Unconfined Pool Boiling ANSYS Fluent Tutorial

$160.00 Student Discount

This project investigates the saturated water pool boiling inside a cylindrical chamber.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Description

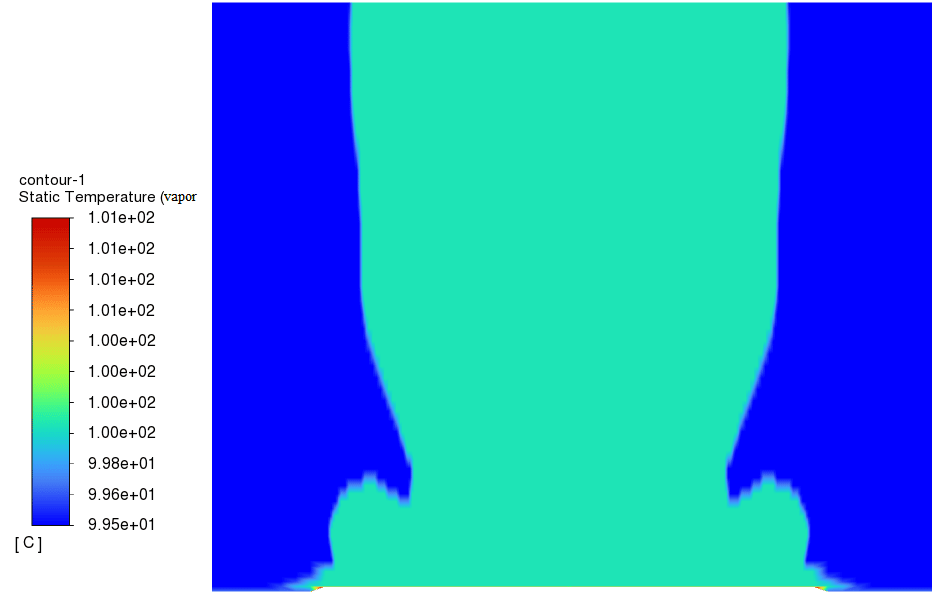

This project investigates the saturated water pool boiling inside a cylindrical chamber. Pool boiling is defined as boiling from a hot surface immersed in a large volume of stagnant liquid. The liquid may be at its boiling point, in which case the term saturated pool boiling is used, or below its boiling point which is called subcooled pool boiling.

This product is the second chapter of the Eulerian Multiphase Model Training Course.

The motion of the liquid induced by the boiling process and the velocities are assumed to be low in academic experimental applications where conditions such as ONB (Onset of Nucleate Boiling), DNB (Departure from Nucleate Boiling), and CHF (Critical Heat Flux) are examined. However, pool boiling is unusual in industrial equipment and applications where extreme conditions such as burnout may occur.

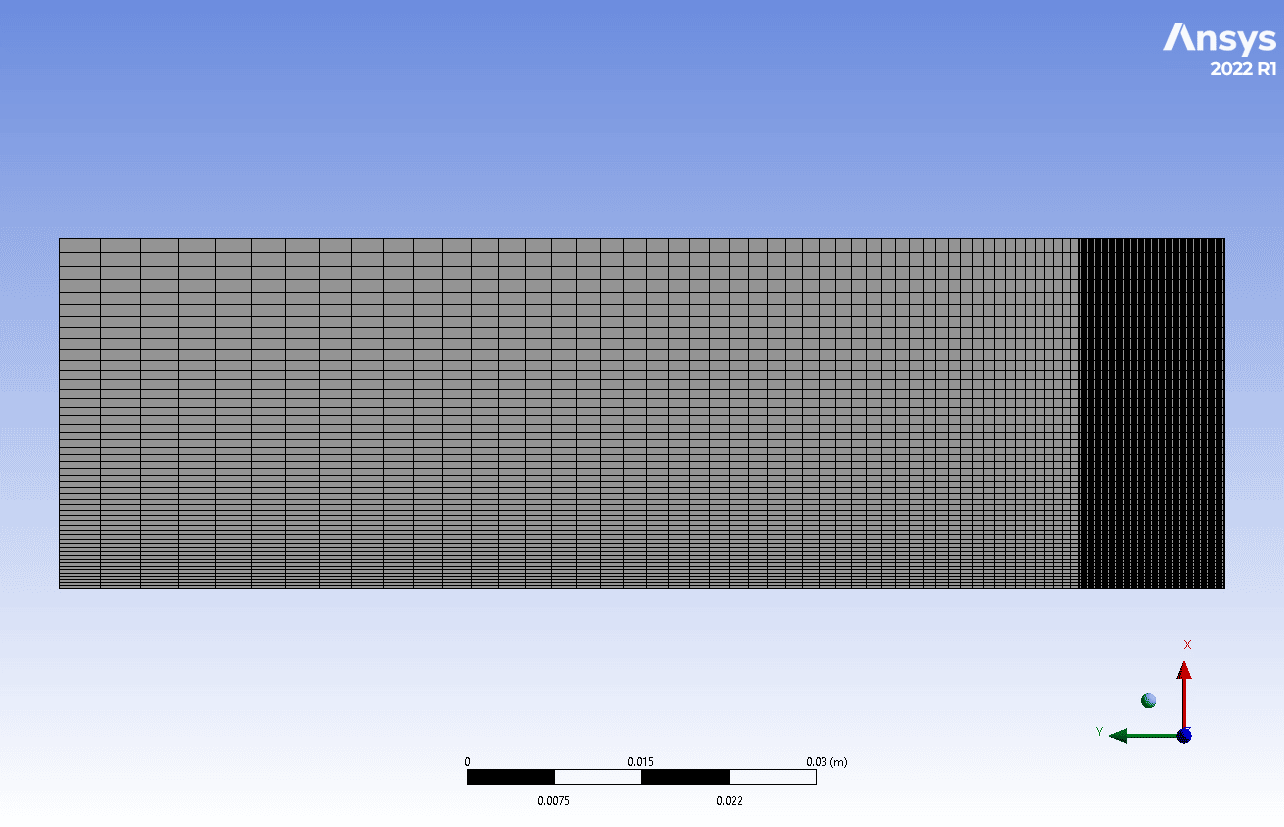

The geometry of the present project is designed in Design Modeler and meshed in ANSYS Meshing software. The mesh type is structured and the element number is equal to 8,750.

Unconfined Pool Boiling Methodology

The Eulerian multiphase model was used in this project to simulate the pool boiling inside the mentioned chamber. The RPI boiling sub-model is enabled and different forces including drag, lift, wall lubrication, turbulent dispersion, along with virtual mass force are enabled. Also, wall adhesion option is enabled to model the vapor bubbles detachment realistically.

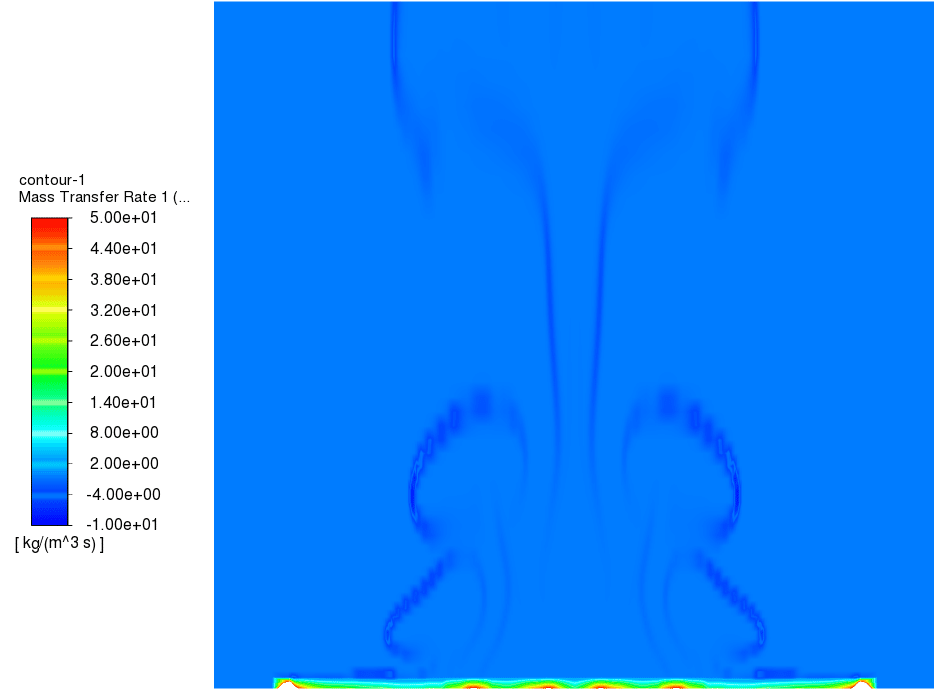

Boiling mass transfer mechanism is also activated and appropriate correlations are used for bubble departure diameter, frequency of bubble departure, nucleation site density, and area influence coefficient. Moreover, the bubble waiting time coefficient for the quenching model correction was set to 0.5.

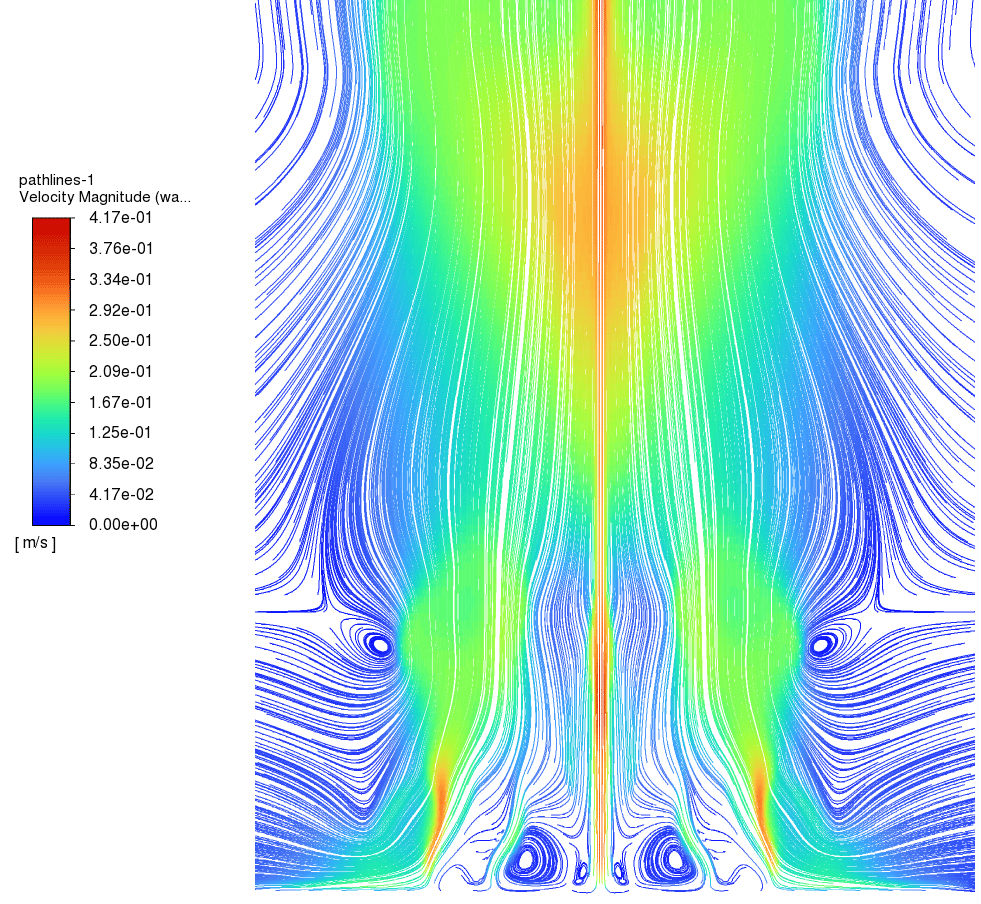

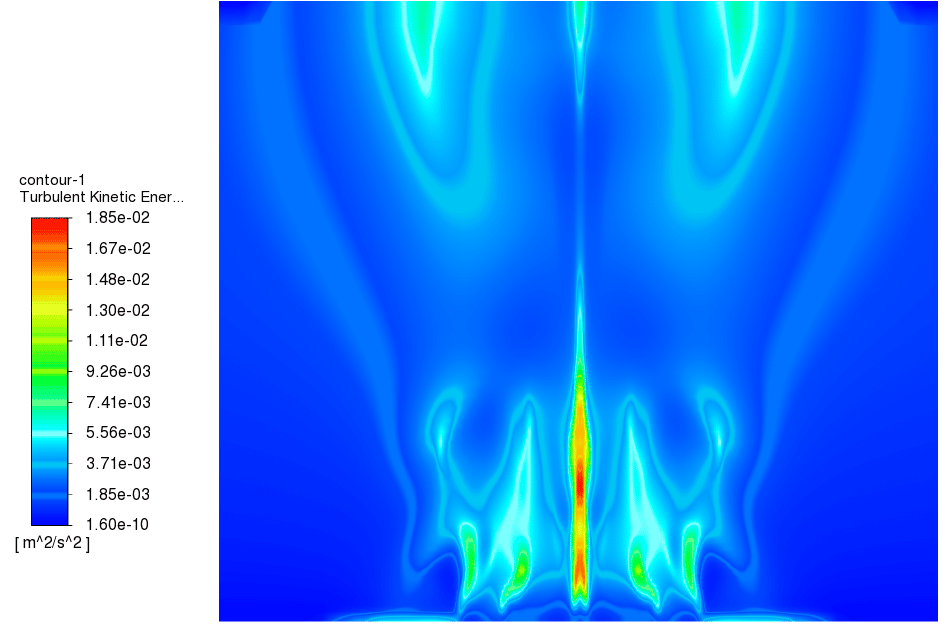

Furthermore, energy equation is enabled to calculate the temperature change inside the domain. Also, realizable k-epsilon model is used to solve for the turbulent fluid equations. The present study is performed in steady format and 2D axisymmetric model is used to simulate the problem inside a cylindrical coordinate.

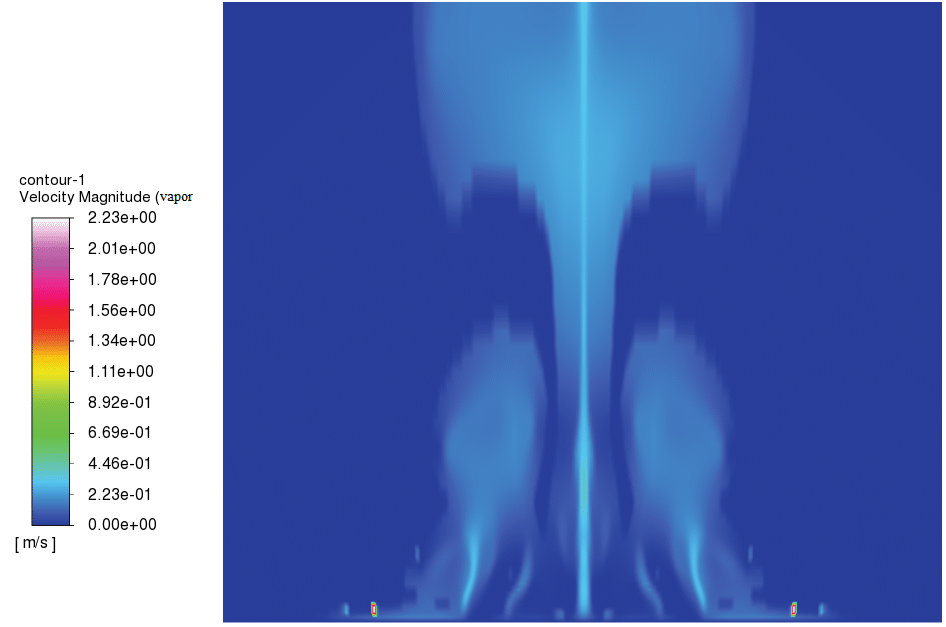

Gravity is also enabled to induce the upward motion of vapor due to the density difference. This difference exists between water and vapor.

Conclusion

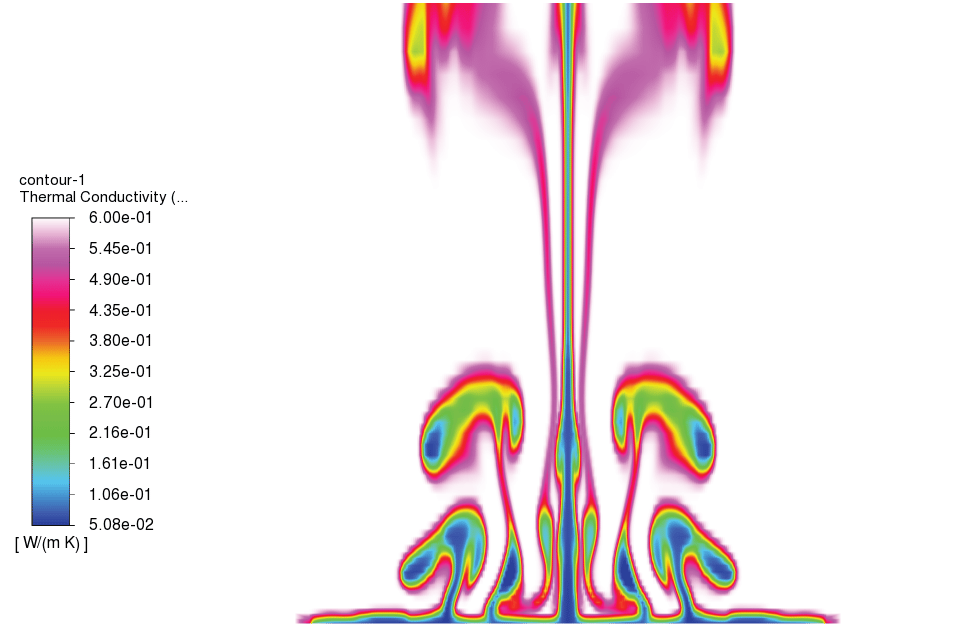

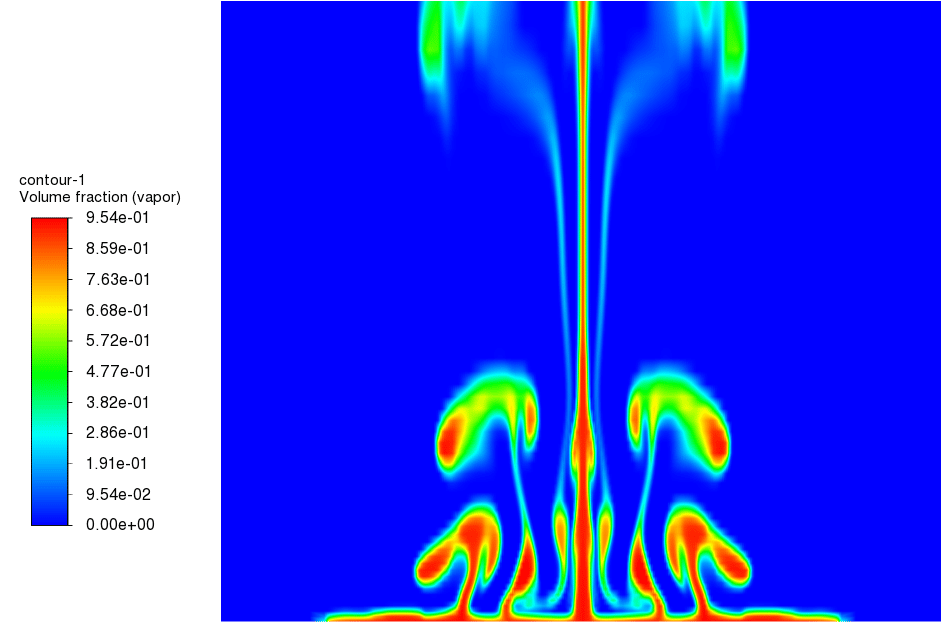

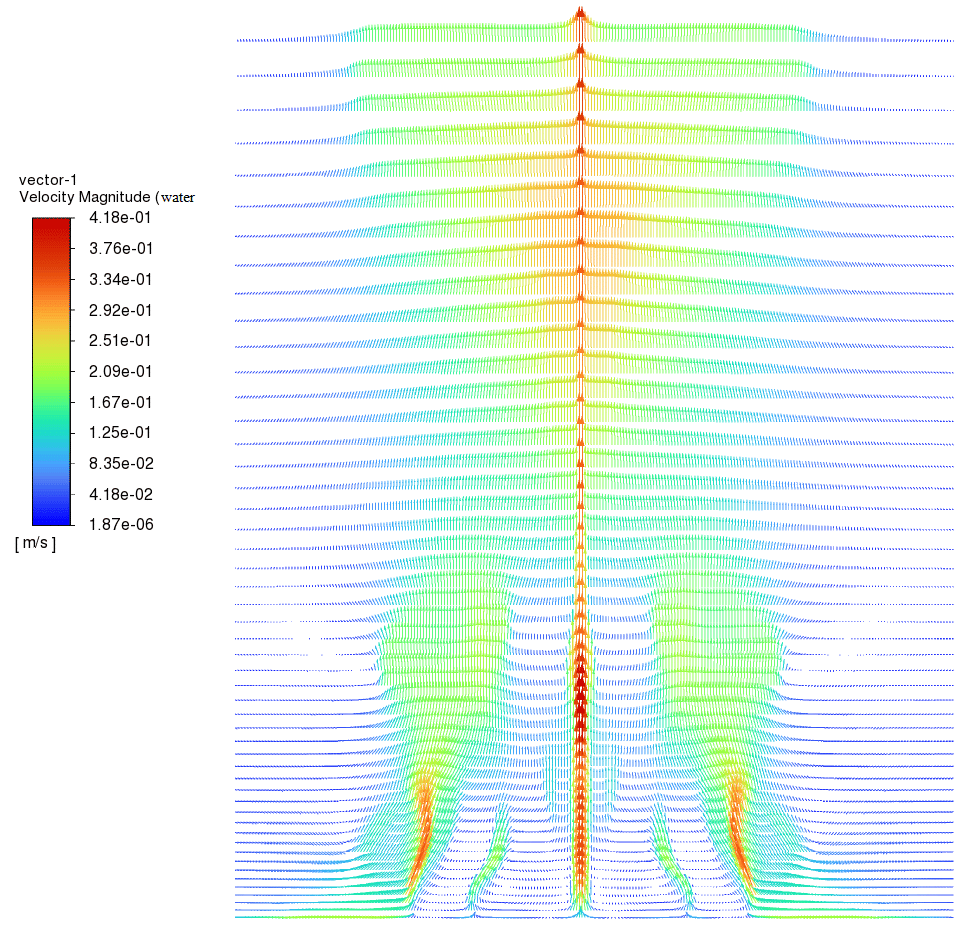

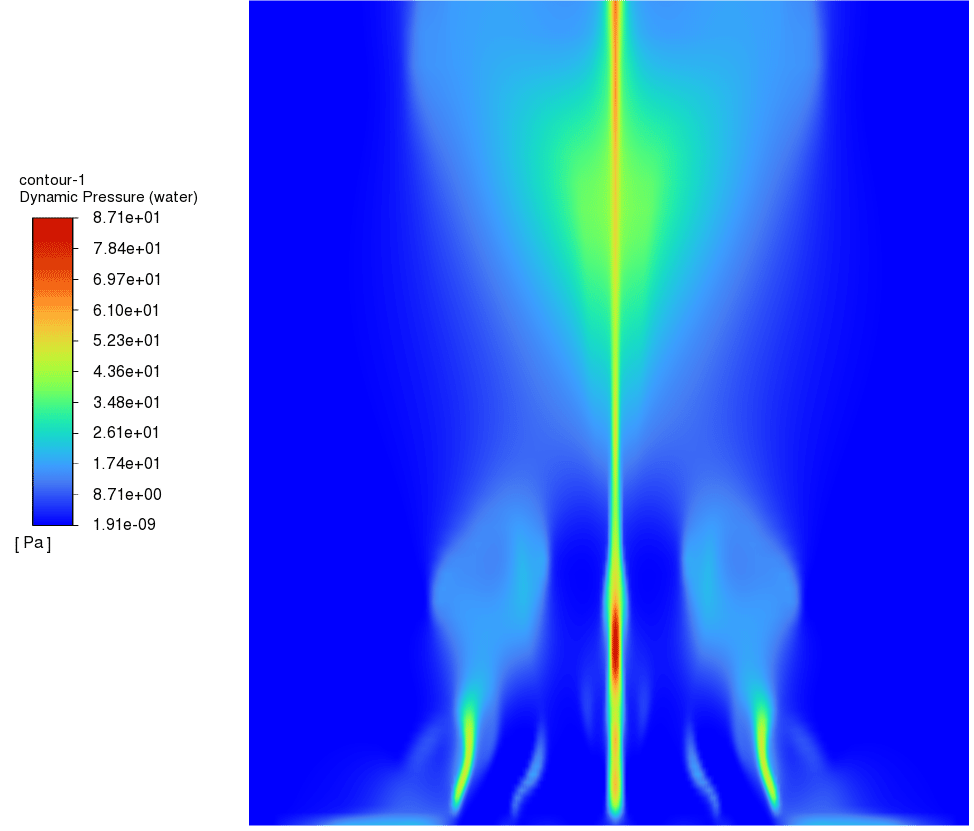

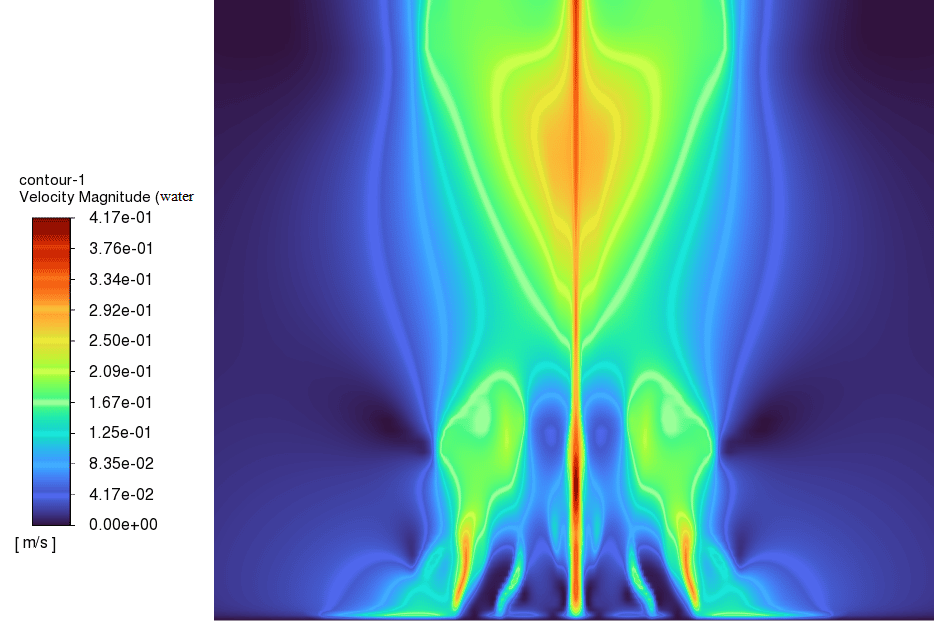

Finally, the results related to the boiling process is obtained and presented. As seen in the volume fraction contour for the vapor phase, vapor tends to move upward. This motion causes a convective motion inside the water culminating in multiple nucleation sites.

Moreover, it can be easily seen that how the shapes of generated bubbles change. Also, its visible how they exchange mass with the surrounding water (condensation) as they ascend toward the outlet.

Frieda Howe –

The tutorial carefully helped me visualize how vapor bubbles form and move in an unconfined pool boiling scenario. It explained complex phenomena like CHF in a way that was easy to understand, which greatly enhanced my learning experience.

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that our Unconfined Pool Boiling ANSYS Fluent Tutorial made complex concepts clear and aided your understanding. We aim to provide high-quality educational material that simplifies learning complex engineering phenomena. If you have any more thoughts or need further assistance, don’t hesitate to reach out!

Eugene Koepp I –

I’m thoroughly impressed with how the Unconfined Pool Boiling tutorial presents the boiling process and demonstrates bubble behavior. The visual aids and detailed explanations greatly enhanced my understanding. Thank you!

MR CFD Support –

Thank you for your kind words! We are delighted to hear that the tutorial was helpful and enhanced your understanding of the boiling process and bubble dynamics. It’s great to know our visual aids and detailed explanations had a positive impact on your learning. If you have any further questions or need more information, please don’t hesitate to reach out.

Savanah Mueller –

I love how this tutorial encompasses both steady state and dynamic aspects of pool boiling with clear demarcations of critical heat flux conditions. Well done.

MR CFD Support –

Thank you! We’re delighted to hear you found the tutorial on unconfined pool boiling in ANSYS Fluent comprehensive and appreciated the inclusion of both steady-state analysis and dynamic boiling phenomena. Your feedback is very encouraging for our team.

Kirk Kautzer –

The tutorial provides an excellent demonstration of pool boiling simulation. The explanations of ONB, DNB, and CHF were exceptionally informative, offering valuable insights into various stages of the boiling process. The inclusion of realistic phenomena like bubble detachment added a layer of complexity to the CFD model. Moreover, the application of different forces within the earliest phase model was clarified thoroughly. The tutorial was instrumental in understanding the interaction between vapor bubbles and surrounding water as well as the role gravity plays in the ascent of vapor. A job well done to the MR CFD team for such a comprehensive and practical learning tool.

MR CFD Support –

We’re delighted that you appreciated the details and complexity we’ve included in the ‘Unconfined Pool Boiling ANSYS Fluent Tutorial’. It is especially gratifying to hear that the aspects of the boiling process we discussed were useful for your understanding. Thank you for taking the time to provide this feedback, and it’s great to know our material has been so well received! Thank you for recognizing the efforts of the MR CFD team.

Dr. Iliana Hamill DVM –

I’m thoroughly impressed by the level of detail in this simulation, particularly how it captures the complex phenomena of pool boiling with such realism. The presence of multiple nucleation sites and the careful consideration of mass transfer has broadened my understanding significantly.

MR CFD Support –

Thank you for your review and for acknowledging the complexity of the phenomena simulated. We’re glad to hear that our product has provided you with valuable insights into pool boiling dynamics. If you have further inquiries or need additional information, feel free to reach out to us. Your feedback is greatly appreciated!

Emmett Ferry –

The tutorial was very informative concerning the pool boiling process simulation. The explanations were clear and provided a good understanding of the role of various forces and mechanisms in the context of a multiphase model using ANSYS Fluent.

MR CFD Support –

Thank you for your kind words and positive feedback! We’re glad to hear that the Unconfined Pool Boiling ANSYS Fluent Tutorial was helpful and that it provided clear insights into the simulation process. If you have any more queries or need further assistance, feel free to contact us.

Prof. Samara Kautzer –

I really appreciate how detailed the methodology is, with a focus on all involved forces and the inclusion of RPI boiling sub-model. It sounds thorough and well-structured.

MR CFD Support –

Thank you for your positive feedback. We prided ourselves on providing comprehensive and detailed methodologies for complex simulations like pool boiling. If you have any further questions or need more information, feel free to ask!

Verdie Veum Sr. –

I’m truly impressed with the simulation of the pool boiling process. The intricate behavior of vapor bubbles and the understanding of CHF with the aid of the RPI model is fascinating!

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear you found the pool boiling simulation compelling and that the detailed behavior of bubbles captured through the simulation met your expectations. Your appreciation motivates us to continue providing high-quality and educational content. If you have any further observations or queries, feel free to reach out!

Carrie Wuckert –

I genuinely appreciate how complex phenomena like pool boiling have been simplified in this Eulerian Multiphase Model course. The structured approach makes it easier to follow and understand each stage, enhancing my grasp of CFD principles applied to boiling processes.

MR CFD Support –

Thank you for taking the time to leave such thoughtful feedback. We’re elated to know that our comprehensive course on the Eulerian Multiphase Model has bolstered your understanding of crucial CFD concepts. Your success in mastering these complex phenomena is our ultimate goal and hearing about your positive learning experience is incredibly rewarding.

Prof. Yasmine Feeney –

Fantastic tutorial! I’m impressed with the level of detail regarding the Eulerian multiphase model, and the clarity with which the concepts of CHF, ONB, and DNB are conveyed. Pool boiling can be quite complex, but this tutorial made it much easier to understand the processes and apply them in ANSYS Fluent. Thank you for such well-structured training material.

MR CFD Support –

We’re thrilled to hear that our Unconfined Pool Boiling ANSYS Fluent Tutorial was able to clarify these complex boiling concepts for you. Thank you for your kind words and for recognizing the effort behind creating detailed and comprehensible training material. Your satisfaction as a learner makes all our efforts worthwhile!

Prof. Natasha Murphy –

The tutorial sounds very comprehensive. The coverage of boiling process dynamics and phase change is particularly interesting.

MR CFD Support –

Thank you for your kind words! We’re glad you found the tutorial on unconfined pool boiling comprehensive and interesting. It’s our goal to provide detailed and educational content that enhances the understanding of complex processes like boiling dynamics and phase changes. If you have any further questions or need additional information, feel free to reach out to us!

Alessandro Reilly –

I just finished the Unconfined Pool Boiling tutorial using the Eulerian Multiphase Model Training Course, and I must say I am very impressed with the depth and detail provided. I now have a solid understanding of how to set up a simulation for a boiling process and interpret the results. The RPI model and the inclusion of bubble dynamics made this tutorial top-notch for someone specializing in thermodynamics.

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear our Unconfined Pool Boiling tutorial from our Eulerian Multiphase Model Training Course has been so beneficial to you. If you’re ever interested in diving deeper into another complex CFD simulation scenario or expanding your expertise further, don’t hesitate to explore our other tutorials and advanced courses. Thanks for choosing MR CFD Company’s learning products, and we look forward to supporting your continued learning journey!