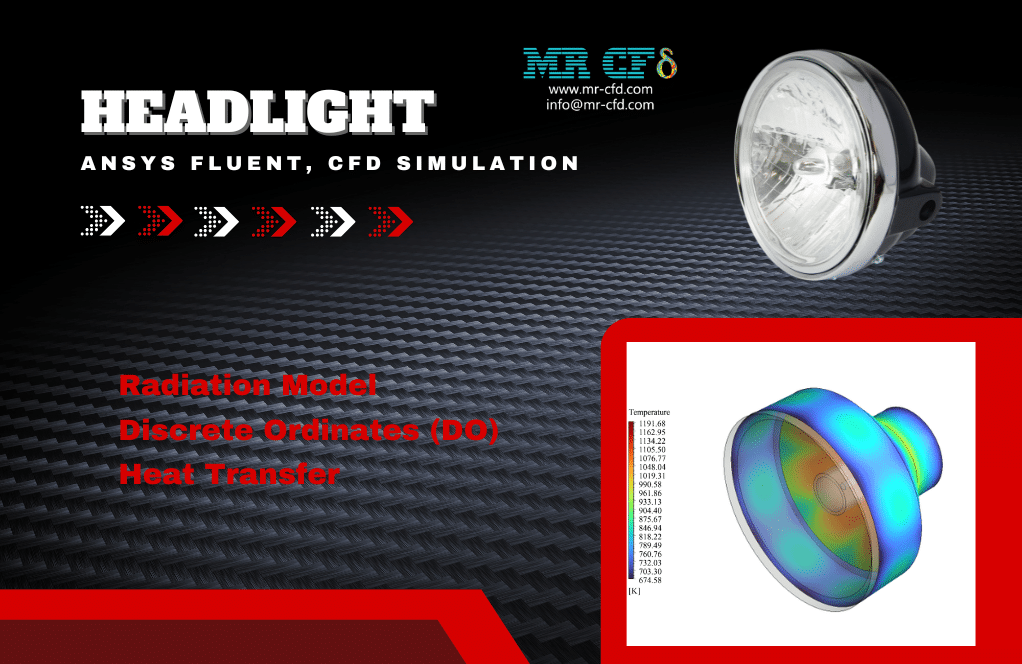

Headlight, Radiation, ANSYS Fluent CFD Simulation

$120.00 $48.00 HPC

- This product numerically simulates the Headlight using ANSYS Fluent software.

- We design the 3D model with Design Modeler software.

- We mesh the model with ANSYS Meshing software, and the element number equals 1322000.

- We use the Discrete Ordinates (DO) Radiation Model to define radiation heat transfer.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Description

In this project, we perform the numerical simulation of a Headlight in ANSYS Fluent software.

A headlight is an electrical component mounted on the front of a vehicle for illuminating the roadway ahead. It is constructed of a special lens, reflector, bulb, filament, etc. The filament is known as a light source in the bulb. Whenever an electric current passes through the filament, it produces light and starts to glow.

Therefore, in the interior of the headlight construction, Irradiation occurs between different components such as the reflector, lens, bulb, etc. So, we intend to analyze the Radiation Heat Transfer inside the headlight.

Methodology

First, we model the headlight geometry in 3D using Design Modeler software. The computational domain is the interior of a headlight, including filament, internal bulb, outer bulb, housing, coating, reflector, and lens.

Then, we mesh the model using ANSYS Meshing software, and about 1,322,000 cells are generated.

Finally, we simulate the headlight radiation in ANSYS Fluent software.

In this project, we use the Radiation Model to define radiative heat transfer in the headlight components.

We utilize the Discrete Ordinates (DO) radiation model to solve the radiative equation for a finite number of discrete solid angles. Every solid angle is related to a vector direction in the global Cartesian coordinate system.

Conclusion

After calculations, we intend to provide a thermal analysis for the radiation operation in the headlight.

Therefore, we obtain the temperature distribution in different components within the headlight construction. So, we present the temperature contours on the filament, inner bulb, outer bulb, housing, reflector, and lens.

The results show that radiation heat transfer between the internal components of the headlight is carried out correctly.

You must be logged in to post a review.

Reviews

There are no reviews yet.