How CFD Consulting Companies Solve Complex Problems (2025)

Imagine a scenario common in high-stakes engineering: A newly designed gas turbine blade is experiencing premature thermal fatigue, threatening to derail a $50 million energy project. Or perhaps an aerospace prototype has failed a crucial wind tunnel test due to unexpected flow separation, putting a certification deadline at risk. These are not just technical glitches; they are business-critical failures that bleed capital and market share.

In these moments, the difference between a costly recall and a market-leading product often lies in the hands of expert cfd consulting companies.

Computational Fluid Dynamics (CFD) has evolved from a niche research tool into the backbone of modern industrial design. However, possessing the software is not the same as possessing the solution. Elite CFD consulting companies do more than generate colorful fluid flow animations; they de-risk innovation, validate complex physics, and provide actionable engineering insights that in-house teams may lack the bandwidth or specialized expertise to uncover.

In this comprehensive guide, we will pull back the curtain on the professional CFD consulting services workflow. Drawing on over two decades of experience at MR CFD, we will walk you through the rigorous 7-phase methodology professional consultants use to translate vague engineering headaches into validated, ROI-driven solutions.

Reserve Best CFD Consulting Service in World NOW

Enter your NAME and EMAIL for a free CFD consultation with our expert.

What Makes CFD Consulting Companies Essential for Modern Engineering?

In an era where engineering software is becoming more democratized, a common question arises in boardrooms: “Why should we hire external cfd consulting companies instead of just buying more Ansys licenses for our internal team?”

The answer lies in the difference between tool access and expert application. Modern engineering problems—such as multiphase cavitation in pumps or hypersonic shock-boundary layer interactions—require a depth of physics knowledge that goes far beyond standard software training.

CFD consulting companies bridge the “Expertise Gap.” While an internal generalist engineer might run a CFD simulation once a month, a specialized consultant logs thousands of hours annually solving specific, high-complexity flow problems. They bring a library of validation against experimental data, ensuring that the results are not just pretty pictures, but physically accurate predictions.

Furthermore, the capital investment for high-fidelity simulations is massive. Building an on-premise High-Performance Computing (HPC) cluster to run Large Eddy Simulations (LES) can cost hundreds of thousands of dollars. Consulting firms absorb this infrastructure cost, offering clients a “speed-to-insight” advantage that accelerates time-to-market by months.

Why Do Companies Choose External CFD Consulting Over In-House Teams?

The decision to outsource to computational fluid dynamics experts is rarely about a lack of internal capability; it is about strategic resource allocation.

- Niche Expertise on Demand: Your team may be brilliant at structural analysis but lack deep experience in reacting flows or Fluid-Structure Interaction (FSI). Consultants fill this specific knowledge void immediately.

- Software & Hardware Access: Leading cfd analysis consulting firms maintain expensive licenses for top-tier solvers (like Ansys Fluent, CFX, Star-CCM+) and maintain massive HPC clusters. This allows them to run high-fidelity models that would crash a standard engineering workstation.

- Scalability: Project demands fluctuate. Hiring full-time senior CFD analysts for a 3-month project is inefficient. Consulting allows you to scale your engineering power up or down instantly.

Cost Structure Comparison:

| Cost Driver | In-House Team | External CFD Consulting |

| Software Licensing | High annual fixed cost ($50k+ per seat) | Included in project fee |

| HPC Infrastructure | High CapEx + Maintenance | Zero CapEx (Pay-per-use) |

| Staffing | High fixed salary + benefits | Variable project-based cost |

| Training/Ramp-up | Months to achieve proficiency | Immediate expert deployment |

What Competitive Advantages Do Professional CFD Consultants Provide?

Beyond cost savings, cfd consulting companies act as technology accelerators.

- Cross-Industry Pollination: A consultant who has solved heat transfer problems in the automotive sector can often apply those same cooling strategies to electronics or aerospace components. This cross-pollination brings fresh, innovative solutions that siloed internal teams might miss.

- Risk Mitigation via Independent Analysis: For safety-critical applications (nuclear, aerospace), having an independent third party validate internal designs is often a regulatory or insurance requirement.

- Methodological Rigor: Top-tier firms operate under strict quality assurance protocols (referencing ISO 9001 certified simulation process standards), ensuring that simulation errors are caught before metal is cut.

How Do CFD Consulting Companies Structure Their Problem-Solving Process?

Effective cfd consulting services workflow is not linear; it is iterative and highly structured. Amateurs jump straight into the software. Professionals spend significant time planning, defining, and validating before a single mesh is generated.

At MR CFD, we utilize a proven 7-phase methodology designed to ensure alignment between business goals and technical outputs.

What Are the Key Phases in a Professional CFD Consulting Project?

- Problem Definition & Requirements Gathering: Translating business pain points into engineering physics and scope.

- Preliminary Assessment & Feasibility Study: Rapidly determining if CFD is the right tool and estimating costs.

- Computational Model Development: Cleaning geometry and generating high-quality meshes (the foundation of accuracy).

- Simulation Setup & Execution: Defining physics models and running the solver on HPC resources.

- Results Analysis & Validation: Verifying solution quality and validating against real-world data.

- Optimization & Design Iteration: Using the data to improve the product, not just analyze it.

- Final Reporting & Knowledge Transfer: Delivering actionable insights and empowering the client team.

Phase 1: How Do CFD Consultants Define and Scope Engineering Problems?

The most critical phase happens before the software is even opened. Phase 1 is where cfd consulting companies protect the client from “scope creep” and misalignment. A vague request like “simulate the airflow” is a recipe for failure. A professional consultant transforms that into: “Determine the pressure drop across the manifold at 5 operating points to within 5% accuracy.”

What Questions Do CFD Consulting Companies Ask During Initial Discovery?

To ensure the cfd project management methodology is sound, expect a rigorous interrogation during the kickoff:

- Business Drivers: “What decision will this simulation help you make? Are you trying to reduce weight, pass a certification, or troubleshoot a failure?”

- Technical Boundaries: “What are the precise operating conditions (inlet velocity, temperature, pressure)? Is the flow steady or transient?”

- Validation Data: “Do you have experimental data or legacy results we can benchmark against?”

- Timeline: “Is there a hard deadline for a design review or manufacturing slot?”

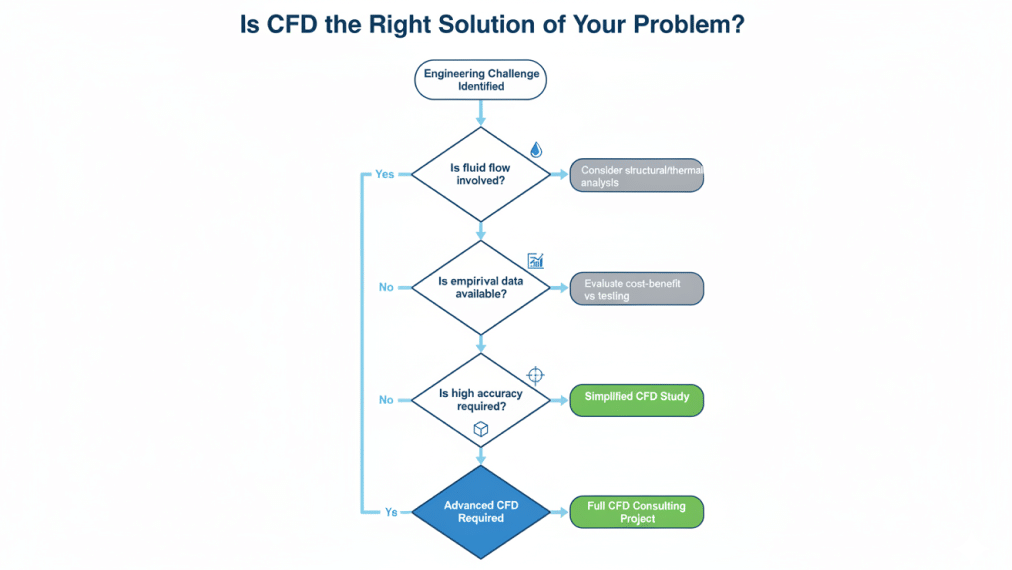

How Do Consultants Determine If CFD Is the Right Solution Approach?

Honest computational fluid dynamics experts will tell you when not to use CFD.

- Good Candidates for CFD: Complex internal flows, hazardous environments (combustion, explosions), prototyping at scales too large/small for wind tunnels, and detailed heat transfer analysis.

- Poor Candidates for CFD: Simple pipe sizing (use correlations), massive system-level logic (use 1D codes), or problems where physics are not well-understood (e.g., certain non-Newtonian chemical reactions without material data).

What Deliverables Should You Expect from the Problem Definition Phase?

You should never proceed without a Statement of Work (SOW). This document must include:

- Success Criteria Matrix: Defining what “done” looks like.

- Data Requirements List: What CAD files and boundary conditions the client must provide.

- Risk Assessment: Potential technical hurdles (e.g., “complex geometry may require simplification”).

- Preliminary Timeline: Milestones for mesh delivery, initial results, and final report.

Phase 2: How Do CFD Consulting Companies Conduct Feasibility Studies?

Before committing to a full-scale analysis, cfd consulting companies conduct a feasibility study. This is a “sanity check” to ensure the proposed physics can be solved within the allocated budget and timeline.

What Does a CFD Feasibility Analysis Include?

This analysis evaluates the “Physics-to-Compute” ratio.

- Physics Assessment: Identification of governing equations. Does the flow require compressible, multiphase, or reacting flow solvers?

- Geometry Evaluation: Consultants inspect client CAD files for “dirty” geometry—gaps, overlaps, or excessive detail (like threads on bolts) that would explode the mesh count without adding value.

- Data Availability: Confirming that all material properties (density, viscosity, thermal conductivity) are known or can be reliably estimated.

How Do Consultants Select the Appropriate CFD Software and Models?

Selection depends on the physics. Ansys Fluent consulting services are often the gold standard for general purpose industrial flows due to their robustness and wide turbulence model library.

- Solvers: Ansys Fluent (General purpose), CFX (Turbomachinery), OpenFOAM (Open source/Budget-constrained), Star-CCM+ (Automotive).

- Turbulence Strategy: Deciding between RANS (Reynolds-Averaged Navier-Stokes) for general engineering speed vs. LES (Large Eddy Simulation) for high-fidelity aeroacoustics.

What Is Included in a Preliminary Simulation Strategy Document?

This roadmap outlines the simulation process:

- Mesh Strategy: Structured vs. Unstructured polyhedral mesh.

- Validation Plan: How the model will be checked against ASME V&V standards.

- Resource Estimation: Estimated CPU-hours required.

- Stop/Go Gates: Points where the project can be paused if results look unpromising.

Phase 3: How Do Professional CFD Consultants Develop Computational Models?

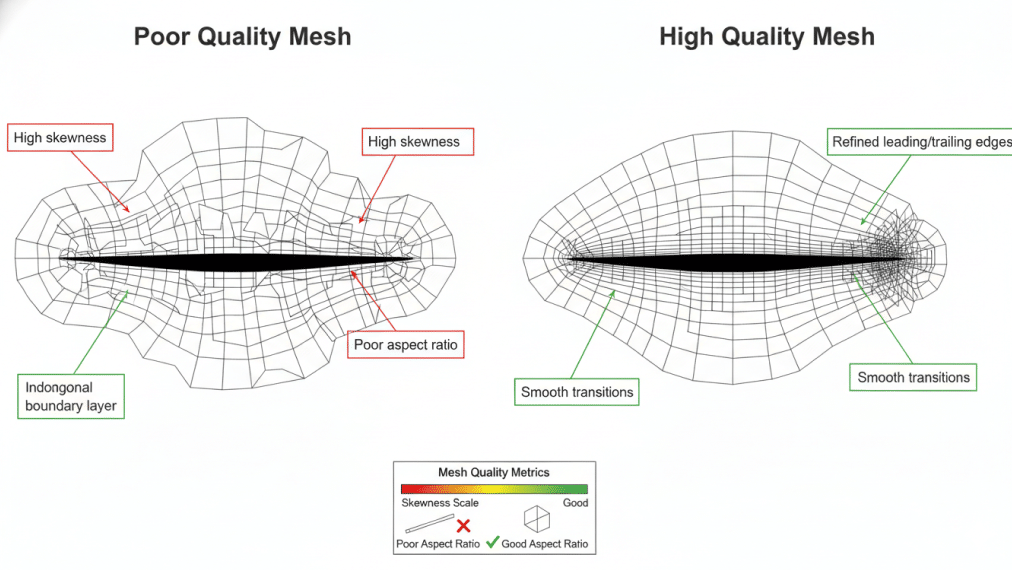

This phase typically consumes 50-70% of the labor hours. A simulation is only as good as its mesh.

What Geometry Preparation Steps Do CFD Consulting Companies Follow?

Consultants use specialized tools (like Ansys SpaceClaim) to prepare the “fluid volume.”

- Defeaturing: Removing nuts, bolts, logo embossments, and small fillets that disrupt flow or create bad mesh elements.

- Domain Extraction: Creating the “negative” of the solid part (the air or liquid volume).

- Documentation: Crucially, consultants document every simplification to ensure the client understands what is being simulated vs. the manufacturing CAD.

How Do CFD Experts Approach Mesh Generation for Complex Problems?

CFD analysis consulting firms focus on the “Boundary Layer.” Capturing the flow gradient near the wall is essential for accurate drag and heat transfer prediction.

- Inflation Layers: Creating prism layers near walls to resolve the boundary layer (targeting specific y+ values based on the turbulence model).

- Mesh Independence: A professional consultant always performs a mesh independence verification study. This involves running the simulation on coarse, medium, and fine meshes to prove that the result is independent of the grid size.

What Quality Checks Do Consultants Perform on Computational Meshes?

Bad mesh quality leads to divergence or, worse, non-physical results. Consultants check:

- Skewness: Keeping it below 0.95.

- Orthogonal Quality: Keeping it above 0.1.

- Aspect Ratio: Ensuring cells aren’t stretched too thin in gradients.

- Volume Change: Ensuring smooth transitions between small and large cells.

Phase 4: How Do CFD Consulting Companies Set Up and Execute Simulations?

With the mesh ready, the physics are applied. This is where industrial cfd simulation consulting expertise shines—knowing which knobs to turn in the solver.

What Physics Models and Boundary Conditions Do Consultants Specify?

- Boundary Conditions: Consultants carefully define Inlet (Velocity vs. Mass Flow), Outlet (Pressure), and Wall (No-slip vs. Slip, Adiabatic vs. Constant Temp).

- Material Properties: Setting up density (Ideal gas vs. Real gas), viscosity models, and species transport for mixtures.

- Solver Settings: Choosing Pressure-Based vs. Density-Based solvers depending on Mach number.

How Do Professional CFD Consultants Ensure Solution Convergence?

Convergence is more than just residuals dropping. Computational fluid dynamics experts monitor specific engineering quantities.

- Monitors: Tracking Drag Coefficient, Mass Balance, or average Outlet Temperature. The simulation is only converged when these values stabilize.

- Residuals: Typically targeting 10−4 or 10−5 for tight convergence.

- Imbalance: Checking that Mass In = Mass Out (global conservation).

What Computational Resources Do Complex CFD Projects Require?

Serious CFD requires CFD HPC services for simulation.

- Parallel Processing: Decomposing the mesh across hundreds of CPU cores.

- MR CFD’s Infrastructure: We utilize high-availability clusters to run transient simulations that might take weeks on a workstation in just a few days.

- Memory Management: Ensuring sufficient RAM (often 256GB+) to handle high-fidelity polyhedral meshes.

Phase 5: How Do CFD Consulting Companies Analyze and Validate Results?

This phase separates the professionals from the amateurs. Any software can produce a color contour; understanding what it means is the service.

What Post-Processing Techniques Do CFD Experts Use to Extract Insights?

- Qualitative: Pathlines to visualize recirculation zones; Contours to spot hot spots or high-pressure regions.

- Quantitative: Integrating forces to get Lift/Drag; Surface integrals for heat transfer coefficients.

- Iso-Surfaces: Visualizing 3D structures, such as Q-criterion for turbulence structures or flame fronts in combustion.

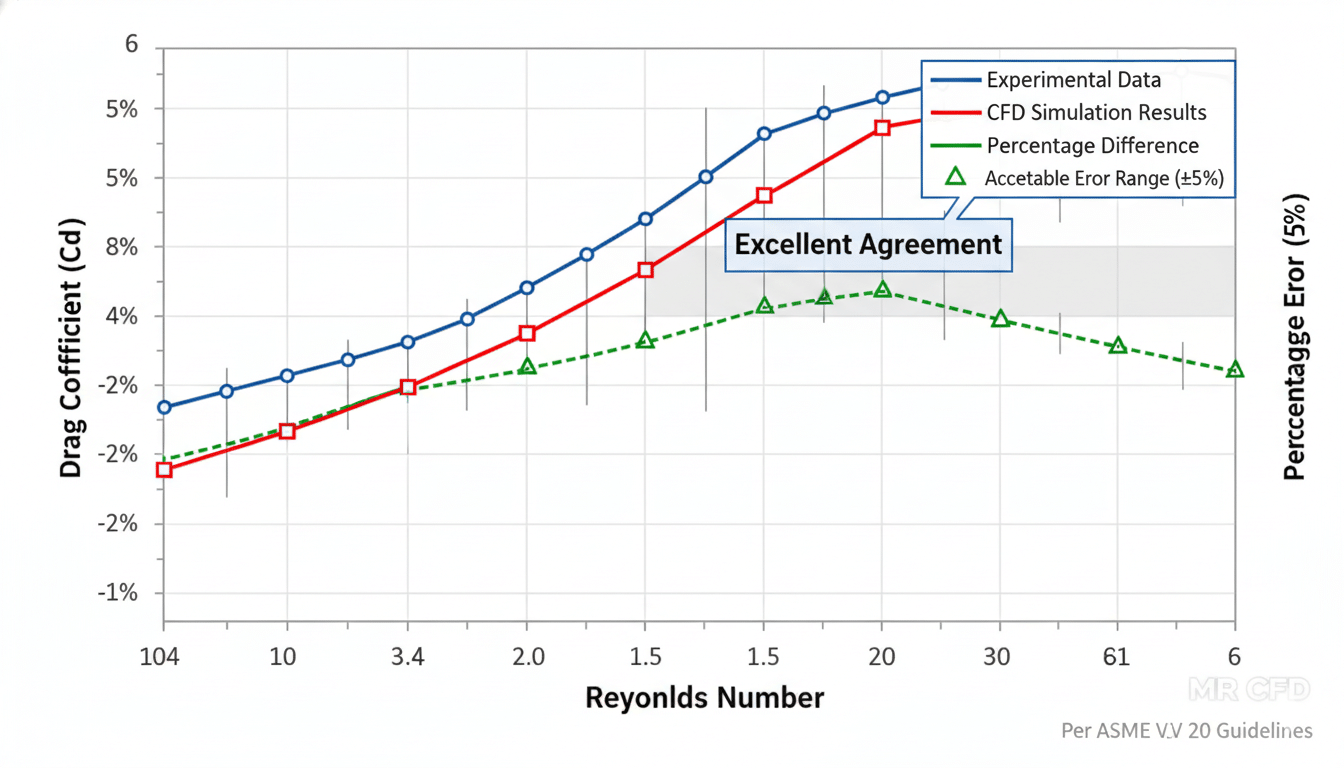

How Do Consultants Validate CFD Results Against Experimental Data?

Validation is the process of determining if the model accurately represents the real world.

- Benchmarks: Comparing results against client-provided test data or relevant academic literature.

- Error Quantification: Calculating the percentage error between CFD and Experiment.

- Standardization: Following ASME V&V 20 (Standard for Verification and Validation in Computational Fluid Dynamics and Heat Transfer).

What Verification Steps Ensure Solution Quality?

- Verification: “Are we solving the equations correctly?” (Addressed via mesh independence and convergence checks).

- Validation: “Are we solving the right equations?” (Addressed via experimental comparison).

- Peer Review: At MR CFD, a senior analyst reviews the setup of every junior engineer to ensure industry best practices for CFD quality assurance are met.

Phase 6: How Do CFD Consulting Companies Approach Design Optimization?

The simulation is done, but the job isn’t. Now, how do we make the product better?

What Optimization Strategies Do Professional CFD Consultants Employ?

- Parametric Sweeps: Systematically varying geometry (e.g., blade angle, pipe diameter) to find the “sweet spot.”

- Adjoint Optimization: A mathematical technique used in aerospace to automatically reshape geometry to minimize a cost function (e.g., minimize drag) without manual iteration.

- Response Surface Methodology (RSM): Creating a mathematical map of the design space to predict performance between simulated points.

How Do Consultants Identify and Prioritize Design Variables?

Using sensitivity analysis, consultants identify which variables matter. If changing the inlet angle by 1 degree changes efficiency by 10%, that is a critical variable. If changing wall thickness has 0.1% impact, it is ignored. This focuses the design effort where the ROI is highest.

What ROI Can Companies Expect from CFD-Driven Design Optimization?

The ROI is measurable and significant:

- Automotive: 3-5% drag reduction leads to massive fuel economy gains.

- Electronics: Optimizing heatsink topology can reduce chip temperature by 10°C, doubling component life.

- HVAC: Reducing pressure drop in ducting allows for smaller, cheaper fans and lower energy consumption.

Phase 7: What Deliverables Do CFD Consulting Companies Provide?

What Should a Comprehensive CFD Consulting Report Include?

A professional report is a legal and technical document. It includes:

- Executive Summary: The “bottom line” for management.

- Methodology: Detailed settings (solver, schemes, mesh stats) for reproducibility.

- Results & Discussion: Not just “what happened,” but “why it happened.”

- Recommendations: Specific design changes (e.g., “Increase guide vane angle by 5 degrees”).

- Appendix: Validation data and mesh independence plots.

How Do CFD Consultants Ensure Knowledge Transfer to Client Teams?

At MR CFD, we believe in empowering our clients. We provide:

- Project Handover Sessions: Walkthroughs of the result files.

- Simulation Files: We deliver the actual Ansys .cas and .dat files (subject to IP terms) so your team can use them as a template.

- CFD Ansys Fluent Training: Identifying skill gaps during the project and offering targeted training to fill them.

What Post-Project Support Do Professional CFD Consulting Companies Offer?

Support doesn’t end at delivery. We offer retainer agreements for ad-hoc questions, follow-up simulations for design tweaks, and implementation support to ensure the manufacturing team understands the CFD findings.

How Do Leading CFD Consulting Companies Ensure Project Success?

What Project Management Practices Do Professional CFD Consultants Follow?

We treat simulations like construction projects.

- Weekly Sprints: Regular updates to keep the client loop tight.

- Milestone Payments: Tying costs to deliverables (e.g., Mesh Acceptance, Preliminary Results, Final Report).

- Change Management: If the client changes the geometry halfway through, a formal Change Order process ensures budget transparency.

How Do CFD Consulting Companies Handle Unexpected Challenges?

Physics can be unpredictable. Sometimes a simulation diverges due to physical instability (e.g., vortex shedding in a steady-state setup). Experienced consultants switch strategies—moving to transient solvers or adjusting turbulence models—and communicate these technical pivots immediately to the client.

What Quality Assurance Processes Do Top CFD Consulting Firms Implement?

Best-in-class firms use a “Two-Man Rule.” The engineer who sets up the simulation is never the only one who checks it. A Solution Architect verifies the physics inputs and mesh quality metrics before the run is submitted to the HPC cluster.

What Industries Benefit Most from Professional CFD Consulting Services?

How Do Aerospace Companies Use CFD Consulting Services?

Aerospace demands the highest fidelity. CFD consulting companies assist with:

- External Aerodynamics: Drag reduction and lift optimization.

- Cabin Comfort: HVAC flow and contaminant dispersion (crucial post-COVID).

- Propulsion: Combustion stability and turbine cooling.

What CFD Consulting Solutions Do Energy Sector Companies Need?

- Renewables: Optimizing wind turbine blade profiles and solar thermal receiver efficiency.

- Oil & Gas: Multiphase flow in separators, erosion prediction in pipelines, and flare stack combustion analysis.

- Nuclear: Thermal-hydraulic safety analysis.

How Does the UAV and Defense Industry Leverage CFD Consulting Expertise?

In the fast-paced UAV sector, consultants help optimize propeller efficiency for battery life extension, analyze stability in gust conditions, and minimize acoustic signatures (noise reduction) for stealth and urban operations.

How Should Companies Select the Right CFD Consulting Partner?

What Qualifications Should You Look for in CFD Consulting Companies?

- Ansys Certified Consulting Partner: This ensures they have legal, up-to-date software and direct support from the software vendor.

- Published Case Studies: Look for published case study validation in your specific industry.

- Academic Pedigree: Top firms often employ PhDs who contribute to peer-reviewed turbulence modeling approaches.

What Questions Should You Ask Potential CFD Consulting Partners?

- “Can you show me a validation case similar to my problem?”

- “What is your QA process for mesh independence?”

- “Do you have your own HPC resources, or do you rent cloud time?”

- “How do you handle IP and data security?”

How Can You Evaluate CFD Consulting Company Case Studies and References?

Look for numbers. A case study that says “We improved flow” is marketing. A case study that says “We reduced pressure drop by 14% compared to experimental baseline” is engineering. Ask for references from past clients to verify adherence to timelines.

What Are the Cost Considerations for CFD Consulting Projects?

How Do CFD Consulting Companies Structure Their Pricing?

- Fixed Price: Best for well-defined scopes (e.g., “Run 5 geometries at 3 speeds”).

- Time & Materials (Hourly): Best for R&D where the scope is evolving.

- Retainer: A monthly fee for a set number of consulting hours.

- Value-Based: Pricing based on the savings generated (less common but high ROI).

What Hidden Costs Should Companies Budget for in CFD Projects

- Geometry Cleanup: If your CAD is messy, expect to pay for the hours to fix it.

- HPC Overages: Extremely complex runs may require extra compute time.

- Additional Design Iterations: “Can we just try one more shape?” usually incurs a change order fee.

How Can Companies Maximize ROI from CFD Consulting Investments?

- Clean CAD: Provide “watertight” geometry to save consulting hours.

- Clear Success Criteria: Don’t pay for infinite accuracy if you only need trend data.

- Leverage Training: Use the project as a learning opportunity for your team to build internal cfd consulting expertise.

How Is CFD Consulting Evolving with New Technologies?

What Role Does Artificial Intelligence Play in Modern CFD Consulting?

AI is not replacing CFD; it is accelerating it. MR CFD monitors trends in Reduced Order Models (ROMs) and AI-driven mesh adaptation. These tools allow us to predict flow fields in seconds based on training data from high-fidelity CFD, enabling real-time design exploration.

How Are Cloud Computing and HPC Changing CFD Consulting Services?

The cloud allows infinite scalability. We can now spin up 1,000 cores for a weekend to rush a project that previously would have taken a month. This elasticity is transforming the cfd consulting project lifecycle.

What Emerging Applications Are Driving Demand for CFD Consulting?

- Hydrogen Infrastructure: Solving leakage and combustion challenges.

- EV Thermal Management: Battery cooling and motor heat dissipation.

- Digital Twins: Creating real-time simulation models that run alongside the physical asset.

Why Choose MR CFD as Your CFD Consulting Partner?

What Makes MR CFD’s Consulting Approach Different?

At MR CFD, we don’t just sell simulations; we sell engineering confidence. Our workflow is deeply rooted in validation against experimental data and ISO 9001 quality standards. We act as an extension of your engineering team, providing the professional cfd simulation services needed to tackle the toughest physics.

How Does MR CFD Combine Consulting Services with Training and HPC?

We offer a unique ecosystem:

- Consulting: We solve the problem for you.

- Training: We teach you how we solved it (via CFD ansys fluent training).

- HPC: We provide the infrastructure to run it. This holistic approach ensures you aren’t just buying a fish; you’re learning to fish.

What Results Have MR CFD’s Consulting Clients Achieved?

- Aerospace Client: Reduced drag on a UAV fuselage by 12%, extending flight time by 20 minutes.

- Automotive Client: Solved a chronic overheating issue in an EV battery pack, preventing a product recall.

- Industrial Client: Optimized a cyclone separator to increase particle capture efficiency from 85% to 96%.

Frequently Asked Questions About CFD Consulting Companies

How long does a typical CFD consulting project take?

Project duration varies by complexity. A simple steady-state flow analysis might take 2-3 weeks. A complex multiphase or transient combustion project typically requires 1-3 months. We provide a detailed timeline Gantt chart during the proposal phase so you can plan your product development cycle accordingly.

Do I need to provide CAD models to CFD consulting companies?

Ideally, yes. Providing clean CAD (STEP, Parasolid, or IGES format) significantly reduces cost and time. However, if you only have 2D drawings or physical prototypes, cfd consulting companies can offer reverse engineering services to create the 3D geometry required for simulation.

Can CFD consulting replace physical testing entirely?

No, and you should be wary of anyone who says it can. CFD reduces the amount of physical testing required (e.g., testing 3 prototypes instead of 30), but final validation usually requires physical testing, especially for safety-critical certification (FAA, ASME). CFD and testing are complementary, not mutually exclusive.

What file formats do CFD consulting companies accept?

We accept all standard neutral formats: STEP (.stp), IGES (.igs), Parasolid (.x_t), and ACIS (.sat). We can also work with native files from SolidWorks, CATIA, and NX. For mesh data, we can import standard formats like .msh or .cgns.

How accurate are CFD simulations performed by consulting companies?

Accuracy depends on the physics and validation. For well-calibrated single-phase flows, accuracy is often within 2-5% of experimental data. For complex multiphase or reacting flows, 5-10% is typical. We always perform mesh independence studies to quantify and minimize numerical error.

What happens if CFD results don’t match expectations?

This is where the value of a consultant lies. We investigate why. Is the expectation wrong (common intuition failure)? Is the boundary condition incorrect? Or is there a physics modeling issue? We transparently document discrepancies and refine the model until the physics are captured correctly.

Can CFD consulting companies work with proprietary or confidential designs?

Absolutely. MR CFD operates under strict Non-Disclosure Agreements (NDAs). We utilize secure data transfer protocols, encrypted storage, and can silo project teams to ensure your Intellectual Property (IP) remains completely confidential throughout the cfd consulting project lifecycle.

Do CFD consulting services include training for our internal team?

Yes. Knowledge transfer is a core part of our value proposition. We can structure the project to include “over-the-shoulder” training sessions, explaining the simulation setup and best practices so your internal team can maintain and update the models in the future.

What software do professional CFD consulting companies use?

We primarily utilize Ansys Fluent and Ansys CFX due to their industry-leading validity and support. However, for specific niche applications or budget-constrained projects, we also have expertise in Star-CCM+ and OpenFOAM. We select the tool that best fits the client’s physics and budget.

How do CFD consulting companies handle projects that exceed initial scope?

We prioritize communication. If a project needs to expand (e.g., you want to test 5 more design iterations than originally planned), we pause, discuss the new requirements, and issue a formal Change Order. This ensures you are never surprised by an invoice and have full control over the budget.

Comments (0)