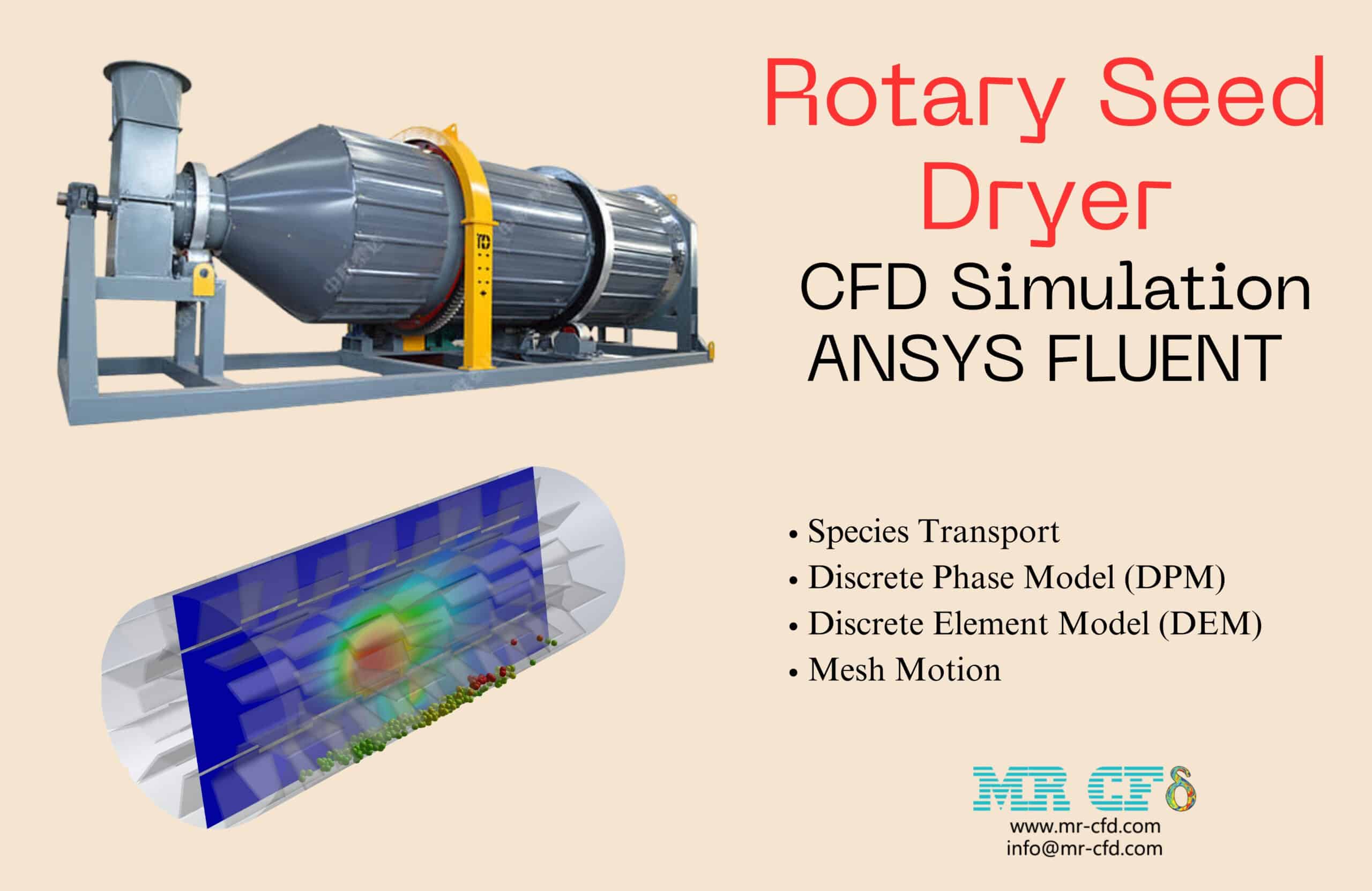

Rotary Seed Dryer CFD Simulation, Using DPM and Moving Mesh, by ANSYS FLUENT

$220.00 $88.00 HPC

- This work presents a CFD–DEM simulation of a rotary seed dryer.

- Hot air flows through the inclined drum at 350 K while the drum rotates at 20 RPM.

- Seeds are modeled with the Discrete Phase Model (DPM) coupled with evaporation into H₂O vapor. The Discrete Element Method (DEM) accounts for particle–particle and particle–wall collisions, improving realism of seed motion.

- Contours of H₂O mass fraction reveal zones of strong evaporation, reaching values up to 0.0026.

- The combined CFD–DPM–DEM approach shows how airflow, fin mixing, and collisions enhance drying efficiency.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Rotary Seed Dryer Simulation: CFD and DEM Analysis of Particle Motion and Moisture Evaporation in a Rotating Drum

Introduction

The efficient rotary drying of seeds plays an essential role in maintaining their quality and reducing post‑harvest losses. Computational Fluid Dynamics (CFD) provides a powerful tool to study heat and mass transfer in drying equipment, offering detailed insights into particle motion, moisture removal, and airflow distribution. In this project, a rotary seed dryer was designed and simulated using ANSYS software to analyze seed–air interactions under transient conditions. The study utilized fluid–particle coupling along with evaporation modeling to capture both airflow dynamics and the drying process inside the cylindrical chamber, aiming to optimize the design for improved drying performance.

Geometry and Mesh

The geometry of the rotary seed dryer consisted of a cylindrical drum with a diameter of 0.5 m and a length of 1.5 m, equipped with several internal fins to enhance particle mixing and drying efficiency. The drum was modeled in ANSYS SpaceClaim and inclined at 10° to induce particle transport along the dryer length. To represent the rotating drum and capture complex recirculation regions around the fins, a volumetric mesh was generated in ANSYS Meshing. A fine tetrahedral mesh containing about 3.5 million elements was produced to balance accuracy and computational expense, ensuring that both continuous gas phase and discrete particles were resolved adequately.

Physical Models and Solver Settings

The simulation of rotary seed dryer was performed in ANSYS Fluent using a pressure‑based transient solver. Gravity was applied with components in the Y and Z directions to reflect the drum’s inclination, and dynamic mesh motion was enabled to rotate the drum at 20 RPM. The realizable k–ε turbulence model was employed to predict turbulent mixing of hot air within the chamber, while the energy equation accounted for heat transfer. The Discrete Phase Model (DPM) and Discrete Element Method (DEM) were coupled to simulate droplet‑like seed particles, including evaporation into H₂O vapor and collisions with both walls and neighboring particles. At the dryer inlet, a velocity of 0.2 m/s and a temperature of 350 K were imposed, while a pressure outlet condition was set at the dryer exit.

Results

The simulation results of rotary seed dryer revealed strong interaction between airflow, rotating fins, and particle motion inside the cylindrical drum. As shown in the contour plots, regions of high H₂O vapor mass fraction developed downstream of the inlet due to evaporation of seeds during heating. A swirling distribution of vapor concentration formed around the fins, with maximum H₂O mass fractions reaching approximately 0.0026 near the mixing zone. The results also indicate that particle motion and seed distribution were strongly influenced by the rotating drum, promoting effective mixing and uniform exposure to hot air. Overall, the CFD analysis demonstrated that the combination of fin geometry, airflow distribution, and rotation speed significantly enhances drying efficiency, making the design suitable for practical seed drying applications.

You must be logged in to post a review.

Reviews

There are no reviews yet.