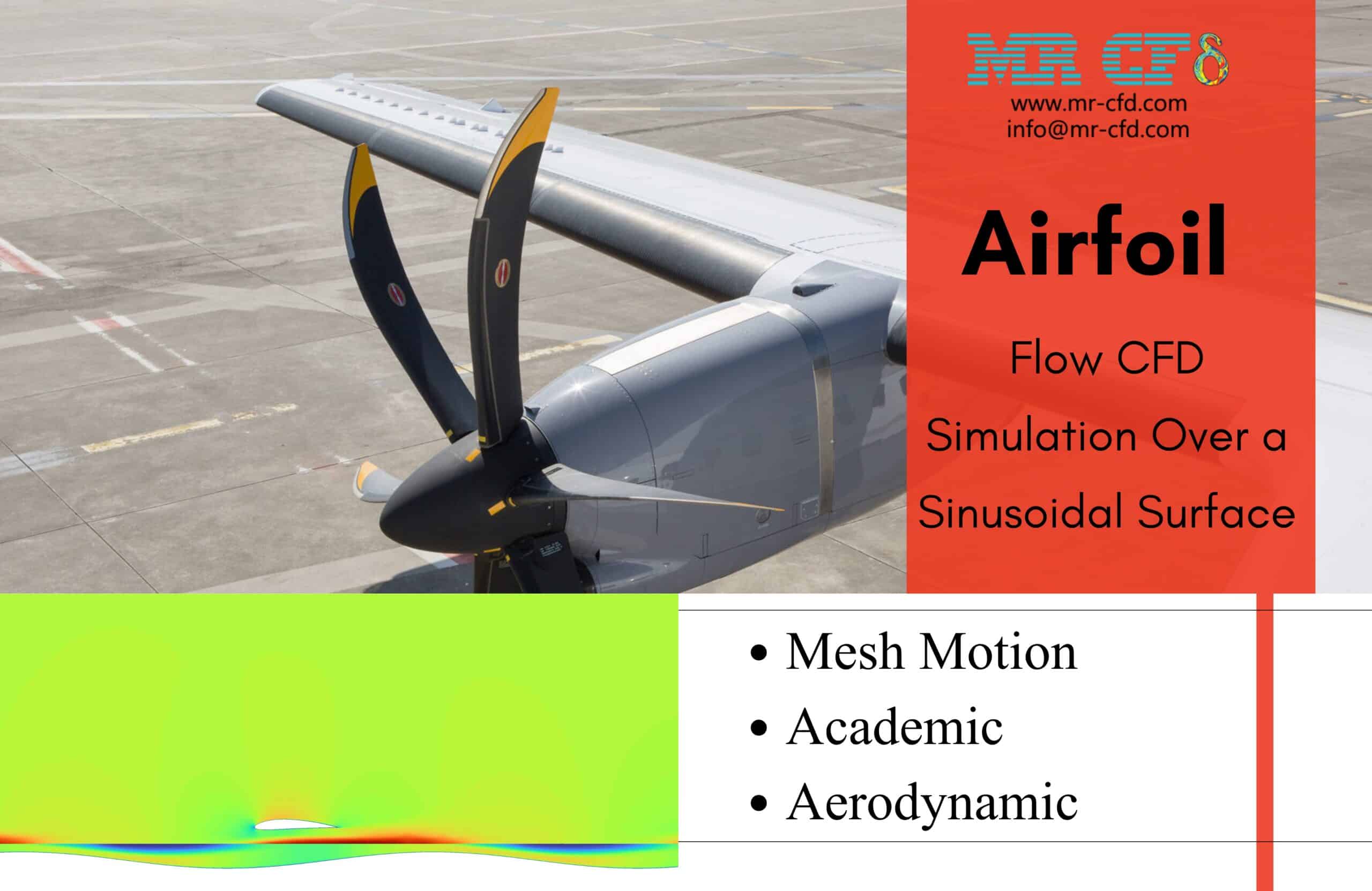

Airfoil Flow CFD Simulation Over a Sinusoidal Surface Using Mesh Motion

$80.00 $32.00 HPC

- This simulation studies airflow around an airfoil placed above a sinusoidal wall using mesh motion in ANSYS Fluent to analyze aerodynamic effects.

- The 2D model includes an airfoil over a wavy bottom surface, divided into stationary and moving zones, with a structured refined mesh near the airfoil and wall.

- A transient pressure-based solver with the k–ω SST turbulence model was applied using a 55 m/s inlet velocity and mesh motion of 56 m/s for the moving zone.

- Velocity contours show accelerated flow over the airfoil’s upper surface, while pressure contours indicate low pressure above and high pressure below, confirming lift generation influenced by the wavy boundary.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

CFD Simulation of Airfoil Flow Over a Sinusoidal Surface Using Mesh Motion in ANSYS Fluent

Description

This simulation was conducted to analyze the aerodynamic behavior of an airfoil placed above a sinusoidal wall in a transient flow field using ANSYS Fluent. The study focuses on evaluating the velocity and pressure distribution around the airfoil and within the flow domain. A moving zone was introduced to replicate relative motion between the airfoil and the surrounding air, providing a more realistic representation of unsteady aerodynamic conditions. The simulation accounts for turbulence, gravity, and the coupling between pressure and velocity fields to ensure physical accuracy. The main objective of this project was to observe how a wavy surface and moving reference frame influence the aerodynamic characteristics of the airfoil.

Geometry and Mesh

The 2D geometry was created in ANSYS DesignModeler and composed of a rectangular computational domain containing an airfoil positioned slightly above a sinusoidal bottom boundary, which represents a wavy ground surface. The domain was divided into two zones: a stationary zone and a moving zone that contains the airfoil. This moving zone allows the airfoil and surrounding fluid to move uniformly at a constant velocity, simulating a relative motion condition.

The mesh was generated in ANSYS Meshing using structured hexahedral elements to ensure high numerical accuracy and stability. The grid was refined near the airfoil surface and the sinusoidal wall to capture the steep velocity and pressure gradients typically observed in these regions. A non-conformal interface was created between the stationary and moving zones to handle mesh motion effectively. The final mesh included a sufficient number of elements to guarantee mesh independence and computational efficiency.

Model and Solver Settings

The simulation was performed in ANSYS Fluent using a pressure-based transient solver suitable for incompressible flow conditions. Gravity was activated to account for body force effects, though its impact on the flow around the airfoil was minimal due to the dominance of dynamic pressure. The k–ω SST turbulence model was adopted because of its robustness and ability to accurately predict boundary layer separation and near-wall effects.

Boundary conditions were specified as follows: a velocity inlet with an inflow velocity of 55 m/s, a pressure outlet with ambient static pressure, and no-slip conditions on the airfoil and sinusoidal wall surfaces. The moving zone was defined with a translational velocity of 56 m/s in the X-direction, close to the inlet velocity, to simulate steady relative motion. The SIMPLE algorithm was employed for pressure–velocity coupling, and second-order spatial discretization schemes were used for momentum and turbulence equations to enhance accuracy.

Results

The simulation results demonstrated the flow behavior around the airfoil placed near a wavy bottom wall. The velocity contour revealed that the maximum flow velocity occurred over the suction surface of the airfoil, where low-pressure regions were formed, leading to lift generation. The velocity decreased significantly in the region behind the airfoil, indicating the formation of a wake zone. The influence of the sinusoidal wall was evident near the lower surface of the airfoil, as it altered the local flow field and affected boundary layer development.

Pressure contours showed a distinct high-pressure region at the leading edge of the airfoil and a low-pressure region over the upper surface, consistent with classical aerodynamic behavior. The pressure field also illustrated how the sinusoidal wall modified local pressure distribution near the bottom boundary. Overall, the use of the k–ω SST turbulence model captured the complex flow separation and reattachment phenomena effectively. The combined use of mesh motion and transient analysis enabled realistic simulation of unsteady flow conditions over a wavy surface.

You must be logged in to post a review.

Reviews

There are no reviews yet.