Mesh Motion Method, Mixing Tank CFD Simulation ANSYS Fluent Tutorial

$100.00 Student Discount

- The problem numerically simulates the performance of a mixing tank using ANSYS Fluent software.

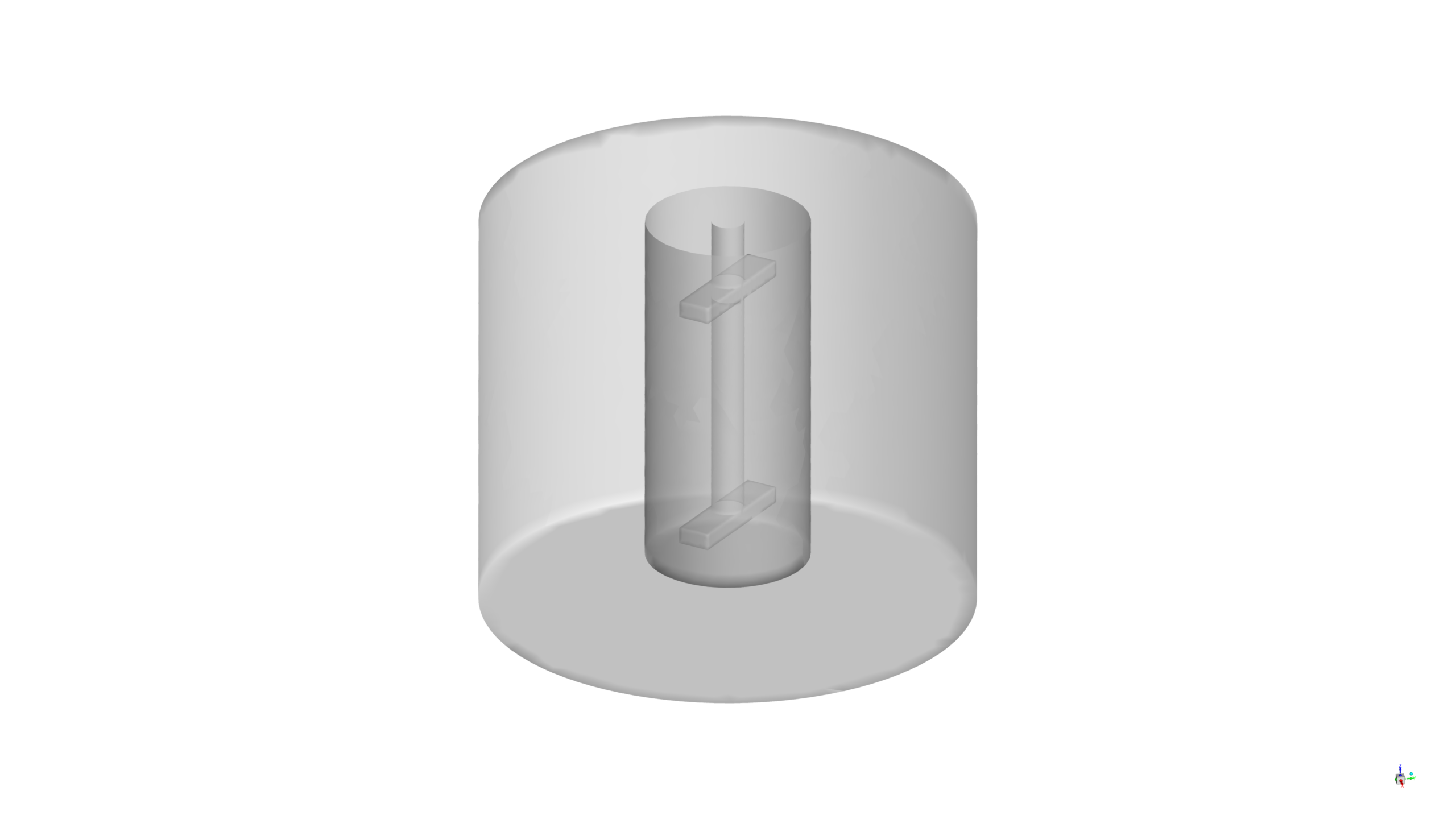

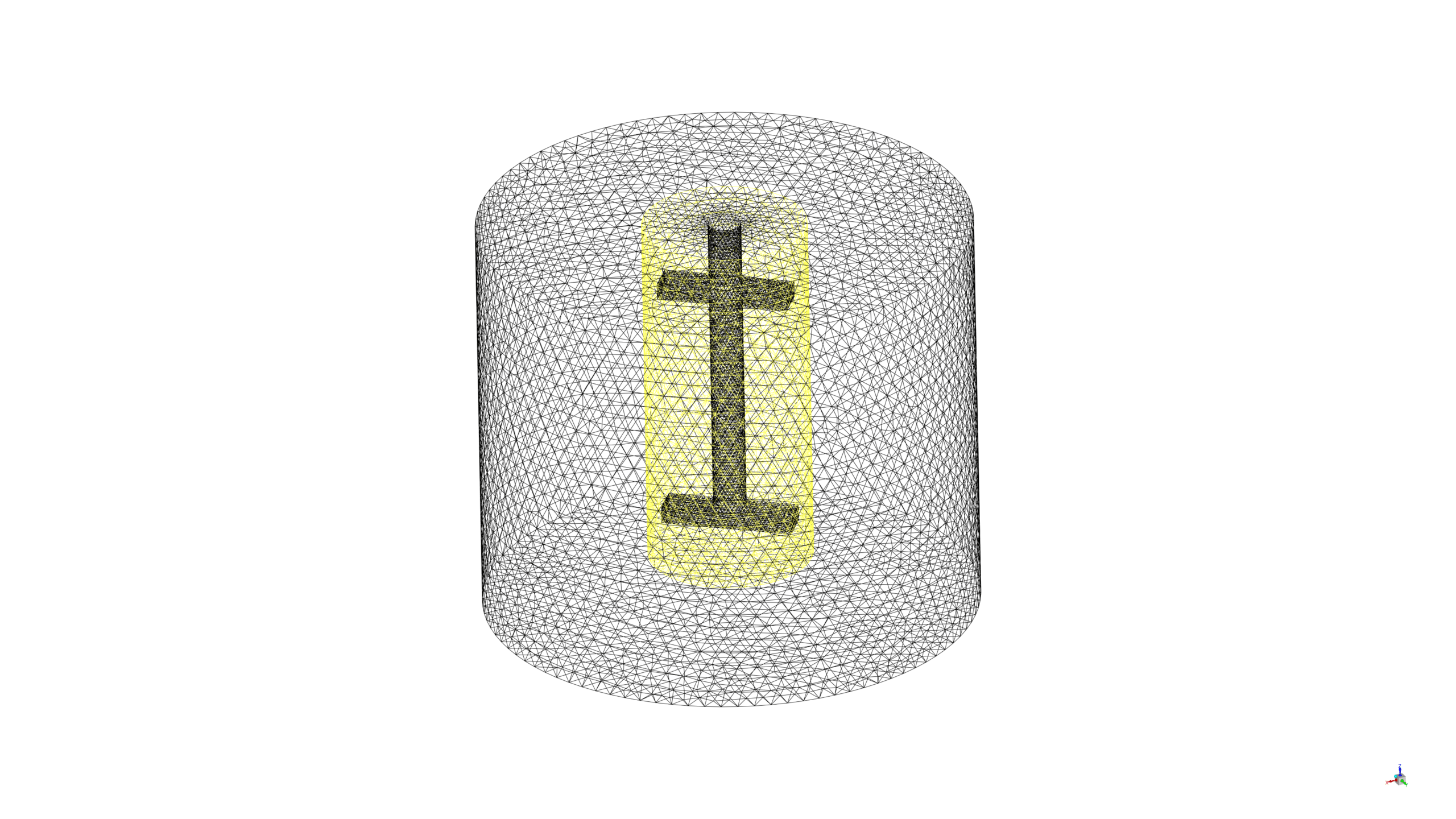

- We design the 3-D model by the Design Modeler and create the mesh using ANSYS Meshing software.

- The element number equals 209,328.

- The Mesh Motion option is enabled to define the rotational motion of the impellers.

- Transient Solver is applied.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Description

The present problem simulates the performance of a mixing tank by ANSYS Fluent software.

The closed mixing tank contains water liquid while the impeller starts rotating with 500 rev/min angular velocity, creating a massive vortex in the middle of the tank.

The geometry of the present model is three-dimensional and has been designed using Design Modeler software. We do the meshing of the present model by ANSYS Meshing software. The mesh type is unstructured, and the element number is 209,328.

This product is the 4th episode of the Turbomachinery Training Course.

Methodology: Mixing Tank CFD Simulation by Mesh Motion Method

The Mesh Motion method is enabled to model the rotational movement of the impeller. In this method, two different zones with interfaces between them should be created, and the rotating zone, which contains the impeller, would rotate independently of other stationary zones.

The solution is Unsteady, and the k- Ꜫ model is chosen to simulate the turbulence of the flow.

Conclusion

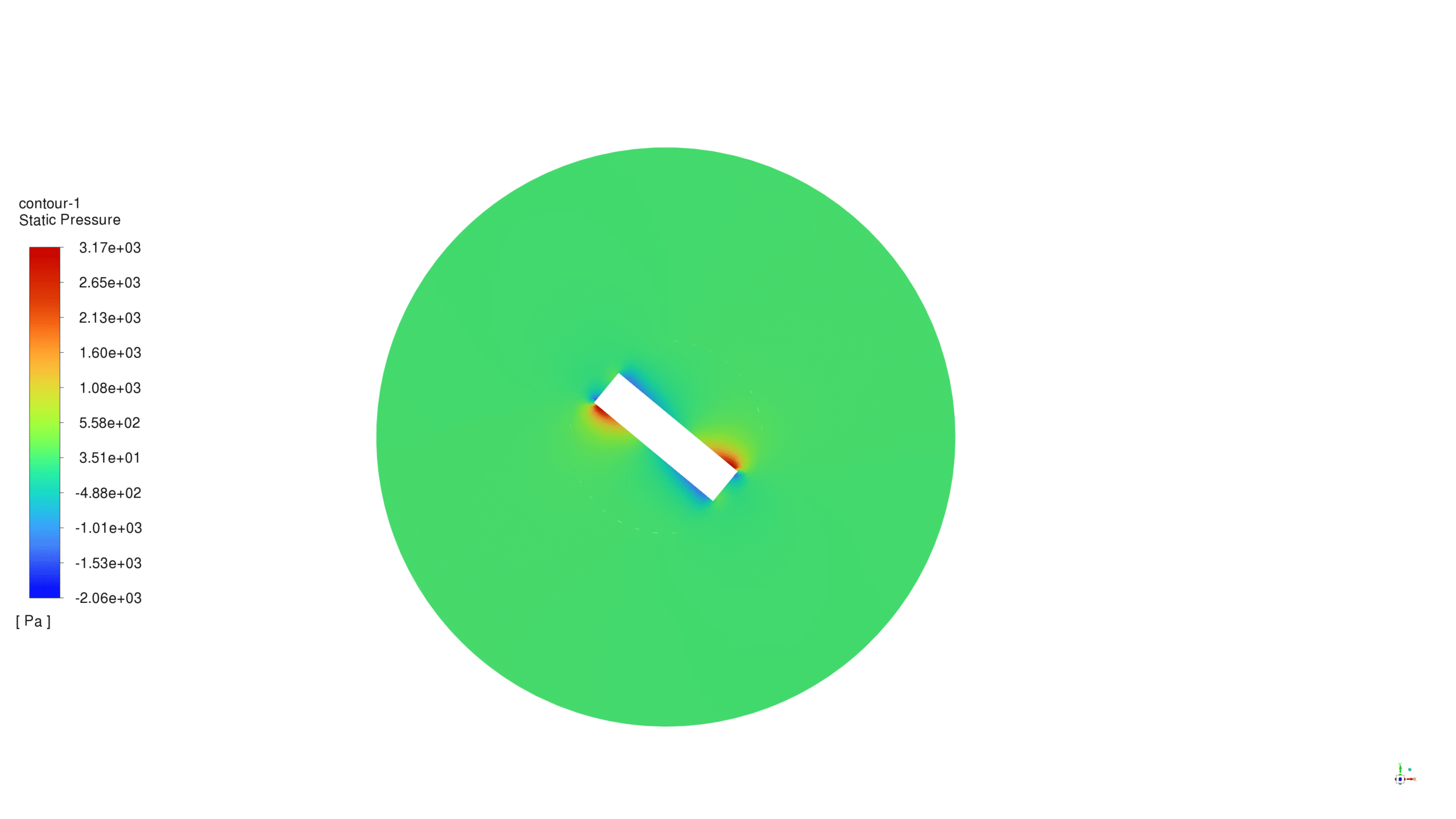

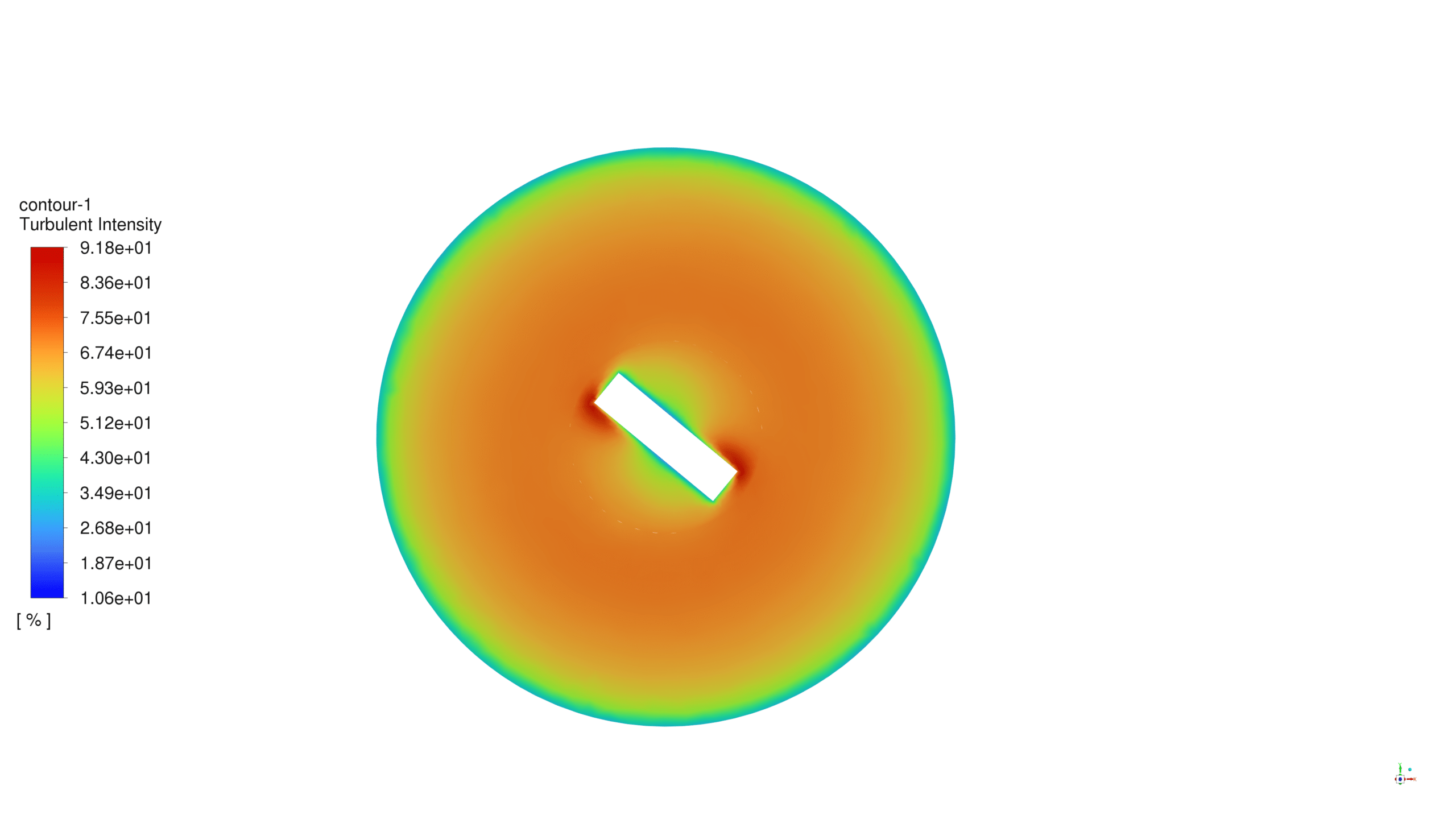

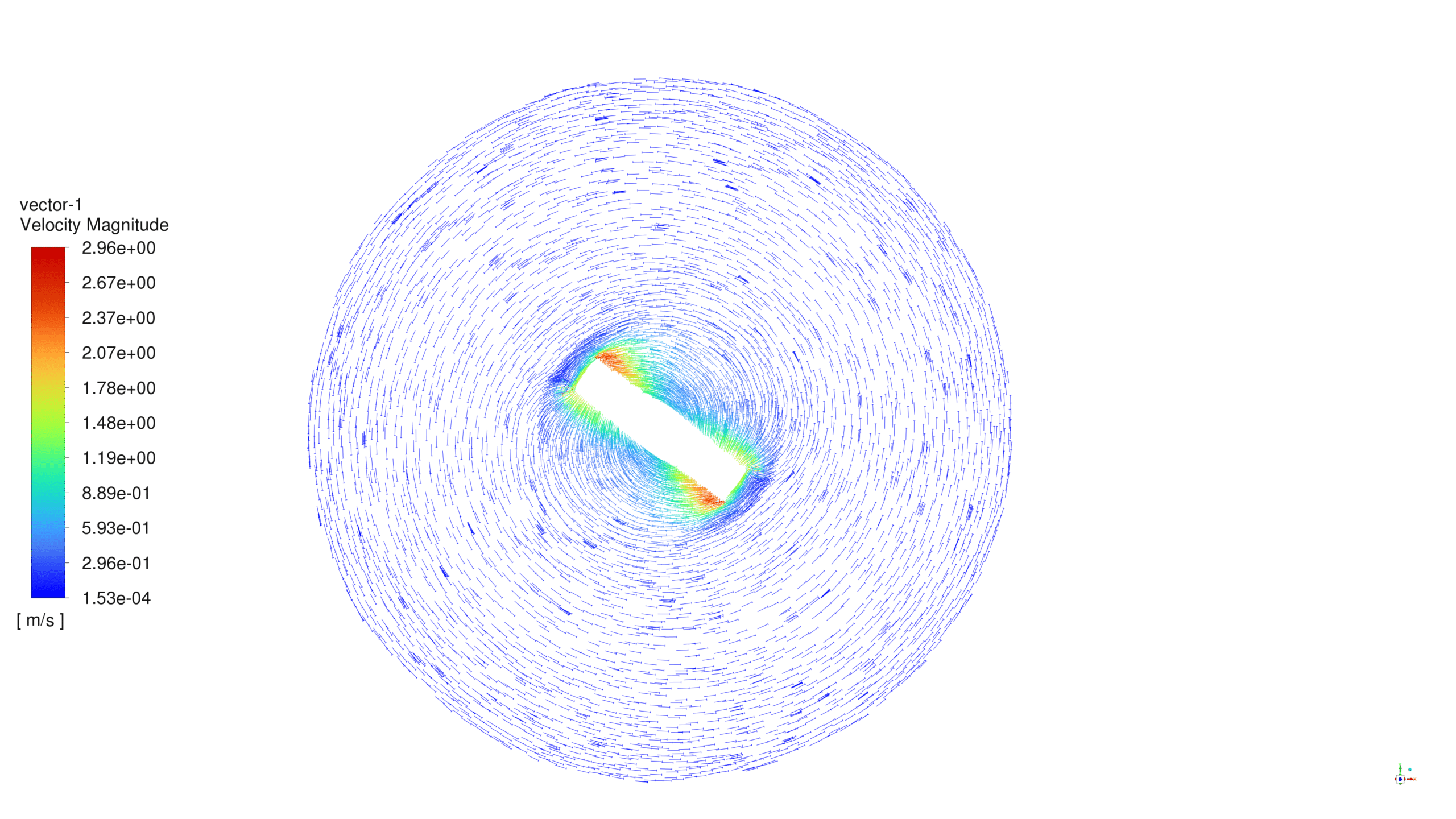

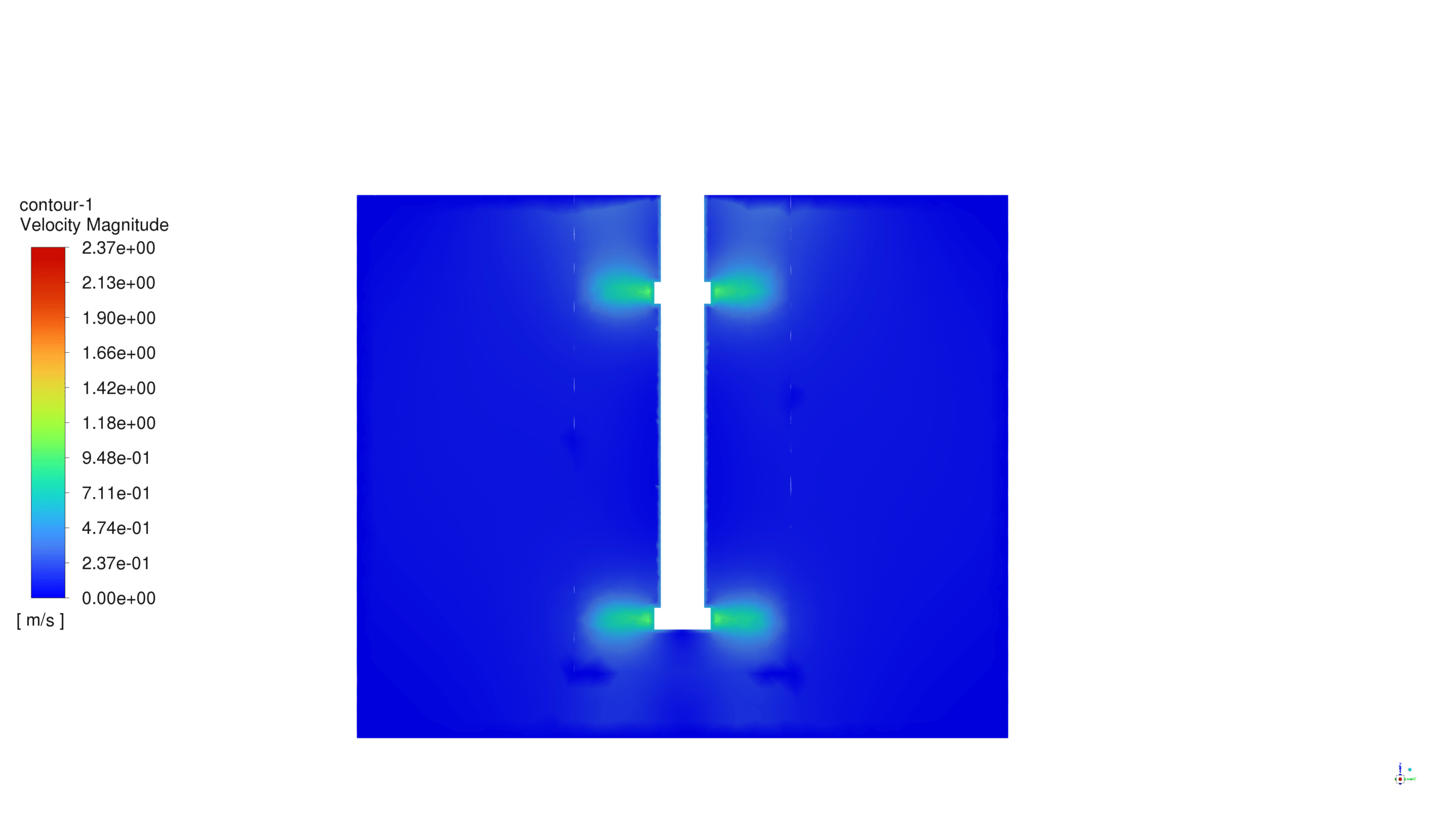

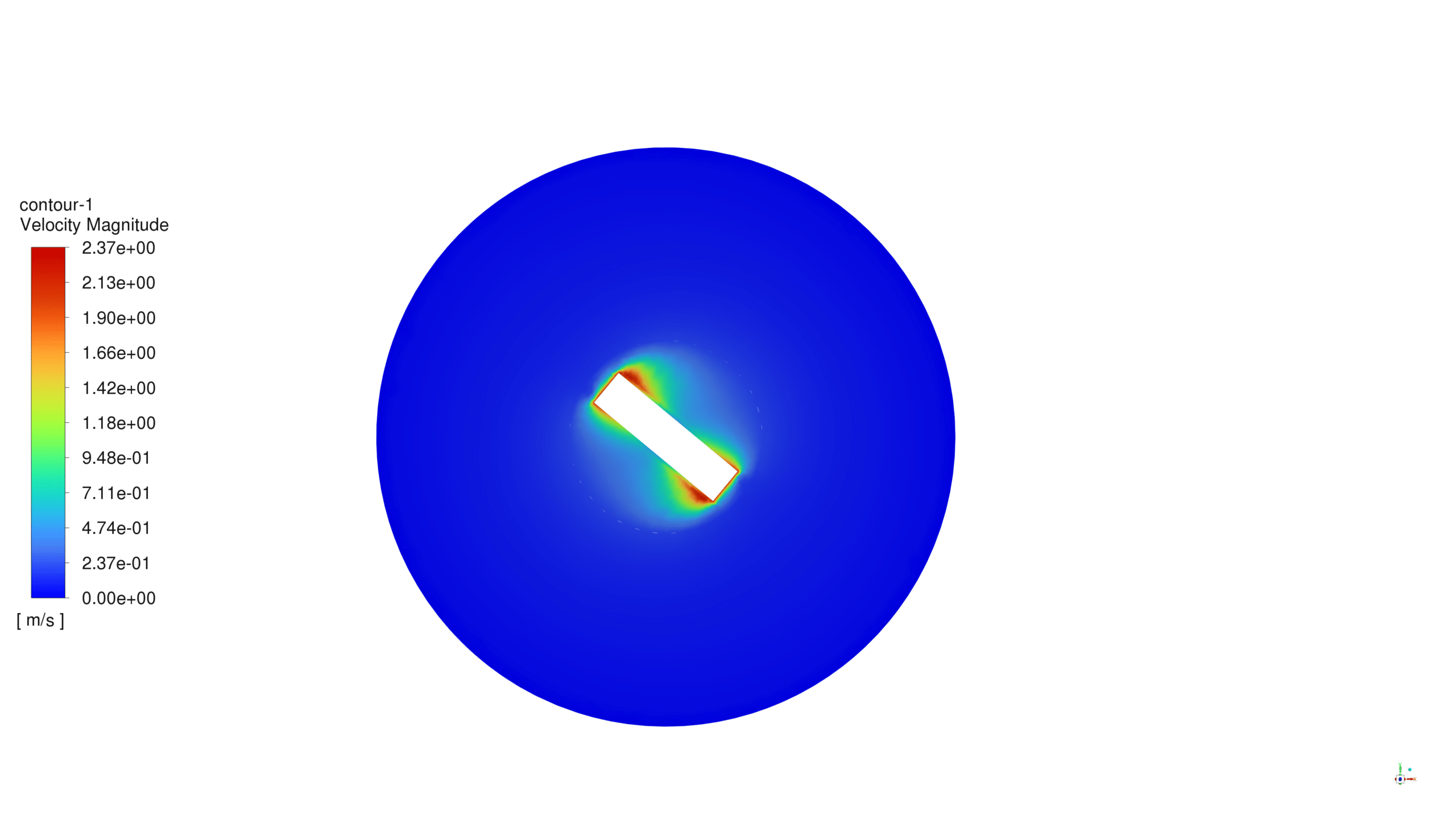

Since the main purpose of the issue is to investigate water movement inside a mixing tank, its related contours can be shown in the figures. Two-dimensional contours related to pressure, velocity, as well as turbulent intensity were obtained.

In the case of pressure, it is visible that the amount of water pressure in front of the impeller is much more than the amount behind it.

As was expected, the speed of the flow behind the impeller is more than in other areas in the domain. Also, the turbulent intensity parameter shows us the turbulence all over the tank.

Arlene Jones –

The step-by-step process of this Mesh Motion method was easy to follow. Now my simulation of a mixing tank closely matches what I observe in real mixing processes!

MR CFD Support –

We’re thrilled to hear that our tutorial on the Mesh Motion method for simulating a mixing tank has been helpful and that your simulation results align with real-life observations. Thank you for your positive feedback!

Mrs. Savanna Johnson –

I’m absolutely thrilled with the Mesh Motion Method, Mixing Tank CFD Simulation tutorial! The step-by-step approach made the complex concepts clear and easy to implement. Watching the mixing process and the resulting vortex evolve in real-time through the simulation was fascinating, and the detailed analysis of pressure, velocity, and turbulence within the tank truly helped me appreciate the dynamics at work.

MR CFD Support –

Thank you so much for your positive feedback! We’re delighted to hear our tutorial made the concepts clear and that you enjoyed the real-time simulation aspect. We strive to create informative and engaging content, and it’s rewarding to know we’ve made a difference. If you have any further questions or need more insight into CFD simulation, feel free to reach out!

Josefina Hegmann –

I really enjoyed learning from the Mesh Motion Method, Mixing Tank CFD Simulation ANSYS Fluent Tutorial. The clear explanation of the impeller’s role in creating flow dynamics within the tank helped me understand the principles involved in turbomachinery. Thanks for such an informative tutorial!

MR CFD Support –

Thank you for your kind words! We are thrilled to hear that our Mixing Tank CFD Simulation tutorial was helpful and informative to you. Understanding the interaction of the impeller and the fluid dynamics is crucial in turbomachinery, and we’re glad we could assist in your learning process. Your enthusiasm for the topic is much appreciated, and we look forward to providing you with more high-quality learning material in the future.

Mylene Bailey –

I am deeply impressed by the detailed contours and the effective simulation of turbulence in the mixing tank model! The use of unsteady-state simulation and the k-ε model in representing the complex fluid dynamics was brilliant. It really helped me to understand the effects of impeller rotation on the water pressure and flow velocity within the mixing tank. Outstanding work!

MR CFD Support –

Thank you for your amazing feedback! We’re elated that the detailed contours and the implementation of the turbulence model in the simulation met your expectations and helped enhance your understanding of fluid dynamics in a mixing tank. Your appreciation truly motivates us to keep offering high-quality and informative educational experiences.

Ms. Ebba Mosciski –

The Mesh Motion method looks fascinating. Can you explain a bit more about how it works to model the rotating impeller, and how it ensures accurate flow representation around the moving parts?

MR CFD Support –

The Mesh Motion method allows the mesh for the impeller region to rotate independently within the stationary tank mesh. It ensures smooth transition of flow properties across the interface between rotating and stationary zones, accurately capturing the impeller’s impact on the fluid dynamics.

Prof. Esta Breitenberg Sr. –

I am very impressed with the detailed results shown in the figures, especially the pressure and velocity contours behind the impeller.

MR CFD Support –

Thank you for your positive feedback on the Mixing Tank CFD Simulation ANSYS Fluent Tutorial! We’re glad to hear that the detailed contours provided a clear understanding of the flow dynamics. If you have any further questions or need more insights, please feel free to reach out to us.

Celestine Satterfield –

I’ve just finished the tutorial for the mesh motion method in the Mixing Tank simulation, and it worked flawlessly. Seeing how the impeller induces the flow and creates turbulence was insightful. The water movement inside the tank was depicted with stunning clarity in the contour figures, especially the difference in pressure in front of and behind the impeller. Really high-quality tutorial, very impressed!

MR CFD Support –

Thank you for the compliments! We’re so glad to hear that the tutorial was clear and helpful. It’s always a pleasure to receive feedback that our products are delivering value and insight into complex simulations like the Mixing Tank CFD using the Mesh Motion method. If you have any more feedback or need further assistance, feel free to reach out!

Mrs. Loraine Bins –

The step-by-step tutorial for this simulation is really well explained. It guided me smoothly through setting up the Mesh Motion method and clearly showed how to analyze the results from the mixing tank. Great work!

MR CFD Support –

Thank you for your kind words! We are thrilled to hear that our tutorial on the Mesh Motion method for the mixing tank simulation was helpful and easy to follow. We aim to provide clear and thorough guidance for our users, and your feedback validates our efforts. If you need further assistance or are curious about advanced applications, feel free to reach out!

Emily Kshlerin –

The product has thorough coverage on the topic. The visuals are top-notch and the step-by-step instructions are easy to follow!

MR CFD Support –

Thank you for your kind words! We’re delighted to hear that you found the tutorial valuable and the visuals effective. If you have any more questions or need further assistance in the future, feel free to reach out!

Prof. Dorian Baumbach –

I’m quite impressed with how the Mesh Motion method was utilized for the impeller rotation. The turbulent flow visualization behind the impeller was insightful. Excellent work!

MR CFD Support –

Thank you for your kind words! We’re glad to hear you found the Mesh Motion method’s application in the mixing tank simulation insightful and that our visualization helped you understand the turbulent flow dynamics. We always strive for clarity and precision in our CFD simulations, so your feedback is very much appreciated.

Dr. Reinhold Crooks II –

I’m thoroughly impressed by the details of the flow dynamics managed by the mixing tank simulator. The contours look precisely clear and provide an excellent visualization of the process. Kudos to the team for a comprehensive tutorial!

MR CFD Support –

Thank you for your kind words! We are thrilled to hear that our product met your expectations and provided valuable insights into the mixing process. We strive to deliver quality educational content, and feedback like yours motivates us to keep improving. Don’t hesitate to reach out if you have any more questions or need further assistance.

Prof. Scottie Stoltenberg –

The tutorial was fantastic! I never knew rotating fluid dynamics could be so clearly demonstrated. Watching the creation of the vortex was enlightening, and the explanation of turbulent intensity across the tank helped me a lot for my project.

MR CFD Support –

Thank you for your kind words! We are thrilled to hear that the mixing tank simulation and the demonstration of the Mesh Motion method was helpful for your project. Your understanding and appreciation of the fluid dynamics involved is exactly what we aim for with our tutorials. If you need further assistance or have more projects in the future, don’t hesitate to reach out!

Alysa Bailey –

I was really impressed by the clarity of simulation results in this tutorial. The vortex created by the impeller was vivid, and pressure differences across the tank were quite informative.

MR CFD Support –

Thank you so much for your positive feedback! We’re thrilled to hear that our simulation results provided clear and informative insights into the fluid dynamics of the mixing tank. If you have any more thoughts or need further information, don’t hesitate to reach out. We are always here to help!

Sammie Dach –

I found the Mesh Motion method fascinating in the simulation of the mixing tank! The graphics really helped convey the dynamic motion within the tank.

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that the Mesh Motion method effectively demonstrated the impeller’s dynamics in the mixing tank. It’s great to know the graphics were helpful in visualizing the flow. Your satisfaction with our tutorial encourages us to maintain high standards in our training materials. If you have any further questions or need more assistance, feel free to reach out!

Berneice Schmitt –

The Mesh Motion method seems effectively used in this tutorial. I find it fascinating how the rotation of the impeller creates fluid motion in the tank. Excellent tutorial!

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear that you found the Mesh Motion method and the simulation of the mixing tank engaging and informative. Your appreciation means a lot to us, and it motivates us to continue providing high-quality tutorials. Don’t hesitate to check out more of our learning materials to enhance your CFD knowledge!

Mrs. Lenna Durgan –

I’ve learned a lot from the Mixing Tank CFD Simulation tutorial. The velocity contours clearly showed the flow dynamics caused by the impeller’s rotation. The outlines of turbulent intensity helped me understand where the most mixing occurs within the tank.

MR CFD Support –

We’re delighted to hear that our Mixing Tank CFD Simulation tutorial was so instructive and informative. Understanding flow dynamics and turbulence is crucial for designing efficient mixing tanks. Thank you for your positive feedback!

Prof. Camron McLaughlin –

The tutorial was fantastic in demonstrating the setup and results of the simulation! The visuals were really helpful for understanding the movements within the mixing tank.

MR CFD Support –

Thank you for your kind words! We’re glad the tutorial was informative and the visual aids contributed to a better understanding of the mixing tank dynamics. If you have any further questions or need assistance with similar simulations, please feel free to reach out.

Mr. Napoleon Schneider –

The simulation’s level of detail is impressive. The moving mesh and turbulence modeling evidently provide a robust analysis for the mixing tank operation. It’s great to see how pressure, velocity, and turbulence intensity are captured around the impeller.

MR CFD Support –

We appreciate your positive feedback on the Mesh Motion method simulation! It’s our goal to provide detailed and accurate analyses. We’re glad you found the visualization of the mixing process and its effects in different regions of the tank helpful. Thank you for your review.