Vortex Separator, Hydrodynamic Eulerian CFD Simulation, ANSYS Fluent Training

$100.00 Student Discount

The present problem simulates two-phase flow inside a hydrodynamic vortex separator using ANSYS Fluent software.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Hydrodynamic Vortex Separator Project Description

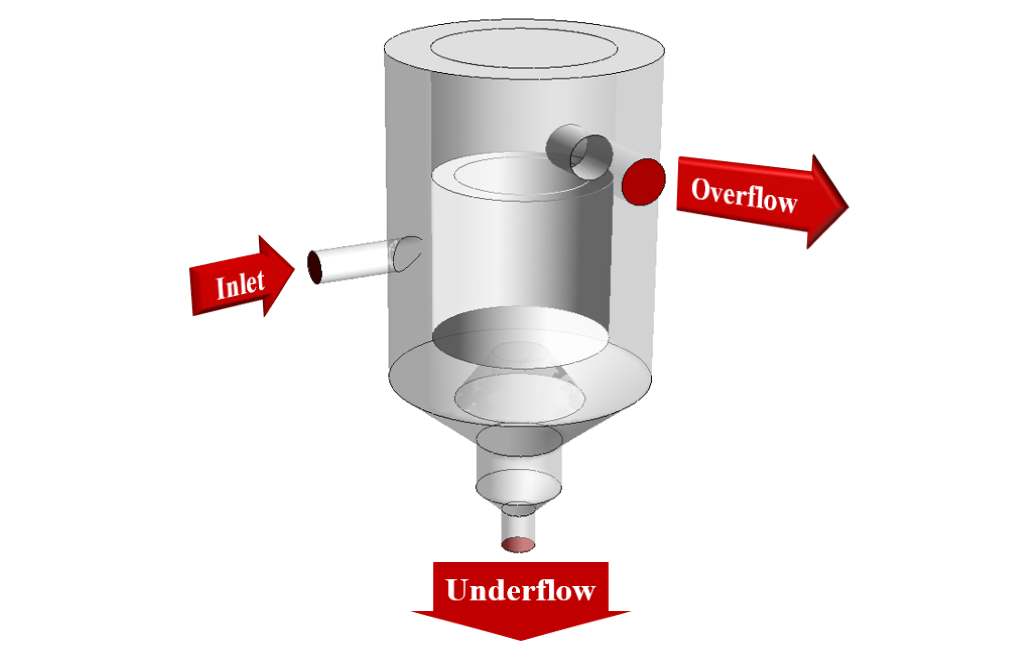

The present problem simulates two-phase flow inside a hydrodynamic vortex separator using ANSYS Fluent software. These hydrodynamic vortex separators (HDVS), can separate soluble particles in a fluid from the base fluid. The structure of these devices is such that the flow of the solution entering the system is significantly rotated. This high rotation of the flow causes the fluid movement path inside the system to be significantly longer. This lengthening of the solvent flow path provides an opportunity to separate the suspended particles in the fluid and settle them in the system. Therefore, the Eulerian multiphase model has been used.

The Eulerian multiphase model is considered the most complex model for defining multiphase flows because it solves a set of momentum and conservation equations for each phase independently. From the Eulerian model in applications such as bubble columns, droplet flows, particle-laden flows with a volume fraction of more than 10%, pneumatic transitions for granular, liquid flows, Fluidized beds are used for solid-gas flows, the slurry flows, particle suspension, and sedimentation phenomena as solid-liquid flows. In the present simulation, water flow is defined as a base fluid with a density of 1000 kg.m-3 and a viscosity of 0.001 kg.m-1.s-.

Hydrodynamic Vortex Separator Project Description

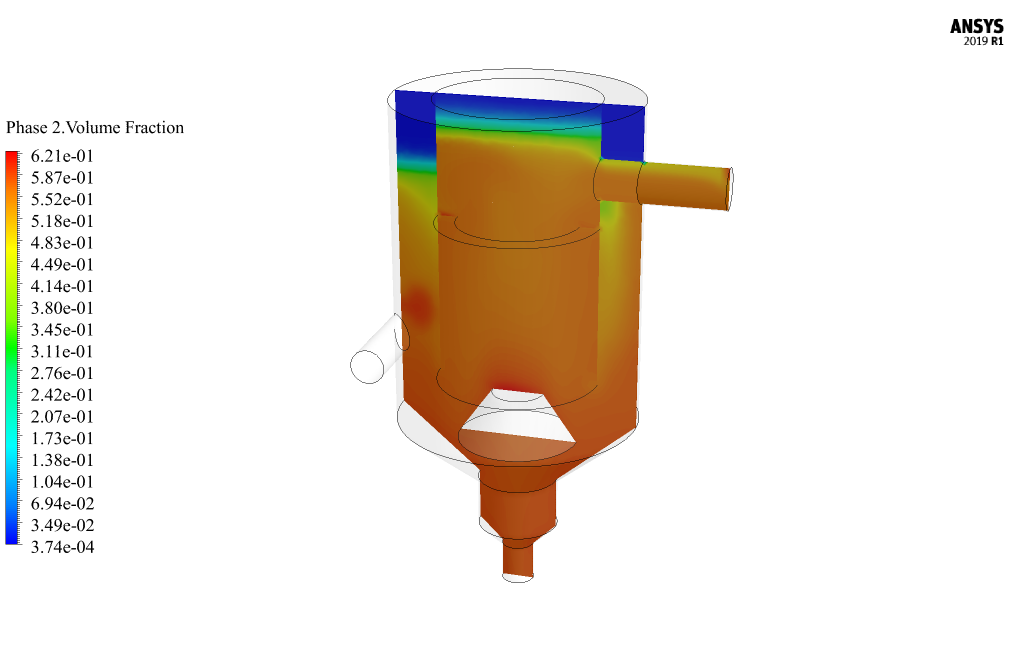

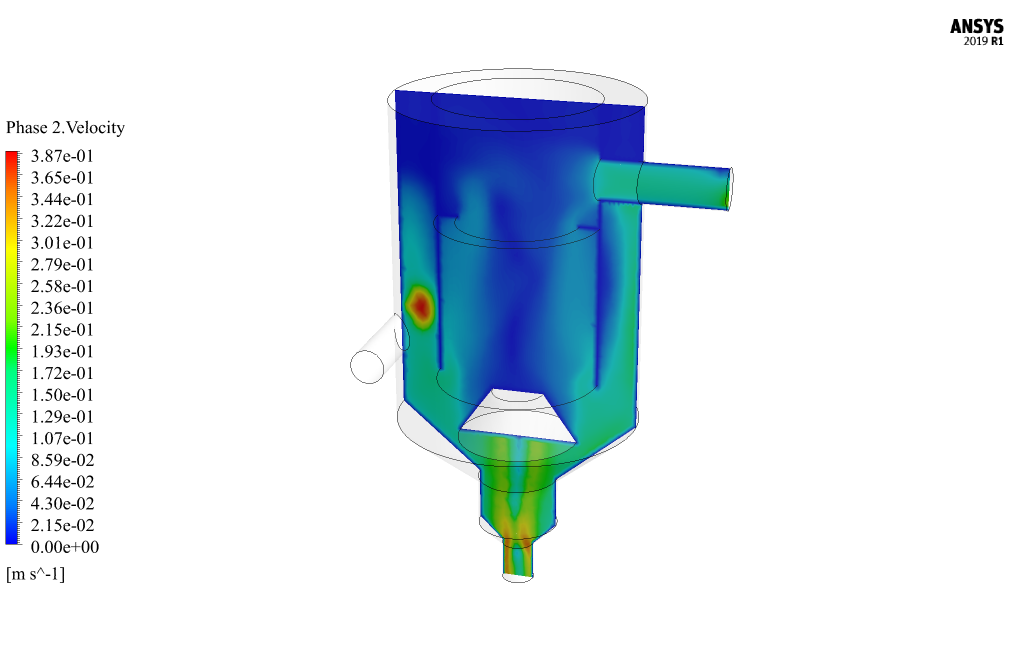

The secondary phase in the form of particles with a density of 1060 kg.m-3 and a viscosity of 0.0046 kg.m-1.s-1 is defined. The particle dispersion in the base liquid is defined as granular, and the particle diameter is defined as 0.000006 m. The flow of water and its soluble particles enter the device at a rate of 0.36 m.s-1 through an intermediate duct; While the volume fraction of water flow is equal to 0.4 and the volume fraction of soluble particles is equal to 0.6. Finally, after the separation process, this solution leaves the outlet ducts at the top of the device (for water passage) and the bottom of the device (for particle settling).

Hydrodynamic Vortex Separator Geometry & Mesh

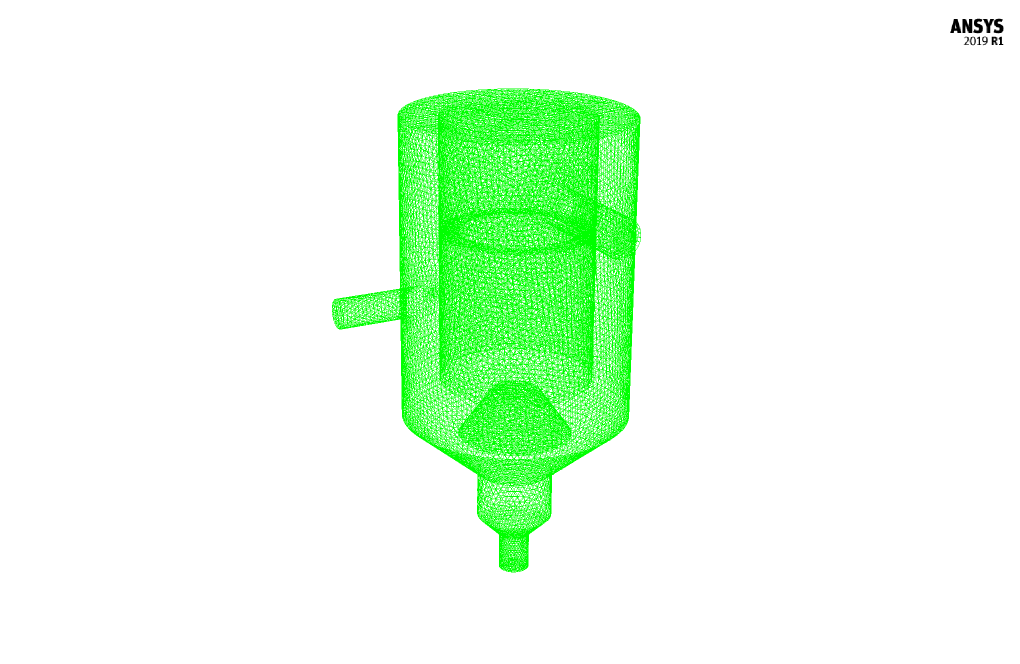

The present model is designed in three dimensions using Design Modeler software. The current model is related to a vertical hydrodynamic vortex separator. The cylindrical part of this vertical device’s body is 0.3 m in diameter and 0.63 m high. In this model, a pipe for inlet current is located on the middle part of the body, and two outlet pipes are located in the lower part of the model and on the upper part of the model body.

We carry out the meshing of the model using ANSYS Meshing software, and the mesh type is unstructured. The element number is 472707. The following figure shows the mesh.

CFD Simulation

We consider several assumptions to simulate the present model:

- We perform a pressure-based solver.

- The simulation is unsteady (Transient Solver).

- The gravity effect on the fluid is equal to -9.81 m.s-2 along the Z-axis.

The following table represents a summary of the defining steps of the problem and its solution:

| Models (Hydrodynamic Vortex Separator) |

||

| Viscous | Reynolds Stress | |

| Reynolds stress model (RSM) | linear pressure-strain | |

| near-wall treatment | standard wall function | |

| Multiphase Model | Eulerian | |

| number of eulerian phases | 2 | |

| formulation | implicit | |

| Boundary conditions (Hydrodynamic Vortex Separator) |

||

| Inlet | Velocity Inlet | |

| gauge pressure | 0 pascal | |

| velocity magnitude for the primary phase | 0.36 m.s-1 | |

| velocity magnitude for the secondary phase | 0.36 m.s-1 | |

| volume fraction for particle | 0.6 | |

| Overflow | Pressure Outlet | |

| gauge pressure | 0 pascal | |

| Underflow | Pressure Outlet | |

| gauge pressure | 0 pascal | |

| Walls | Wall | |

| wall motion | stationary wall | |

| Methods (Hydrodynamic Vortex Separator) |

||

| Pressure-Velocity Coupling | Phase Coupled SIMPLE | |

| Pressure | PRESTO | |

| momentum | second order upwind | |

| volume fraction | first order upwind | |

| turbulent kinetic energy | second order upwind | |

| turbulent dissipation rate | second order upwind | |

| Reynolds stresses | first order upwind | |

| Initialization (Hydrodynamic Vortex Separator) |

||

| Initialization methods | Hybrid | |

Results

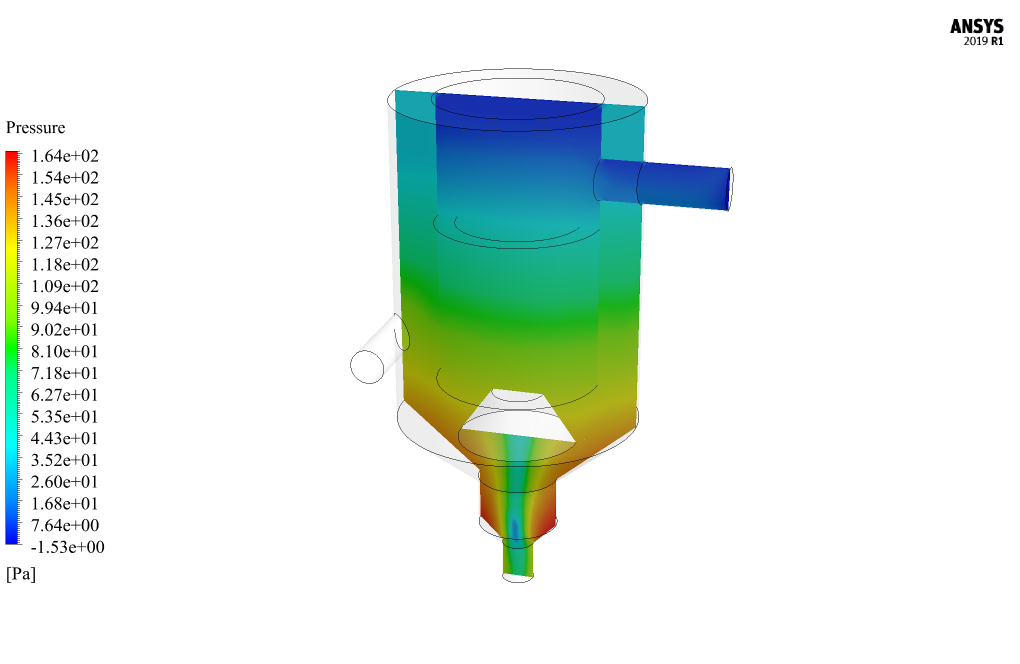

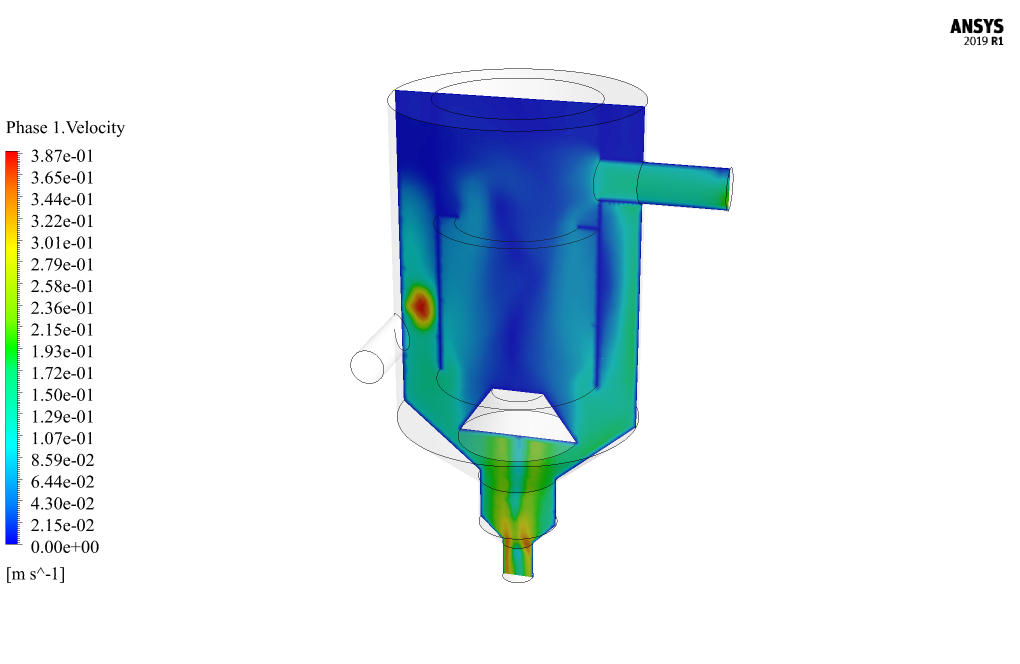

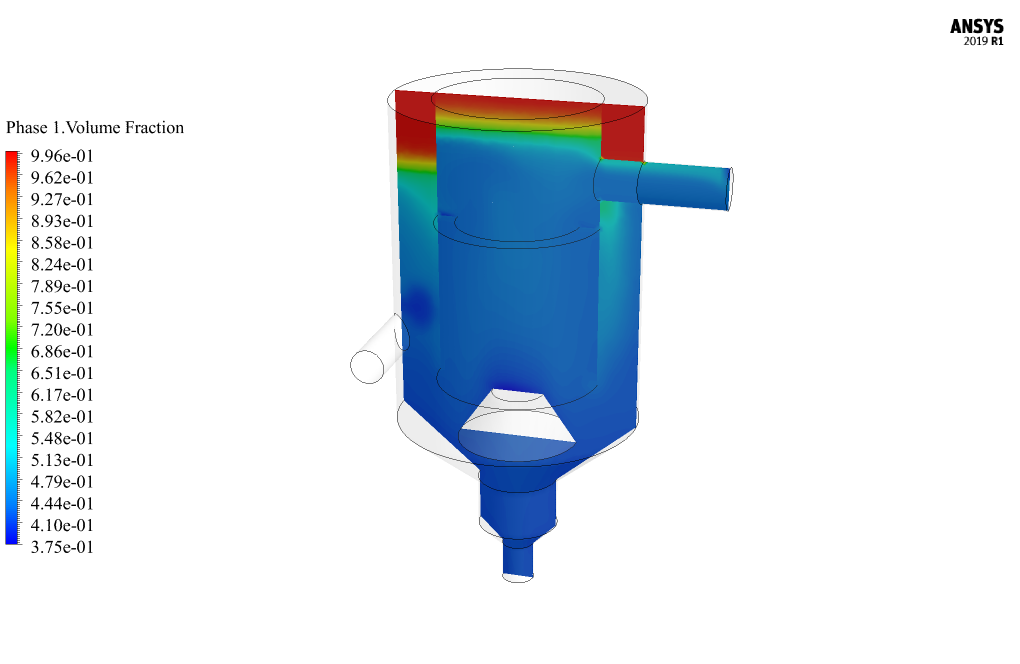

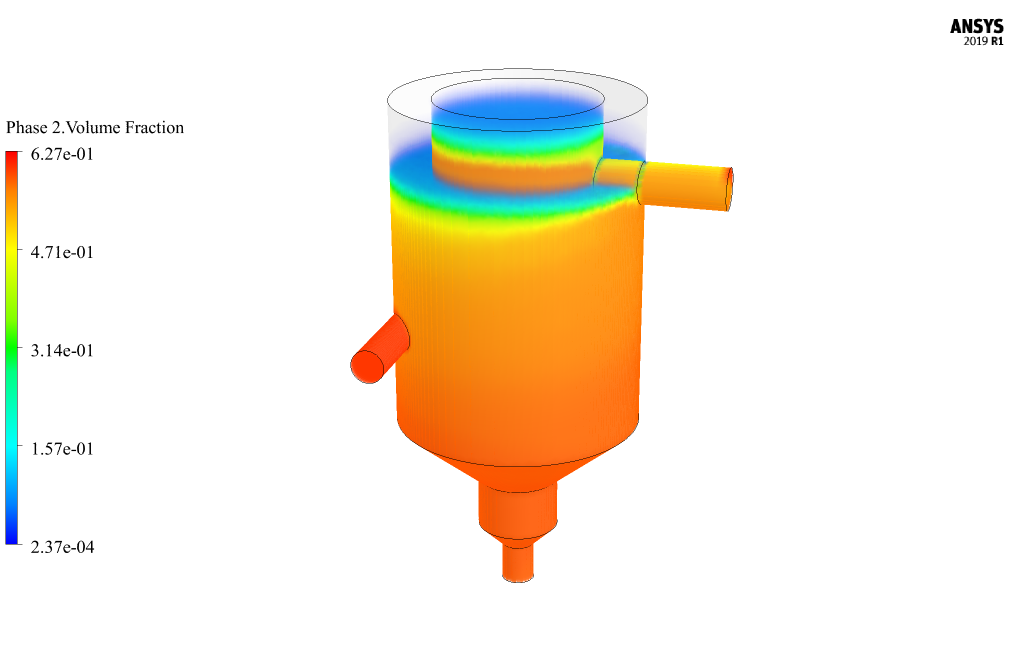

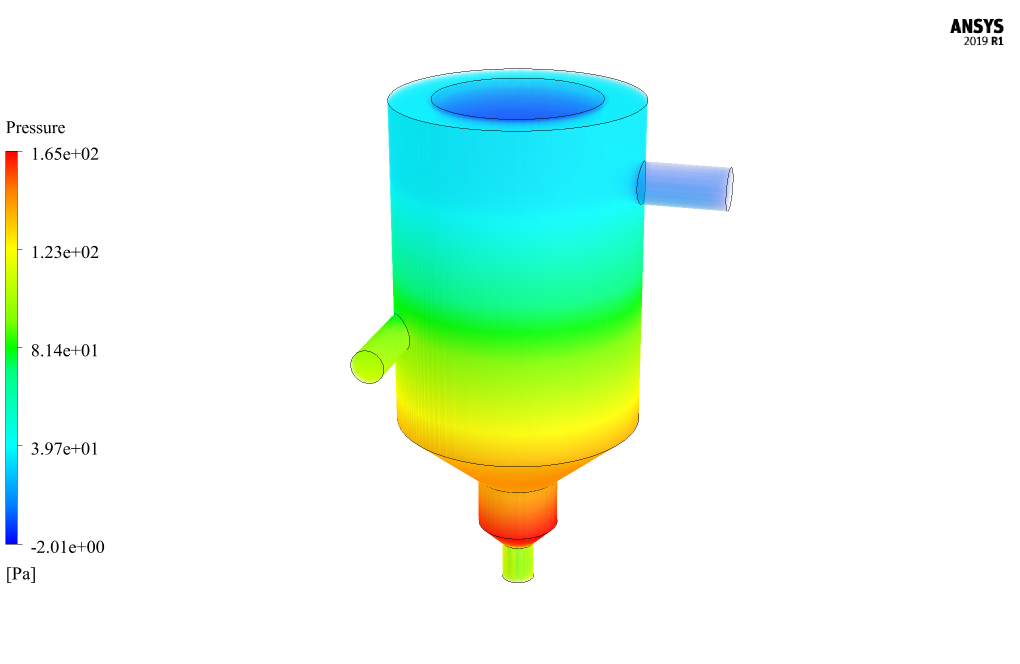

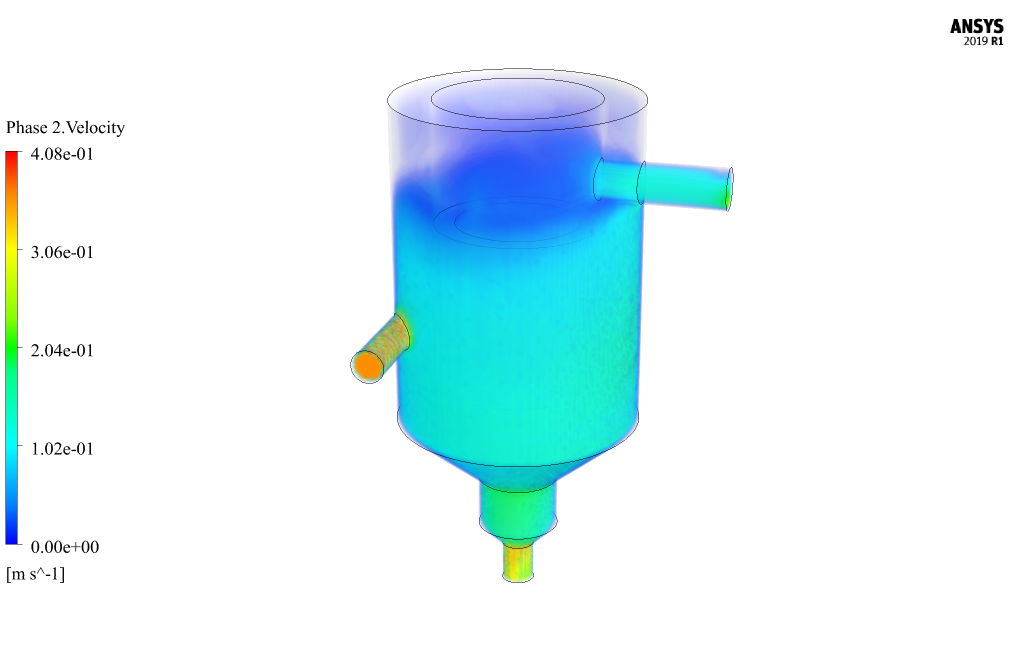

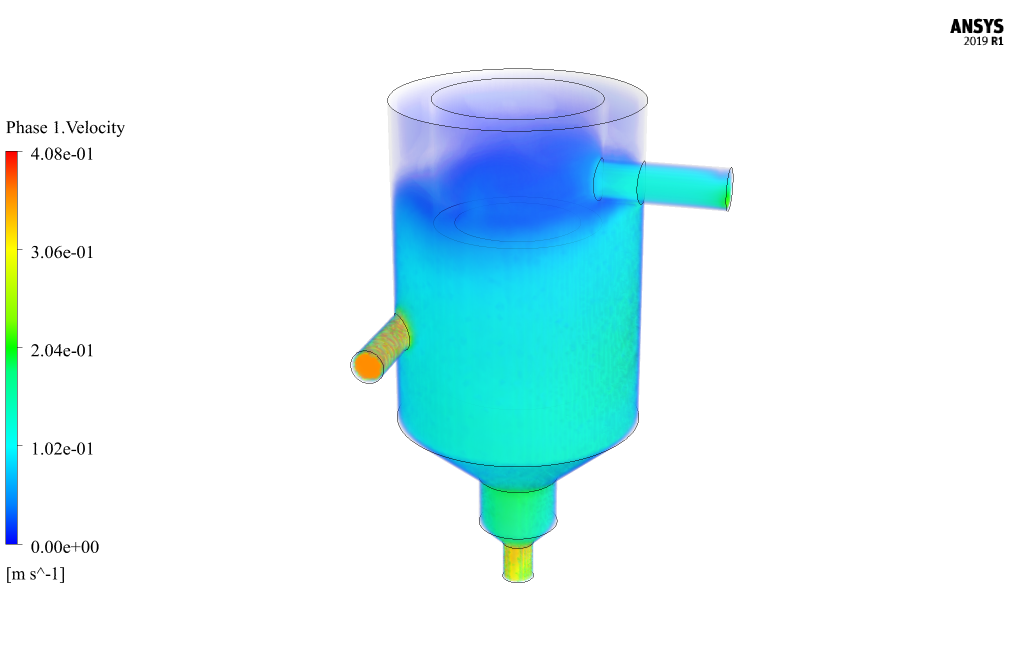

At the end of the solution process, two-dimensional and three-dimensional contours related to the mixture pressure, base fluid velocity, soluble particle velocity, and the volume fraction of the base fluid and soluble particles are obtained. As can be seen from the pictures, it can be said that the flow of water is directed to the upper outlet of the device, and the flow of settled particles is directed to the lower outlet of the device. This shows that the system’s performance is good and exhibits its primary task of separating soluble particles from the base fluid.

Dr. Brian Bergnaum I –

I have some ideas for improving this simulation. Can I contribute?

MR CFD Support –

We welcome and appreciate contributions. Your ideas could help us improve our simulations and provide better solutions to our users. Thank you for your interest and support!

Dr. Karelle Langosh –

How accurate is this simulation in predicting the performance of a hydrodynamic vortex separator?

MR CFD Support –

This simulation uses advanced numerical methods and accurate models of the separator to provide a highly accurate prediction of its performance. However, like all simulations, it should be used in conjunction with other engineering analyses and not as a sole decision-making tool.

Katrine Rempel –

How can I use this simulation to optimize the separation efficiency of my separator?

MR CFD Support –

You can use this simulation to optimize the separation efficiency of your separator by changing the design and operating conditions of the separator and observing their effect on the separation efficiency.

Abdollah –

when will the training files be ready if I purchase this product?

Mr CFD Support –

Almost all the training files for all of our products are ready and you can download them instantly. However, if you are purchasing a newly added product it may take 24 hours at max to prepare them for you.

Domenic Prohaska MD –

Wonderful learning product! The practical application of the hydrodynamic vortex separator was both insightful and enlightening. The detailed results clearly demonstrated the separator’s efficacy in particle separation which was intriguing and beneficial for my research!

MR CFD Support –

We are thrilled to hear you had such a positive experience with our Hydrodynamic Vortex Separator CFD simulation training! Thank you for taking the time to share your thoughts, and we’re glad to have been able to contribute to your research. If there’s anything else you need or if you have more to learn, feel free to reach out to us. Thank you for choosing MR CFD Company for your learning journey!

Eunice Kreiger –

How accurate is this simulation in predicting the performance of a hydrodynamic vortex separator?

MR CFD Support –

This simulation uses advanced numerical methods and accurate models of the separator to provide a highly accurate prediction of its performance. However, like all simulations, it should be used in conjunction with other engineering analyses and not as a sole decision-making tool.

Marion Zieme –

Could you please explain the specific benefits of using the Eulerian multi-phase model for this hydrodynamic vortex separator simulation?

MR CFD Support –

The Eulerian multi-phase model allows for the independent solution of momentum and conservation equations for each phase of the flow. In this case, it’s beneficial for accurately tracking the interaction and separation of the dispersed particles from the water within the hydrodynamic vortex separator, which can include complex particle-fluid interactions and high volume fractions of solids, both of which are well-represented by this model.

Dr. Estell Gleason DDS –

This training on the hydrodynamic vortex separator was very comprehensive. The explanations and visual aids provided a deep understanding of the Eulerian multiphase model and its application in separator design. Fantastic work by the MR CFD team!

MR CFD Support –

Thank you for this wonderful feedback! We are genuinely pleased to hear that the course on hydrodynamic vortex separators was helpful to you and that the use of the Eulerian multiphase model was comprehensively explained. Your satisfaction with our training materials is a great source of motivation for us. If you have any more questions or need further assistance, feel free to reach out.

Dahlia Trantow –

I was particularly impressed with the detailed explanation of the multiphase model and how the velocity inlets were configured. The hydrodynamic vortex separator sounds like it effectively accomplishes the separation process—great work on the simulation’s intricacy!

MR CFD Support –

We’re thrilled to hear you found the multiphase model explanation and velocity inlet configuration details impactful in understanding the performance of the hydrodynamic vortex separator. It’s rewarding to know the simulation’s complexity is appreciated. Thank you for your positive feedback on our work!

Roberto Renner –

This Hydrodynamic Vortex Separator simulation seems interesting! Could you please clarify how the separation of particles occurs within the device? Does the rotational flow create a centrifugal force that supports this process?

MR CFD Support –

Yes, exactly! Within the hydrodynamic vortex separator, a strong rotational flow is induced, which causes the suspension to experience centrifugal forces. Lighter particles, likely to be the base fluid in this case, move towards the centre of the rotation due to the lower centrifugal force they experience, while heavier particles, which are subject to greater centrifugal forces, move outward. As a result, the fluids are separated with the lighter base fluid like water exiting through the top and the heavier settled particles exiting through the lower outlet.

Dovie Jones –

I’m thoroughly impressed with the detailed analysis of the hydrodynamic vortex separator! The use of the Eulerian multiphase model seems particularly suited for this complex simulation. Appreciating the deep dive into technicalities and sharing such clear results that demonstrate the effectiveness of the device. Great job!

MR CFD Support –

Thank you for your kind words! We’re glad to hear that you appreciated the complex nature of the simulation and found the analysis detailed and informative. It’s wonderful to see users like you recognize the effectiveness of the device through our simulations. If you have any further questions or need more information, feel free to ask. Thank you for choosing our learning product!

Prof. Hunter Moore III –

I am thrilled with the level of detail in the hydrodynamic vortex separator simulation. The contour results clearly demonstrated the successful particle separation process. Great product!

MR CFD Support –

We truly appreciate your positive feedback on our hydrodynamic vortex separator simulation! We’re glad to hear that the results and the details met your expectations. Thank you for choosing our product, and we’re here if you need any further support!

Virgil Ernser –

After reading the review, I’m really curious about something. Could you please explain how the volume fractions for water and particles are determined and initialized in this simulation?

MR CFD Support –

The volume fractions for water and particles in this simulation were determined based on the desired mixture entering the hydrodynamic vortex separator. For initialization, a volume fraction of 0.4 for water flow and 0.6 for soluble particles were defined as per the simulation setup. These values determine the relative amount of each phase in the multiphase flow at the beginning of the simulation, ensuring that the solver initializes the fluid properties accordingly to accurately capture the dynamics of separation through the device.

Markus Reinger –

This training offers a great hands-on insight into multiphase flow simulation! Thanks to MR CFD, I fully understand the separation process in the hydrodynamic vortex separator and the practical application of the Eulerian model in industry.

MR CFD Support –

We’re thrilled to hear that our training helped you understand the complexities of the hydrodynamic vortex separator and the industrial application of the Eulerian model. Thank you for leaving such positive feedback; it’s very encouraging for our team!