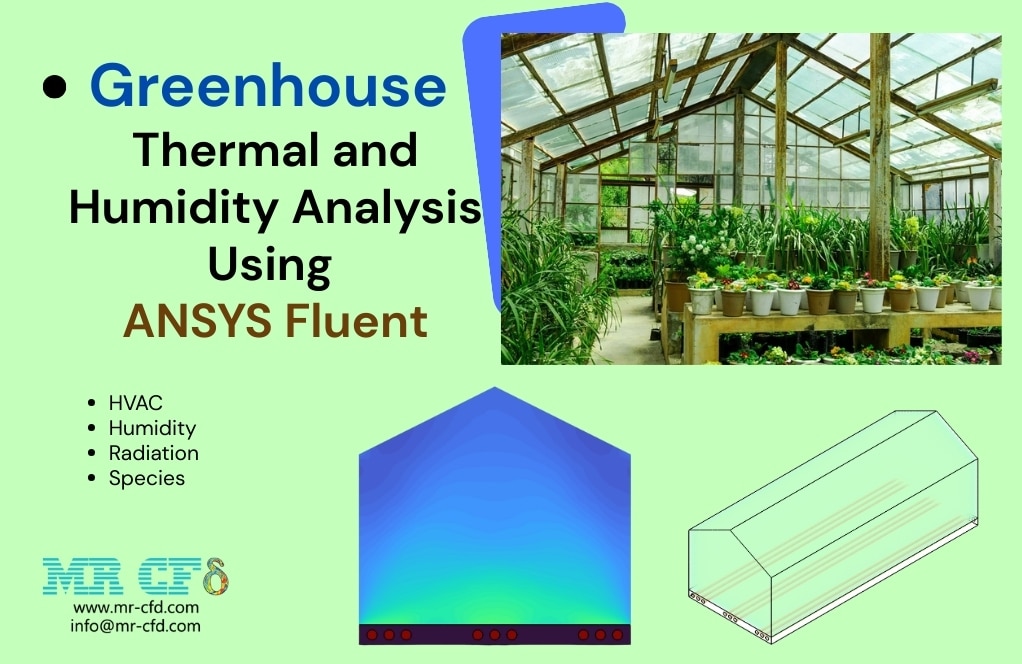

Greenhouse Thermal and Humidity Analysis Using ANSYS Fluent

$180.00 $72.00 HPC

- The problem numerically simulates airflow, heat transfer, solar radiation, and humidity inside a greenhouse using ANSYS Fluent software.

- We perform this simulation as steady-state.

- The study incorporates the Discrete Ordinates radiation model with solar ray tracing and species transport for air–water vapor mixture analysis.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Greenhouse Thermal and Humidity Analysis

Project Description

This project involved numerical simulation of greenhouse airflow, heat transfer, solar radiation, and moisture behavior inside the greenhouse using ANSYS software. The goal was to investigate how environmental factors and boundary conditions affect the internal temperature distribution, heat transfer from the floor through the embedded pipes, air velocity, and moisture content to better understand the thermal performance of the greenhouse. The simulation was performed under steady-state conditions to capture the long-term behavior of the system, taking into account the effects of solar radiation through ray tracing and the specific thermal properties of the materials applied to the structure.

Geometry and Mesh

The 3D geometry of the greenhouse was created using ANSYS SpaceClaim software. The model consisted of a computational domain, a room region, and 9 pipes in the floor, representing

the fluid domain, and a ground region modeled as a solid body. The computational domain was 30 m wide, 10 m high, and 40 m long, and the greenhouse was 4 m wide, 3.8 m high, and 10 m long. The greenhouse floor, 3.3 m high, contained 9 pipes with a cross-sectional area of 0.017671 m and a length of 10 m. The model was then imported into ANSYS Meshing software, where a computational mesh of approximately 4,800,000 cells was generated, providing sufficient resolution to balance simulation accuracy and computational cost.

Setup

The greenhouse simulation setup in ANSYS Fluent employed a pressure-based solver, chosen because the problem was steady-state and not dependent on transient effects. The gravitational acceleration was set to −9.81 m/s² in the Y-direction. The energy equation was activated to account for heat transfer within the domain. Turbulence was modeled using the realizable k–ε model with standard wall functions for near-wall treatment. Radiation effects were included using the Discrete Ordinates (DO) model with solar ray tracing enabled to account for solar heating. Humidity effects were simulated by enabling the species transport model, with density set to an incompressible ideal gas mixture of air and water vapor.

The inlets boundary condition was defined as a mass flow rate of 0.032 kg/s, while nine surfaces acted as pressure outlets, each with a gauge pressure of 0 Pa. All the walls were modeled with a no-slip condition. The pressure-velocity coupling was performed using the Coupled algorithm to ensure strong convergence, and the solution was initialized using the standard initialization method in Fluent. These settings provided a stable numerical basis for solving the governing equations for the transfer of mass, momentum, energy, radiation, and species in the greenhouse environment.

Results

The results of the simulation include detailed distributions of temperature, velocity, radiation heat flux, and water vapor mass fraction within the greenhouse. These results can be presented through contour plots and vector fields for visual interpretation, along with quantitative data for key locations inside the structure. Analysis of the output allows for evaluation of temperature uniformity, ventilation effectiveness, solar radiation absorption, and moisture distribution.

You must be logged in to post a review.

Reviews

There are no reviews yet.