Fluidized Bed Reactor with Reaction CFD Simulation Training

$200.00 Student Discount

- The problem numerically simulates Fluidized Bed Reactor with Reaction using ANSYS Fluent software.

- We designed the model with the Design Modeler software.

- We mesh the model with ANSYS Meshing software, and the element number equals 938,174 .

- The Eulerian Multi-Phase model was used to simulate the solid particles.

- Species transport model was used to model the reaction.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Description

This simulation is about a fluidized bed polymerization reactor via ANSYS Fluent software. We perform this CFD project and investigate it by CFD analysis. A reactor is a device for performing chemical reactions (conversion, composition, decomposition, etc.) using catalysts and, as a result, the conversion of raw materials into desired products.

The fluidized bed-type reactor has advantages such as a high heat transfer rate and high mass transfer rate, lower heat transfer surface, uniform temperature distribution, proper temperature control, and complete and rapid mixing of reactors and catalysts.

Based on our previous project we have validated the results of a fluidized bed reactor with the numerical investigation, now we have investigated full reactions inside our reactor and the results have compared to the model without reaction

The gas flow enters vertically and upwards at a speed of 0.3 m/s, while no solid particles enter the reactor. The present study investigates the behavior of suspended solid particles in the gas flow over time and the pressure drop generated from the reactor inlet to the outlet.

The geometry of the present model is drawn by Design Modeler software. The model is then meshed by ANSYS Meshing software. The model mesh is unstructured, and 938174 cells have been created.

Fluidized Bed Method

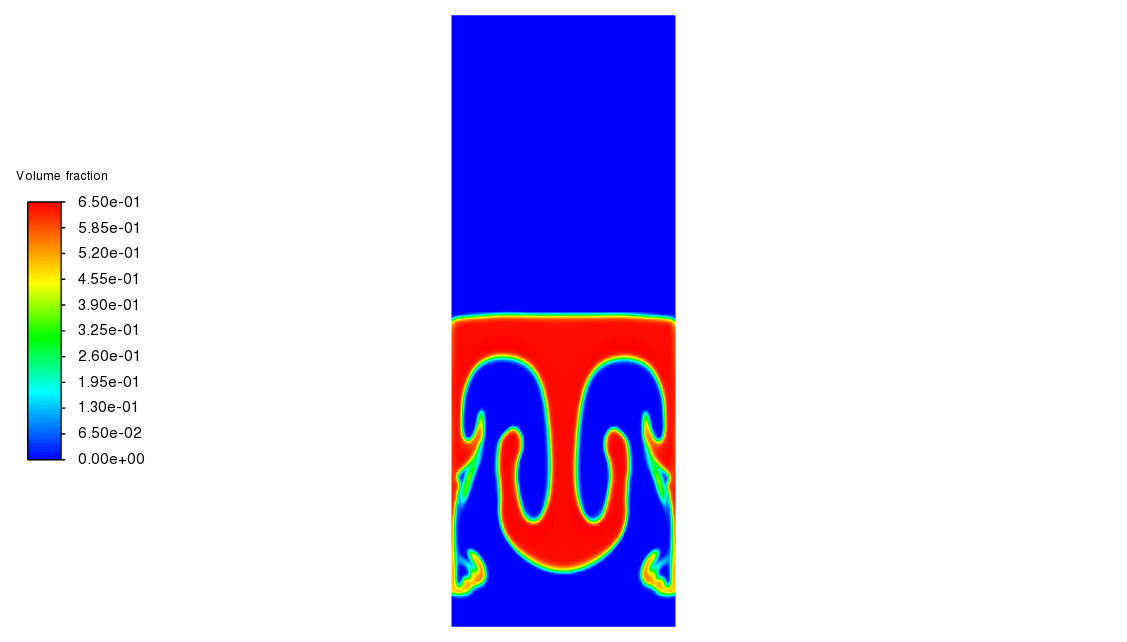

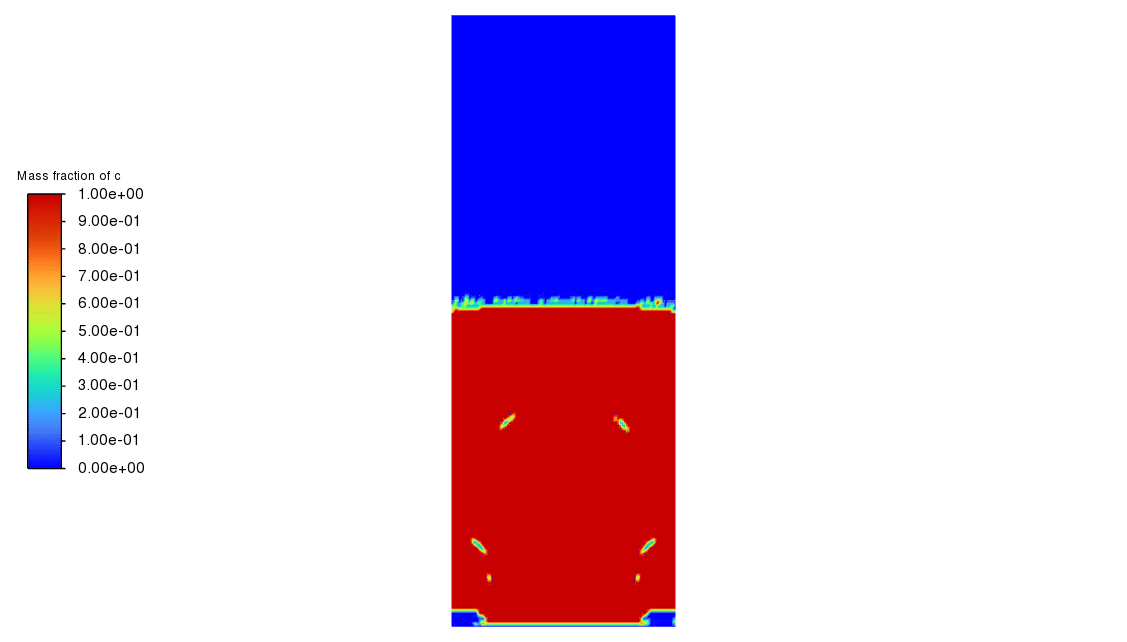

Since the performance of reactors is inherently based on the mixing of flows and particles as reactants and catalysts in the chemical reaction process, a multi-phase model has been used to define the fluid flow within the model.

Also, considering the present model is related to simulating the suspension of solid particles within a fluid flow like a fluidized bed model, choosing the Eulerian multi-phase flow model is the most appropriate option.

Therefore, the model includes a gas flow defined as the primary phase and suspended solids defined as the secondary phase. The present model is unsteady; because the model’s nature is such, the behavior of the particles in the model changes over time. The simulation process was performed for 4 s with a time step of 0.001 s. for the reactions we have species transport which reacts with the eulerian phase.

Fluidized Bed Conclusion

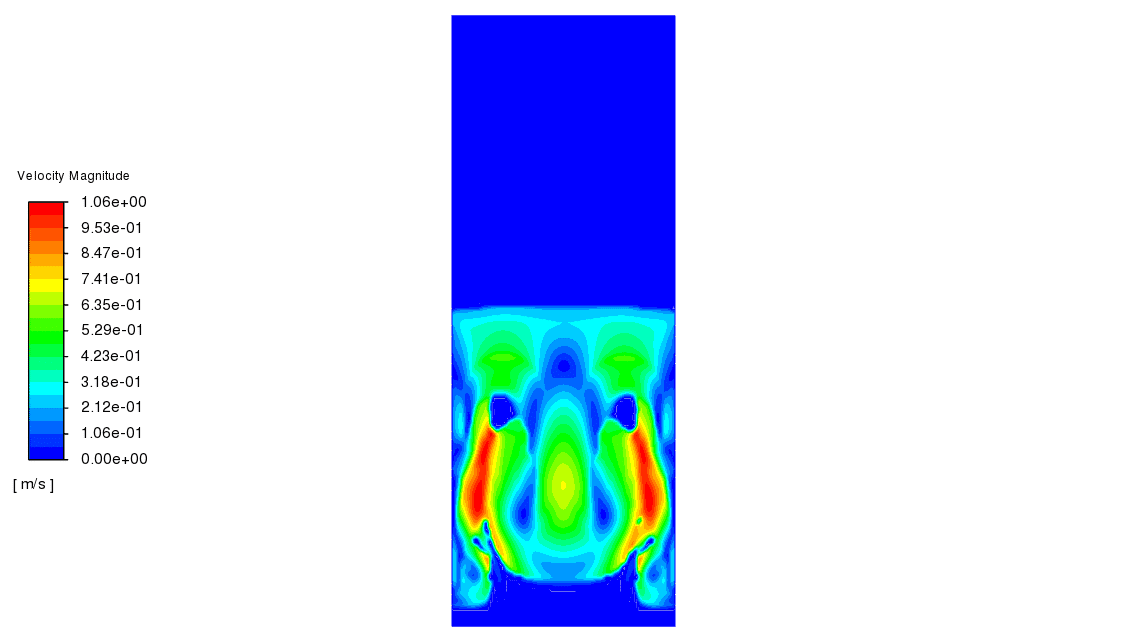

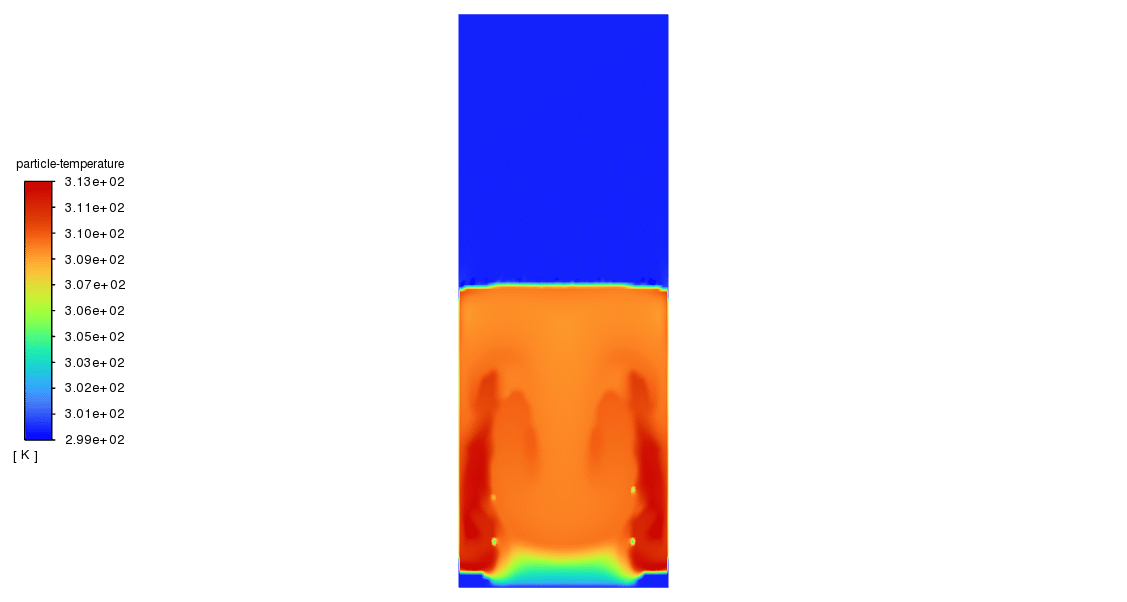

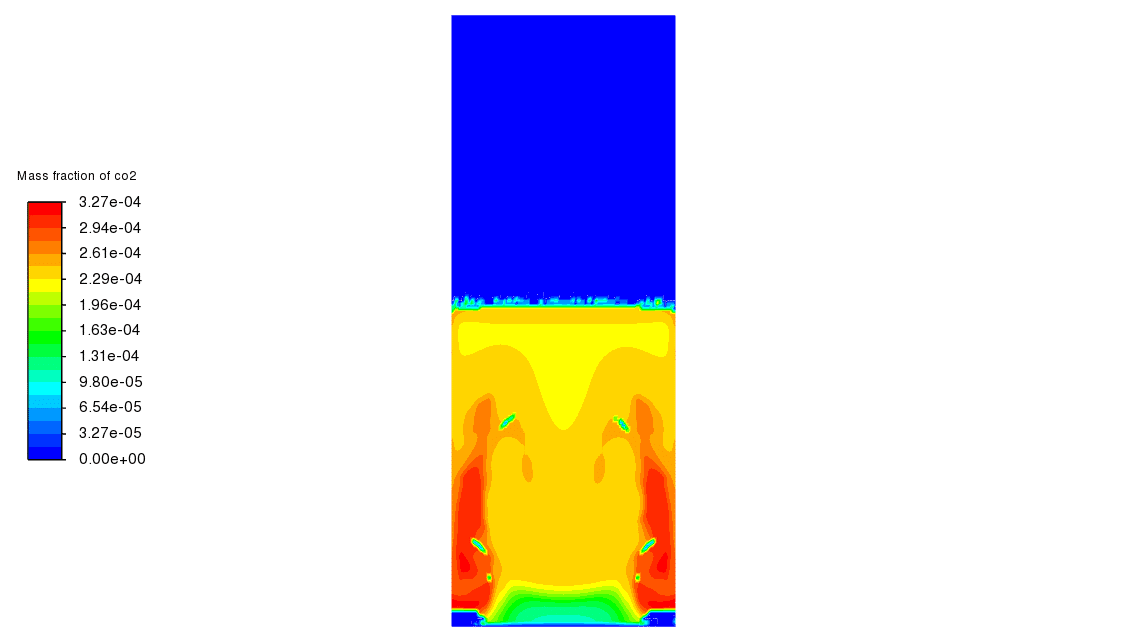

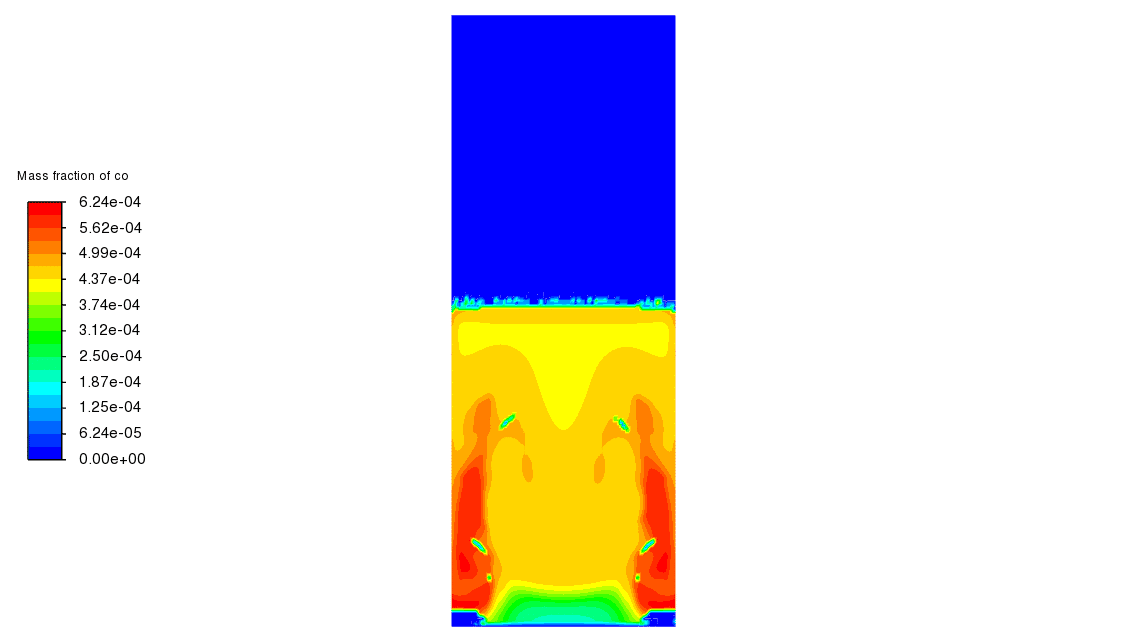

After simulation, two-dimensional contours related to the mixture pressure, gas flow velocity and suspended solids, and volume fraction of the gas flow and solid suspended particles from zero to one second are obtained.

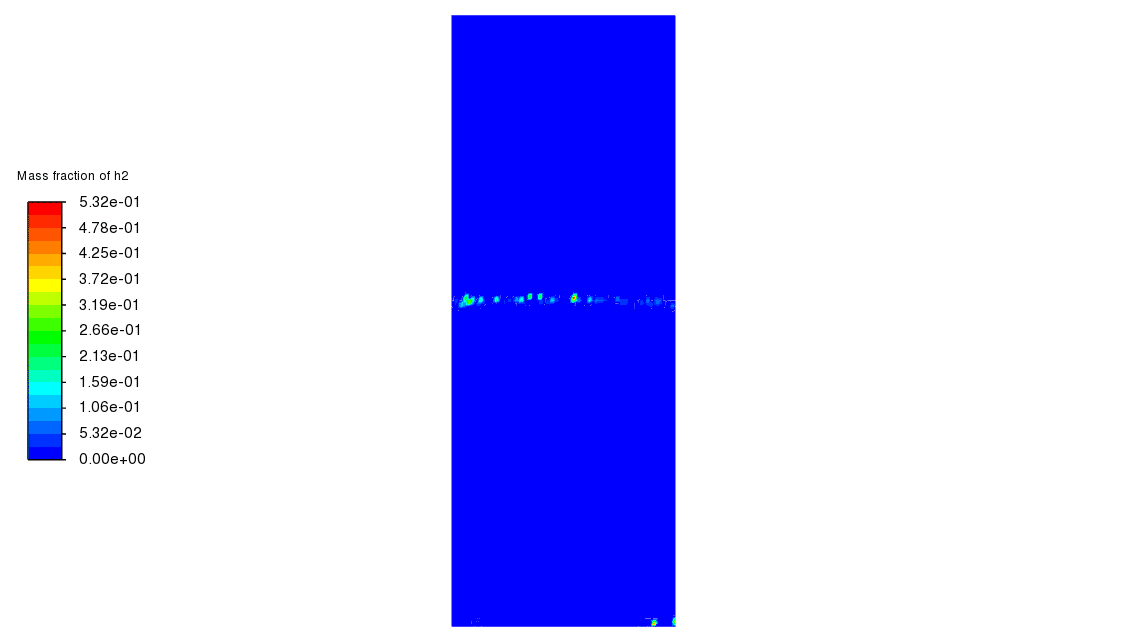

Because of our previous simulation now our focus is on the reactions, the temperature rise due to the reactions is visible and by monitoring the species generated due to the reactions, you can see the cycle of the reactions and species present in the domain in the limited time.

Vita Brown II –

I’m curious about the initial conditions for the fluidized bed simulation. What was the initial volume fraction of the suspended solid particles?

MR CFD Support –

In the simulation setup for the fluidized bed reactor, the initial volume fraction of the suspended solid particles needs to be prescribed before starting the simulation. This ensures the physical accuracy and proper initialization of the multi-phase flow dynamics. Typically, an initial guess informed by experimental data or prior simulations is used as the starting condition. For the specifics in this learning product, refer to product documentation or support for precise values.

Rowan Crist –

Is this fluidized bed reactor simulation only applicable for polymerization reactions, or can it be used for other chemical reactions as well?

MR CFD Support –

The simulation process and methodology described here are specific to fluidized bed polymerization reactors, but the fundamental principles can be applied to other chemical reactions as well. By adjusting the input parameters and reaction kinetics, the CFD model can be adapted to simulate different reactions within a fluidized bed reactor, making the simulation versatile for various chemical processes.

Fern Franecki –

The reactor simulation is fascinating. However, can you share insights or images regarding how temperature and species concentration change over time due to chemical reactions?

MR CFD Support –

Glad to hear that you find the reactor simulation insightful! Absolutely, the simulation provides time-dependent results that showcase shifts in both temperature and species concentration as a result of the chemical reactions taking place. Unfortunately, I can’t show images here, but I can confirm that ANSYS Fluent effectively visualizes these dynamic changes with detailed temperature contours and species concentration profiles over time, giving you a clear indication of the reaction progress and efficiency.

Morton Dickinson –

This Fluidized Bed Reactor simulation seems comprehensive. Can you elaborate on how the gas-solid reactions are modeled within ANSYS Fluent, particularly within the context of the species transport model?

MR CFD Support –

In the Fluidized Bed Reactor simulation with ANSYS Fluent, the gas-solid reactions are modeled using the species transport model, where we define multiple species and their reactions. The Eulerian multiphase approach models the solid particles as a secondary phase with its own volume fraction. Reactions between the gas and solid phases are set up using predefined reaction mechanisms where reactants, products, and reaction rates are specified. Each reaction takes into account the local concentration of the species and the temperature, allowing for the accurate calculation of the reaction rates and the resulting product distribution over time.

Dayne Dare –

I was thrilled with the fluidized bed reactor simulation training! The detail on the behavior of particles and the visualization of temperature changes due to reactions were superb. It was especially interesting to see the cyclic nature of the reactions and species presence. Keep up the great work!

MR CFD Support –

Thank you for your kind feedback! We’re glad to hear you found the training on the fluidized bed reactor informative and that the visualizations enhanced your understanding. Your appreciation means a lot to us, and we’ll continue to provide high-quality simulations and training. If you have more queries or need further assistance, feel free to reach out!

Elise Stehr –

I had a fantastic learning experience with the Fluidized Bed Reactor with Reaction CFD Simulation training! The complex interactions between the fluid flow and suspended particles were illustrated clearly through the simulations, making the concepts much easier to understand.

MR CFD Support –

We’re delighted to hear that you enjoyed the Fluidized Bed Reactor with Reaction CFD Simulation training and that it aided in your understanding of the reactor dynamics. It’s great to know that the detailed simulations helped clarify the intricate interactions between the fluid and particles. Thank you for sharing your positive experience with us!

Mr. Israel Zieme –

What do the results provide in terms of the impact of reactions in the fluidized bed?

MR CFD Support –

The results showcase the dynamics of chemical reactions in the fluidized bed reactor by demonstrating temperature variations due to exothermic or endothermic reactions, as well as providing detailed information on the concentration of species, both reactants, and products, throughout the reactor space over time. This insight allows us to observe the cycle of the chemical reactions and effectively analyze the performance of the fluidized bed reactor with and without engaging in the chemical reaction process.

Serena Tillman Jr. –

I’ve really enjoyed learning how fluidized bed reactors work through this practical CFD simulation training! It was fascinating to see how minute variances in parameters affect the reaction processes and particle suspension within the reactor. The visualizations provided clear insights into the complexities of reactor behaviors. Overall, an excellent resource for gaining a deeper understating of chemical engineering principles in action!

MR CFD Support –

We’re thrilled to hear that our Fluidized Bed Reactor CFD Simulation Training has significantly contributed to your understanding. We always strive to provide clear visualizations and comprehensive details, and your feedback validates our efforts. Thank you for taking the time to leave a positive review!

Prof. Mack Daniel II –

Can you explain what species transport with reactions in the Eulerian phase entails in this simulation?

MR CFD Support –

Sure, species transport with reactions in the Eulerian phase involves the tracking and calculation of the concentrations of different chemical species within the multiphase flow. During the simulation of the fluidized bed reactor, this means the interactions and consumption or production of species due to chemical reactions are considered for both the gas (primary) phase and the suspended solid (secondary) phase. The species transport model is coupled with the Eulerian multiphase model to predict these reactions within the reactor.

Rocio Russel Jr. –

The training program seems detailed, but does it include any tutorials for understanding the tuning of parameters involved in the reaction kinetics for the fluidized bed reactor?

MR CFD Support –

The training program includes comprehensive guidance on setting up and solving the CFD simulation of a fluidized bed reactor. However, for detailed insights on tuning reaction kinetics parameters, you can refer to our advanced modules or consult with our experts for personalized assistance.

Mrs. Penelope Stiedemann –

Would it be possible to use this simulation to assess the performance of different catalysts?

MR CFD Support –

Certainly, this simulation allows for the variation of parameters including the type of catalyst used, which means you can assess the performance of different catalysts using the model. Just ensure that the physical and chemical properties of the catalysts are accurately inputted into the software.

Flavie Runte –

What makes the Eulerian multi-phase model suited for simulation of a fluidized bed reactor?

MR CFD Support –

The Eulerian multi-phase model is well-suited for simulating a fluidized bed reactor because it allows for the detailed representation of the interaction between multiple phases. In the case of fluidized beds, the solid catalyst particles are a secondary phase suspended within the primary gas flow phase. This model can capture the dynamic behavior of the particles as they are fluidized by the gas flow, including the mixing and mass transfer processes necessary to accurately simulate a fluidized bed reactor.

Prof. Maximus Goldner –

I’m interested in the temperature control aspect. How is the temperature within the fluidized bed reactor maintained uniform throughout the simulation process?

MR CFD Support –

The uniform temperature distribution in fluidized bed reactors is achieved through the high rates of heat and mass transfer due to the fluidization. In the simulation, temperature is controlled by carefully setting boundary conditions and reactor design parameters, which put together engender an environment conducive to efficient heat transfer, inherently enabling a uniform temperature result throughout the simulations. The use of appropriate models to simulate the heat transfer characteristics of both the gas and solid phases is key, and checking temperature contours ensures it remains uniform.

Adan DuBuque –

The information was really comprehensive, and it helped grasp the concept of how a fluidized bed reactor works in a CFD context. However, are there tutorials or step-by-step guidelines included in the training to help replicate the project or understand how to set up my own simulations?

MR CFD Support –

Yes, our training materials include detailed tutorials and step-by-step guidelines that will help you replicate the project on your own. We ensure you understand every aspect of setting up the simulations, from geometry creation to interpreting the results.

Mr. Rex Schaden –

The training material seems very in-depth. Could you tell me more about how the species transport model was integrated with the Eulerian multi-phase model for reacting flows?

MR CFD Support –

In the Fluidized Bed Reactor CFD Simulation Training, the integration of the species transport model with the Eulerian multi-phase model enables the simulation of chemical reactions within the fluidized bed. This setup takes into account the distribution of reactants and products across different phases. The species transport model accounts for the chemical species involved in the reactions and their transportation due to convection and diffusion. Coupled with the Eulerian multi-phase model, this allows for a detailed analysis of reaction kinetics and the effect of the multi-phase flow dynamics on the progression of chemical reactions within the reactor.

Ottilie Schinner –

Was the heat generation from the reactions taken into account for the simulation and how does it affect the reactor operation?

MR CFD Support –

Yes, the heat generation from the chemical reactions was taken into account for the simulation. It is a critical aspect of the process, affecting the temperature distribution within the reactor and, consequently, the reaction rates, product formation, and operational safety. The heat generated can cause temperature gradients, can be used to control reaction rates, and may require additional cooling or heating systems to maintain optimal reactor operation.

Noe Orn –

The explanation is quite technical, but I am curious, what kind of polymer products were studied in the simulation and how does that relate to the reactor’s efficiency?

MR CFD Support –

In this simulation, we focus on the polymerization reaction within a fluidized bed reactor without specifying a particular polymer product. The reactor’s efficiency is gauged by analyzing suspension behavior, pressure drop, temperature changes, and the reaction cycle over time. For specific polymer products, different parameters and reaction schemes would be investigated.

Prof. Juwan Berge DVM –

Is there a mechanism in place to track and analyze the specific polymer reactions occurring in the fluidized bed reactor simulation?

MR CFD Support –

For tracking and analyzing the specific polymer reactions in the fluidized bed reactor simulation, a species transport model is utilized, coupled with the Eulerian multiphase flow model. This allows us to monitor the reaction cycle and the species generated as a result of the reactions over the simulation time.