Vortex Combustion Chamber CFD Simulation, ANSYS Fluent Tutorial

$140.00 Student Discount

- The problem numerically simulates the Vortex Combustion Chamber using ANSYS Fluent software.

- We design the 3-D model and then mesh it with Gambit software.

- The mesh cells equal 757886.

- We use the Species Transport model to define a combustion reaction.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Description

In this project, a combustion reaction is simulated inside a vortex combustion chamber by ANSYS Fluent software.

Combustion is the result of a chemical process between combustible material and an oxidizing agent that is associated with the production of heat and the chemical change of raw materials in a combustion chamber.

Heat can be released by producing light in the form of a flame or a glow. Fossil fuels are usually made of organic compounds in the form of gases, liquids, or solids.

As mentioned above, burning is a type of oxidation reaction. However, due to the high speed of the combustion reaction, which leads to the production of a high amount of heat in a short time, the increase in the ambient temperature, and the creation of light and flame, it falls into a special category.

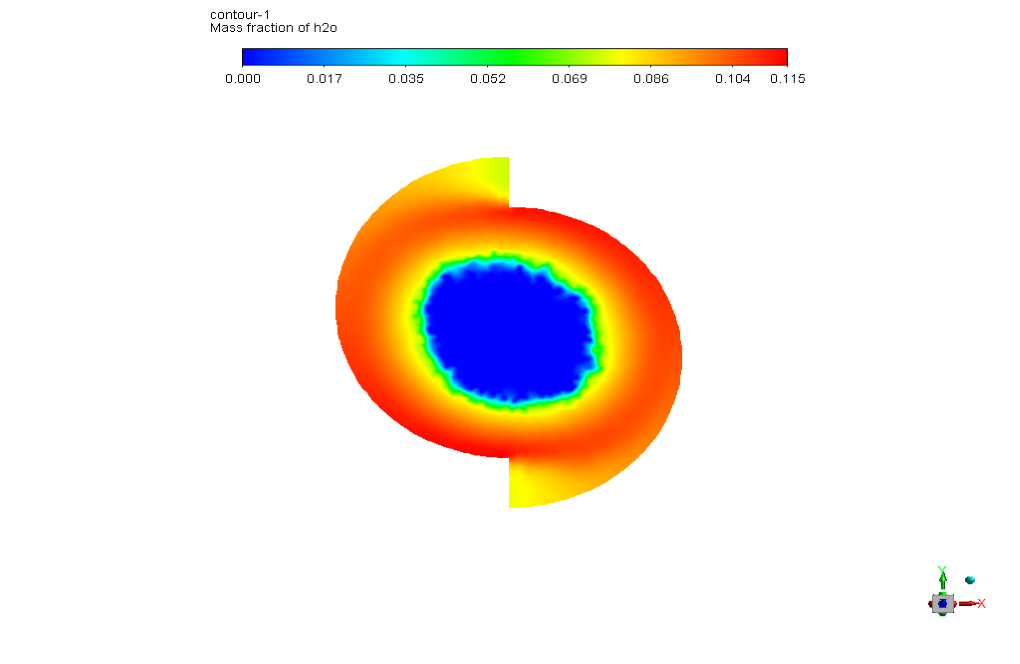

The vortex combustion chamber is a new generation of liquid fuel internal combustion engines in which, a whirlpool flow is created with a different arrangement of injectors.

This whirlpool helps to cool and increase the mixing of propulsion components in the combustion chamber, and complete combustion can be reached in smaller volume chambers.

The geometry of this project is designed and meshed inside GAMBIT®. The mesh type used for this geometry is unstructured and the total element number is 379535 cells.

Vortex Methodology

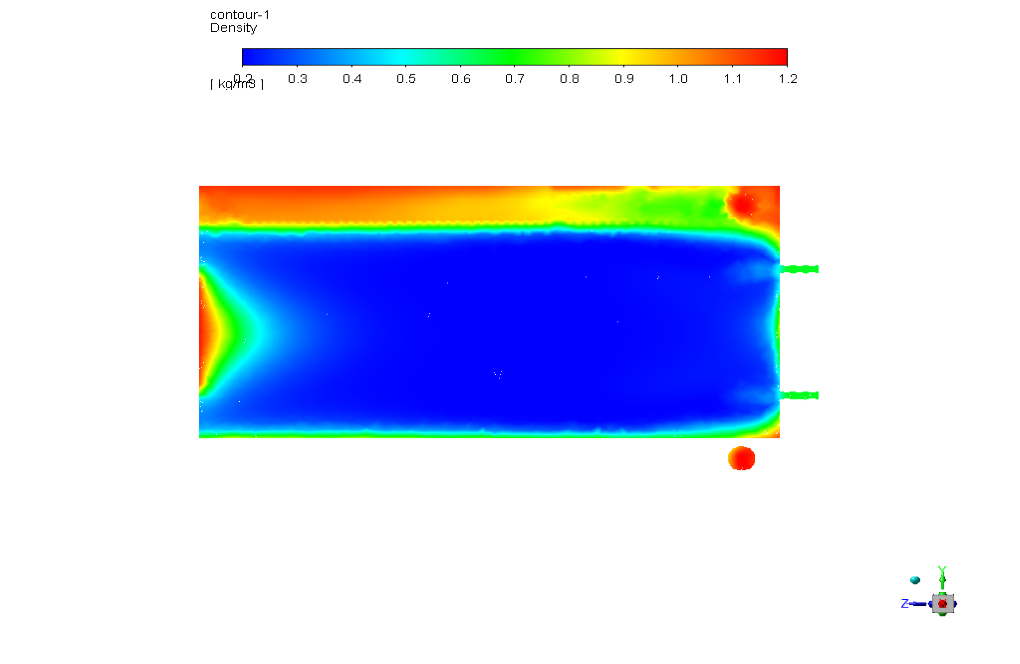

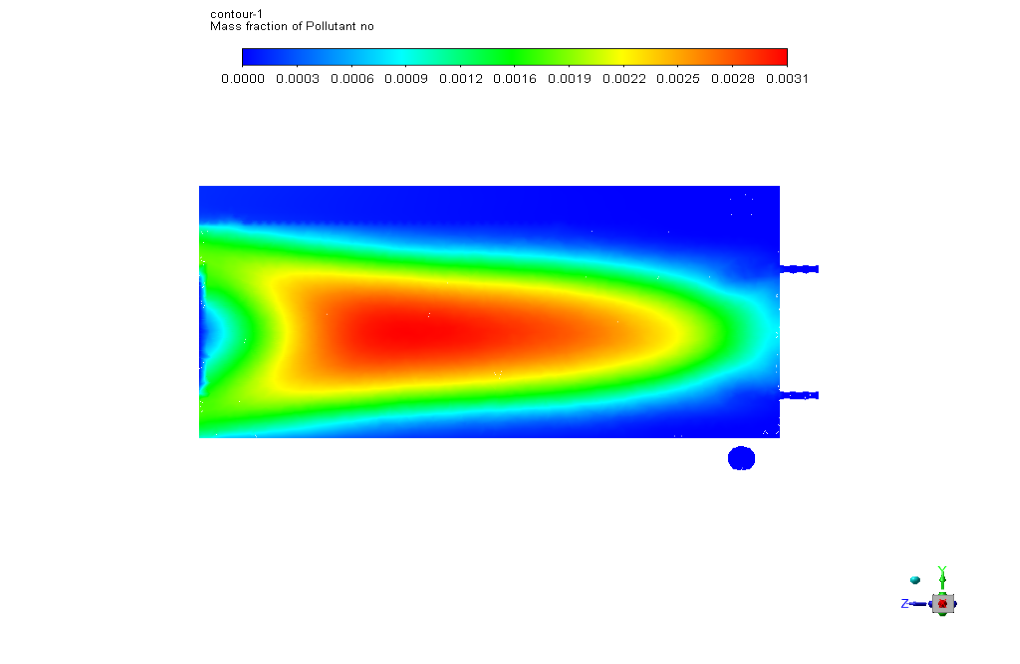

The species transport model is used to analyze the combustion process. A mixture of air and methane is used as the fuel mixture. Eddy-Dissipation method has been used to investigate the chemical-turbulent interaction of combustion reactants and the NOx anticipation model is activated and the Temperature method is used for Turbulence Interaction mode. The ideal gas equation has also been used to determine the density changes due to changes in temperature.

Vortex Conclusion

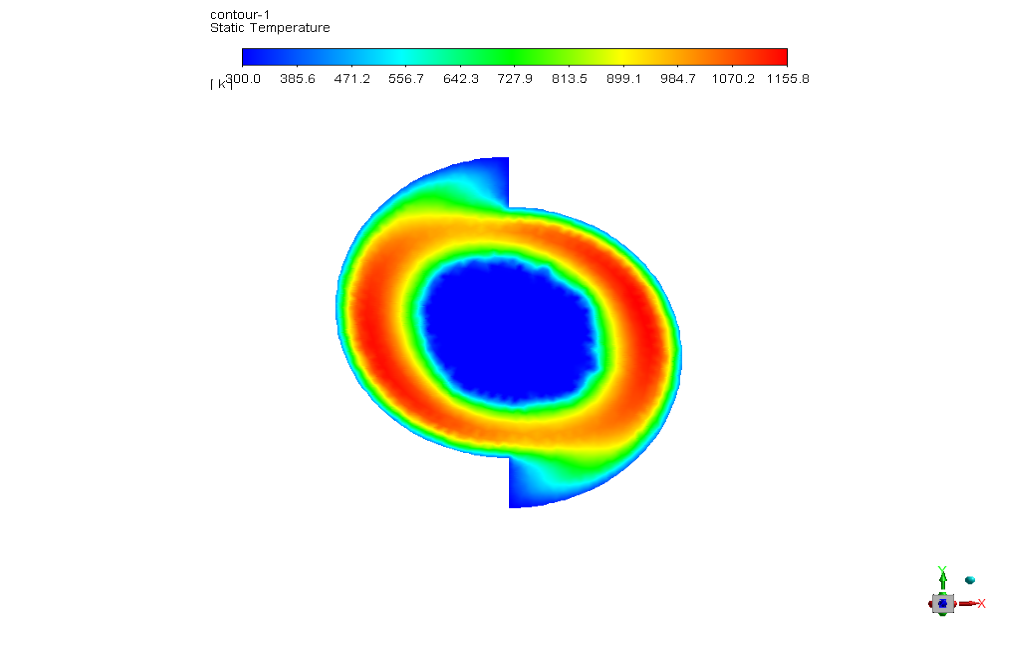

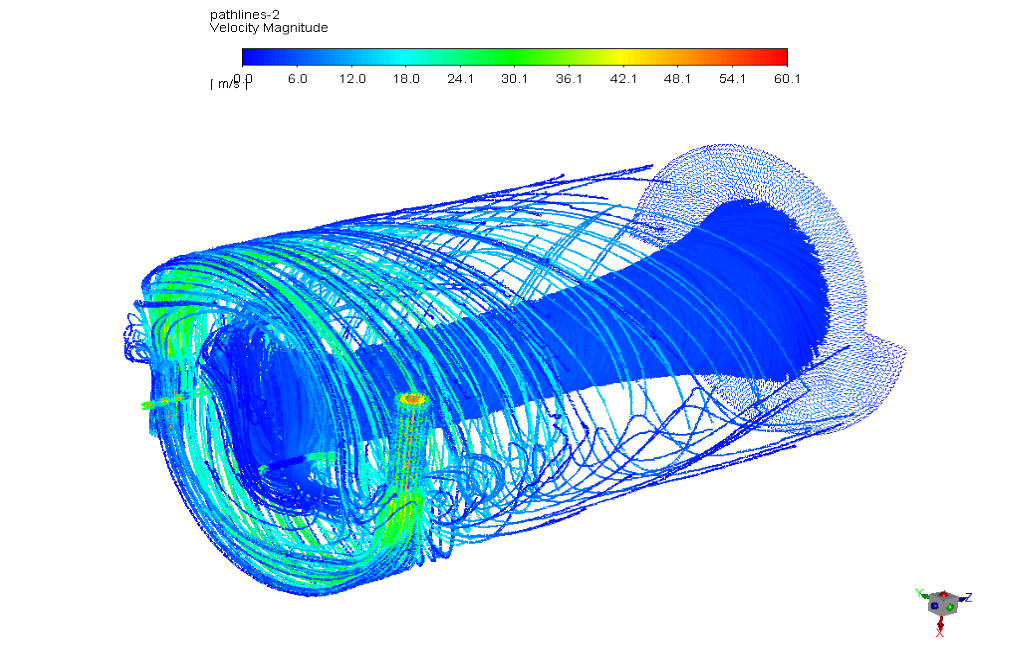

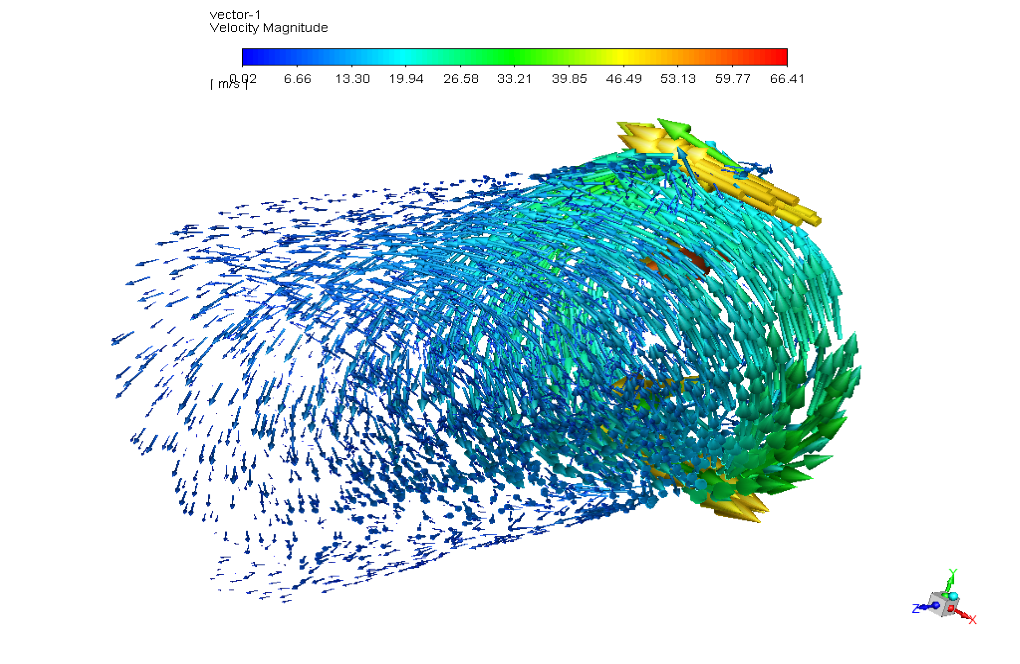

Different contours of velocity, pressure, temperature, species mass fraction, etc. are presented in 3D and 2D. As can be seen from the contours, the combustion flame is well formed and the temperature changes caused by the combustion are well visible.

The vectors also show that the flow turbulence in this problem is very high. The contours show that this indicates that the performance of this combustion chamber has been simulated correctly.

Camila Lindgren –

how does the simulation figure out the liquid dance in the combustion chamber?

MR CFD Support –

Well, the simulation has a pretty solid fluid dynamics model. It’s really good at catching how the fluid moves around in the combustion chamber, even when it starts doing the twist and turn thing, you know, creating vortices.

Dr. Agustin Wuckert Sr. –

So, how’s the simulation dealing with the nasty stuff released during combustion?

MR CFD Support –

Well, the simulation has got this cool model that really nails down how much of the bad stuff gets out during combustion. It’s super important for understanding how well the combustion chamber is doing its job.

Humberto Kuphal I –

Can the simulation model the effect of different types of fuel on the combustion process?

MR CFD Support –

Yes, the simulation can be adjusted to model different types of fuel, which can significantly affect the combustion process and the performance of the combustion chamber.

Carroll Becker –

This vortex combustion chamber simulation seems complex. Could you tell me which models were selected to simulate the chemical reactions and turbulence within the chamber?

MR CFD Support –

In the vortex combustion chamber simulation using ANSYS Fluent, the ‘species transport model’ is used to analyze the combustion process. To model the chemical-turbulent interaction of the combustion reactants, the ‘Eddy-Dissipation method’ is utilized. Additionally, the ‘Temperature’ method is selected for the Turbulence Interaction mode. The ‘NOx prediction model’ is also activated to anticipate nitrogen oxide formations. And to account for density changes due to temperature variations, the ‘ideal gas equation’ is applied.

Kaylee Rodriguez –

I’m very interested in the combustion simulation process. Could you explain how the Eddy-Dissipation method is applied in this scenario to model the chemical-turbulent interactions?

MR CFD Support –

The Eddy-Dissipation method utilized in the combustion simulation models the chemical reactions and turbulence interactions based on the concept that the reaction rate is limited by the mixing process. It operates on the assumption that the small, turbulent eddies in the flow are responsible for bringing the reactants together. This method considers the microscopic mixing timescales and compares them with the chemical kinetic timescales to determine the reaction rate. In the scenario of the vortex combustion chamber, the inputs necessary for the model, like the molecular diffusivity and the rate of dissipation of the turbulent kinetic energy, enable the simulation to predict the combustion process more accurately within high-turbulence flow fields.

Raphael Howell Jr. –

I was impressed by the CFD simulation of the vortex combustion chamber. The visualization of temperature changes and combustion flame formation helped me understand the mechanics at play. Excellent tutorial for grasping the complexities of vortex dynamics in combustion processes.

MR CFD Support –

Thank you for your positive review! We’re delighted to hear that the tutorial on the vortex combustion chamber CFD simulation was helpful for your understanding. It’s great to know that the visualizations effectively illustrated the complex dynamics in such processes. Your feedback is greatly appreciated.

Dr. Gerhard O’Kon –

How does the simulation model the combustion process in the vortex combustion chamber?

MR CFD Support –

The simulation uses a detailed combustion model that accurately captures the combustion process in the vortex combustion chamber, including the chemical reactions and heat release.

Haven Wolf –

I am pleased with the robust and complex details of the internal flow within the combustion chamber. However, can you explain a little more how the computationally predicted temperature and pressure profiles within the chamber assist in improving chamber design to ensure complete combustion?

MR CFD Support –

Thank you for your positive remarks on our tutorial. The predicted temperature and pressure profiles generated from the CFD analysis are crucial for understanding the thermal and fluid dynamics within the combustion chamber. These profiles help in identifying the regions of high temperature and pressure, which are essential for complete combustion of the fuel mix. Designers use this information to optimize the injector angles, chamber shape, and the size of the chamber ensuring that there is efficient mixing of fuel and oxidizer, adequate residence time, and appropriate temperature for the combustion reaction to proceed to completion. Studying these profiles also helps in reducing the formation of unwanted emissions, maximizing energy output possibly influencing the selection of materials to withstand the high temperatures.

Rashad Johnston –

How does the simulation handle the emission of pollutants from the combustion process?

MR CFD Support –

The simulation includes a model that accurately captures the emission of pollutants from the combustion process, which is a critical aspect of the performance of the combustion chamber

Miss Clotilde Bernhard –

I must say, the results of the simulation are quite impressive! Could you tell me more about the eddy-dissipation method and how it was crucial in predicting the interaction of chemical and turbulent features during combustion?

MR CFD Support –

Thank you for your positive feedback on the simulation results! The Eddy-Dissipation method is essential in combustion modeling as it accounts for the interactions between the turbulent eddies and chemical reactions. It makes the assumption that the reaction rate is controlled by the turbulent mixing. Therefore, it allows us to accurately capture the combustion characteristics which in turn result in realistic simulation of temperature, flame propagation, and species concentration within the vortex combustion chamber. If you have any further inquiries, feel free to ask!

Dr. Makenna Tremblay –

The tutorial was really illuminating regarding the species transport model. The attention to detail laid out step by step made it easier to comprehend the combustion process in a vortex chamber. I especially appreciate the visual representations through the various contours; made it really come alive for me.

MR CFD Support –

Thank you for your feedback! We’re delighted to hear that our tutorial was helpful and that the visual representations added value to your understanding of combustion in a vortex chamber. If you have any further questions or need more assistance with your CFD learning journey, feel free to reach out.