulation, we customized the drag force calculation between particles and fluid by implementing a User-Defined Function, coded in C programming language, utilizing the DEFINE_DPM_DRAG macro within ANSYS Fluent. This macro allowed us to refine the relationship between the Reynolds number and drag force, ensuring a more accurate and tailored simulation for our specific scenario. While the code itself is proprietary information, the methodology employed ensures that the calculated drag forces align with the physical phenomena being modeled.

Mellie Schmeler –

This product seems very informative. Can you clarify if the User-Defined Function (UDF) here allows adjusting the drag force based on different physical scenarios or if it’s only limited to predefined scenarios in ANSYS Fluent?

MR CFD Support –

The User-Defined Function (UDF) used in this product allows you to create custom relations for the drag force, which means you can account for various physical scenarios beyond the predefined drag laws in ANSYS Fluent. You can adjust the UDF to cater to specific needs whether that involves changes to environmental conditions, particle properties, or flow dynamics.