Air Gap Membrane Distillation (AGMD), Paper Numerical Validation, ANSYS Fluent Training

$360.00 $180.00 Student Discount

- The problem numerically simulates the Air Gap Membrane Distillation (AGMD) using ANSYS Fluent software.

- We design the 3-D model with the Design Modeler software.

- We mesh the model with ANSYS Meshing software.

- The mesh type is Structured, and the element number equals 344400.

- We define porous medium and heat sources in cell zone conditions.

- This simulation is validated with a reference article.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Description

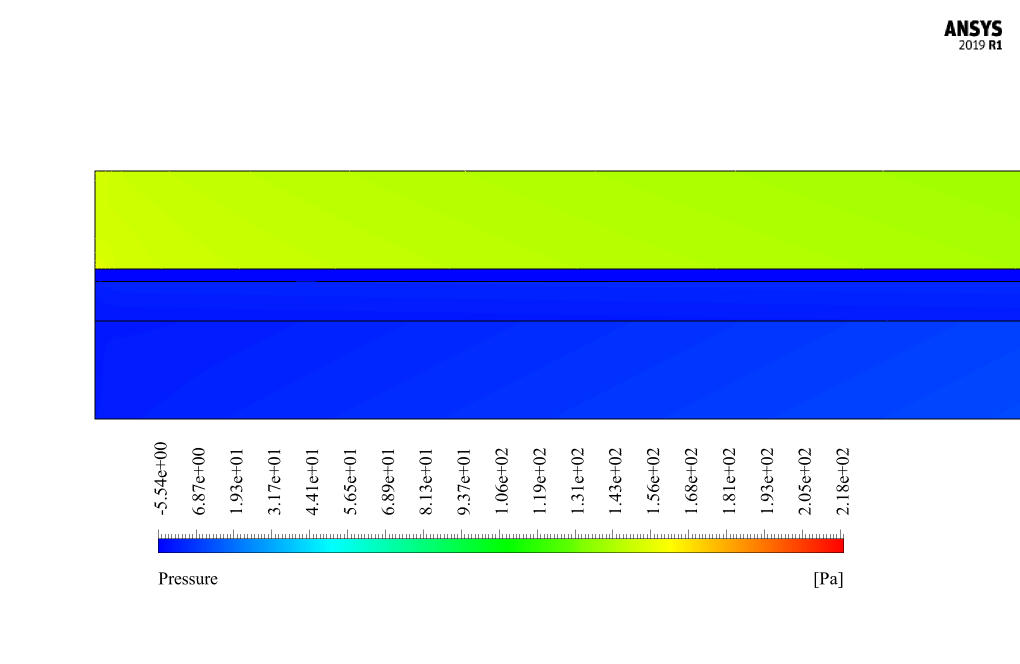

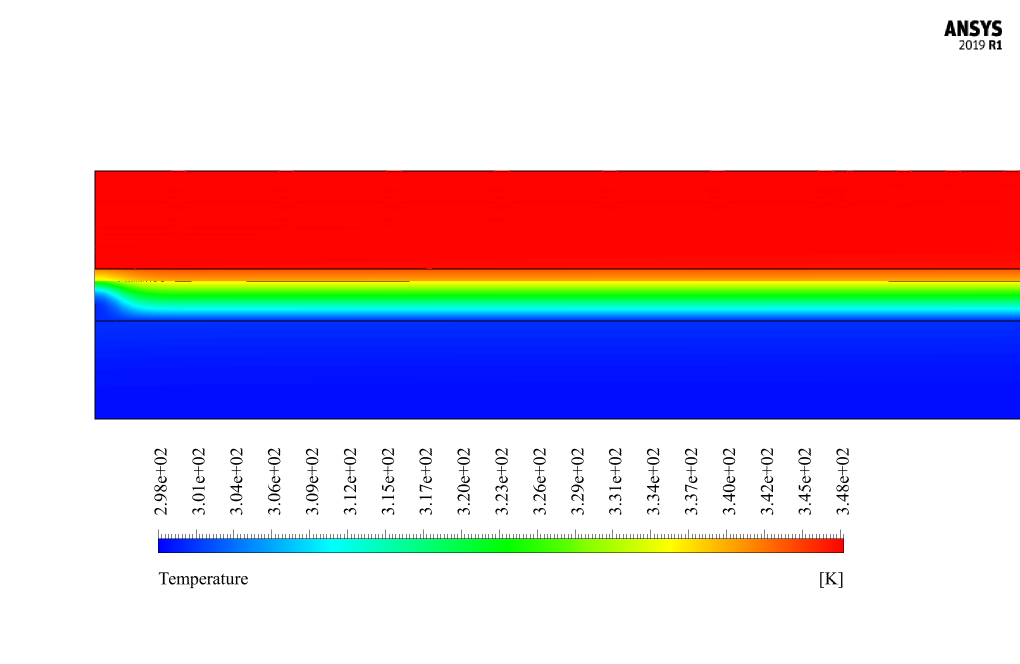

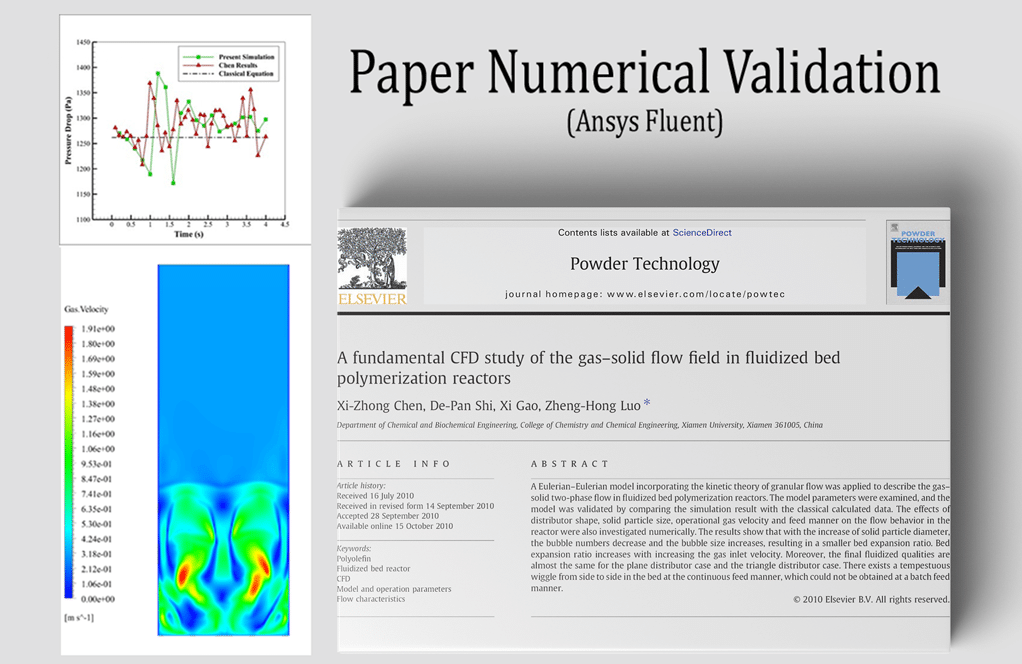

The present problem simulates the air gap membrane distillation (AGMD) by ANSYS Fluent software. This simulation is based on the data in the reference article “Numerical investigation of air gap membrane distillation (AGMD): Seeking optimal performance.”

Its results are compared and validated with the results in the article. The chamber of these membrane distillation systems is made of 4 different parts, including the space for the passage of saline water flow as the system feed water, the space for the passage of cold water flow, and the space for the air gap, and the space for membranes or filters.

It is installed between air and hot water. The working mechanism of these membrane distillation systems is such that the flow of hot salt water enters its chamber from one side, and the cold water enters it from the other side.

Eventually, these vapors collide with the cold surface of the space for the passage of cold water flow, and by losing their heat, they distill and turn into pure fresh water.

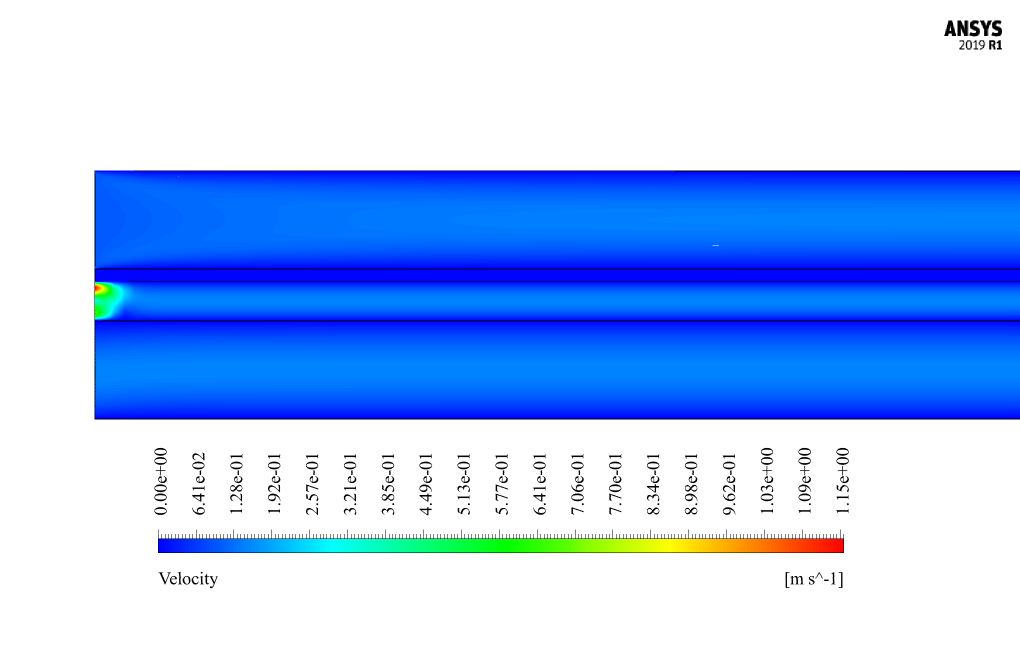

It is assumed that the water flow inside the model has a Reynolds equal to 100 and, consequently, the inlet velocity of the hot salt water flow, the airflow, and the cold water flow has an inlet velocity of 0.1 m/s; the direction of salt water flow is from left to right, and the direction of air and cold water flow is from right to left.

According to the functional mechanism of this system, heat is transferred from the space related to the flow of hot salt water to the membrane part of the model, and then the same amount of heat is transferred from the membrane part to the space for airflow.

The present model is drawn in 2 dimensions using Design Modeler software. The present model is rectangular and consists of four parts: hot salt water flow space, cold water flow space, air gap, and membrane as a porous medium.

The meshing has been done using ANSYS Meshing software, and the mesh type is structured. The element number is 344400, and boundary layer mesh is also used.

Air Gap Membrane Distillation Methodology

So that the membrane in the form of a filter and an air gap is placed in the space between these two streams, the saline feed water, passing through its common surface with its adjacent membrane, gives off its heat to the membrane environment and is converted to pure vapor inside the membrane.

This steam then passes through the porous medium and enters the air in the air gap with its high temperature. Also, the inlet temperature of salt water is equal to 348.15 K. The inlet temperature of air and cold water is equal to 298.15 K.

In the inner space of the membrane part of the model, water vapor is defined as a flowing fluid. Since the space for the membrane is filtered, a porous medium model is used, which is made of a material called PVDF with a porosity coefficient of 0.85.

Hence, the interface wall between the hot salt water flow and the membrane as a heat sink with a value equivalent to -62122.815 W/m3 (according to relationships 7 to 9 of the article) and the interface wall between the membrane and the airflow as a heat source with a value equal to +62122.815 W/m3.

In the current paper, several different materials are used to define salt water, pure water, water vapor, air, and a type of membrane (PVFD) whose properties include density, specific heat capacity, thermal conductivity, and viscosity.

| material | saline water | pure water | water vapor | air | PVFD |

| density (kg.m-3) | 1013.2 | 995.2 | 0.5542 | 1.225 | 1175 |

| specific heat (j.kg-1.K-1) | 4064.8 | 4182.1 | 2014 | 1006.43 | 1325 |

| thermal conductivity (W.m-1.K-1) | 0.642 | 0.613 | 0.0261 | 0.0242 | 0.2622 |

| viscosity (kg.m-1.s-1) | 0.000586 | 0.000838 | 0.0000134 | 0.000017894 |

Air Gap Membrane Distillation Conclusion

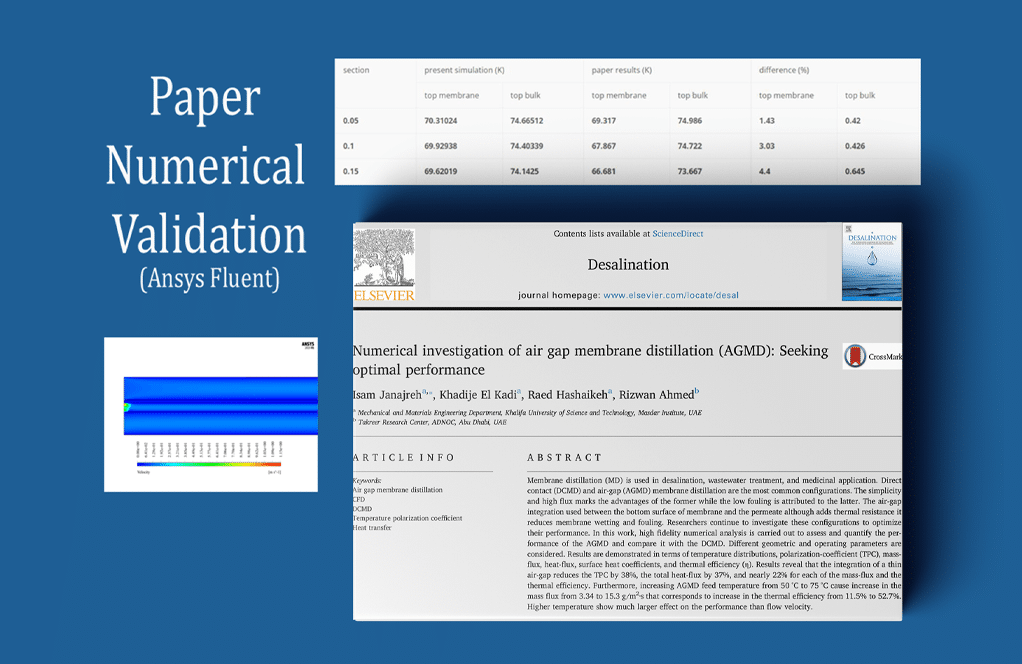

At the end of the solution process, the results of the present work were compared and validated with the results in the reference article. Thus, the results are validated by the diagram in Figure 12-c of the paper (in Reynolds mode equal to 100 and surface water temperature equal to 75 ° C).

For this purpose, the fluid bulk temperature in the passage of salt water flow space and the temperature of the upper wall of the membrane space in three different sections, including 0.05 m, 0.10 m, and 0.15 m, are obtained.

To obtain the temperature, the REPORT command is used, and also lines and points are created in the three mentioned sections. The comparison of the results of the present work with the article is shown in the table below.

| section | present simulation (K) | paper results (K) | difference (%) | |||

| top membrane | top bulk | top membrane | top bulk | top membrane | top bulk | |

| 0.05 | 70.31024 | 74.66512 | 69.317 | 74.986 | 1.43 | 0.42 |

| 0.1 | 69.92938 | 74.40339 | 67.867 | 74.722 | 3.03 | 0.426 |

| 0.15 | 69.62019 | 74.1425 | 66.681 | 73.667 | 4.4 | 0.645 |

Also, at the end of the solution, two-dimensional counters of temperature, pressure and velocity were obtained.

Vilma Roberts –

The training clearly represents complex CFD concepts very well. This air gap membrane distillation simulation helped me to grasp the underlying mechanisms and causes of distillation efficiency I’ve been trying to interpret. Thanks for such a detailed explanatory session and practical demonstration!

MR CFD Support –

We’re delighted to hear that our Air Gap Membrane Distillation (AGMD) training has effectively clarified the complex concepts for you. It’s rewarding for us to know that the detailed explanations and hands-on demonstrations were helpful in understanding the distillation efficiency. Thank you for taking the time to share your positive experience, and we appreciate your kind words!

Durward Lockman –

The AGMD simulation ultimately produces some discrepancies in temperature readings when compared with the reference paper. What specific measures does MR CFD Company employ in their training to ensure the reduction of such discrepancies in future simulations?

MR CFD Support –

In our training, we focus on teaching proper setup techniques for simulations, including fine-tuning mesh density, accurate material property definition, and advanced boundary condition applications to reduce discrepancies in computed CFD results. Furthermore, our lessons cover verification and validation processes to help learners understand the importance of comparing simulation results with experimental or reference data and the methods to adjust their models to align with real-life findings.

Mrs. Edwina Blick –

Fantastic training! The comparison table and the thorough explanation made it easy to understand the validation process. Well done MR CFD!

MR CFD Support –

Thank you for your kind words! We are thrilled to learn that the course materials and the validation process were clear and helpful to you. We strive for that level of excellence in all our training products.

Dr. Maci Murphy –

I really appreciate the detailed setup shared from the AGMD simulation using ANSYS Fluent. The comparison of results between the simulation and reference paper is extremely insightful. This exemplifies how crucial accurate numerical validation is in CFD studies. Well done on the highly detailed training content!

MR CFD Support –

Thank you very much for your positive feedback. It’s our goal to provide detailed and accurate simulations that align with respected publications for our learners. We are glad to hear that the content met your expectations and helped you appreciate the importance of numerical validation in CFD. Should you have any more insights or require further learning material, please feel free to reach out to us.

Mrs. Estefania Sporer MD –

The training goes into excellent detail and technical depth, allowing not only for a clear understanding of MD processes but also how to set up and simulate them using ANSYS Fluent. The comparison to the academic paper is especially valuable for validating the simulation accuracy.

MR CFD Support –

Thank you for your positive feedback! We are thrilled to hear that you found our ANSYS Fluent training for Air Gap Membrane Distillation not just informative, but also practical with a robust validation aspect. We strive for our customers to achieve accuracy in their simulations that can stand up to academic scrutiny. Your appreciation motivates us to continue delivering high-quality learning experiences.

Bert Padberg DDS –

I’m ASTONISHED by how accurately the results from the AGMD simulation aligned with those of the reference article. The effort put into capturing the fine details is genuinely commendable!

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear that you’re impressed with the accuracy of our ANSYS Fluent training simulation for the AGMD process. We always strive to provide precise and detailed simulations for our users. Your feedback is greatly appreciated!