Heat Exchanger with Baffle Cut and Mixture Nano Fluid

$140.00 Student Discount

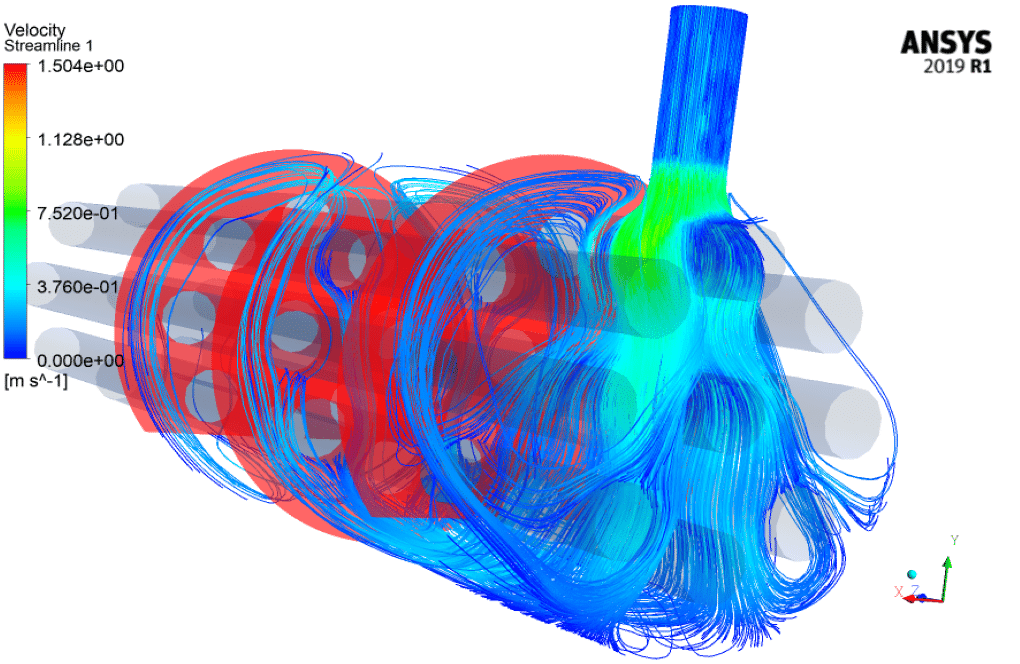

- A Shell and tube heat exchanger applying a Nanofluid is simulated by ANSYS Fluent software.

- 3-D Geometry is designed by Design Modeler software. The Heat exchanger was designed with a volume of 450,980 elements by ANSYS Meshing software.

- In order to model the Nano Fluid, a multi-phase model using the Mixture method was used.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Shell and Tube Heat Exchanger with Baffle Cut and Mixture Nano Fluid by ANSYS Fluent

Nano Fluid Influence on Shell and Tube Heat Exchanger Efficiency

A Shell and tube heat exchanger with baffle cut applying a Nanofluid is simulated by ANSYS Fluent software.

Heat exchangers have a wide range of applications in power generation, chemical and food industries, electronics, environmental engineering, heat dissipation, manufacturing, ventilation, refrigerators, space industries, and more. There are many ways to improve the thermal properties of a heat exchanger. These include creating plates to increase heat transfer, vibration, and the use of microchannels. Thermal efficiency can also be increased by increasing the conductivity of the working fluids. Fluids commonly used in industry, such as water, ethylene glycol, motor oil, etc., often have lower conductivity than solids. Solids can be used to improve performance in the form of solid particles (nanoparticles) added into the fluid and make a Nano Fluid. On the other hand, these particles can also cause scavenging or blockage of the channels or their corrosion, which itself has the potential to increase the conduction coefficient in order to increase efficiency.

Many materials can be used as nanoparticles. Since the thermal conductivity of materials, whether in the form of metal or non-metallic state Al2O3, CuO, TiO2, SiC, TiC, Ag, Au, Cu, and Fe are generally several times higher, even at a low concentration, which results in an effective heat transfer coefficient.

Heat Exchanger Applying Nano Fluid CFD Simulation and Geometry

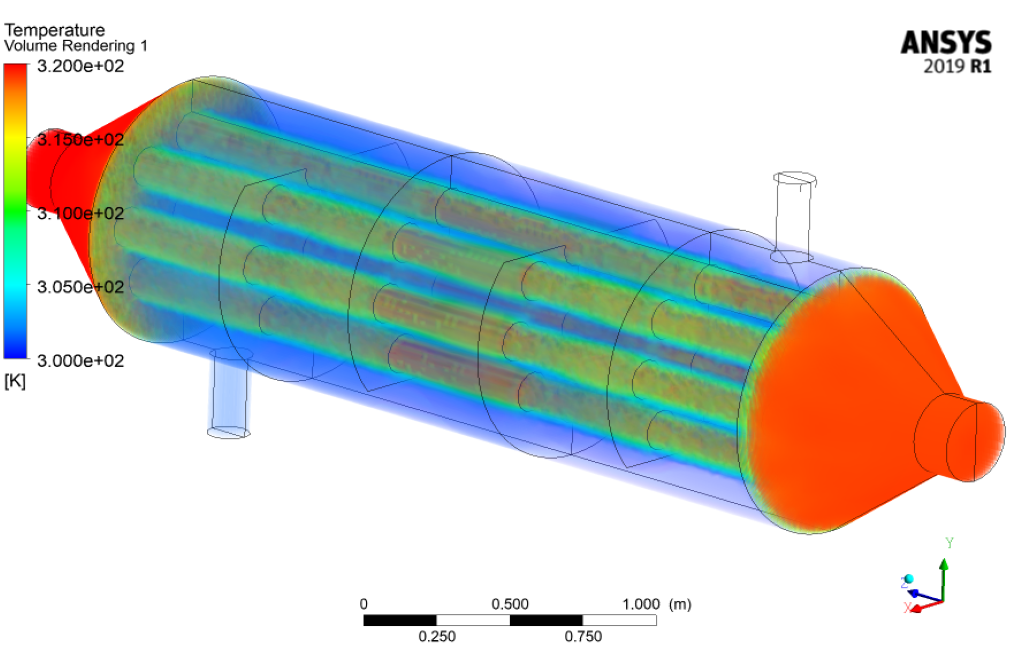

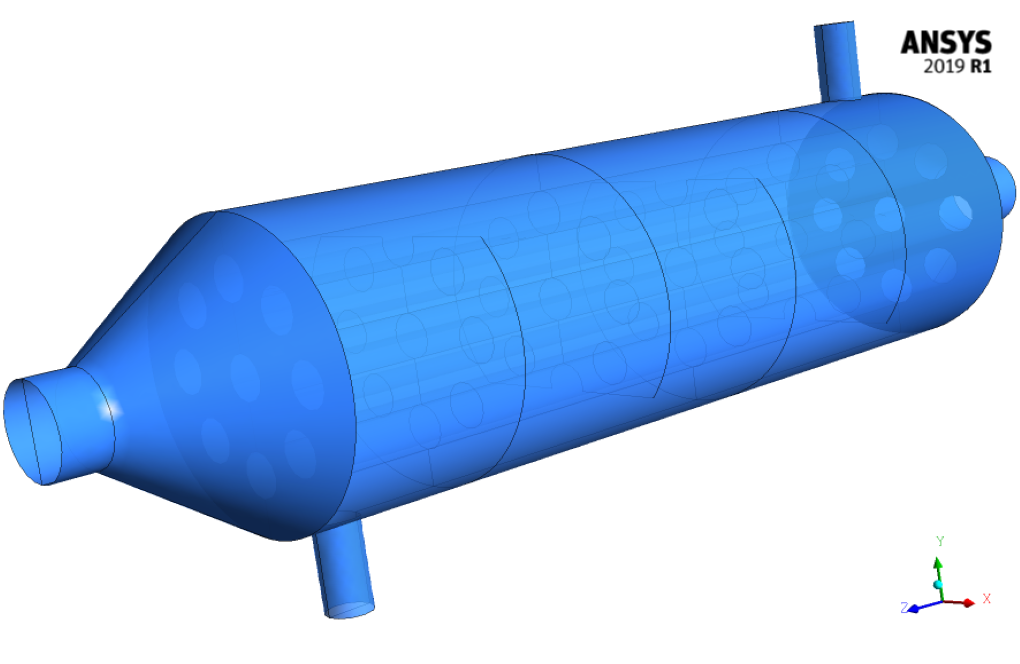

3-D Geometry is designed by Design Modeler software. In order to model the four-layer baffle shell and tube heat exchanger to increase the effects of shell fluid circulation, geometry properties are described below in the table.

| Shell (Cold Flow) | ||||||

| HEX Diameter | HEX Length | Inlet Nozzle Diameter | Outlet Nozzle Diameter | Baffle Number | Baffle Length | Fluid Type |

| 1 m | 4.5 m | 0.15 m | 0.15 m | 4 | 0.7 m | Al2O3+water |

| Tube (Hot Flow) | ||||||

| Tube Diameter | Length (Tube) | Inlet Nozzle Diameter | Outlet Nozzle Diameter | Distance between Inlet Nozzle and Tubes | Distance between outlet Nozzle and Tubes | Fluid Type |

| 0.15 m | 3 m | 0.3 m | 0.3 m | 0.5 m | 0.5 m | water |

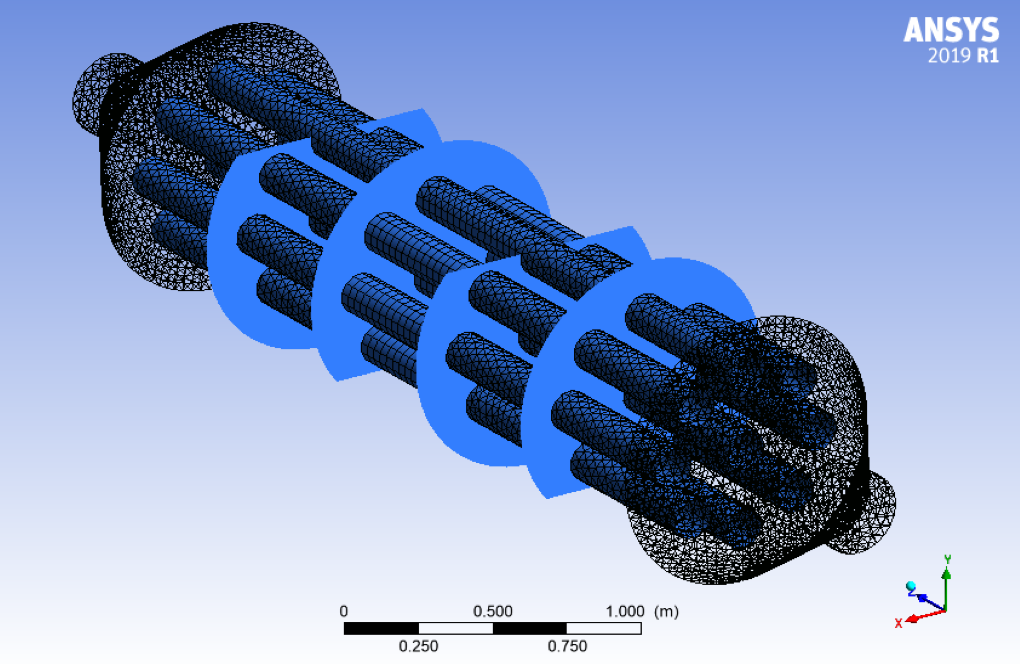

Mesh

The Heat exchanger was designed with a volume of 450,980 elements by ANSYS Meshing software.

Heat Exchanger Set-Up

Finally, in order to model the Nano Fluid, a multi-phase model using the Mixture method was used. In this model, the solid phase is also assumed to be fluid. In this case, two-phase fluid will interact to simulate the numerical model.

| Model | |||||

| discretization | Time | Multi-Phase | Solver | Turbulence | Wall Func. |

| Second Order | Steady | Mixture | Coupled | K-e | Standard |

The properties of the used fluids will also be as follows. (All units are in accordance with the standard Fluent unit.)

| Material Properties | ||||

| Fluid | Viscosity | Thermal Conductivity | Density | Specific Heat |

| Al2O3 | 0.001003 | 40 | 3970 | 765 |

| Water | 0.001003 | 0.6 | 998.2 | 4182 |

Finally, the results are presented in the form of temperature contours and fluid path lines (to observe the effect of baffles) of the heat exchanger.

Maggie Bahringer –

so amazing

Wilfredo Nader –

You can make the simulation run faster using high-performance computing super processors… the work looks cool.

Adrain Mayer –

Can this simulation be customized to model different types of HEX and nano fluids?

MR CFD Support –

Yes, we can accommodate your desired simulations. Please share more details about your specific requirements.

Brady Dare –

Can this simulation be used to optimize the design of the HEX?

MR CFD Support –

Absolutely! The results from this simulation can provide valuable insights into the performance of the HEX, which can be used to make necessary design modifications for optimization.

Trystan Quitzon –

What benefits do nanofluids provide in a shell and tube heat exchanger with a baffle cut as compared to traditional fluids?

MR CFD Support –

Nanofluids enhance the thermal conductivity and heat transfer efficiency of the heat exchanger. Even in low concentrations, nanoparticles such as Al2O3, when mixed with water or other base fluids, can significantly improve overall heat transfer compared to traditional fluids without nanoparticles.

Yesenia Conroy –

The way the nanofluid interacts with the flow in the heat exchanger is fascinating. How are nanoparticles in the nanofluid modeled to experience and contribute to the convection process within the simulation?

MR CFD Support –

In the simulation using ANSYS Fluent, the nanoparticles are represented as a discrete phase within the mixture. A multiphase mixture model is used in which the solid nanoparticles and the base fluid—water in this case—are treated as interpenetrating continua. This method enables us to capture the behavior of nanoparticles in the flow, allowing them to enhance the thermal conductivity and contribute effectively to the overall heat transfer process in the heat exchanger.

Kyla Cremin –

This course looks perfect for increasing heat exchanger efficiency through the use of Nanofluids. The details on the geometry and meshing process are clear, but I wonder if I can extrapolate this to optimize existing heat exchanger designs in my field?

MR CFD Support –

Absolutely, the principles taught in this course can be applied to optimize your existing heat exchanger designs. It illustrates how using Nanofluids can significantly enhance thermal conductivity. You will learn the necessary simulation steps, enabling you to adjust and apply these methods to heat exchangers in your specific industry or application.

Amos Nader –

This product nails it with the heat exchange efficiency! It’s clear that adding nanoparticles can have a dramatic effect on performance. The comprehensive description of setup and conditions makes it easy to understand how the simulation reflects real-world applications.

MR CFD Support –

Thank you so much for your review! We’re thrilled to hear that our detailed simulation of the heat exchanger using nanofluids could effectively demonstrate the enhanced thermal efficiency. It’s great to know that our efforts to clearly explain the setup and reasoning behind each step were helpful. Your feedback is much appreciated, and it reinforces our commitment to providing thorough and understandable CFD simulations.

Leonora Quigley –

I’m intrigued by the use of nanoparticle mix in the fluid. Could you elaborate on how the presence of Al2O3 nanoparticles impacts the overall heat transfer efficiency in comparison to using water alone?

MR CFD Support –

The inclusion of Al2O3 nanoparticles increases the thermal conductivity of the base fluid, water in this case. This increase in conductivity enhances the heat transfer rate due to the improved ability of the nano fluid to conduct heat. As a result, even with a low concentration of nanoparticles, the overall heat transfer efficiency of the shell and tube heat exchanger is significantly improved compared to using water alone.

Dr. Deon Schmidt –

I’m impressed with the level of detail in the heat exchanger simulation using nanoparticle-infused fluids. The methodology appears precise and comprehensive, aimed at determining the efficiency gains from nanofluids. Your application of nanotechnology in thermal systems is innovative.

MR CFD Support –

Thank you! We are glad to hear that you appreciate the detail and methodology of our heat exchanger CFD simulation with nanoparticle-infused fluids. It’s motivating to know that the innovative application of nanotechnology in our study resonates with you.

Prof. Kadin Schinner –

Fantastic product! The detailed description of the heat exchanger simulation, especially the thorough implementation of nanofluid with ANSYS Fluent, shows MR CFD’s meticulous approach. The addition of nanoparticle materials with higher thermal conductivity offers a realistic means of increasing efficiency. It’s great to see comprehensive data like thermal properties and geometry detailed elegantly.

MR CFD Support –

Thank you for your kind words and for appreciating the detailed simulation of the heat exchanger with nanofluids. We at MR CFD Company are committed to providing realistic and high-quality simulations to help our customers understand and predict system behaviors accurately. Do not hesitate to reach out again if you need further assistance or information regarding our products and services.

Irma Wintheiser –

I’ve found the detailed technical aspects of the simulation using Al2O3 nanoparticles in enhancing the efficiency of the heat exchanger quite interesting. The explanations regarding the implementation of the nanoparticles and the setup were very clear and comprehensive. It’s great to see such thorough computational research contributing to improvements in heat transfer for various industrial applications.

MR CFD Support –

We genuinely appreciate your review and are glad that you found the simulation and the detailed implementation strategies insightful. Knowing that our customers see the value in our simulations and recognize the practical improvements they can offer is incredibly rewarding for our team. Thank you for your kind words!

Alexandra Zulauf –

I found the use of nanofluids in increasing the efficiency of heat exchangers interesting. Could you clarify the specific mixture ratio of the Al2O3 nanoparticles to the water used in this simulation?

MR CFD Support –

In the mentioned simulation, the precise mixture ratio of Al2O3 nanoparticles to water is not provided. This ratio significantly impacts the nanofluid’s thermal properties and the overall efficiency of the heat exchanger. For details regarding the mixture ratio and its effects, it is best to refer to the original study or simulation setup within the ANSYS Fluent software documentation or to consult the MR CFD Company for further technical insights.

Prof. Ashley Corwin IV –

The results offered quite a comprehensive view of the thermal behavior, but I was particularly interested in the nanofluid particles distribution within the fluid. Were there any particular findings or images that highlighted the distribution of the Al2O3 nanoparticles in the flow?

MR CFD Support –

In our simulation, we focused on assessing the overall thermal efficiency improvements rather than tracking individual nanoparticles. However, we utilized the Mixture multi-phase model to simulate the nanofluid, ensuring that the interaction between the particles and the base fluid is adequately represented. While the simulation does not provide specific visualizations of nanoparticle pathways, their concentration and influence on thermal properties are integral to observing the enhanced thermal exchange in the temperature contours.

Mr. August Weissnat II –

I’m impressed by the complexity of the simulation and the use of nanoparticles to enhance the heat exchanger’s efficiency. It sounds like a significant advancement in thermal management fields. The marriage of CFD tools and engineering innovation to achieve such results is quite captivating.

MR CFD Support –

Thank you for your enthusiastic review! We’re glad our simulation on the heat exchange with baffle cut and mixture nanofluid has intrigued you. Our aim is always to push the boundaries of what CFD can achieve and to provide insightful and practical solutions in thermal management and beyond. We appreciate your recognition of this innovative approach.

Miss Cleora Hane –

I’m truly impressed with the detailed breakdown of the heat exchanger’s features! The use of nanofluid seems fascinating. Could you let me know the efficiency gain when using Al2O3 nanofluids as compared to standard fluids without nanoparticles?

MR CFD Support –

Thank you for your interest in our product on the Shell and Tube Heat Exchanger simulation with baffle cut and Nanofluid using ANSYS Fluent. The use of Al2O3 nanofluids generally improves the heat transfer efficiency due to higher thermal conductivity compared to standard fluids. For exact efficiency gains, you would need to refer to the simulation results within ANSYS Fluent, which would provide a quantitative measure of the performance increase. Please let us know if you need further assistance or clarification with the simulation results.

Lavonne Satterfield –

The simulation results depicted a thorough numerical examination. Nicely done!

MR CFD Support –

Thank you for your kind words! We are glad to hear that our simulation met your expectations and the detailed presentation of the results provided you with a comprehensive understanding. It’s always our goal to deliver thorough insights to our customers.

Mr. Dawson Schoen –

I recently completed my project using the Heat Exchanger with Baffle Cut and Mixture Nano Fluid tutorial. The incorporation of nanoparticles truly enhanced the thermal conductivity as advertised. The interactive approach of learning through the ANSYS Fluent simulation made complex concepts easy to grasp. The visualization of the flow patterns with the baffles in place provided a lot of insight into how effective the design changes. Really a fantastic resource for anyone looking to improve their understanding of heat transfer in heat exchangers.

MR CFD Support –

Thank you for your positive feedback on the Shell and Tube Heat Exchanger with Baffle Cut and Mixture Nano Fluid tutorial. It’s great to hear that the tutorial helped clarify complex concepts and provided valuable insights into heat transfer and flow patterns. Your project success is exactly what we aim for with our learning products. Should you have any more inquiry or if you decide to tackle another simulation challenge, remember we’re here to support you.

Dr. Dominic Becker DVM –

What is the benefit of using nano fluid in the HEX?

MR CFD Support –

Nano fluid can enhance the heat transfer performance of the HEX due to its higher thermal conductivity compared to conventional fluids.

Teresa Littel –

The comprehensive information about the baffle cut and the mixture nano fluid in the shell and tube heat exchanger is fascinating! I’m particularly impressed by the detailed simulation approach and the geometry specifications provided. This level of detail really helps understand how the nano fluid influences heat exchanger efficiency. Great job on employing such high-fidelity tools for this analysis!

MR CFD Support –

Thank you so much for your positive feedback on our simulation project! We are thrilled to hear you found the details and approach of our study to be helpful and informative. It’s always exciting for us when customers appreciate the efforts we put into enhancing the understanding of nano fluid’s impact on heat exchanger efficiency. We’re glad you enjoyed the comprehensive review and the results from ANSYS Fluent modeling. If you have any more questions or there is anything else we can help you with, please feel free to let us know!

Oleta King –

The tutorial on the Shell and Tube Heat Exchanger with Baffle Cut using Nanofluid was incredibly detailed and the results were very clear. The visualization of temperature contours and fluid path lines really helped to understand the effect of baffles and the efficiency boost from nanofluids. Great work!

MR CFD Support –

Thank you so much for your kind words! We’re thrilled to hear that our tutorial on Shell and Tube Heat Exchangers was informative and that the visualizations added clarity to the complex concepts. Your positive feedback is very encouraging for our team. If you ever have more questions or another topic you’re curious about, don’t hesitate to reach out!

Marcia Abshire DDS –

I was fascinated by how the inclusion of nanofluid impacts the heat exchanger efficiency. Could you illuminate the degree of increase in thermal conductivity when Al2O3 nanoparticles are added to water?

MR CFD Support –

The addition of Al2O3 nanoparticles to water can significantly enhance the thermal conductivity of the working fluid. The specific increase depends on the concentration of nanoparticles, their size, and distribution. These improvements enable the heat exchanger to operate more efficiently due to increased heat transfer rates.

August Aufderhar –

The description of the heat exchanger is very detailed, but I’m curious to know whether corrosion of the pipes was considered in the CFD simulation when using nanoparticles within the fluid?

MR CFD Support –

In the simulation of the shell and tube heat exchanger using nanoparticles, the primary focus is typically on the thermal efficiency and the fluid dynamics within the system. However, typically, phenomena such as corrosion would require additional complex modeling and are not generally included in the thermal performance simulations. For accurate assessments of corrosion, separate analyses, possibly including electrochemical models, would have to be performed.