Hiring a CFD Consultant: 7 Critical Questions You Must Ask First

In the high-stakes world of industrial engineering, the margin for error is non-existent. Whether you are designing a high-efficiency gas turbine, optimizing the aerodynamics of an EV battery cooling system, or ensuring the safety of a petrochemical reactor, the behavior of fluids (liquids and gases) dictates your success. This is where Computational Fluid Dynamics (CFD) shifts from being a “nice-to-have” visualization tool to a critical pillar of engineering integrity.

However, the barrier to entry for running a simulation has lowered. Software is more accessible, but the expertise required to interpret the physics correctly remains rare. If you are looking to hire cfd Consultant, you are not just buying colorful contour plots; you are purchasing risk mitigation, design validation, and engineering insight.

Choosing the wrong partner leads to “Garbage In, Garbage Out” scenarios—wasted budgets on simulations that look correct but yield physically impossible results, leading to catastrophic prototype failures or costly manufacturing delays.

As a Senior Solutions Architect with MR CFD, having overseen thousands of simulations across aerospace, energy, and automotive sectors over the last 20 years, I have seen the difference between a “software operator” and a true engineering partner. This guide outlines the 7 essential questions and criteria you must evaluate to ensure you hire a computational fluid dynamics consultant who can deliver ROI, not just pretty pictures.

Why Does Hiring the Right Fluid Dynamics Consultant Matter for High-Risk Engineering Projects?

CFD is often misunderstood as merely a digital wind tunnel. While it serves that function, its true value lies in its ability to predict the invisible and quantify the complex. When dealing with high-risk engineering projects—such as analyzing thermal runaway in battery packs or predicting cavitation in high-speed pumps—the simulation results become the foundation for multimillion-dollar decisions.

Hiring the right computational fluid dynamics consultant matters because the cost of failure far exceeds the cost of consulting. A generic analyst might run a simulation using default software settings, unaware that the turbulence model selected is incapable of capturing the flow separation occurring in your specific geometry. The result? You proceed to manufacturing with false confidence, only to find the real-world component overheats or vibrates to failure.

Expert consultants do more than run software; they act as an extension of your R&D team. They bridge the gap between theoretical physics and manufacturing reality. They understand that a mesh count isn’t just a number—it’s a balance between accuracy and computational cost. They know that CFD for product design is iterative. By selecting a partner with deep industrial CFD analysis services experience, you are essentially buying an insurance policy against physics-based failure.

Furthermore, the right consultant directly impacts your Time-to-Market (TTM). Outsource CFD simulation to a specialist, and you eliminate the months of trial-and-error your internal team might face learning a new solver. You gain immediate access to validated methodologies that have been refined over decades. In the competitive landscape of modern engineering, speed and accuracy are the currency of success; the right consultant provides both.

What Technical Competencies Should a CFD Consultant Demonstrate Before You Hire Them?

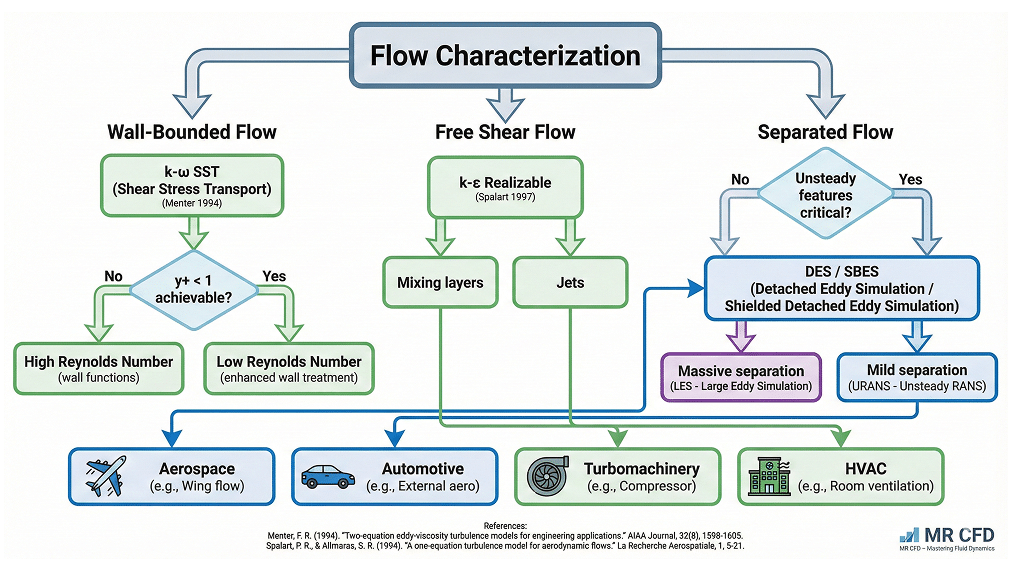

Any engineer can learn to click buttons in a GUI. A true expert understands the governing equations beneath the interface. When evaluating candidates, you must probe their technical depth. Do they understand the limitations of RANS (Reynolds-Averaged Navier-Stokes) versus the computational demands of LES (Large Eddy Simulation)? Can they discuss the intricacies of chemical kinetics in combustion or the drag laws in multiphase flows?

To hire CFD engineer talent that is truly top-tier, look for mastery in Ansys Fluent, OpenFOAM, or Star-CCM+, but more importantly, look for the physics expertise that transcends the tool.

How do you verify their experience with real industrial geometries—not just academic cases?

Academic CFD is often performed on sanitized, simplified geometries—perfect cylinders or spheres. Industrial CFD is messy. It involves complex CAD assemblies with thousands of parts, missing surfaces, overlapping faces, and microscopic gaps that can crash a mesher instantly.

A seasoned advanced meshing consultant will have a robust workflow for CAD cleanup and “defeaturing.” Ask them: “How do you handle dirty CAD files imported from SolidWorks or CATIA?” Their answer should involve specific tools (like Ansys SpaceClaim or specialized pre-processors) and strategies for wrapping or repairing geometry without compromising the fidelity of the simulation.

If they only show you simulations of airfoils or flow over a cylinder, be wary. You need to see complex manifolds, under-hood automotive assemblies, or intricate heat exchangers. They must demonstrate the ability to generate high-quality conformal meshes on geometries that would make a novice weep.

Can they solve your exact physics problem (turbulence, combustion, multiphase, non-Newtonian)?

CFD is broad. An expert in external aerodynamics (compressible flow, shock waves) might be completely lost when trying to simulate a non-Newtonian slurry in a mixing tank. You must ensure their expertise matches your specific physics.

- Turbulence: If your project involves swirling flows (cyclones) or jets, ask if they use standard k-epsilon models or if they know when to switch to Reynolds Stress Models (RSM) or Detached Eddy Simulation (DES). A turbulence modeling consultant knows that one size does not fit all.

- Multiphase: If you have gas and liquid interacting (like in a separator or a splashing tank), ask about their experience with VOF (Volume of Fluid) vs. Euler-Lagrange approaches.

- Thermal: Do they understand conjugate heat transfer (CHT) involving solid-fluid coupling?

At MR CFD, we explicitly categorize our case studies by physics—combustion, HVAC, turbomachinery—so clients know exactly what our capabilities are. Do not hire a generalist for a specialist’s job.

What questions prove they understand model sensitivity and uncertainty quantification?

This is the litmus test for professionalism. Inexperienced analysts present a single result as “The Truth.” Experts present results with confidence intervals and sensitivity analysis.

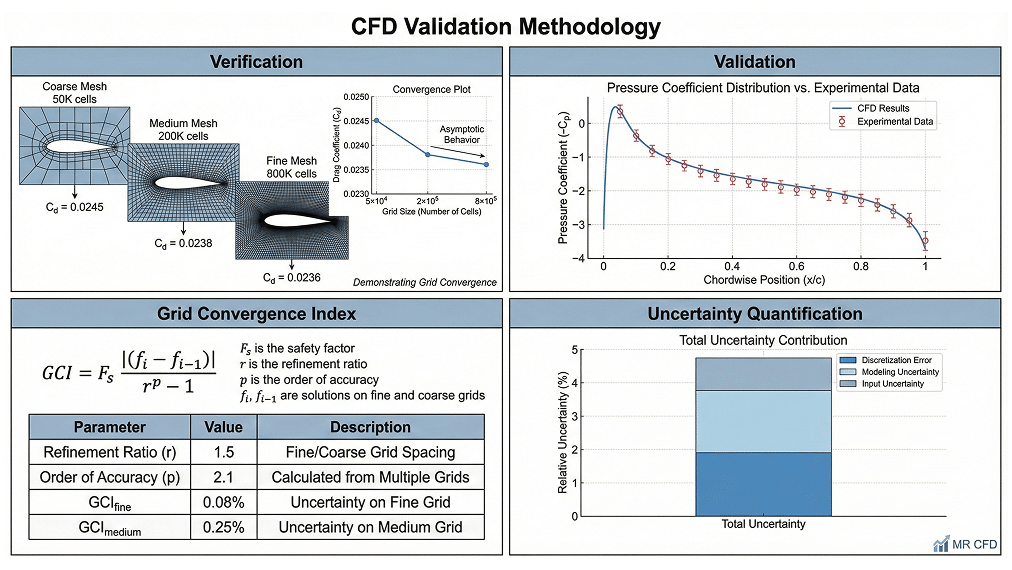

Ask the candidate: “How do you ensure grid independence?”

If they look confused, end the interview. A professional must prove that their result does not change if the mesh density is increased. They should talk about:

- Grid Convergence Index (GCI): A method to quantify discretization error.

- Time-step sensitivity: Proving that the chosen time-step is small enough to capture the transient physics.

- Parametric uncertainty: How sensitive is the output to the input boundary conditions (e.g., inlet velocity profile)?

Demonstrating an understanding of verification and validation separates the hobbyists from the engineers.

How Can You Assess a Consultant’s Experience Through Real Case Studies and Benchmarks?

A portfolio is the consultant’s resume. However, in the simulation world, pretty colors can mask bad physics. You need to look past the “rainbow plots” and interrogate the data behind the case studies. A legitimate CFD consulting services MR CFD provider will have a repository of documented case studies with ROI clearly visible.

Do they provide validation against experimental or field data?

This is the gold standard. A simulation is a mathematical approximation. It is only as good as its correlation to reality. When reviewing a consultant’s past work, look for graphs that overlay “CFD Results” with “Experimental Data.”

- Did they match the pressure drop curve of a valve within 5%?

- Did their thermal prediction match the thermocouple readings from the prototype?

Even if they cannot share proprietary client data, they should have public validation cases—benchmarking their solver against standard NASA or ERCOFTAC datasets. This shows they care about accuracy. Validation against experimental data is the strongest indicator of E-E-A-T (Experience, Expertise, Authoritativeness, and Trustworthiness) in this industry.

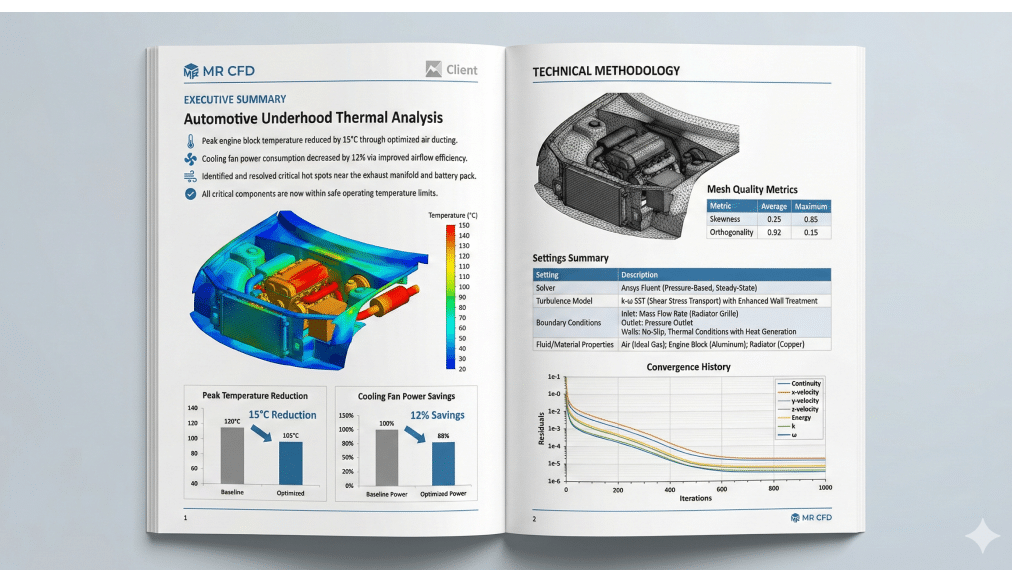

Can they quantify performance improvements, cost reductions, or safety margins?

Engineering is a business function. A consultant must speak the language of business. A case study shouldn’t just say, “We simulated the flow.” It should say:

- “We optimized the manifold design, reducing pressure drop by 15%, which saved the client $50k annually in pumping energy costs.”

- “We identified a dead-zone in the mixing tank, reducing cycle time by 20%.”

Look for the metrics. If they can quantify the value of their work, they understand that you are hiring them to improve your bottom line, not just to solve differential equations.

Are they willing to show blind test simulations or benchmark tasks?

If you are planning a massive, long-term project, it is reasonable to request a paid pilot or a “blind test.” Give the consultant a simplified version of your problem for which you already know the answer (from experiments or previous data) but do not tell them the result.

Ask them to simulate it.

- Did they get close to your known data?

- Did they justify their setup?

- Were they transparent about where the errors might come from?

A confident Ansys Fluent specialist or CFD expert will welcome this challenge as an opportunity to prove their competence.

What Tools, Software, and HPC Resources Should a Professional CFD Consultant Use?

The tools make the master. While open-source software like OpenFOAM is powerful, it requires a different infrastructure than commercial codes. You need to know what engine is powering your analysis.

Do they use licensed commercial solvers or cracked/unverified versions?

This is a critical legal and technical risk. Many freelance platforms are flooded with engineers using cracked versions of expensive software like Ansys Fluent or Star-CCM+.

Why is this dangerous?

- Legal Liability: If you use results generated on pirated software for commercial product design, you expose your company to massive lawsuits from software vendors.

- Accuracy: Cracked versions often lack updates, patches, or are unstable, leading to erroneous results.

- Support: Legitimate consultants have access to tech support from Ansys or Siemens to troubleshoot bugs. Pirates do not.

Always ask for proof of license or verify they are using legitimate open-source alternatives if budget is a constraint. At MR CFD, we pride ourselves on full compliance and access to certified Ansys Fluent expert resources.

Do they have access to HPC infrastructure for large transient models?

Industrial CFD is heavy. A simulation of a transient combustion process or external aerodynamics of a truck can involve 50 to 100 million cells. This cannot be solved on a standard engineering laptop.

Ask: “What hardware will you run this on?”

A professional consultant should have access to:

- HPC (High-Performance Computing) Clusters: Either on-premise or cloud-based (AWS, Azure, Rescale).

- Parallel Processing: The ability to run on 64, 128, or more cores simultaneously.

If they plan to run your complex transient simulation on a 4-core workstation, the project will take months instead of days. HPC CFD simulation services are essential for timely delivery.

How do they handle pre-processing and meshing at scale (polyhedral, hex-core, overset)?

The mesh is the discretization of space. The type of mesh used affects both accuracy and speed.

- Tetrahedral meshes: Easy to generate but computationally expensive and less accurate for wall-bounded flows.

- Hex-core / Polyhedral meshes: The modern standard. They offer better convergence and accuracy with fewer cells.

- Overset Meshing: Crucial for moving parts (like gears or store separation).

Ask about their meshing strategy. A consultant who relies solely on automatic tetrahedral meshing without understanding boundary layer resolution ($y+$ values) is a novice. They should be discussing prism layers, inflation layers, and mesh quality metrics (skewness, orthogonal quality) fluently.

What Questions Reveal Whether a Consultant Can Communicate Engineering Results Clearly?

The best simulation in the world is useless if the results are buried in a confusing report. You need a partner who bridges the gap between the color map and the boardroom.

Do they translate CFD results into actionable design recommendations?

You don’t just want data; you want answers.

- Bad Report: “Here is the velocity profile.”

- Good Report: “The velocity profile indicates a recirculation zone at the inlet elbow. We recommend increasing the radius of curvature by 20mm to eliminate this and reduce erosion risk.”

During the interview, ask to see a sample report (redacted). Does it end with an “Executive Summary” and “Recommendations”? If it’s just 50 pages of rainbow pictures, they are analysts, not consultants. MR CFD emphasizes delivering executive-ready insights that engineers can act on immediately.

Can they explain limitations, assumptions, and model boundaries?

No model is perfect. A trustworthy consultant will tell you what the model cannot do.

- “We used a steady-state RANS model, so we are capturing the average flow, not the instantaneous turbulence.”

- “We assumed adiabatic walls, so heat loss to the environment is neglected.”

If a consultant claims their simulation is “100% accurate to reality” without listing assumptions, run away. Honesty about CFD verification and verification limits builds trust.

Do they offer design optimization, sensitivity studies, or parametric sweeps?

A single simulation is a snapshot. True value comes from trends. Ask: “Can you run a parametric sweep to tell me the optimal valve angle?”

Advanced consultants utilize tools (like Ansys Workbench or Adjoint Solvers) to automatically vary geometry and find the global optimum. This capability turns CFD from a verification tool into a design driving tool.

What Should You Ask to Understand Their Project Workflow and Quality Assurance Process?

Chaos in workflow leads to errors in results. You need a structured partner.

What is their standard workflow from CAD → mesh → setup → solve → post-processing?

A professional CFD project workflow should look like this:

- Scoping: Defining physics, boundary conditions, and goals.

- Geometry Prep: Cleaning CAD, extracting fluid volumes.

- Meshing: Generating and refining the grid (Mesh Independence Study).

- Setup & Solving: Applying physics models and running the solver.

- Convergence Check: Monitoring residuals and monitors.

- Post-Processing: Extracting data and visualizations.

- Reporting: Documentation and recommendations.

If they skip steps—especially the scoping or mesh independence phase—quality will suffer.

How do they handle verification and validation (V&V)?

V&V is the scientific method applied to simulation.

- Verification: “Am I solving the equations correctly?” (Checking math, mesh, time-step).

- Validation: “Am I solving the right equations?” (Comparing against reality).

Ask specifically for their QA checklist. Do they have a peer-review process where a senior engineer checks the setup of a junior engineer? At MR CFD, every project undergoes a rigorous internal audit before the client ever sees a preliminary result.

What risk-mitigation strategies do they use for unstable or diverging simulations?

Simulations crash. It’s a fact of life. Highly non-linear problems (shock waves, combustion) are prone to “blowing up.” Ask: “What do you do if the residuals don’t converge?” A pro will talk about:

- Ramping up boundary conditions.

- Reducing under-relaxation factors.

- Initializing with a potential flow solution.

- Switching to a transient solver to capture unsteady vortex shedding.

Their answer will reveal their troubleshooting depth.

How Do You Evaluate the Cost, Timeline, and Value of a CFD Consultant?

The cost of CFD consulting varies wildly. Understanding why helps you budget effectively.

What impacts cost more: geometry complexity or physics complexity?

Educate yourself so you aren’t overcharged.

- Geometry: Complex CAD requires human time to clean. This increases labor costs.

- Physics: Complex physics (combustion, multiphase) requires computer time (HPC) and senior-level expertise to set up.

Often, a simple geometry with complex physics is more expensive than a complex geometry with simple physics due to the computational resources and expertise required.

How do you compare hourly vs. fixed-price CFD consulting models?

- Hourly: Good for open-ended R&D or troubleshooting. You pay for the effort. Risk: Scope creep can blow the budget.

- Fixed Price: Best for well-defined projects (e.g., “Simulate this specific valve”). You know exactly what you pay. MR CFD typically recommends fixed-price contracts for defined scopes to protect the client’s budget.

What deliverables justify premium consulting fees?

Why pay $150/hr instead of $40/hr?

- Deliverables: You get the raw data, the case files, fully automated scripts, and a comprehensive engineering report.

- Insight: You are paying for the 20 years of experience that prevents a 3-week delay.

- Liability: You are paying for licensed software and insurance.

Cheap simulation is usually the most expensive kind because it has to be re-done.

What Guarantees, Confidentiality Policies, and IP Protections Should You Expect?

Your CAD data is your intellectual property. It must be protected.

Who owns the simulation models and CAD files after delivery?

This must be in the contract.

- Standard: Client owns the results and reports.

- Premium: Client owns the simulation case files (setup, mesh, results).

Make sure you own the output so you aren’t held hostage by the consultant for future changes.

How do they ensure confidentiality with sensitive industrial data?

Ask for their NDA (Non-Disclosure Agreement) policy.

- Do they use encrypted transfer protocols for data?

- Do they store data on secure, air-gapped servers?

- Do they delete data after a set period?

Trust is paramount.

Can they maintain long-term support and version control of your models?

Engineering is lifecycle management. Six months from now, you might need to re-run the simulation with a slightly different inlet temperature. Ask: “Do you archive projects? Can we re-open this case in a year?” A structured firm will have a data retention policy and version control (Git for scripts, huge storage for data) to support you long-term.

When Should You Choose MR CFD as Your Fluid Dynamics Consultant?

After 20 years in the trenches of industrial simulation, MR CFD has built a reputation not just for solving equations, but for solving business problems. We don’t just sell hours; we sell certainty.

What industries and physics does MR CFD specialize in?

We have moved beyond generalist capability into deep vertical expertise:

- Aerospace: Aerodynamics, avionics cooling, cabin comfort.

- Automotive: Battery thermal management, under-hood flow, external aero.

- Energy & Petrochemical: Combustion, separators, pumps, wind turbines.

- Biomedical: Blood flow, respiratory devices, cleanroom ventilation.

Our team is composed of specialists. If you have a combustion problem, you get a combustion engineer, not a generalist.

What guarantees and transparency does MR CFD offer compared to others?

We believe in benchmarked CFD results.

- Transparency: We provide regular progress updates and preliminary results to ensure we are on the right track.

- Accuracy: We adhere to strict best-practice guidelines for mesh quality and convergence.

- Education: We don’t just give you the fish; we teach you to fish. Through our CFD training courses, we can train your internal team to take over the models we build.

How can you start your CFD project with MR CFD today?

Don’t let engineering uncertainty stall your project. Whether you need a full turnkey simulation, a second opinion on existing work, or training for your team, we are ready to deploy our HPC resources and expertise for you.

🚀 Ready to de-risk your design? Contact MR CFD for a Free Consultation regarding your project requirements today. Let’s simulate reality before you build it.

Frequently Asked Questions (FAQ)

How much does it cost to hire a fluid dynamics consultant for an industrial project?

The cost varies significantly based on complexity. A simple steady-state flow analysis might range from $1,500 to $4,000. Complex multiphase or transient combustion projects can range from $10,000 to $50,000+ due to the high engineering hours and HPC costs involved. Always look for a detailed breakdown in the quote (setup vs. compute time) to understand where your budget is going. Avoid “too good to be true” quotes, as they often imply unverified software or inexperienced students.

What software platforms do CFD consultants typically use?

Top-tier consultants primarily use Ansys Fluent or Ansys CFX due to their industry-standard validation and robust support. Siemens Star-CCM+ is also common in the automotive sector. OpenFOAM is a powerful open-source alternative used by consultants to reduce licensing costs for massive parallel runs, provided they have the scripting expertise to verify the code. At MR CFD, we specialize in Ansys Fluent but can adapt to client-preferred toolchains.

How long does a typical CFD consulting project take?

Timeline depends on scope. A standard CFD project workflow usually follows this timeline:

- Geometry & Cleanup: 2–5 Days

- Meshing & Setup: 3–5 Days

- Solving (Computation): 1–7 Days (highly dependent on physics/HPC)

- Analysis & Reporting: 3–5 Days Total typical turnaround is 2 to 4 weeks. Rush services are available but usually incur a premium for prioritizing HPC queues and weekend engineering hours.

What should I prepare before contacting a CFD consulting company?

To get an accurate quote and fast start, prepare:

- CAD Files: Ideally in STEP or Parasolid format (native files like .SLDPRT are okay but less universal).

- Boundary Conditions: Know your inlet velocities, pressures, temperatures, and fluid properties.

- The “Question”: Clearly define what you want to learn (e.g., “What is the pressure drop?” or “Is there a recirculation zone?”).

- Timeline: When do you need the results?

Can CFD replace physical prototyping entirely?

Not entirely, but it drastically reduces it. CFD for product design allows you to test 100 design variations virtually and only build physical prototypes for the top 3 contenders. This approach, known as “Virtual Prototyping,” cuts R&D costs by 40-70%. However, a final physical validation test is always recommended for safety-critical applications to validate the simulation model before mass production.

What industries benefit the most from CFD consulting?

Industries involving fluid flow, heat transfer, or chemical reactions benefit most.

- HVAC: Data center cooling, cleanrooms.

- Automotive: Aerodynamics, battery cooling, engine combustion.

- Oil & Gas: Separation, pipeline assurance, erosion prediction.

- Aerospace: Lift/drag analysis, cabin environmental control.

- Marine: Hull resistance, propeller cavitation. Anywhere a fluid moves, CFD can optimize the process.

Does MR CFD offer student or academic discounts?

Yes, MR CFD supports the academic community. While our consulting rates reflect premium industrial expertise, we offer specialized CFD courses and educational resources for students and researchers at discounted rates. We also collaborate on university research projects where our HPC resources can support academic publication goals. Contact our support team for specific academic packages.

How do I know if my project is suitable for CFD analysis?

If your problem involves knowing flow patterns, temperature distributions, pressure drops, or chemical mixing inside or around a complex geometry where you cannot easily place a sensor, CFD is suitable. If you can solve the problem with a simple spreadsheet calculation (Bernoulli’s equation) or a quick hand calc, CFD might be overkill. A consultant’s job is to tell you honestly if CFD is the right tool or if a simpler 1D code would suffice.

What data do I need to provide for accurate CFD simulations?

Accuracy depends on inputs (“Garbage In, Garbage Out”). You need to provide:

- Accurate Geometry: The CAD must represent the real fluid volume.

- Fluid Properties: Density, viscosity, thermal conductivity (and how they change with temperature).

- Operating Conditions: Inlet flow rates, outlet pressures, heat generation rates (Watts).

- Material Properties: If heat transfer is involved, we need the thermal properties of the solid walls.

Can I request a sample benchmark before committing to a full-scale project?

Absolutely. A reputable hire CFD Consultant should be willing to perform a small, low-cost (or sometimes free, depending on scale) Proof of Concept (PoC) or benchmark simulation. This allows you to evaluate their communication style, mesh quality, and reporting clarity before signing a large contract. At MR CFD, we often start with a “Pilot Phase” to align expectations and demonstrate our peer-reviewed simulation methods.

Comments (0)