Air Freshener Spray Device CFD Simulation

$120.00 Student Discount

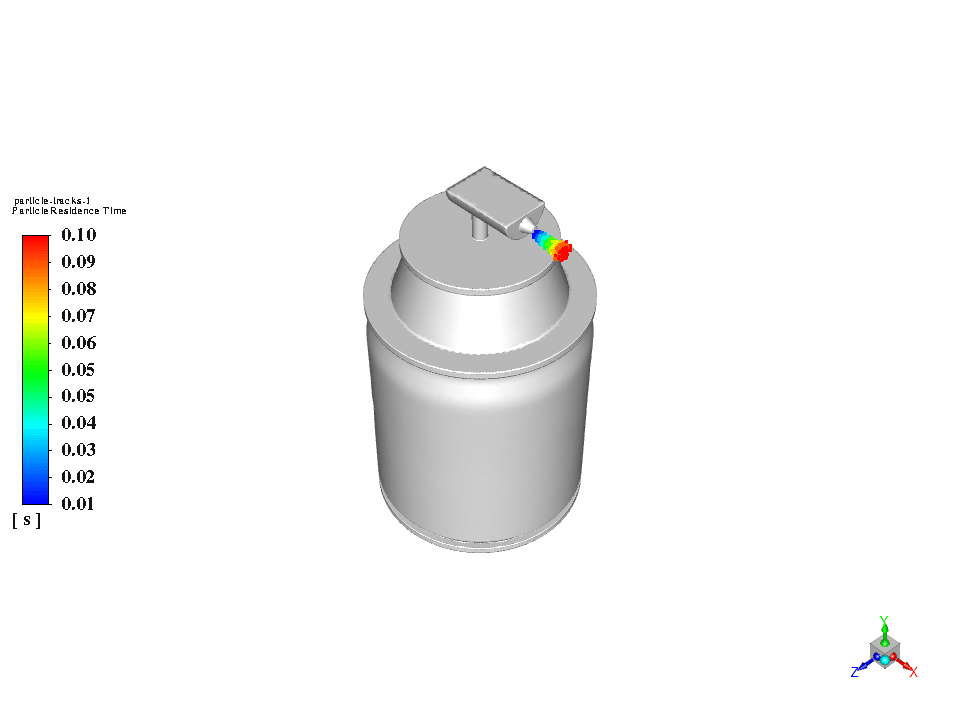

- The problem numerically simulates the Air Freshener Device using ANSYS Fluent software.

- We design the 3-D model with the Design Modeler software.

- We mesh the model with ANSYS Meshing software, and the element number equals 357758.

- We use the discrete phase model (DPM) to define a Spray process.

- The Species Transport is defined to select Evaporative Droplet injection for particles.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Air Freshener Spray Device CFD Simulation, ANSYS Fluent

This project is related to the numerical simulation of the Air Freshener Device using Ansys Fluent software.

The air freshener is used to spray aromatic substances. This device is used in homerooms and public places. The mechanism of these devices is based on the spray. The aromatic liquid is filled in the chamber of these air fresheners. Then by spraying, they spread in the surrounding space.

We modeled the geometry of the project using Design Modeler software.

The geometry is related to an air freshener. The computational zone includes a sample box around this device to study the spraying process in this space.

Then we meshed the model with Ansys Meshing software. The model mesh is unstructured, and the number of cells is equal to 357758.

Air Freshener Methodology

In this project, we have simulated the process of spraying fragrant particles. So we have to use the Lagrangian approach. According to this approach, we should investigate particle by particle in a discrete space.

Then we used the Discrete Phase Model (DPM). Then we have defined an Injection for dispersing discrete particles.

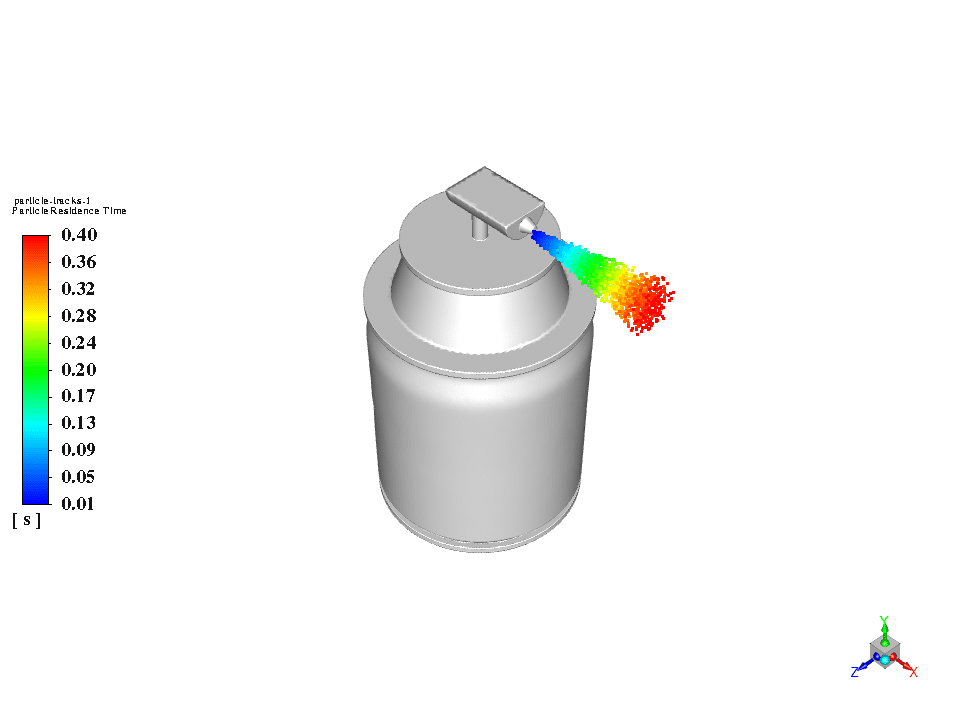

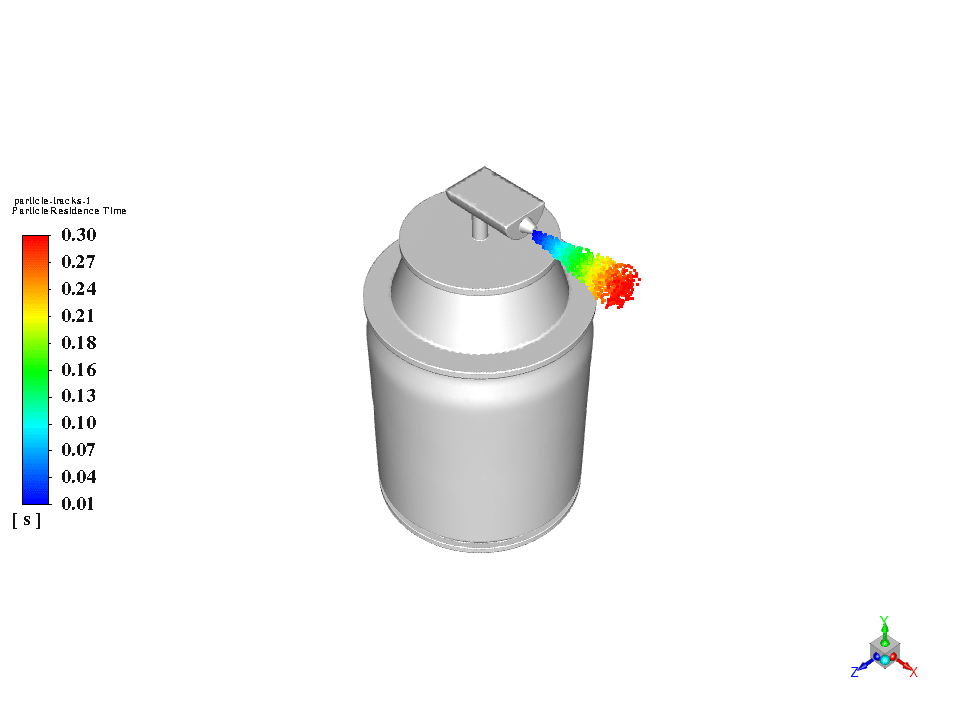

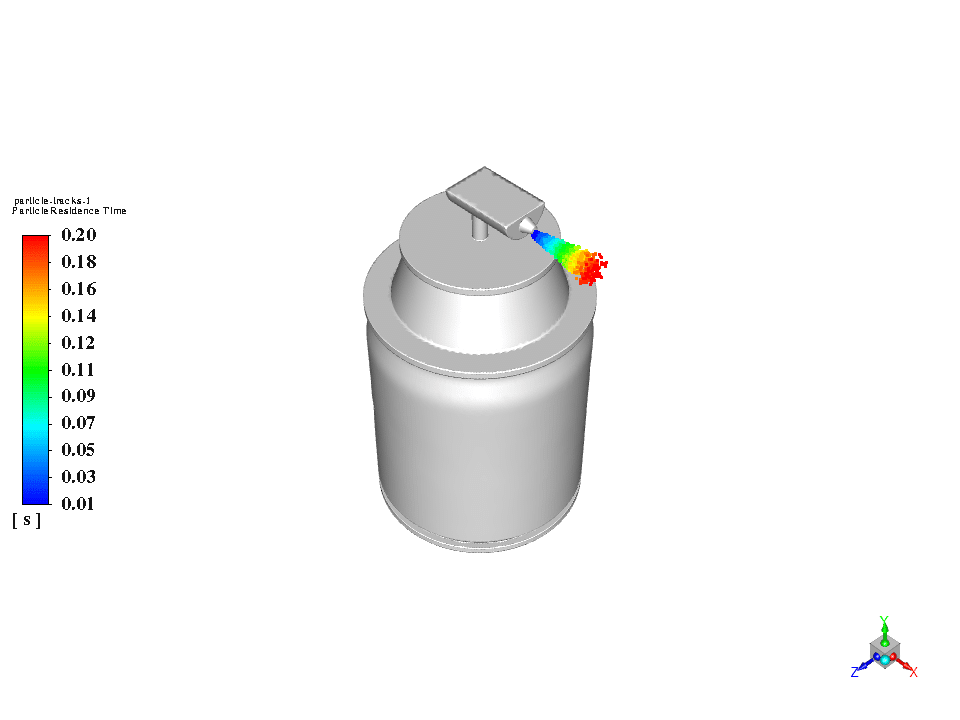

The injection type is Conical, and the particle type is the Droplet. The injection of particles is unsteady and happens within 0.4 seconds.

To use droplet injection, we have also defined the Species Transport Model. We defined three volumetric species, including oxygen, nitrogen and water vapor.

Air Freshener Conclusion

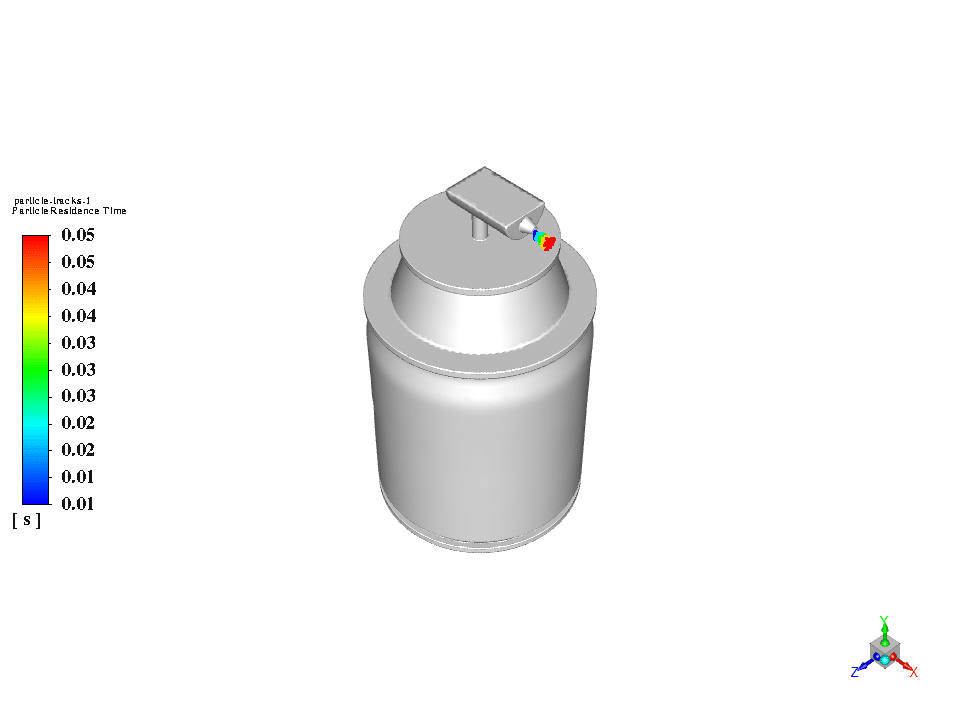

After the solution, we studied particle tracking. At different times, we have investigated particle tracking. We also obtained an animation of particle injection.

By checking the particle over time, the spraying process of this device can be studied. The results show that the simulation is done correctly. This device sprays fragrant particles well.

Alberta Jenkins –

The simulation details provided really put into perspective the intricate process of modeling spray devices! I’m really impressed by how you’ve implemented the Lagrangian approach for particle distribution through the Discrete Phase Model. I’m especially curious about how you set up the species transport model, particularly for the reaction mechanism, if at all, that considers interaction between the fragrance substances and ambient air.

MR CFD Support –

In this simulation, the species transport model is used to track the concentration of different gaseous components. While the primary focus is on the distribution of fragrance particles as a discrete phase, the species transport model helps provide a detailed representation of gaseous species, like oxygen and nitrogen. In the case of this air freshener device, we do not specifically model chemical reactions between the fragrance substances and the ambient air. Instead, we monitor the dispersion of water vapor (representing the fragrance particles) within the airspace, considering the primary physical dispersal without detailed chemistry.

Ms. Birdie Hansen –

Great simulation! The visual animation helped me understand the functionality much clearer. Superb work!

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear the animation was helpful in understanding the air freshener spray device simulation. Your feedback motivates us to continue providing high-quality simulations and results.

Charlene Koss –

The tutorial on simulating an air freshener spray device is fascinating! It was clear and easy to follow. I was able to understand the steps taken for the particle injection and the species definition used to simulate the fragrance dispersion in a room. Great work!

MR CFD Support –

Thank you for your positive feedback on our Air Freshener Spray Device CFD Simulation tutorial! We’re delighted to hear that it was clear, easy to follow and helpful for your understanding of the complex processes involved in the dispersion of fragrance. We appreciate your acknowledgement of our efforts to create detailed and informative content. If you have any further questions or need more insight on any other simulations or tutorials, feel free to reach out!

Montana Douglas –

I’m impressed with how thorough the CFD simulation of the Air Freshener Spray Device is. The modeling, including the injection and species selection, seems well-considered. Excellent work!

MR CFD Support –

Thank you very much for your feedback! We are thrilled to hear that you are satisfied with the simulation quality and detail of the Air Freshener Spray Device project. Our team always strives to provide in-depth analyses and accurate simulations. If you need further assistance or have additional projects in mind, don’t hesitate to reach out.

Rosemary Ankunding –

I’m really impressed with how the simulation captures the spraying process in such a clear way. The unsteady particle injection and droplet breakup look extremely realistic. Beautiful work with particle tracking and the animations too!

MR CFD Support –

Thank you for your kind words! We work hard to create realistic and accurate simulations that help understand complex processes like the spraying mechanism in air freshener devices. It’s great to hear that the results have met your expectations and that the particle tracking and animations provided a clear representation of the spraying process.

Mireya Bartoletti –

The simulation of the air freshener spray device is incredibly detailed. The explanation of the methodology helps to understand the process behind the device’s spray mechanism. It’s informative to learn that multiple volumetric species were taken into account to ensure a realistic simulation.

MR CFD Support –

Thank you for your kind words! We are delighted to hear that you found the details of the simulation comprehensive and educational. Our goal is to provide thorough simulations that capture real-world phenomena, and we’re glad you appreciate the efforts taken with the various volumetric species in the air freshener device. If you have any further questions or need additional information, please feel free to ask. We’re here to help!