Diesel Spray Ultra-High Injection, Paper Numerical Validation, ANSYS Fluent Tutorial

$200.00 Student Discount

- The problem numerically simulates Diesel Spray Ultra-High Injection using ANSYS Fluent software.

- We design the 3-D model by the Design Modeler software.

- We Mesh the model by ANSYS Meshing software.

- The mesh type is Structured, and the element number equals 675000.

- This project is simulated and validated with a reference article.

- We use the Discrete Phase Model (DPM) to define the fuel injection process.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Project Description

The present problem simulates fuel injection through an injector into a chamber by ANSYS Fluent software.

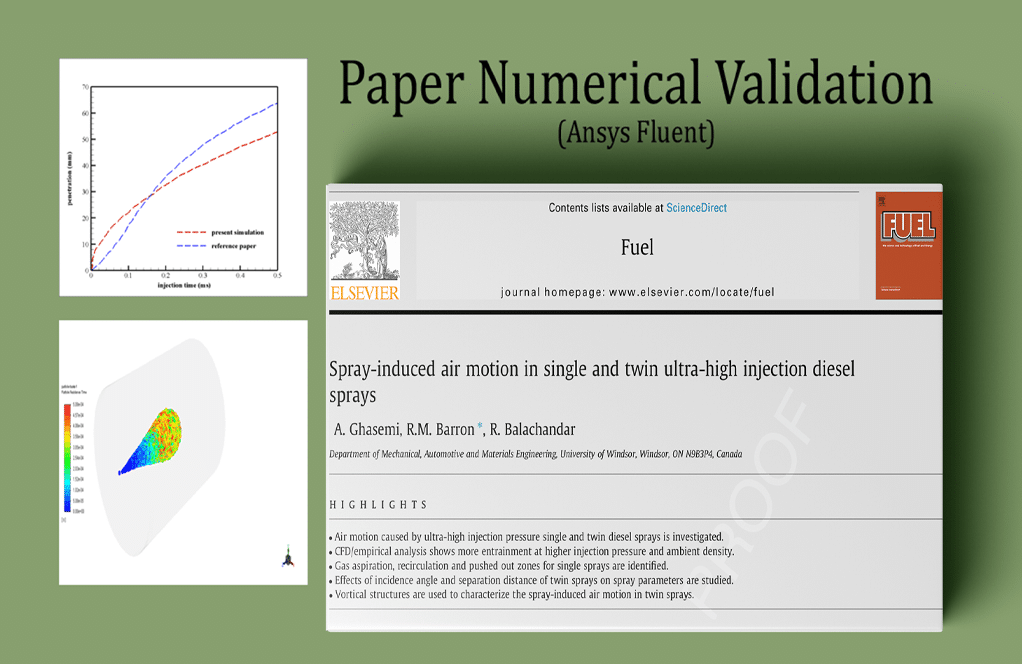

This simulation is based on the information in the article “Spray-induced air motion in single and twin ultra-high injection diesel sprays” and its results are compared and validated with the results in the article.

The fuel used in this model is diesel and its properties include density equal to 830 kg/m3, specific heat capacity equal to 1680 j/kg.K, droplet surface strain equal to 0.0255 n/m and viscosity equal to 0.0027888 kg/m.s.

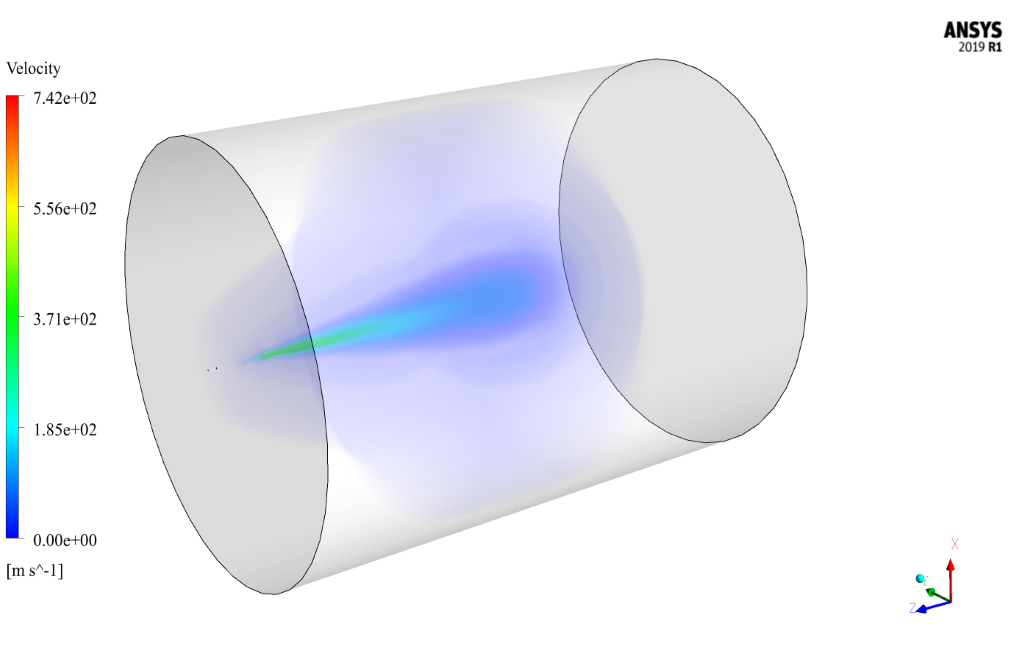

An injection process is also defined to define the fuel injection process. Thus, the fuel flow is injected into the chamber with a flow rate of 14 g/s, a velocity of 850.23 m/s and a temperature of 298 K.

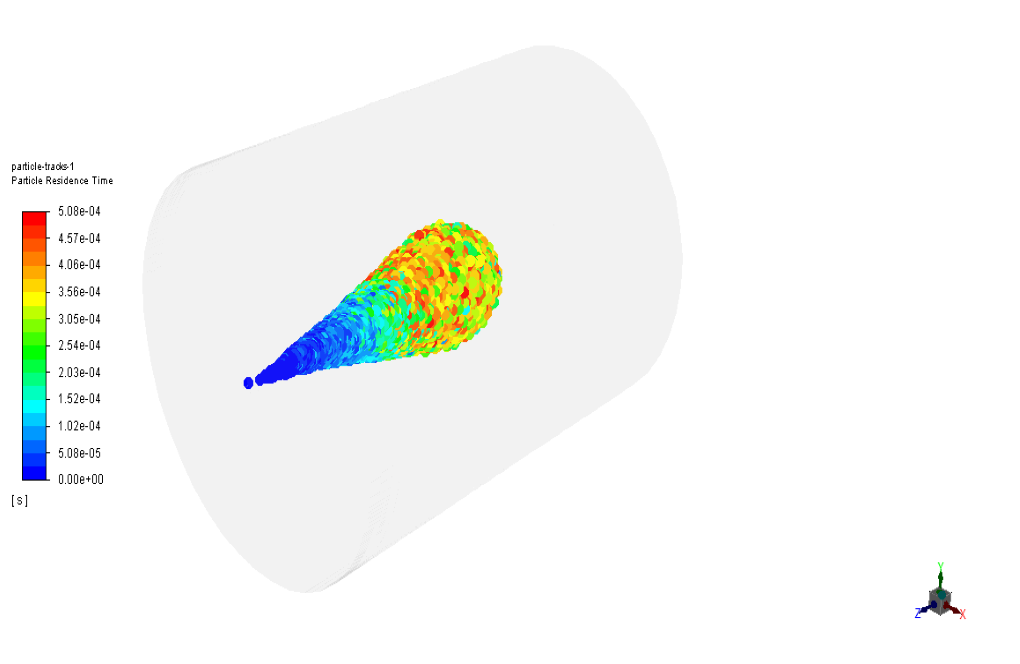

The diameter of the fuel particles is considered to be 0.00016 m and the type of fuel injection into space is defined as single. The duration of the injection process in the time interval is equal to 0.001 s.

The present 3-D model is designed using Design Modeler software. The meshing of the model has been done using ANSYS Meshing software and the mesh type is structured. The element number is 675000.

Diesel Spray Methodology

In this project, the discrete phase model (DPM) is used. The behavior of discrete phase particles in the unsteady state is also defined and it is also assumed that the behavior of the particles is affected by the continuous flow (interaction with the continuous phase).

The physical states defined for the discrete phase model include stochastic collision, which means that fuel particles collide with each other, coalescence, which means that fuel particles combine with each other, and breakup, which means the decay of fuel particles.

Diesel Spray Conclusion

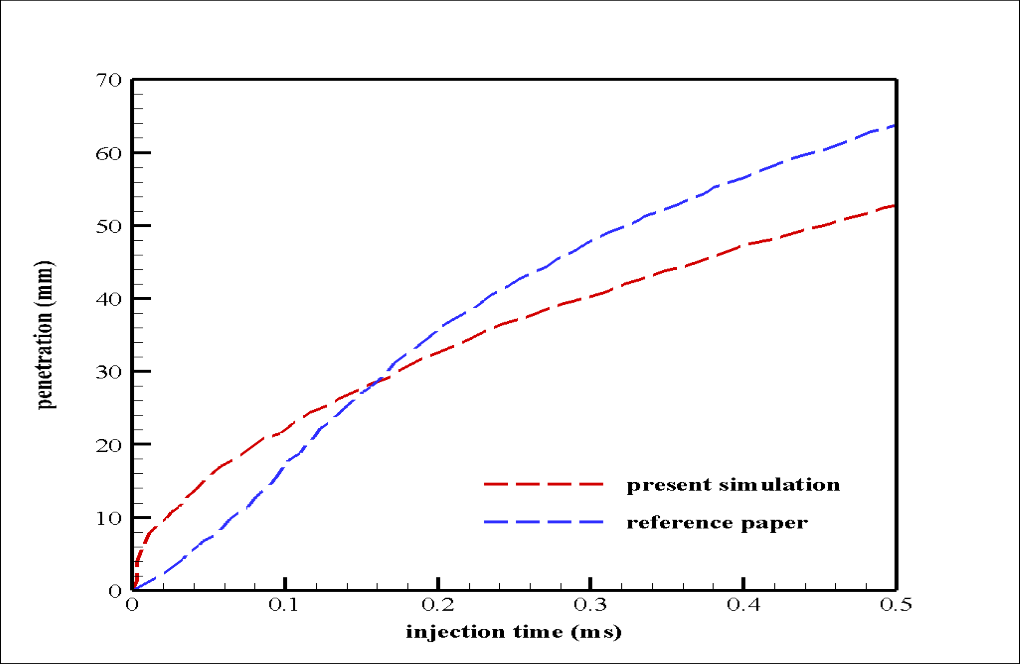

At the end of the solution process, the results of the present numerical study are compared and validated with the results of the laboratory (experimental results)of the mentioned article.

Validation is based on Figure 3 of the article. Since the present simulation was performed at a time interval of 0.5 ms, the results of the numerical work were compared only in the first 0.5 ms.

This simulation was performed at an injection pressure of 300 MPa, which according to the Bernoulli principle, the particle injection rate is considered to be 850.23 m/s.

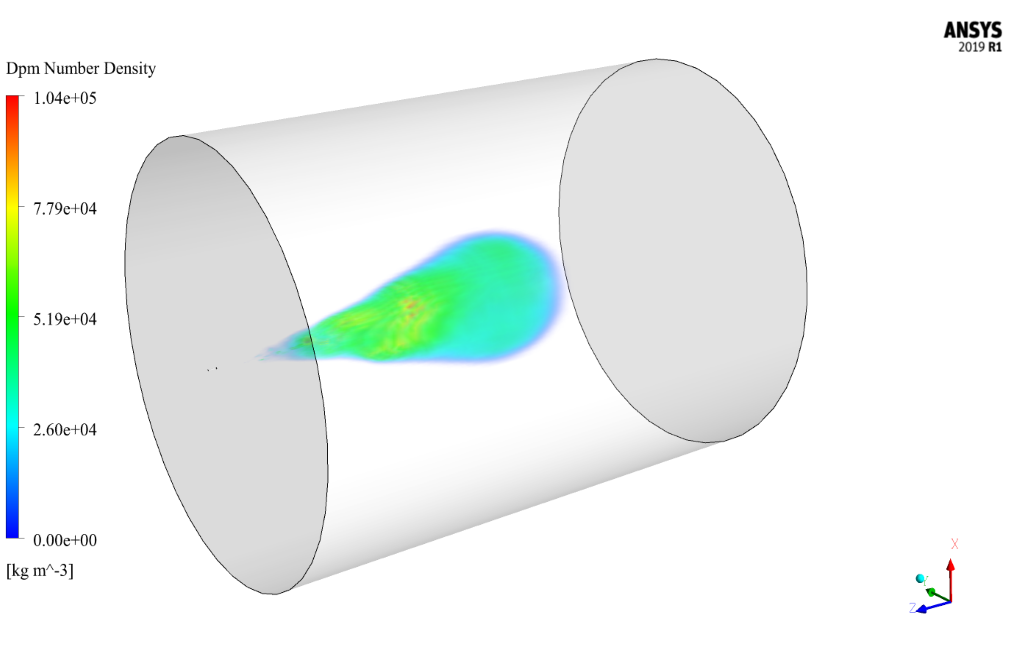

Also after the solution process, two-dimensional and three-dimensional contours related to velocity, DPM density, discrete phase model number and volume, and particle tracking in terms of residence time and diameter size are obtained for better understanding.

Saul Rath –

Hi, MR-CFD explained the concepts very well.

Miss Ruby Ledner II –

This simulation is a breakthrough in the field of diesel engine design and optimization!

Dr. Travis Wilkinson –

What is the meaning of Penetration Length compared to the reference paper?

MR CFD Support –

Hi, my friend

The penetration length is the distance from the nozzle outlet to the mass of the fluid in the computational range.

Simone Bechtelar –

Hi, I had a problem that I had to solve with the injection type group that used this product. Thankful

Carroll Osinski V –

The detailed visualization of the results is very helpful for understanding the diesel spray behavior.

Jadyn Mueller –

I’m very impressed with how the results from the simulation align with the experimental data from the paper. Can MR CFD’s tutorials be followed by someone new to ANSYS Fluent, or do they require prior experience with the software?

MR CFD Support –

Thank you for the positive feedback! MR CFD’s tutorials are designed to be as accessible as possible, allowing both beginners and experienced users to follow along. Newcomers to ANSYS Fluent will find step-by-step instructions and explanations that will help them through the learning process, while more advanced users can benefit from the specific insights and tips provided for more complex simulations.

Kyla Farrell –

Fantastic tutorial! It’s great to see the validation of the simulation against laboratory results. How closely did the simulation results match the experimental data from the article?

MR CFD Support –

The simulation results demonstrated a good agreement with the experimental data from the article. The validation was based on direct comparison for the first 0.5 ms of injection, considering variables such as velocity, DPM density, and particle size distribution. The match within the early injection phase indicates the correct setup and accuracy of the CFD model in capturing the essential physics of the diesel spray.

Lucio Pagac –

I’m impressed by the level of detail in the methodology. It’s interesting how the simulation considers collision and coalescence of fuel particles. Can we examine how variations in injection pressures affect the outcomes?

MR CFD Support –

Thank you for your kind words and keen observation! The current simulation was conducted at a fixed injection pressure of 300 MPa to validate the study against experimental data. However, variations in injection pressures can indeed affect the outcomes and can be studied by setting up different scenarios in the ANSYS Fluent software to observe changes in the spray pattern, penetration, and atomization processes. Sensitivity studies regarding injection pressure can provide more insights into the spray characteristics and fuel-air mixing efficiency.

Dr. Kristofer Toy –

The ability to customize this simulation for different injection systems and fuel types is a game-changer!

Ms. Christelle Muller –

The tutorial was extremely helpful, and the step-by-step approach made replicating the validation process seamless. I now have a better understanding of high-pressure diesel injection simulations, and the comparison with the article’s data reassured me of the accuracy of your methodology.

MR CFD Support –

We’re thrilled to hear you found the tutorial helpful and that it enhanced your understanding of high-pressure diesel injection simulations. It’s great to know the validation process was clear and that our approach to accuracy was beneficial for you. Thank you for taking the time to provide your feedback!

Kim Torphy –

Is MR CFD’s tutorial detailed enough for beginners to follow along? Did it include explanations on how to interpret the results compared to the experimental data provided in the referenced article?

MR CFD Support –

The provided tutorial is designed specifically to guide users through each step from model setup to interpreting results, making it suitable for a range of skill levels including beginners. The validation portion of the tutorial ensures that users are taught how to properly compare the simulation data with the experimental results from the article.

Derek Paucek –

The Diesel Spray Ultra-High Injection project looks quite comprehensive. It’s impressive to see the validation against experimental results, ensuring the accuracy of the simulation. Great job on creating a structured mesh with that many elements for detailed analysis!

MR CFD Support –

Thank you for your positive feedback on the Diesel Spray Ultra-High Injection project. Validation to experimental data is key in the work that we do, and we are glad to hear that our efforts in meshing and simulation accuracy meet your standards. Your acknowledgment truly means a lot to us!

Jadon Gibson V –

I appreciate the commitment to accuracy and validation in this simulation.

Mohammed Botsford –

Absolutely excellent tutorial! The detailed steps for DPM setup and the validation process at the end provided me with a strong understanding of how to approach an ultra-high injection diesel spray simulation. Comparing the results with those in the referenced paper was incredibly helpful and gave me a lot of confidence in the accuracy of ANSYS Fluent in complex simulations like this. Outstanding work!

MR CFD Support –

Thank you so much for your kind words and positive feedback! We’re delighted to hear that our tutorial helped you grasp the complexities of using the discrete phase model for diesel spray simulation and that the validation process added to your confidence. Your praise is greatly appreciated and motivates us to continue creating high-quality tutorials for our customers. Don’t hesitate to reach out if you need any further guidance!

Josh Mills –

The product’s application of the discrete phase model and validation methods are clear, but could you clarify what specific criteria from the paper’s results were used for the validation in this simulation?

MR CFD Support –

The validation process included comparing the simulation data with the experimental data on spray penetration and angle, fuel droplet sizes, velocities, and their respective distributions as presented in the verification paper, specifically matching the results provided in Figure 3 in the time interval of 0.5 ms.

Alexandrine Abshire –

I thoroughly enjoyed the detail and accuracy in the Diesel Spray Ultra-High Injection tutorial. Learning to validate numerical simulations with experimental data is crucial for my projects, and this tutorial made the concepts very accessible. The inclusion of relevant figures from the paper provided a helpful comparison and made the learning process much more interactive. Looking forward to more such tutorials!

MR CFD Support –

Thank you for your wonderful feedback! It’s great to hear that the tutorial was informative and beneficial to your projects. We strive to deliver quality educational content that helps bring clarity to complex engineering concepts. Keep an eye out for more tutorials, and happy learning!

Adelia Schuster Sr. –

This tutorial was impressive, especially for understanding the DPM model and injection processes. Great comparison with the experimental data provided in the source paper as well.

MR CFD Support –

Thank you for your positive feedback! We’re pleased to hear that our tutorial on Diesel Spray with Ultra-High Injection helped you understand the DPM model and injection processes effectively. We strive to provide thorough comparisons with experimental data to ensure the validity and usefulness of our simulations. We appreciate your review.

Dr. Margret Crooks –

The tutorial and simulation were accurately detailed and instrumental for understanding diesel fuel injection dynamics, especially the results validation with the numerical study. Well done!

MR CFD Support –

Thank you for your positive feedback on our Diesel Spray Ultra-High Injection tutorial. We are delighted to hear that the simulation provided clear and insightful results, and helped enhance your understanding of diesel fuel injection dynamics. We aspire to maintain high-quality content for our customers, and your compliments are truly appreciated!

Crystal Funk –

I was really impressed by the in-depth approach taken in this tutorial! Validating the CFD model against published experimental results contributed greatly to understanding diesel spray dynamics. Well done!

MR CFD Support –

Thank you for your kind feedback! We are thrilled to hear that the tutorial was helpful and provided a thorough understanding of diesel spray physics. Accurate validation is key to our approach, and we’re glad it has made a significant impact on your learning experience.

Bart Bayer –

What steps were taken in the numerical validation process to match the simulation results with the experimental data from the referenced paper?

MR CFD Support –

To match the simulation results with the experimental data from the paper, the simulation was carefully set up to replicate the conditions stated in the article. Parameters such as the fuel properties, injection rate, velocity, temperature, and injection duration was obtained from the article and used to precisely define the simulation settings. Additionally, the discrete phase model was configured to include interactions like stochastic collision, coalescence, and breakup of fuel particles. The results were specifically compared at the 0.5 ms interval against the experimental figures in the article to ensure accuracy.

Leonardo Hansen –

My compliments on the clarity of the Diesel Spray tutorial. Following along with the actual paper helped reinforce my understanding of how CFD analysis can match experimental data. The side-by-side validation was particularly enlightening. Well done, MR CFD team!

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear that the Diesel Spray tutorial was helpful in understanding the validation process between CFD analysis and experimental data. Our goal is always to provide clear and insightful learning experiences. Your feedback is much appreciated!