Drying Seed Process CFD Simulation Using Porous Medium in ANSYS Fluent

$100.00 $40.00 HPC

- This study simulates the drying seed process in a semi-cylindrical porous domain to analyze airflow, heat, and moisture transfer.

- The drying seed model uses a half-domain with about 4.5 million tetrahedral cells, including fluid and porous seed zones.

- A transient, pressure-based solver with the RNG k-ε model and species transport simulates the drying seed.

- The drying seed simulation shows uniform temperature and decreasing moisture, indicating efficient drying performance.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Numerical Investigation with ANSYS: Drying Seed Behavior in a Porous Medium

Description

The present work investigates the drying seed process inside a semi-cylindrical domain filled with seed particles. The simulation was conducted using ANSYS Fluent to study the coupled heat and mass transfer behavior during the drying operation. The model includes airflow interaction with a porous zone of seeds to understand the temperature, moisture distribution, and velocity field within the seed zone. The objective of this project is to analyze how the drying process evolves over time under the given thermal and flow boundary conditions. The simulation provides detailed insight into the drying efficiency, local heat transfer, and vapor concentration patterns around and inside the porous seed bed.

Geometry and Mesh

The computational geometry was created using ANSYS SpaceClaim and DesignModeler. The domain represents half of the physical model due to symmetry, with the bottom surface set as a symmetry boundary condition to optimize computational resources. Two main zones were defined: a fluid zone representing the drying air, and a seed zone, modeled as a porous medium to simulate the resistance to airflow through the packed seeds. The porous region has a porosity value of 0.418, corresponding to the physical packing characteristics of the seeds. The geometry was discretized using the ANSYS Meshing tool, where a tetrahedral mesh with approximately 4.5 million cells was generated to accurately capture the complex flow and thermal gradients around the seed particles. The high mesh density ensured adequate resolution for both temperature and velocity fields during the drying simulation.

Model and Solver Setting

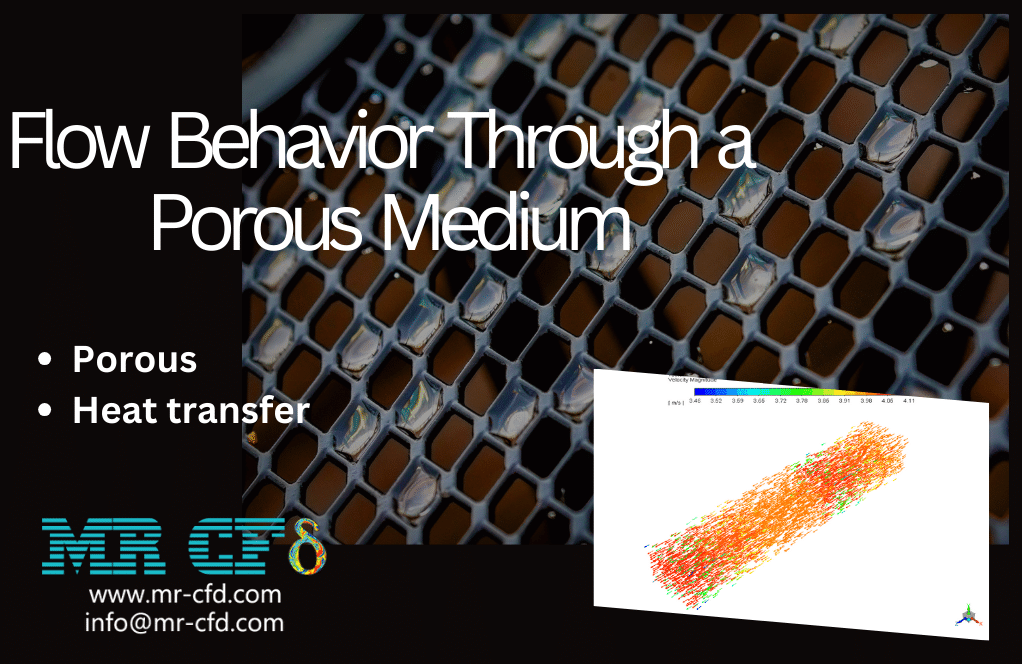

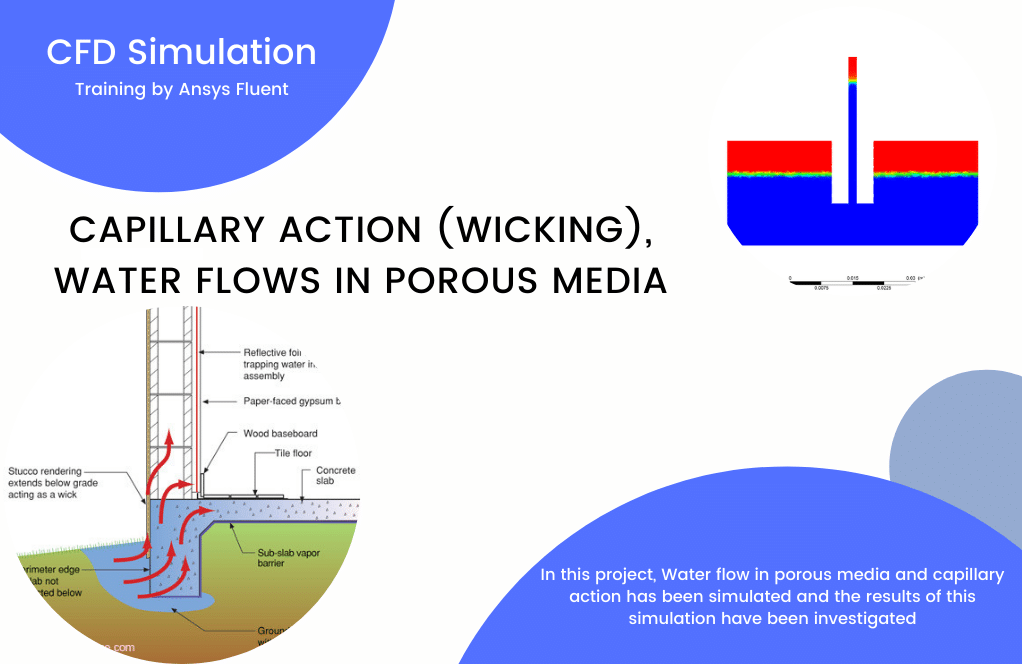

The drying analysis employed a pressure-based transient solver to resolve the time-dependent heat and mass transfer phenomena. The gravity was set to −9.81 m/s² in the Y-direction to correctly model the buoyancy effects. The energy equation was activated to account for heat exchange between the hot air and seed surfaces. For turbulence modeling, the RNG k-ε model was selected due to its superior accuracy in predicting recirculating and swirling flows within the porous media. The species transport model was enabled to track the water vapor (H₂O) concentration throughout the drying process, considering the materials air, H₂O, and wheat. The Simple algorithm was used for pressure–velocity coupling, with a velocity inlet defining the incoming hot air and a pressure outlet for outflow. The time-dependent formulation allowed monitoring of the transient temperature and moisture variations in the drying seed zone.

Results

The simulation results illustrate the thermal and moisture transport behavior during the drying seed operation. The temperature contour plots show a gradual temperature rise across the seed bed, with values ranging approximately between 302.6 K and 303.1 K, indicating an efficient but gentle drying seed process. The mass fraction of H₂O contours reveal that the vapor concentration decreases progressively along the airflow path, confirming effective moisture removal from the seed surfaces. Velocity streamlines show that the air accelerates through the porous region, enhancing convective heat and mass transfer. The coupled flow, temperature, and species fields demonstrate that the designed drying configuration efficiently distributes hot air within the porous medium, ensuring uniform drying seed conditions across the domain. The findings can guide optimization of airflow velocity, porosity, and temperature for improved drying seed performance in industrial applications.

You must be logged in to post a review.

Reviews

There are no reviews yet.