Reverse Cross Flow Plate Heat Exchanger Simulation

$80.00 Student Discount

- The problem numerically simulates Reverse Cross Flow Plate Heat Exchanger using ANSYS Fluent software.

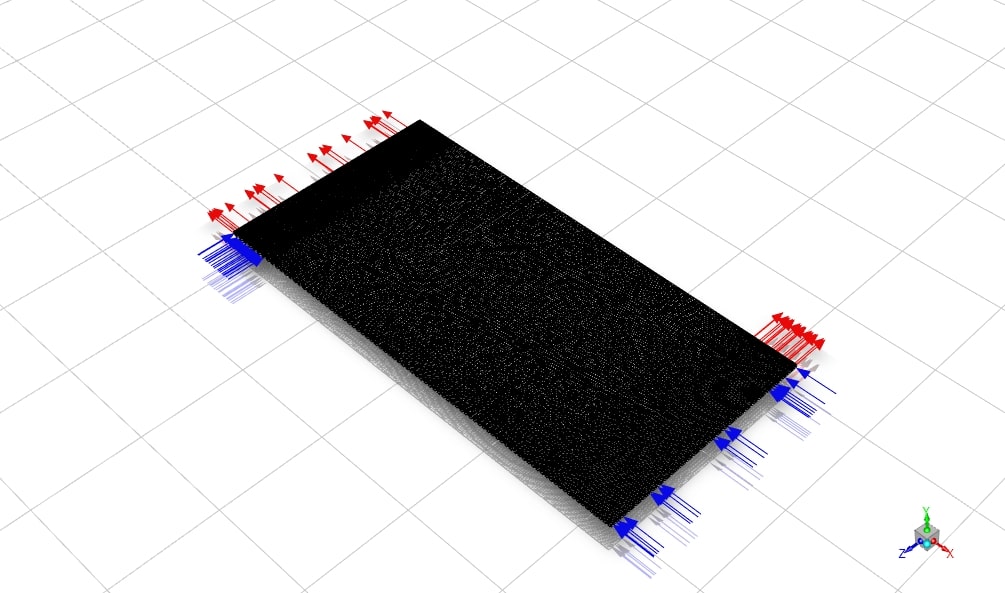

- We design the 3-D model by the Design Modeler software.

- We Mesh the model by ANSYS Meshing software, and the element number equals 155000.

- Ethylene Glycon is used as an operating fluid whose properties are defined as temperature-dependent polynomials.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Reverse Cross Flow Plate Heat Exchanger, ANSYS Fluent CFD Simulation Training

The problem simulates Reverse Cross Flow Plate Heat Exchanger using ANSYS Fluent software. We perform this CFD project and investigate it by CFD analysis.

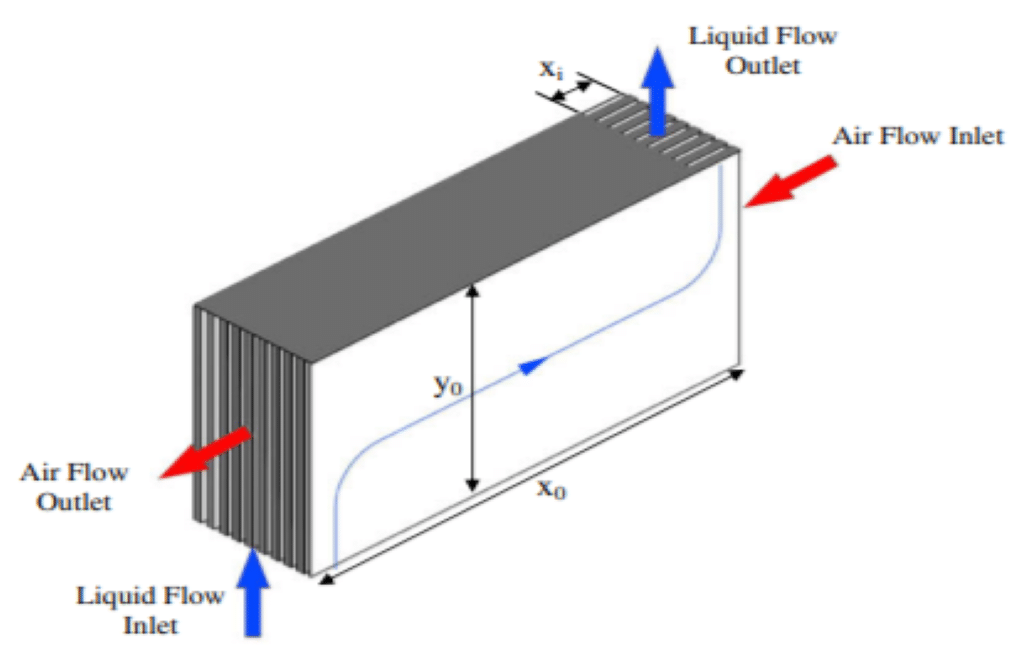

This heat exchanger consists of two special flow channels such that the air flows from one side of the central panel and the solute flow to the other but in the opposite direction to the airflow. The fluids used in the present model include air, Ethylene Glycol, or (CH2OH).

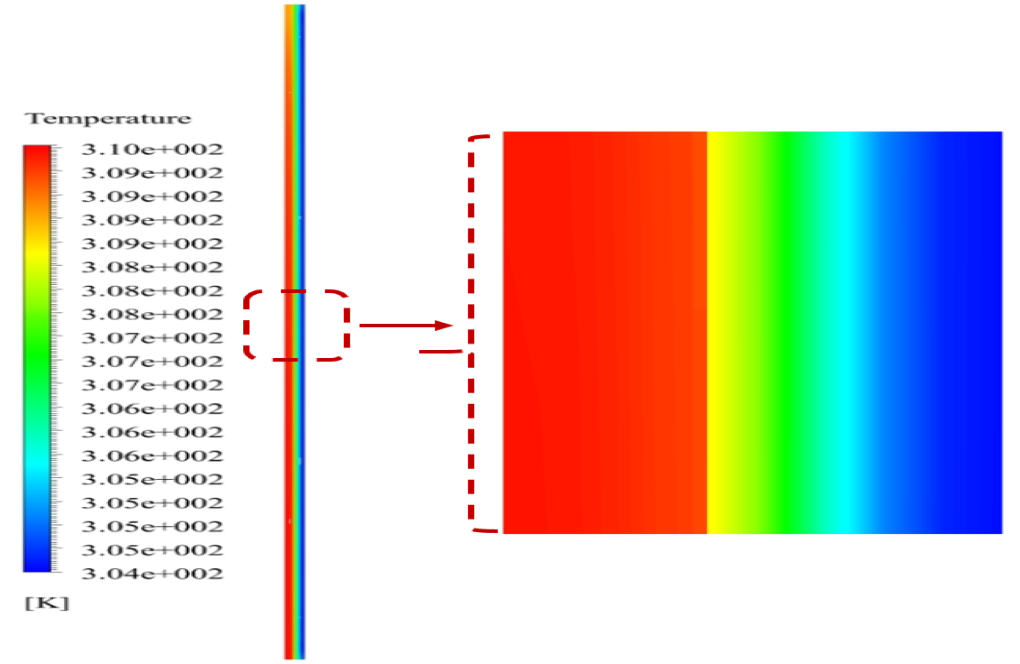

On the other hand, a separator plate is used as an interface. The liquid has a higher temperature than the airflow. The present study investigates the fluid behavior and heat transfer in the heat exchanger and evaluates its performance based on the Number of Transfer Units (NTUs).

The 3-D geometry of the present model is designed by Design Modeler software. The current model is a heat exchanger panel with two flow paths, such that, on the one hand, the hot liquid flow and, on the other hand, cold airflow in the opposite direction to the liquid flow. The outer walls also act as insulators.

The meshing of the present model is performed by ANSYS Meshing software. The mesh is unstructured, and the element number is 155,000. The cells are smaller and more accurate near the wall boundary.

Plate Heat Exchanger Methodology

In this project, Ethylene Glycon is one of two operating fluids. Ethylene Glycol is a colorless, odorless, low-volatility, low-viscosity material whose properties are defined as temperature-dependent polynomials.

Since the hot and cold flows do not integrate within the heat exchanger, there is no need to use a Multiphase flow module.

Plate Heat Exchanger Conclusion

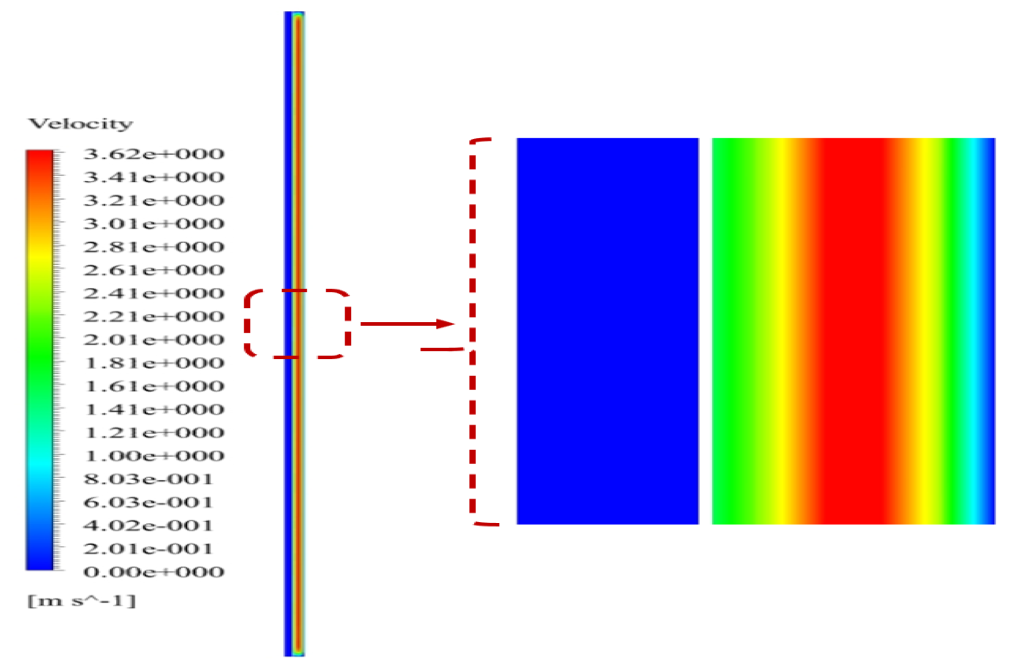

Velocity, temperature, and contours don’t need any extra explanation since they are so clear to understand. The results show the temperature changes well. Heat is transferred from the hot part to the cold part.

The training video obtains the heat transfer rate, and the Nusselt number is obtained.

Hattie Howell –

please upload mesh file link

MR CFD Support –

hi, you can go to the following link:

http://www.mr-cfd.com/shop/reverse-cross-flow-plate-heat-exchanger-cfd-simulation

Ida Zulauf –

Can you explain the advantage of using the RNG k-epsilon turbulence model in this simulation?

MR CFD Support –

The RNG k-epsilon model is chosen because it can accurately predict the onset and amount of turbulent kinetic energy dissipation, which is crucial in heat exchanger simulations.

Bethel Johns –

I’m looking for a simulation of a shell and tube heat exchanger. Can you help with that?

MR CFD Support –

Absolutely! We can certainly help with simulations of shell and tube heat exchangers. Please provide more details about your requirements, and we’ll do our best to accommodate your request.

Mrs. Pearline Prosacco II –

What are the main factors affecting the performance of a reverse cross flow plate heat exchanger?

MR CFD Support –

The main factors include the design of the heat exchanger (e.g., plate geometry and arrangement), the properties of the fluids (e.g., flow rates, temperatures, and thermal properties), and the operating conditions.

Izabella Spinka –

I’ve completed the Reverse Cross Flow Plate Heat Exchanger CFD Simulation training, and I found the results quite impressive. The clarity in the presentation of velocity and temperature changes enhanced my understanding of thermal exchange processes. Excellent module!

MR CFD Support –

Thank you for your positive review! We’re thrilled to hear our Reverse Cross Flow Plate Heat Exchanger training provided you with a clear understanding, and you’re satisfied with the outcomes. Don’t hesitate to reach out should you have more feedback or need further assistance in your learning journey.

Mr. Tyrique Koss –

I’m really impressed by the level of detail in the simulation of the Reverse Cross Flow Plate Heat Exchanger. The contour results must look fascinating. Am I able to visualize the temperature distribution across the separator plate between the hot and cold fluids?

MR CFD Support –

Thank you for your kind words! Yes, the temperature distribution across the separator plate is one of the key results that can be visualized in the simulation. It showcases the effectiveness of the heat exchanger by displaying how the heat is transferred from the hot to the cold fluid, maintaining a necessary barrier so that there’s no mixing of the different streams.

Fredy Stamm –

I was impressed by the level of detail in the Reverse Cross Flow Plate Heat Exchanger simulation tutorial. The clarity of your results made it very easy to understand. Thanks for a great learning tool!

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that our tutorial for the Reverse Cross Flow Plate Heat Exchanger simulation in ANSYS Fluent was clear and helpful in understanding the heat transfer process. Your satisfaction is our top priority, and we’re glad we could assist in your learning experience.

Llewellyn Jacobi –

What makes the Reverse Cross Flow Plate Heat Exchanger efficient in terms of design and flow arrangement, and how does the layout influence its performance relative to other types of heat exchangers?

MR CFD Support –

The Reverse Cross Flow Plate Heat Exchanger is designed to provide high heat transfer efficiency due to the thin plates that create a large surface area over which the fluid flows. The reverse cross-flow arrangement allows for close temperature approach between the fluids since one is flowing in the opposite direction to the other across the plate, maximizing the temperature gradient and heat transfer rate. This counterflow configuration can achieve higher thermal efficiency compared to parallel flow heat exchangers.

Bobbie Conroy –

Really learned a lot from the Reverse Cross Flow Plate Heat Exchanger simulation! I could clearly observe the temperature changes and heat transfer from the hot to the cold parts. Great job on showcasing the intricacies of this process!

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that the simulation helped enhance your understanding of the heat transfer process in a Reverse Cross Flow Plate Heat Exchanger. Your comprehension of the temperature changes really underscores the effectiveness of our training materials. If you have any more questions or need further information, please feel free to reach out.

Keanu Hegmann –

I absolutely enjoyed learning with the Reverse Cross Flow Plate Heat Exchanger simulation training. The details on how the heat transfer rate and Nusselt number were obtained were thoroughly understandable. Great work on explaining the temperature dependencies for Ethylene Glycol and the insulation effects on the outer walls.

MR CFD Support –

Thank you for your feedback! We’re glad to hear that the training provided clear explanations and was easy to understand. It’s great to know that the heat transfer concepts and the application using Ethylene Glycol in the simulation were well received. Your satisfaction with our products is our top priority, so we’re delighted they could contribute to your learning experience.

Amanda Hand –

This module sounds fantastic! Particularly impressed by the temperature-dependent polynomial properties for Ethylene Glycol. Could you share some results on the effectiveness of the heat exchanger and how the NTUs were derived?

MR CFD Support –

Thank you for your positive feedback! The effectiveness of the heat exchanger is evaluated based on its performance and the Number of Transfer Units (NTUs). The results, presented in the study, show temperature changes indicating successful heat transfer from the hot liquid to the cold air side. NTUs are typically calculated by comparing the heat transfer rate to the maximum possible heat transfer rate, though specific results or methods per this simulation were not detailed. If you wish to learn the detailed derivation for NTUs, you may find this information in the training materials or outcomes of the CFD analysis supported by the product.

Miss Laila Beatty IV –

The Reverse Cross Flow Plate Heat Exchanger simulation sounds quite comprehensive. How easy was it to follow the instructions and set up the necessary parameters for this simulation, especially for those who might be new to ANSYS Fluent?

MR CFD Support –

Thank you for your curiosity and for considering the usability of our simulation training. We strive to make the instructions as clear and user-friendly as possible, guiding even those new to ANSYS Fluent through each step of the setup process. I’m glad to hear that you found the materials comprehensive. If there is anything specific you need help with or any suggestions you have on how we could make our training even better, please let us know!

Reggie Ratke –

I’ve benefited a lot from the Reverse Cross Flow Plate Heat Exchanger simulation training! The animated conduction really made it clear how heat transfers within the exchanger. Awesome presentation, MR CFD!

MR CFD Support –

Thank you so much for your positive feedback! We’re thrilled to hear that the simulation training for the Reverse Cross Flow Plate Heat Exchanger was clear and beneficial for you. Visual learning tools like animations can indeed make complex processes easier to understand. We appreciate your compliment on our presentation and are glad you found the training awesome!

Bernie Blanda –

The tutorial was spot on. I could follow easily and the video enhanced my understanding of heat transfer within the exchanger. The clarity and pace made it especially accessible for beginners like me. Great job!

MR CFD Support –

Thank you so much for your review! We’re thrilled to hear that the tutorial was helpful for you and that the video was a valuable resource for enhancing your understanding. Your feedback is greatly appreciated, and we hope to continue providing clear and informative content in the future!

Sebastian Crona –

The software package and tutorial were fantastic! I was particularly impressed by how clear the temperature and velocity contours were. They illustrated the heat transfer process vividly from the hot liquid to the cold air streams!

MR CFD Support –

Thank you for your positive feedback! We are thrilled to hear that our Reverse Cross Flow Plate Heat Exchanger simulation training was helpful and that the visuals provided a clear understanding of the heat transfer process. Your satisfaction with our learning product is our top priority!

Sabina Muller DDS –

Do we have to use only design modeler for this geometry?

MR CFD Support –

Not only design modeler, but we use SpaceClaim software to create the 3D models for our simulations. These tools allow us to create detailed and accurate models of the heat exchangers.

Devyn Heathcote –

I was impressed with the clear presentation of velocity and temperature contours in the reverse cross flow plate heat exchanger simulation. The visualization made it easy to grasp how heat was effectively transferred from the hot liquid to the cold airflow.

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that the visualization in our reverse cross flow plate heat exchanger simulation was clear and informative. Understanding heat transfer dynamics is crucial, and we’re glad our training materials helped make this complex process easier to comprehend. We appreciate your review and hope our products continue to support your learning journey.