DPM to VOF, Color Spray Gun CFD Simulation Tutorial

$240.00 Student Discount

- The current CFD Analysis simulates the Color Spray Gun with Wall Film via ANSYS Fluent software.

- We have designed the initial geometry using ANSYS Design Modeler software and created the mesh on this geometry using ANSYS Meshing software.

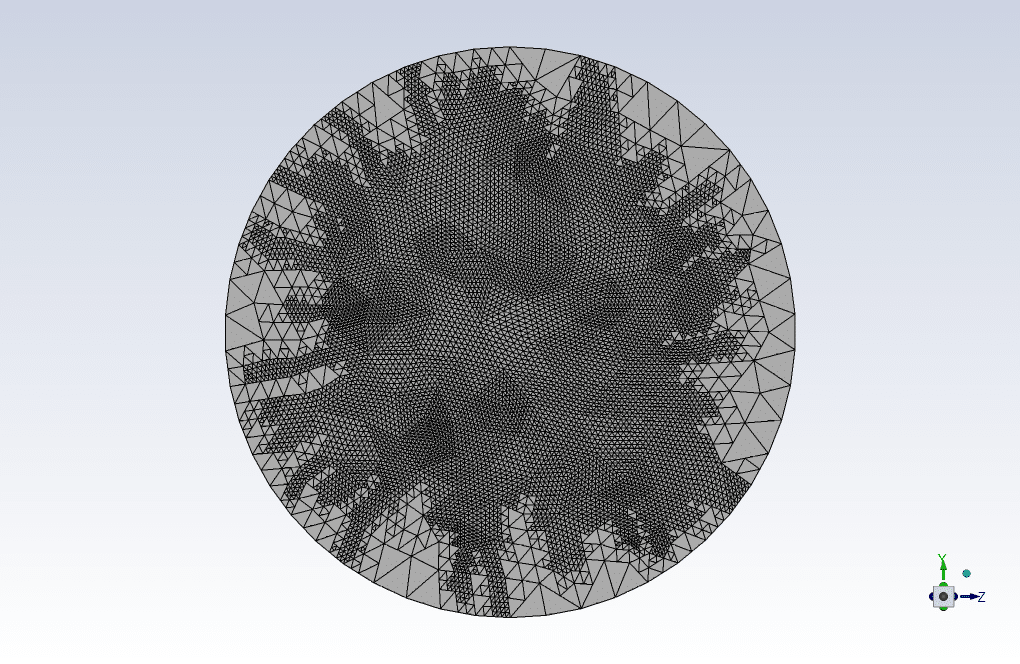

- The mesh type is tetrahedral with 560,134 cells.

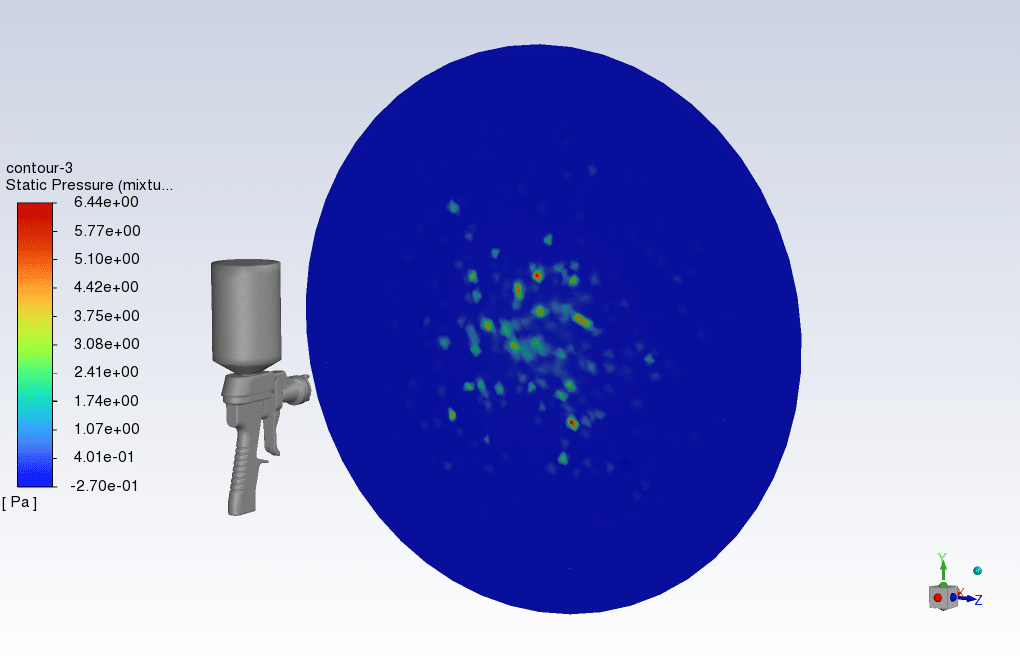

- VOF multiphase model, along with the Discrete Phase Model, is used.

- The liquid wall film boundary condition is also enabled over the painted wall.

- The Automatic Mesh Adaptation option is used to enhance the quality of the mesh.

- The solution is Transient.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Description

A spray gun is a painting tool that uses compressed air from a nozzle to atomize a liquid into a controlled pattern. The spray nozzle operates by impinging high-velocity turbulent air on the surface of filaments or films of liquid, causing them to collapse into droplets with a wide range of sizes.

Spray guns are used to paint any surface. Liquid droplets leaving the nozzle with high velocity can sit over the surface and create a liquid layer, forming the paint layer.

The geometry of the present project was created using ANSYS Design modeler and is meshed in ANSYS Meshing. The mesh type is unstructured, and the initial mesh number equals 560,134.

Color Spray Gun with Wall Film Methodology

In this project, the formation of a paint layer over an arbitrary wall is simulated. Different modules, including the VOF multiphase model along with the DPM, are enabled to model such a process.

When enabling the two models of VOF multiphase and dpm simultaneously, two transition mechanisms of DPM-to-VOF and VOF-to-DPM become available, which the user can use to switch between discrete phase elements to the eulerian VOF model or vice versa.

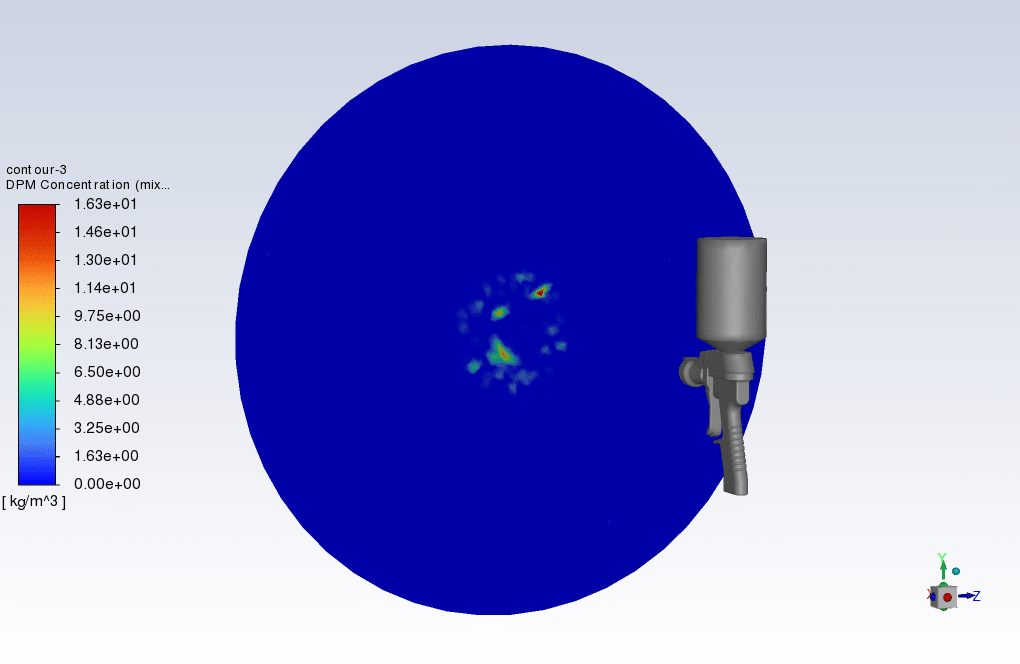

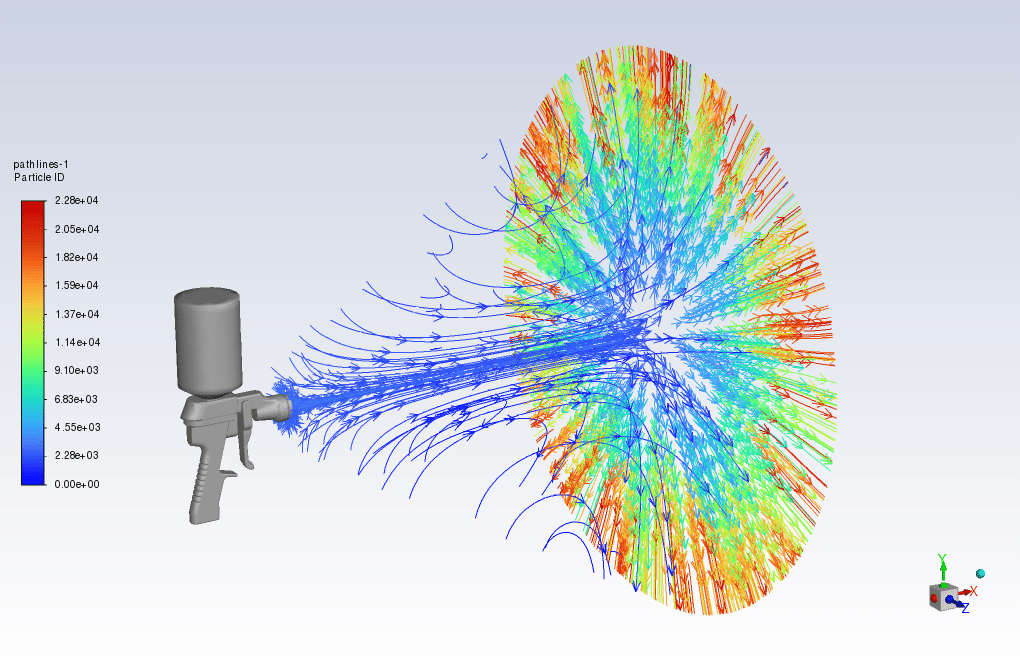

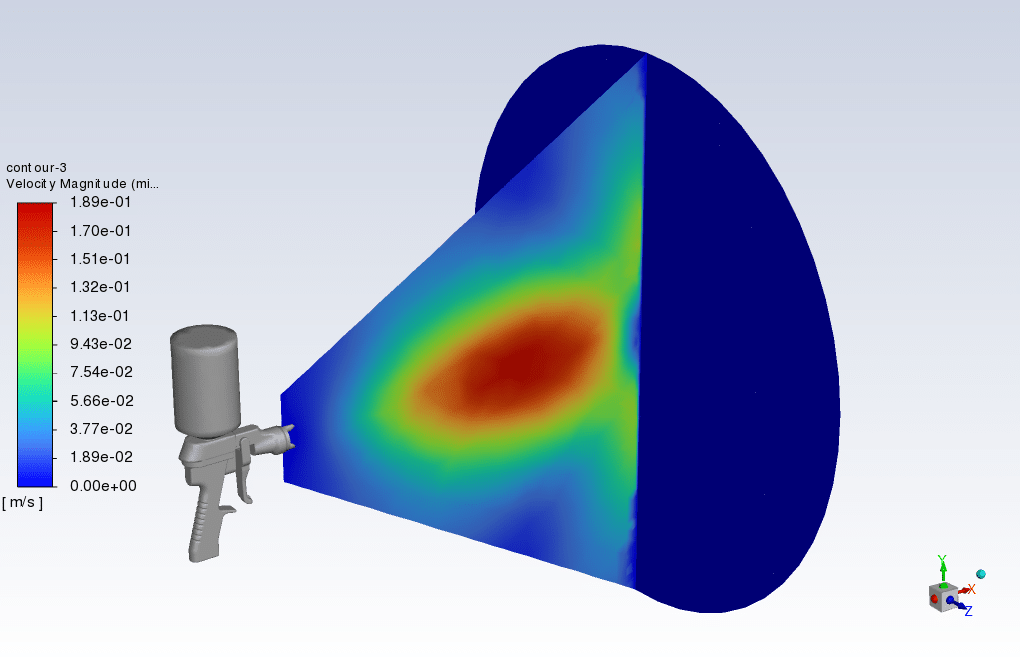

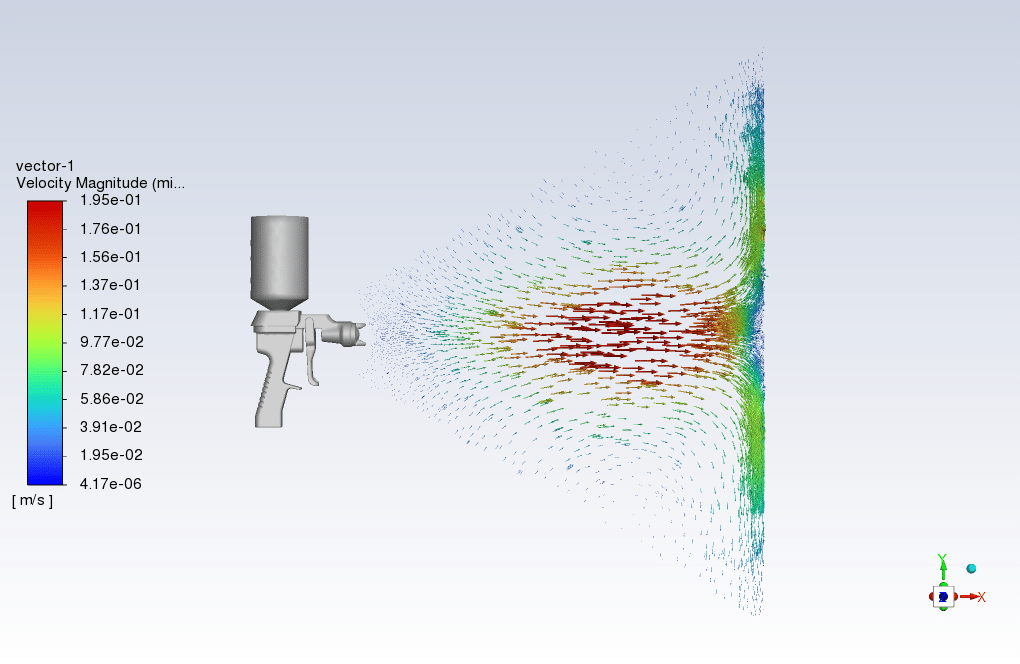

This project uses the DPM-to-VOF model to model the transition of liquid droplets into a paint layer over a wall boundary. The particles are injected from the spray gun’s nozzle in a conical shape with a velocity of 2 m/s.

Furthermore, the liquid wall film boundary condition is also enabled over the painted wall so that the particles are first immobilized on the painted wall.

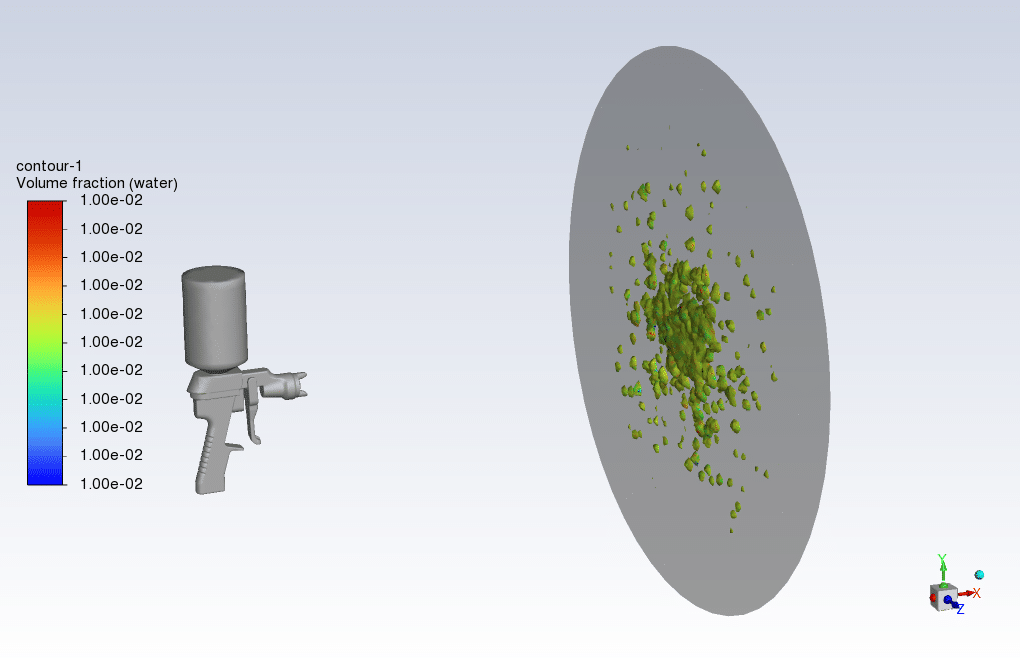

After some time, when the volume fraction of liquid droplets is high enough to form the paint layer, the discrete particles are converted into the VOF layer, forming the final paint layer on the wall.

Moreover, the automatic mesh adaptation is a mandatory option that needs to be enabled. Of course, small mesh cells are not needed in the stage where the trajectories of particles are calculated.

Once the particles are converted into VOF, the mesh cells must be made as small as possible to capture the paint layer interface with the surrounding matter (i.e., the air). Otherwise, the simulation results are subjected to error and inaccuracies.

On top of the mentioned activated models, the Realizable k-epsilon model is used to solve the turbulent fluid equations. The present study is performed in transient format and 3D.

Conclusion

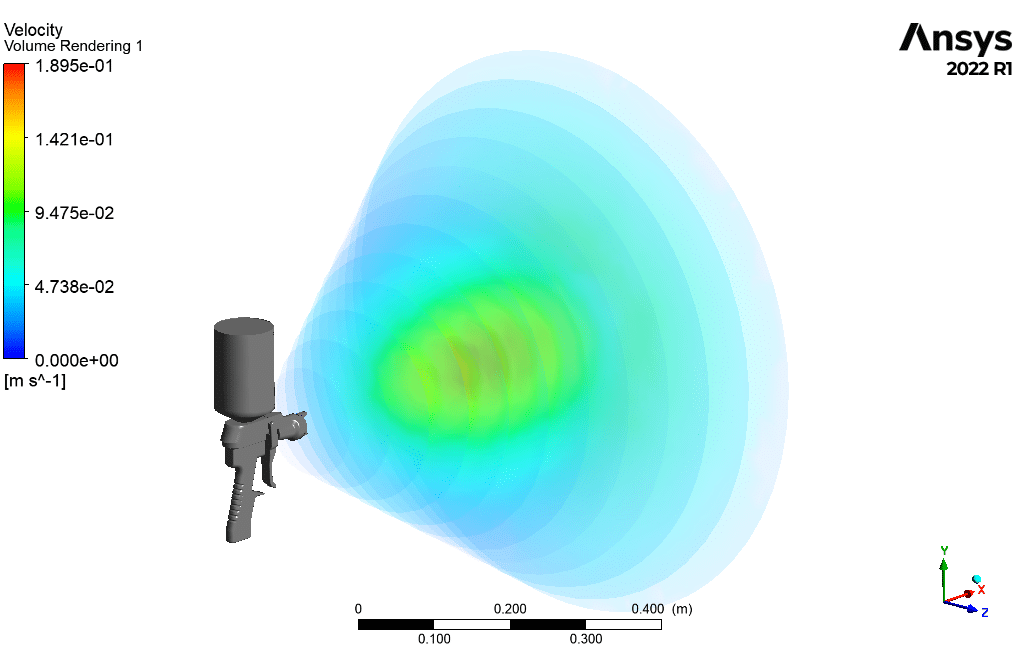

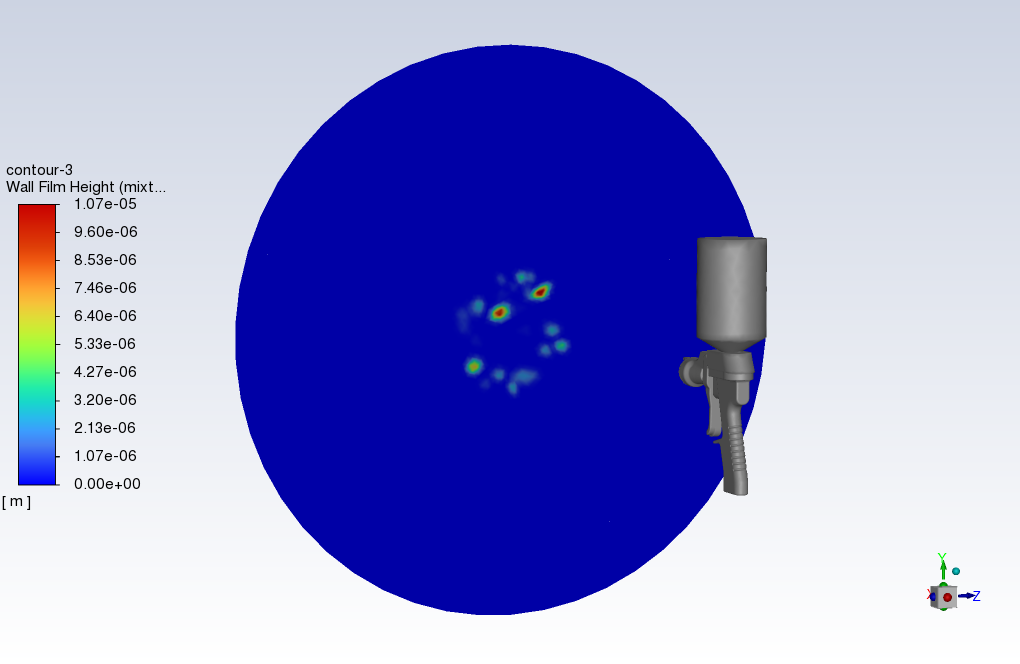

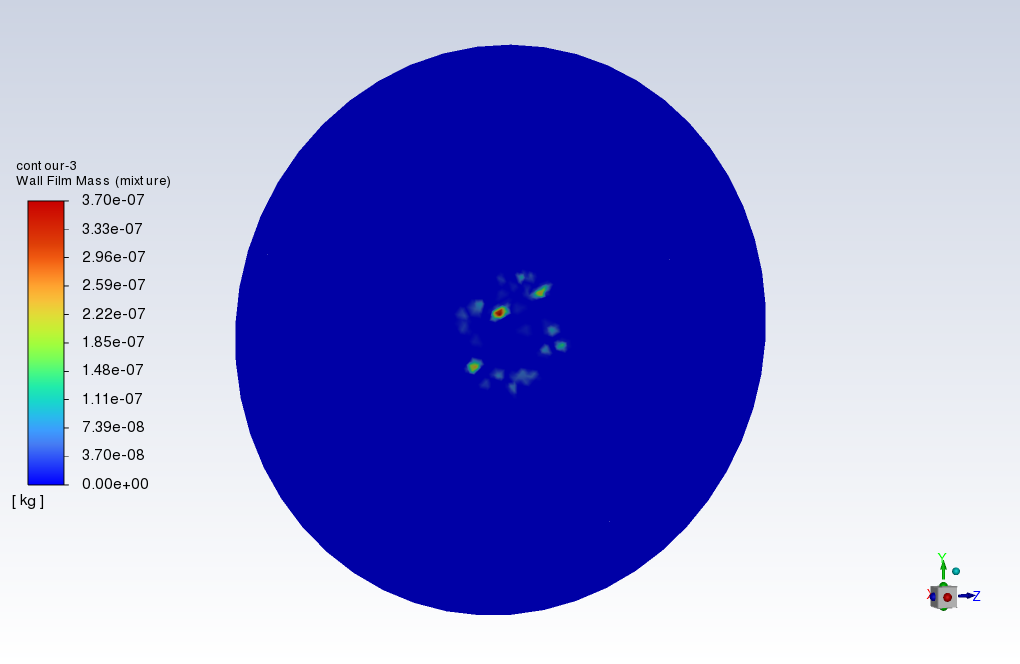

The results show that the paint layer is formed on the wall. The particles accumulating on the painted wall were converted to a VOF layer, forming separate layers of paint. Due to the flow pattern formed inside the domain due to the particle injection jet, the formed VOF layers on the painted wall tend to move radially away from the wall’s center point.

This motion triggers the automatic mesh adaption, and as depicted in the final mesh image, mesh cells are made distinctively smaller than the mesh cells in some specific locations.

Moreover, even in the final time step, some wall film particles are still on the painted wall. The value of lagrangian wall film particles under the dpm-to-of session box must be altered to remove the existing wall film particle when they touch the VOF layer to prevent the existence of both wall film particles and the VOF layer simultaneously.

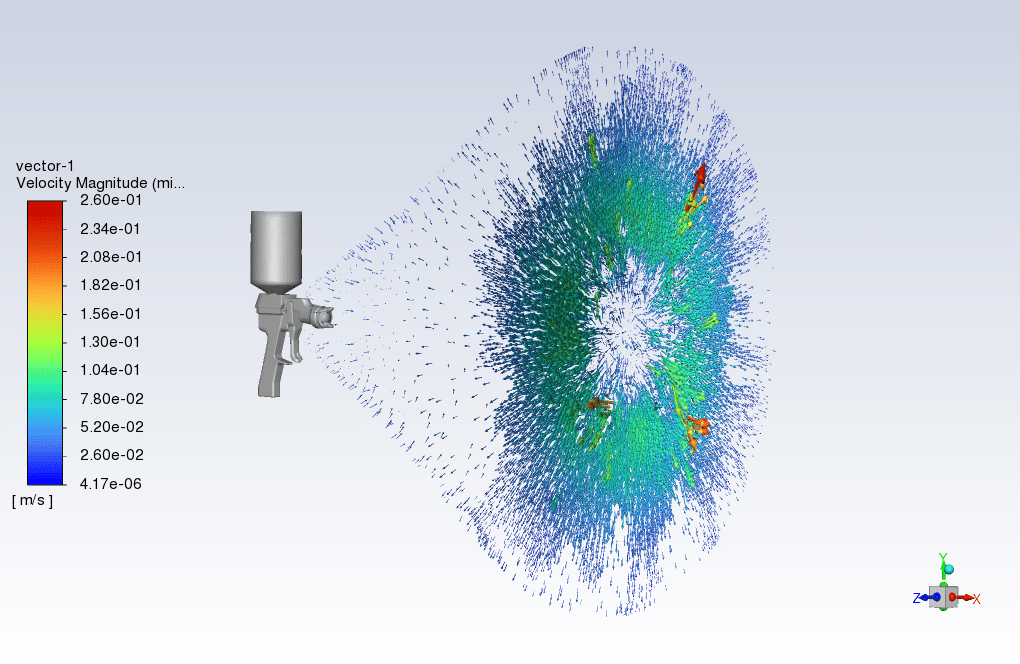

Also, viewing the velocity vectors inside the computational domain makes it interesting to observe the flow pattern created by the injection jet flow.

Donald Schmidt –

I am blown away by the capabilities of the simulation to adapt the mesh automatically and handle both DPM and VOF modules! It’s fascinating to see how droplets transition into a paint layer.

MR CFD Support –

Thank you so much for your kind words! We’re thrilled to hear that the tutorial not only clarified the process but left a great impression. The interplay between DPM and VOF and the smart mesh adaptation are indeed formidable features, and it’s our pleasure to present them in an accessible way. We appreciate your feedback!

Prof. Katelin Boyle –

I’m curious about how the DPM-to-VOF transition mechanism accounts for different paint behaviors due to variations in type and viscosity. Are these properties adjustable to simulate different painting scenarios?

MR CFD Support –

Yes, these properties are indeed adjustable in the simulation. The DPM-to-VOF transition mechanism can be set up to account for different physical properties of the paint, including type, viscosity, surface tension, and more. These factors influence how the paint droplets behave upon impact with the surface and during their transition into a VOF layer. The liquid properties in the discrete phase model (DPM) can be customized to reflect different paint characteristics, ensuring an accurate simulation of various real-world painting scenarios.

Janelle Gulgowski –

The description of the paint layer simulation is fascinating. Great detail is provided on the process—very helpful for those of us looking to understand CFD applications in surface coating processes.

MR CFD Support –

Thank you very much for your positive feedback. We’re glad to hear that the detail provided in our tutorial has been helpful for your understanding of CFD applications, especially in the field of surface coatings. If you have any more questions or need further assistance, please don’t hesitate to reach out.

Fritz Herzog –

What spray gun positions did you find most effective for creating an even VOF layer of paint, based on your simulations?

MR CFD Support –

In our simulations, utilizing the DPM to VOF methodology, we found that an optimal spray gun position is perpendicular to the target surface at a consistent distance, with a controlled spray angle to ensure the most effective and even distribution of the paint VOF layer formation. Adjustments to the distance and angle, depending on the spray pattern and paint viscosity, are critical for achieving an ideal coating.

Maryjane Hand –

The simulation looks incredibly detailed. Just wondering about the technical process—how does the transition from the DPM to VOF get determined within the simulation? Is there a sort of threshold for when particles become part of the paint layer?

MR CFD Support –

In the simulation, the transition from the Discrete Phase Model (DPM) to the Volume of Fluid (VOF) model is governed by settings that dictate at what volume fraction the discrete particles accumulate enough mass to form a continuous liquid layer. Once this threshold is reached on the wall, the DPM-to-VOF transition turns these discrete particles into a VOF representation, allowing for the simulation of the liquid layer formation as a continuous phase. This is essential to accurately modeling the paint layer’s formation on the surface.

Prof. Tatyana Gibson –

This all sounds fascinating! How does the choice of turbulence model, like the Realizable k-epsilon in this case, impact the results in this simulation of the color spray gun?

MR CFD Support –

The Realizable k-epsilon turbulence model provides an improved prediction for the flow by adjusting the turbulence kinetic energy and its dissipation rate more accurately in high-strain rate flows, which are typical in spray painting applications. This helps in capturing the complex air-paint interactions, ensuring that the behavior of the liquid droplets as they disperse from the nozzle and their impact on the wall is modeled with greater fidelity. Altering the turbulence model can lead to variations in predicted particle paths, resulting in changes in the coverage and thickness uniformity of the paint layer on the wall.

Prof. Diego Sporer DDS –

The tutorial was clear and easy to follow. The visualization of forming the paint layer using the DPM to VOF transformation provided great insight into the real-life painting process using a spray gun. Mesh adaptation made a significant improvement in capturing the details of the layer formation.

MR CFD Support –

Thank you for your positive feedback! We are delighted to hear that the tutorial was helpful and that the visuals provided clear understanding of the paint layer formation process. We always strive to create high-quality materials that are both educational and engaging. Your praise encourages us to continue doing just that. If there’s anything else you’d like to learn about, please let us know!

Jake Bradtke –

I appreciated the detail in this tutorial for the ‘Color Spray Gun CFD Simulation’. It was extremely helpful in understanding how to set up a liquid layer formation using a combination of VOF and DPM models. The description of the automatic mesh adaption process was especially enlightening and provided clarity on ensuring simulation accuracy.

MR CFD Support –

Thank you for your positive feedback! We strive to deliver detailed and clear guidance for our simulations. It’s great to hear that our Color Spray Gun CFD Simulation tutorial contributed to your understanding of complex modeling techniques. We’re pleased that the section on mesh adaptation was particularly useful for you. If you have any more questions or need further assistance, please don’t hesitate to reach out!

Roy Zieme –

I really appreciated the detailed explanation of the transition of liquid droplets into a paint layer using the DPM-to-VOF methodology. The concept of particles becoming immobilized on the wall before forming a liquid layer was very insightful.

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that the detailed explanation of the particle transition and the immobilization process in our Color Spray Gun CFD Simulation Tutorial was informative and helpful. If you have any further questions or need more insight, feel free to reach out. It’s always a pleasure to assist our customers with their learning journey!

Gerard Rodriguez –

Does the model account for different types of paints and their properties, such as viscosity or color, which can affect the outcome of the layer formed?

MR CFD Support –

Yes, in these simulation types, the physical properties of the paint like viscosity, surface tension, and color can be defined in the material properties section under the setting of the liquid or multiphase model, which affects the formation and quality of the paint layer on the surface.

Jeremy Metz –

I really appreciate the detailed explanation of the spray gun simulation; the ways in which you’ve described converting DPM to VOF to capture the paint layer formation is fascinating. It has provided great insights into the capabilities of ANSYS for such complex simulations.

MR CFD Support –

Thank you so much for your kind words! We’re thrilled to hear that our tutorial on DPM to VOF color spray gun CFD simulation met your expectations and offered helpful insights. Our goal is to provide clear and thorough guidance to assist researchers and engineers in their simulation projects. Your satisfaction means a great deal to us, and we’re glad we could help. If you have any more feedback or require further assistance with your simulation studies, please do not hesitate to reach out.

Lottie Medhurst –

The high level of detail in this simulation is impressive. The way the paint layer forms and the flow pattern’s impact are very well-explained. It’s fascinating to have insight into the DPM-to-VOF transition and the use of automatic mesh adaptation. That should make for an engrossing and educational tutorial!

MR CFD Support –

Thank you for your compliment! We’re thrilled to hear you find the simulation details impressive and your understanding of the DPM-to-VOF transition enriched by our tutorial. Your appreciation encourages us to continue providing high-quality and insightful learning materials. If there is anything more we can assist you with, please let us know!