Non-Premixed Combustion, ANSYS Fluent CFD Simulation Training

$140.00 Student Discount

- The problem numerically simulates Non-Premixed Combustion using ANSYS Fluent software.

- We design the 3-D model by the Design Modeler software.

- We Mesh the model by ANSYS Meshing software, and the element number equals 11202.

- We use the Species Model to define the chemical reaction between fuel and oxidizer.

- We select the Non-Premixed Combustion because the fuel and oxidizer enter the chamber from separate paths.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Description

This simulation is about Non-Premixed Combustion via ANSYS Fluent software. We perform this CFD project and investigate it by CFD analysis.

In this project, a two-dimensional combustion chamber is designed in which air flow and fuel flow enter simultaneously from two different inlets with different flow rates.

The combustion process occurs when some air is combined with some hydrocarbon fuel to convert fuel energy into heat energy. After the combustion occurs, the products of chemical reactions leave the combustion chamber.

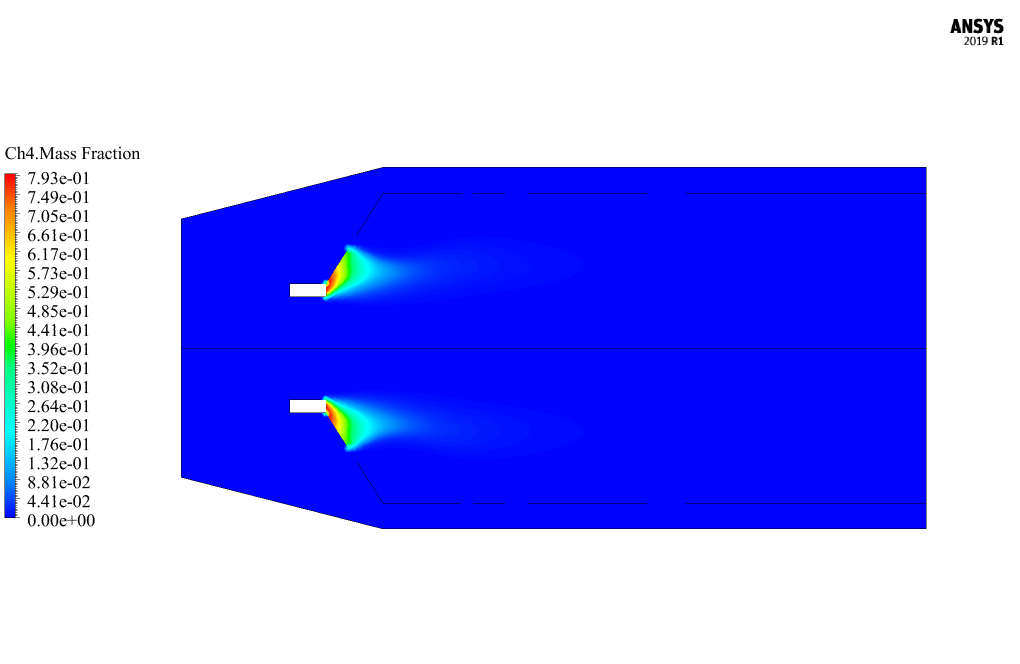

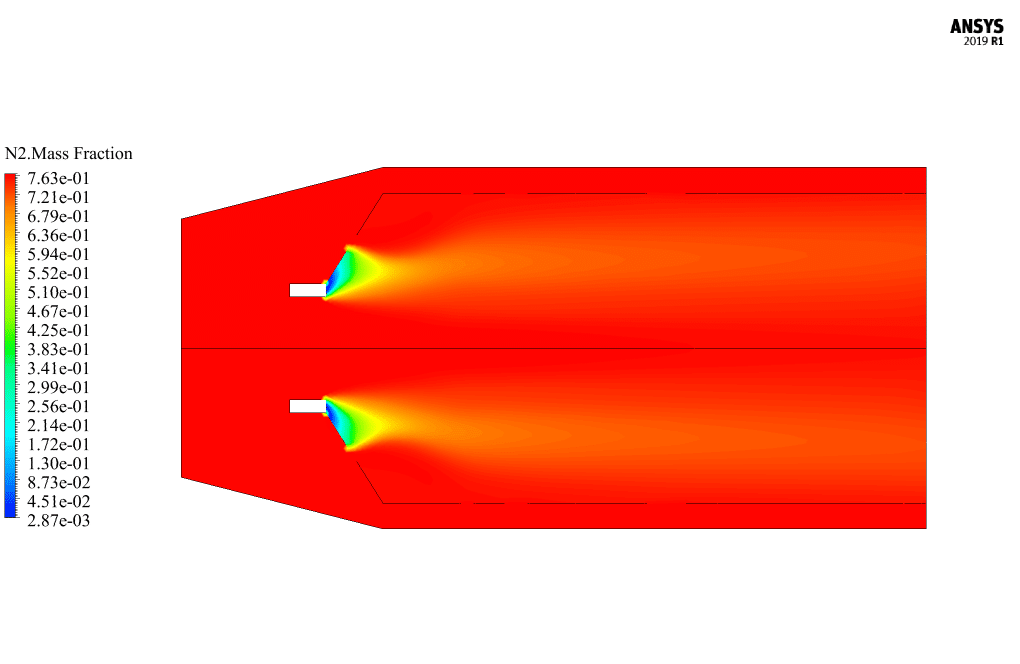

Airflow (consisting of N2 with a mass fraction of 0.767 and O2 with a mass fraction of 0.233) at a temperature of 300 K and mass flow rate of 1.19 kg/s, and fuel flow (consisting of CH4 with a mass fraction of 1 At a temperature of 300 K and a flow rate of 0.019 kg/s) enter the combustion chamber through two separate and independent inlets to combine the chemical reaction of combustion to occur.

The geometry of the present model is drawn by Design Modeler software. The model is then meshed by ANSYS Meshing software. The model mesh is unstructured, and 11202 cells have been created.

Non-Premixed Method

The Species model has been used in this numerical simulation to model the combustion and the chemical reaction. A non-premixed model has been used to define species composition.

In this type of combustion, fuel and oxidizer enter the reaction zone of the combustion chamber through separate paths; They do not mix (premix) before fully entering the combustion chamber.

The non-premixed combustion model defines the mixture fraction, which represents the mass fraction derived from the fuel flow. In other words, the mixture fraction is equivalent to the local mass fraction of fuel flow elements (such as C, H, etc.) in different species (such as CO2, H2O, O2, etc.).

Non-Premixed Conclusion

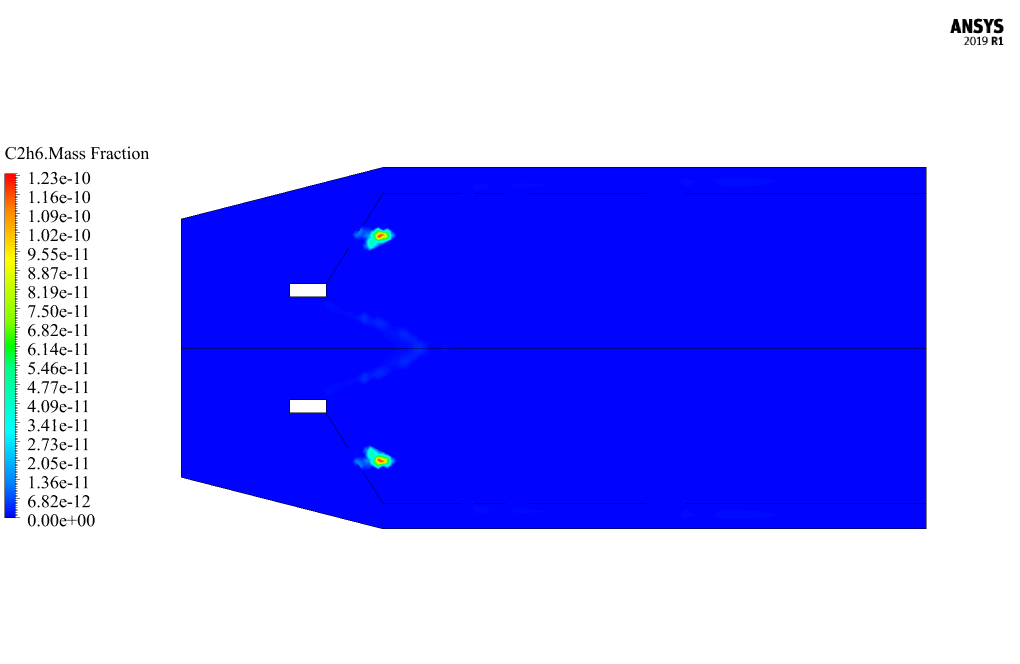

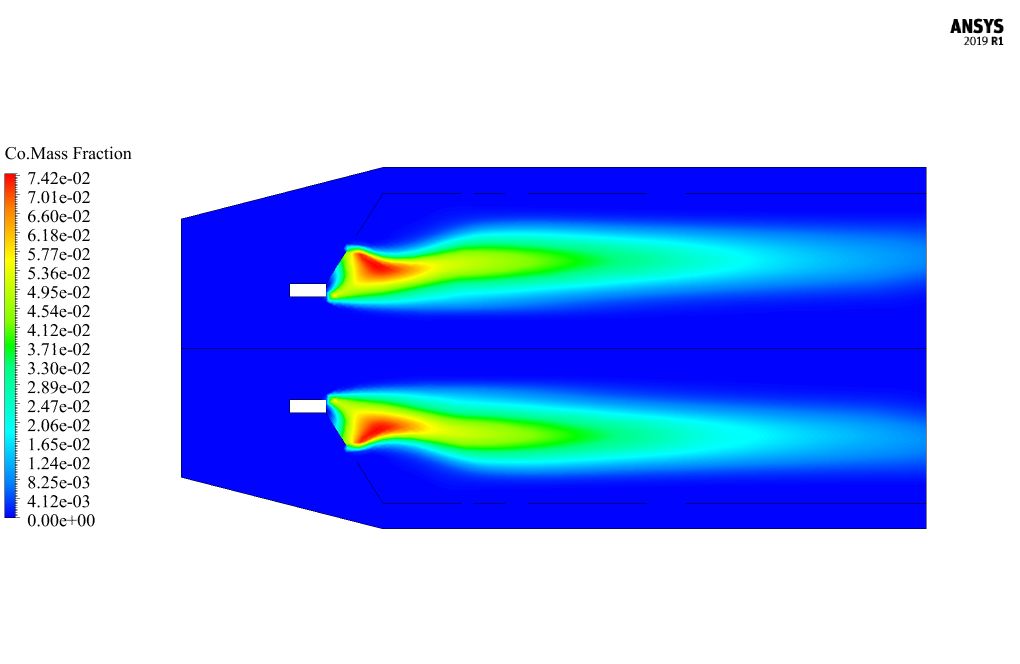

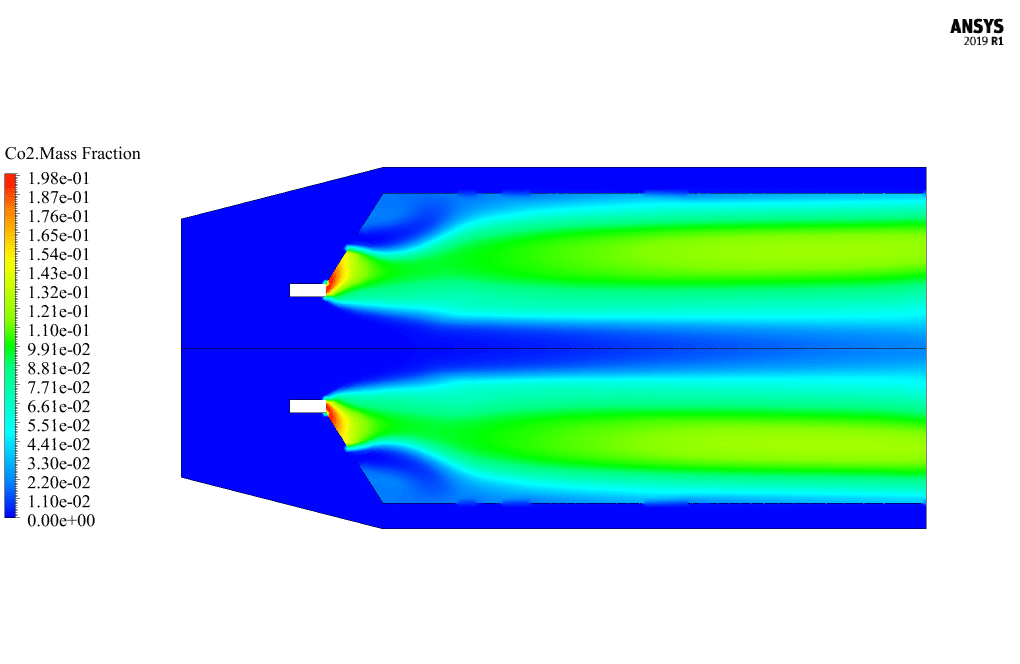

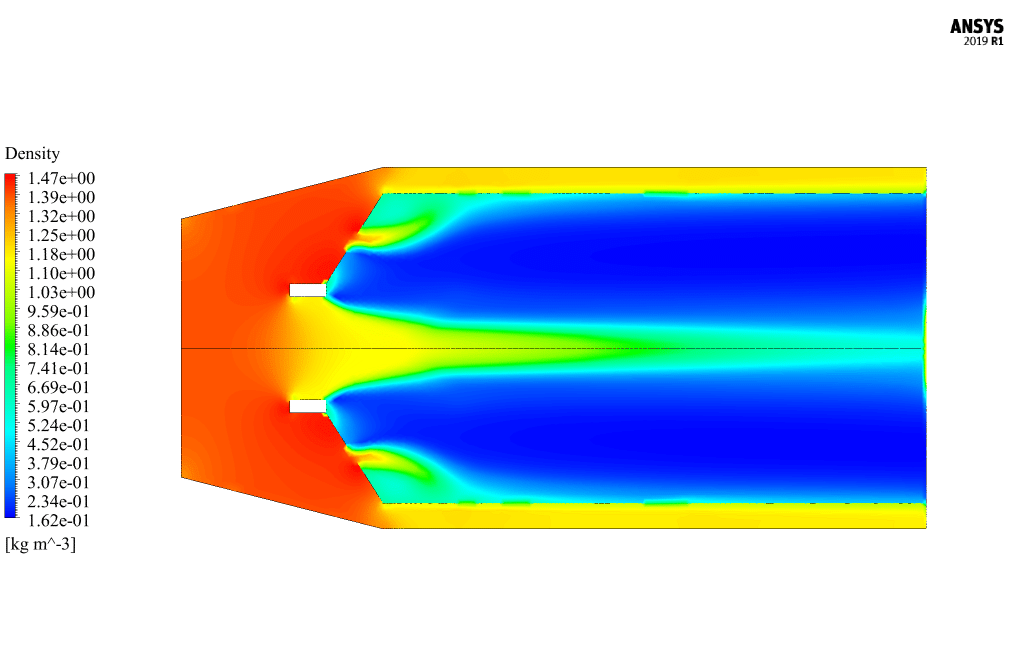

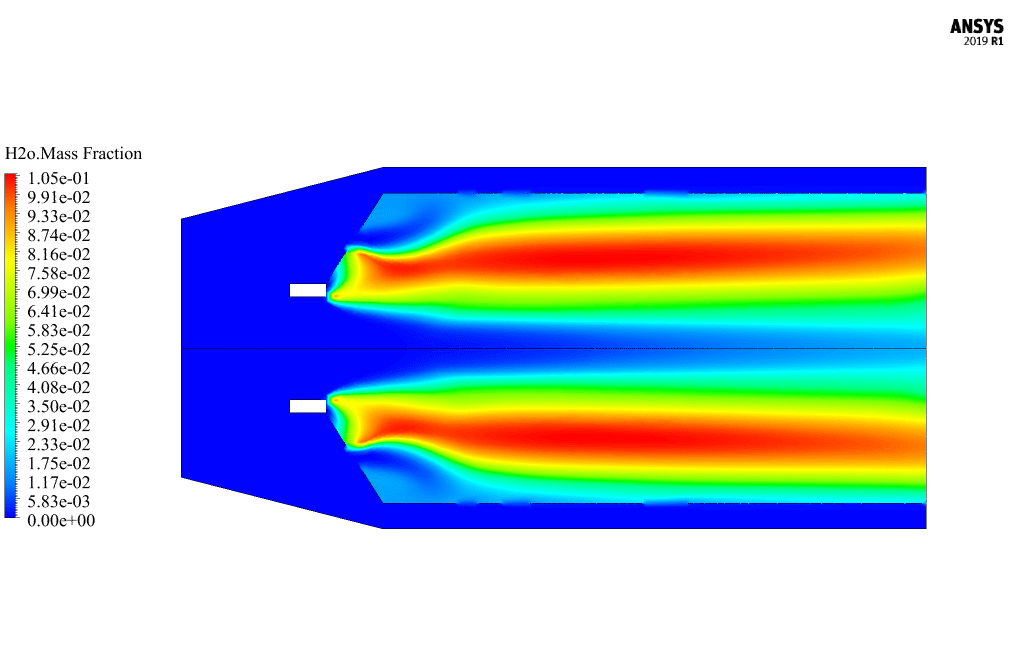

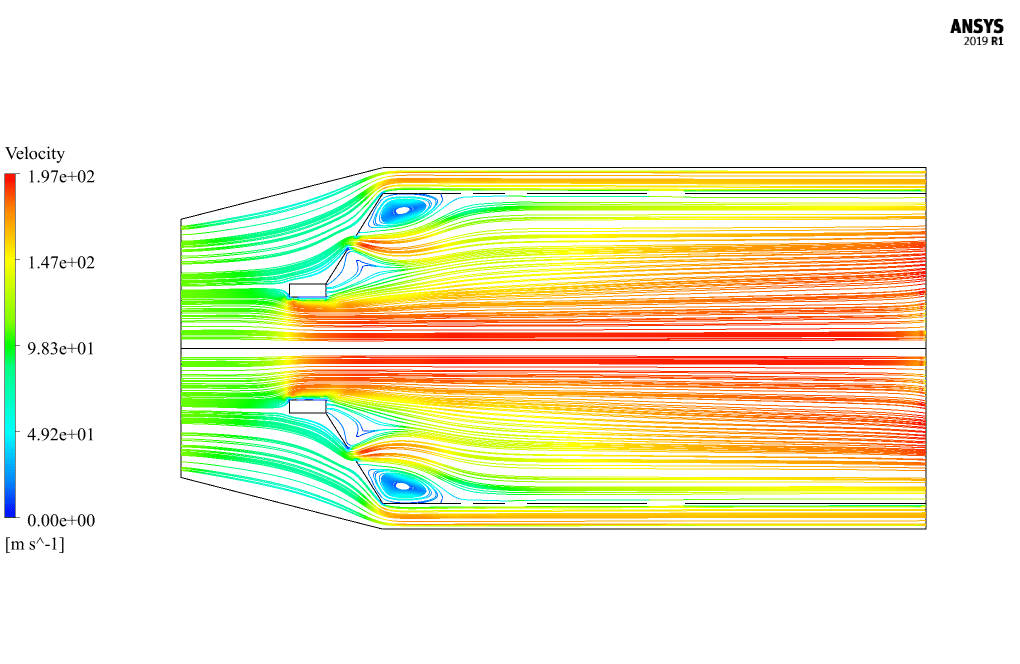

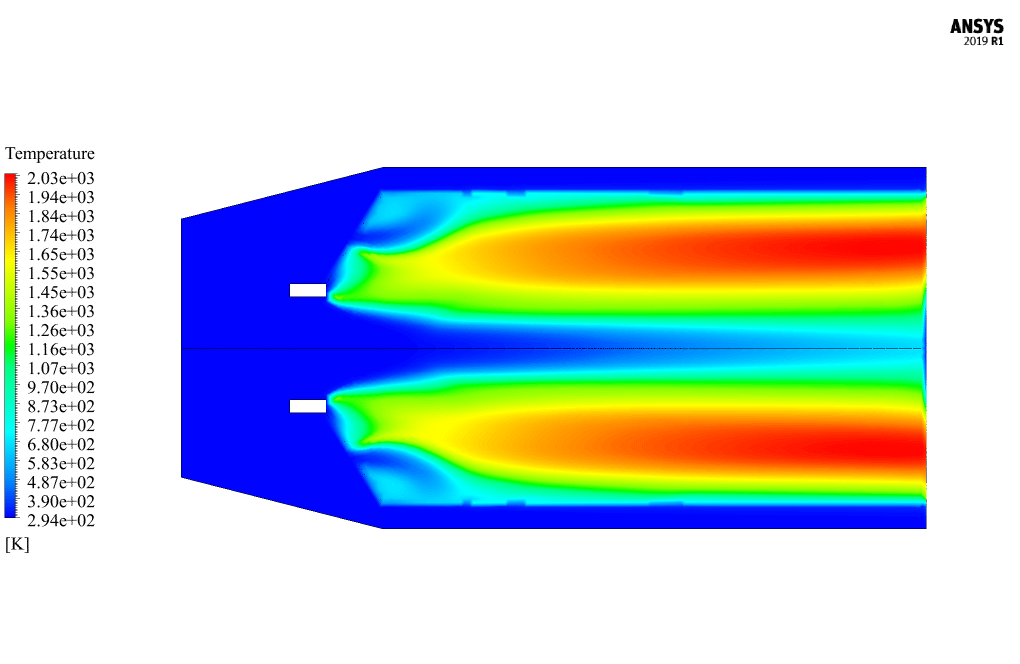

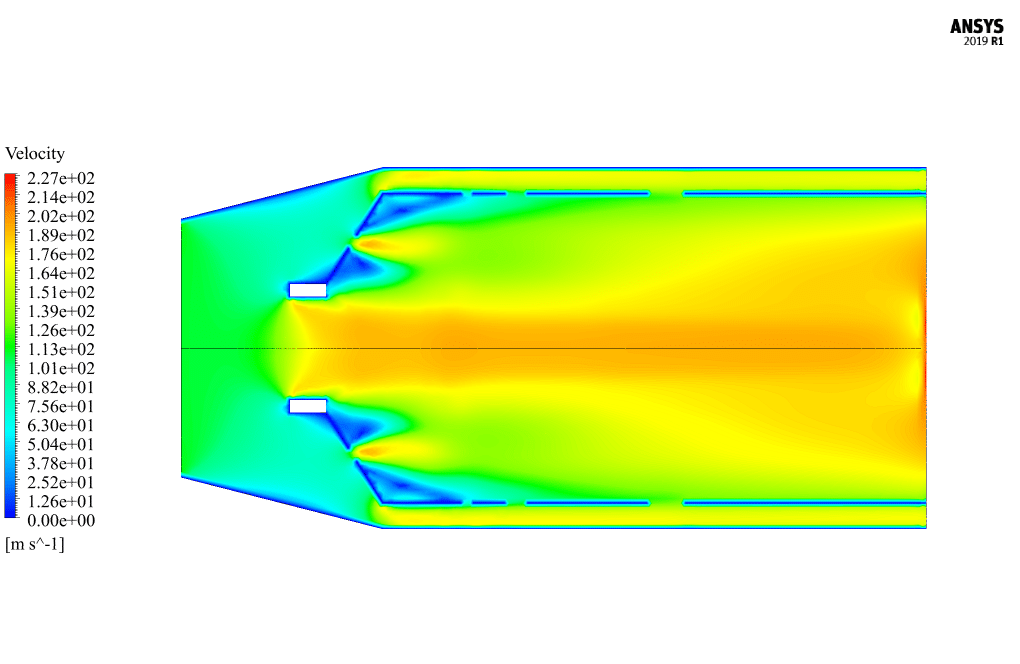

After simulation, 2D contours related to pressure, temperature, velocity, density, and mass fraction O2, CH4, H2O, CO2, N2, CO, and C2H6 are obtained.

Also, 2D pathlines inside the chamber are obtained. The results show that The combustion reaction occurred properly inside the combustion chamber.

As a result of the combustion reaction between the reactants (methane fuel and airflow), the products of the reaction, such as CO, CO2, H2O, etc., are produced.

Bette Kertzmann –

How does the simulation handle the chemical reactions involved in non-premixed combustion?

MR CFD Support –

The simulation uses the Finite-Rate/Eddy-Dissipation model to handle the chemical reactions involved in non-premixed combustion. This model combines the detailed kinetics of the Finite-Rate model with the simplicity and robustness of the Eddy-Dissipation model, making it suitable for combustion simulations.

Adan Cormier –

Can this simulation be used to optimize the efficiency of combustion processes?

MR CFD Support –

Absolutely! By analyzing the combustion characteristics and identifying areas of inefficiency, this simulation can help in optimizing the design and operation of combustion systems, thus improving their efficiency.

Lila Schmitt –

I’m interested in using a different hydrocarbon for the fuel. Can non-premixed combustion simulations handle different fuels, and how would this affect the setup?

MR CFD Support –

Yes, non-premixed combustion simulations in ANSYS Fluent can handle a variety of fuels by updating the species transport and reaction mechanisms accordingly. When changing the hydrocarbon fuel, you need to configure the species’ properties and reaction kinetics based on the new fuel choice. This could also potentially affect the combustion temperature, reaction rates, and product species, so you would need to adjust inlet conditions and potentially the mesh for optimal resolution of the different flame characteristics.

Ms. Emmanuelle Will –

The training was top-notch! It helped me understand the non-premixed combustion process so well, especially the way the species model is used in the simulation.

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that our Non-Premixed Combustion, ANSYS Fluent CFD Simulation Training was helpful to you and made the concept clear. If you have any more questions or need further assistance, don’t hesitate to reach out.

Chris Rutherford III –

I’m really impressed by the level of detail that the Non-Premixed Combustion simulation provided. The contour plots for all the reaction products gave me a complete perspective on the combustion progress throughout the chamber.

MR CFD Support –

Thank you for your valuable feedback! We’re delighted to hear that you found our Non-Premixed Combustion simulation insightful and that the detailed contour plots provided a thorough understanding of the combustion process. It’s always rewarding to know that our efforts to deliver comprehensive CFD analysis are appreciated. Should you have any inquiries or need further information about our learning products, please don’t hesitate to reach out.

Price Schaden –

Fantastic resource! The level of detail in both the setup and the results for the Non-Premixed Combustion makes it invaluable for understanding combustion simulations.

MR CFD Support –

Thank you so much for your kind words! We are thrilled to hear that you found the Non-Premixed Combustion simulation training so detailed and helpful. Understanding combustion is crucial and it’s great to see our simulation could aid in that. If you have any further feedback or require additional information, please let us know.

Saige Wiegand –

I’m highly impressed with the precise control over reactant flow rates in the robust design of the combustion chamber. It is evident that the results accurately map out the dynamics of non-premixed combustion. Excellent training material for anyone studying combustion processes.

MR CFD Support –

We gratefully acknowledge your positive feedback and are thrilled to learn the Non-Premixed Combustion simulation has met your educational needs. Thank you for choosing our CFD Simulation Training for your combustion study and sharing your experiences!

Frederic Hettinger Sr. –

I’m quite fascinated by the use of two separate inlets for fuel and oxidizer in this non-premixed combustion simulation. Is this a common setup for industrial combustion systems, and what is the primary advantage of using segregated inlets over a premixed approach?

MR CFD Support –

Yes, using two separate inlets for the fuel and oxidizer in non-premixed combustion is common in industrial applications. The primary advantage is that it offers more control over the combustion process, improving efficiency and safety. In non-premixed systems, the mixture of fuel and air doesn’t occur until they reach the combustion zone, which allows for more stable combustion and reduces the risk of backfire. Furthermore, it can be beneficial for achieving higher temperatures and controlling emissions.

Mrs. Antonetta Hettinger –

Can I contribute to this simulation or request a customized simulation?

MR CFD Support –

We welcome contributions and customization requests. If you have specific scenarios, parameters, or conditions you’d like to explore, please reach out to us. We’re here to accommodate your simulation needs.

Jan Bode –

What are the main products of the combustion reaction in this simulation, and are the results showing any incomplete combustion phenomena such as the formation of CO?

MR CFD Support –

The main products of the combustion reaction in the simulation are CO2, H2O, and N2. The results also indicate the presence of CO, suggesting incomplete combustion phenomena. This could be due to various factors within the combustion chamber such as temperature gradients, mixing rates, or insufficient residence time.

Mr. Albin Torp –

The simulation explanation is quite detailed, but does it address possible pollutants created during combustion like NOx or SOx?

MR CFD Support –

The specific simulation outlined for Non-Premixed Combustion using ANSYS Fluent doesn’t explicitly mention tracking or analyzing the formation of pollutants such as NOx or SOx. It details the primary combustion products such as CO2, H2O, CO, and C2H6. To consider the formation of pollutants like NOx or SOx, specific models like NOx formation models would need to be included in the simulation setup.

Miss Loraine Farrell –

I’m intrigued by how the non-premixed combustion process is simulated. Could you clarify what distinguishes the non-premixed model from other combustion models in ANSYS Fluent?

MR CFD Support –

In the non-premixed combustion model used by ANSYS Fluent, fuel and oxidizer enter the reaction zone through separate paths and only mix when they reach the combustion chamber. This contrasts with premixed combustion models where the fuel and oxidizer are premixed before introduction to the combustion chamber. The disparity lies in the different control and influence over mixing and reaction rates, influencing flame stability, combustion intensity, and emissions.

Prof. Dudley Adams DDS –

This product makes the complex concept of non-premixed combustion quite easy to grasp. Through the detail oriented stages of this tutorial, I firmly understood how the combustion process works in theory and how it can be accurately simulated within ANSYS Fluent. Seeing the end-to-end process including chemistry and physics of combustion, flow pathways, temperature contours, and the behavior and distribution of species was incredibly insightful.

MR CFD Support –

We truly appreciate your feedback and are glad to hear that our Non-Premixed Combustion simulation training helped clarify the intricacies of combustion processes for you. It’s especially rewarding to know that you found the content detailed and comprehensive. Thank you for recognizing our effort to provide high-quality learning materials. If you need further assistance or have more enquiries about the simulations, feel free to reach out!

Dr. Liana Rau –

The innovative use of CFD in this simulation is commendable!

Mrs. Misty Koss –

I am entirely satisfied with the Non-Premixed Combustion CFD simulation training. The level of detail provided in the simulation of the combustion chamber was exceptional, with a clear representation of different species and temperature distribution being simulated accurately.

MR CFD Support –

Thank you so much for leaving a positive review of our Non-Premixed Combustion CFD simulation training and mentioning the clarity and details of our product. We’re really glad to hear that the training was effective and met your expectations. Your feedback is greatly appreciated, and we look forward to providing you with more high-quality learning experiences in the future!

Reginald Langworth –

Is the Species model appropriate for all types of combustion simulations, or does it have certain limitations in ANSYS Fluent?

MR CFD Support –

The Species model is particularly suited for simulations involving separate fuel and oxidizer streams, such as in non-premixed or partially premixed combustion scenarios. Though widely used, it may have limitations for premixed combustion cases or scenarios where detailed chemistry or pollutant formation need to be analyzed.