HAWT (Horizontal Axis Wind Turbine) ANSYS Fluent CFD Simulation Training

$140.00 Student Discount

- The present study investigates the airflow passing over a 3-blade horizontal axis wind turbine (HAWT) by ANSYS Fluent software.

- The present 3-D model was designed by SOLIDWORKS software and imported to Design Modeler software.

- The meshing of the model has been done using ANSYS Meshing software. The mesh type is structured, and the element number is 4270222.

- The present simulation aims to investigate the effect of wind flow on the turbine blades and calculate the Drag and Lift forces applied to the blade surfaces.

- Using the Frame Motion (MRF) method.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

HAWT Description

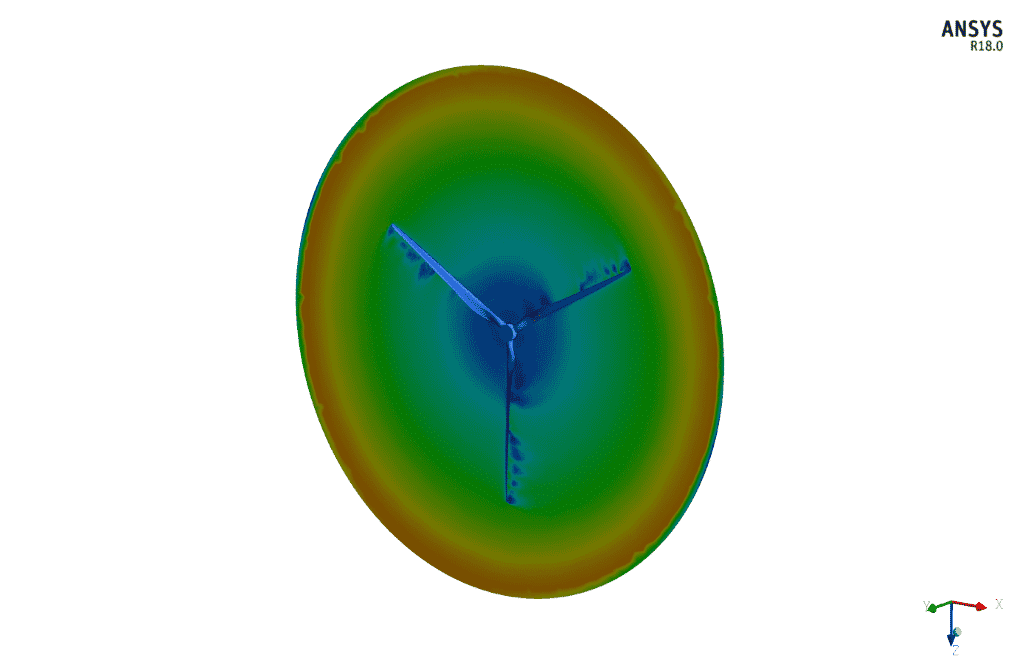

The present study investigates the airflow passing over a Horizontal Axis Wind Turbine (HAWT) by ANSYS Fluent software. The purpose of the problem is to study the distribution of velocity and pressure on the surface of the blades and their body.

The present 3-D model was designed by SOLIDWORKS software and imported to Design Modeler software. The present turbine has three blades, a rotary axis, and a domain around the blades. The meshing of the model has been done using ANSYS Meshing software.

The mesh type used for this geometry is structured, and the element number is 4270222.

Methodology

The present simulation aims to investigate the effect of wind flow on the turbine blades. It calculates the Drag and Lift forces applied to the blade surfaces of the HAWT. In this problem, the turbine blades rotate at a rotational speed of 72 rad.s-1 on the horizontal axis. The air in the area surrounding the blades is stationary.

Using the MRF method, the blades can be assumed to be constant. The wind flow around the blades is rotated to the same rotational velocity of 72 rad.s-1 around the y-axis.

Since the present simulation is related to the external flow, the K-Omega SST model has been used. This model of k-omega operates as a hybrid function. This results in a gradual transfer of flow from the k-omega model for near-wall regions to the k-epsilon model in areas beyond the boundary layer.

Moreover, the air enters the domain with a velocity of 15m/s. It leaves it through a pressure-outlet boundary to atmospheric pressure.

HAWT Conclusion

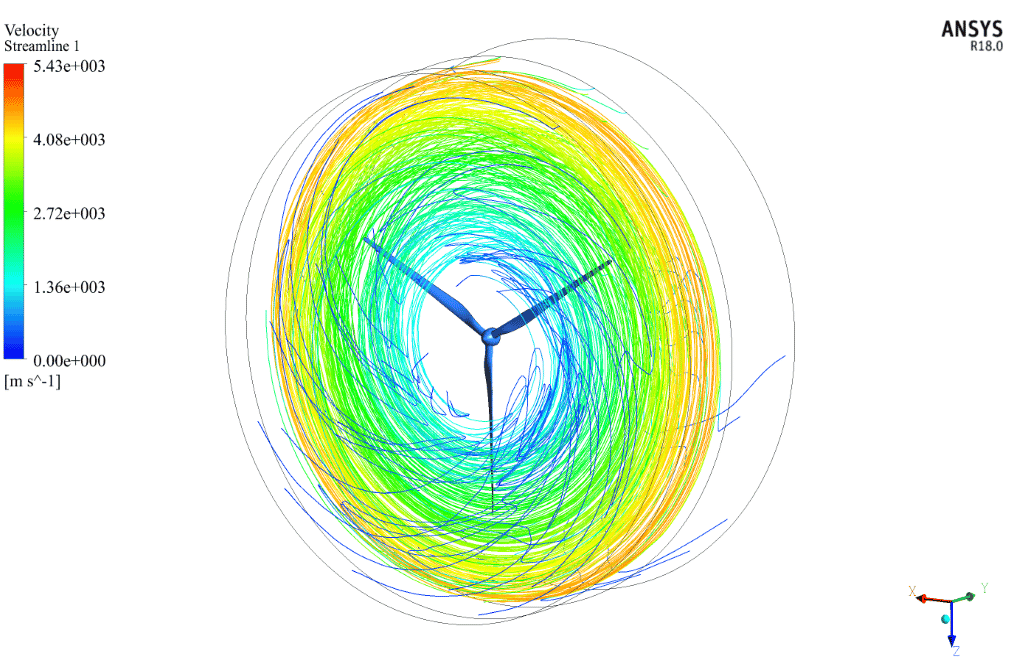

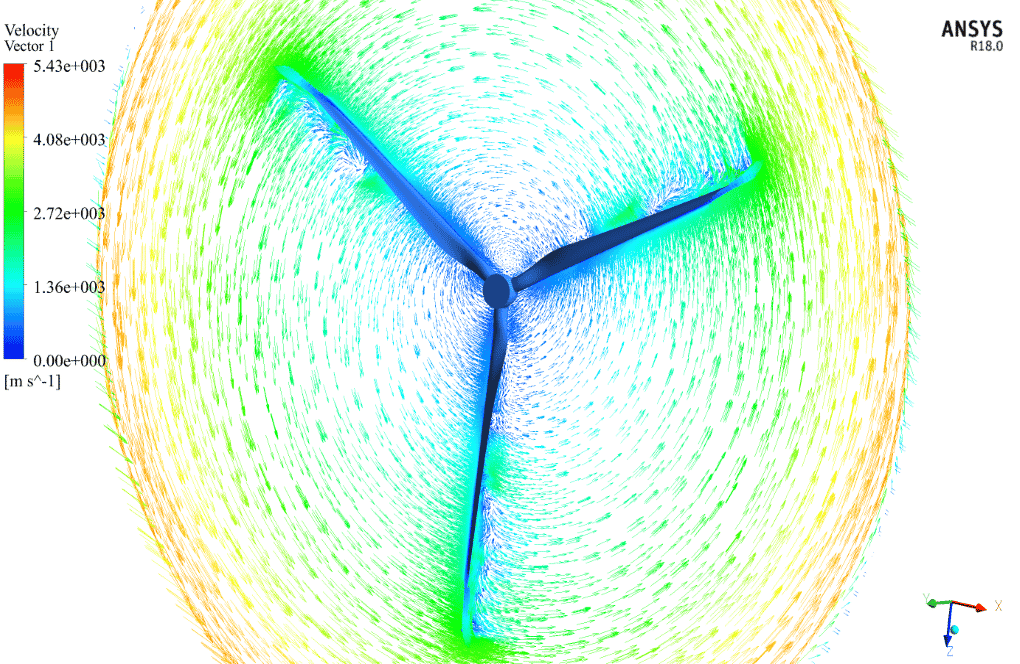

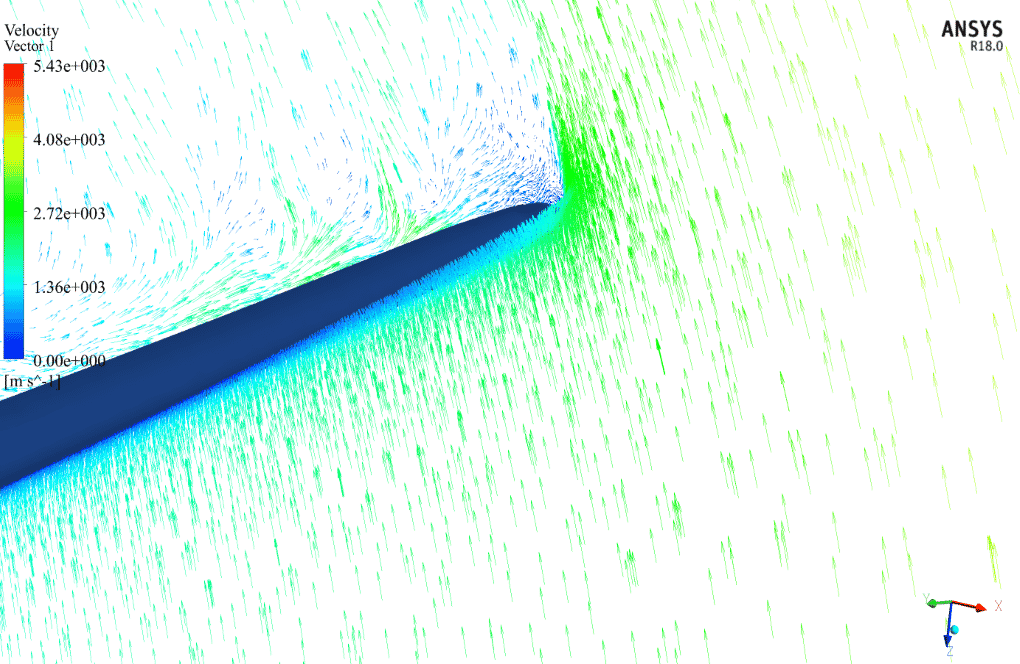

At the end of the solution process, contours related to the velocity, streamlines, and velocity vectors are obtained. As seen in velocity contour, the radial airflow distribution is obvious due to the turbine blades’ rotating motion. Also, by viewing the velocity vectors near the blade’s surface, the interaction between airflow and the turbine blade can be seen in detail.

Lenna Olson –

How accurate are the power output predictions from your HAWT simulation?

MR CFD Support –

Our HAWT simulation is designed to provide highly accurate power output predictions. We use advanced meshing techniques and robust solvers to ensure the reliability of our results.

Mrs. Sonya Franecki –

What are the aerodynamic principles behind the operation of the HAWT in your simulation?

MR CFD Support –

The HAWT operates on the principle of lift and drag. When wind passes over the blades, a lift force is generated due to the pressure difference on the two sides of the blade, causing the blades to rotate.

Dangelo Reinger –

How does your simulation handle turbulent wind conditions?

MR CFD Support –

Our simulation uses advanced turbulence models to accurately capture the effects of turbulent wind conditions on the performance of the HAWT.

Prof. Al Hartmann –

In this simulation, MRF method is also used?

Prof. Rosalind Cremin MD –

Can the HAWT simulation be customized to model a different number of blades or a different blade design?

MR CFD Support –

Absolutely! We can customize our simulation to accommodate different blade designs or a different number of blades. Please get in touch with us to discuss your specific needs.

Nora Botsford –

The structured mesh was really well done, and I appreciated how the contours illustrated the airflow around the blades effectively. Great job on detailing the MRF method and k-omega SST model application in the study!

MR CFD Support –

Thank you for your positive feedback! We are pleased you recognized the intricate work done on the mesh and the detail provided on the methodology. It is gratifying to know that our approach to simulation provides clear and useful information to our users. If you have any further inquiries, feel free to ask.

Lavonne Jacobi –

The training for HAWT CFD Simulation using ANSYS Fluent was incredibly insightful. It deepened my understanding of wind turbine simulations, smooth meshing techniques, and the use of the MRF method to model rotation. The k-omega SST model was the perfect choice for demonstrating the transition in flow regions around the turbine. The illustrations of contours for velocity and pressure provided clear visual validation of the simulation’s accuracy. A real standout training module for anyone interested in renewable energy applications!

MR CFD Support –

Thank you for your kind words and positive feedback on the HAWT ANSYS Fluent CFD Simulation Training! We are thrilled to hear that you found the training module insightful and that it helped deepen your understanding of wind turbine simulations. It is wonderful to know our diagrams and the contour illustrations proved useful for validation. Your enthusiasm for renewable energy applications is shared by our team, and we remain committed to providing valuable, high-quality training content. Thank you for choosing our product!

Humberto Satterfield –

I am impressed by the detailed analysis capability of the HAWT simulation! Did the training also cover how to interpret the complex flow patterns around the blades and calculate the performance of the wind turbine efficiently?

MR CFD Support –

Thank you for the compliment! Our training indeed covers the interpretation of the airflow patterns around the turbine blades as well as techniques for calculating the turbine’s performance metrics such as torque, power output, and efficiency. It’s designed to provide comprehensive insights into turbine aerodynamics using ANSYS Fluent.

Camren Lindgren –

The visual aids and graphical representations in the training are superb! They really helped me understand the complex flow dynamics involved in the operation of a HAWT.

MR CFD Support –

We are thrilled to hear that you appreciated the visual components of our HAWT ANSYS Fluent CFD Simulation Training. Our goal is to make learning accessible and intuitive. Thank you for your feedback, and we look forward to serving your educational needs in the future!

Aleen Langworth –

This training on HAWT CFD simulation via ANSYS Fluent is fantastic! The detailed approach helps in understanding the flow dynamics and forces on the turbine blades. Can you tell me more about the post-processing steps that were followed after the solution process to interpret the results accurately?

MR CFD Support –

In the post-processing stage, we focus on visualizing the simulation data meaningfully. This typically involves generating velocity and pressure contour plots to visualize the distribution of these fields around the turbine blades. Streamline plots are also used to depict the airflow pattern, allowing us to observe the aerodynamic behavior created by the rotating blades. Additionally, vector plots show the directional velocity near the turbine’s surface for a more detailed view of blade-interaction effects. Assessing the generated data helps in analyzing blade performance and turbine efficiency.

Mrs. Rosalyn Schinner PhD –

This training content was impeccable. As someone who has always been fascinated by wind energy, going through the HAWT simulation using ANSYS Fluent was both informative and intriguing. The detailed methodology, combined with a structured approach to explaining the aerodynamics involved, was commendable. Additionally, seeing the practical application of the MRF method and the k-omega SST turbulence model was extremely valuable. Hats off to the MR CFD team for devising such a thorough and professionally enriching learning module.

MR CFD Support –

We’re delighted to hear that you enjoyed the HAWT ANSYS Fluent CFD Simulation Training and found it to be both informative and practical. Thank you for recognizing the effort our team has put into creating a thorough educational experience that explores the intricacies of wind energy simulation. Your feedback and appreciation mean a great deal to us. If you have any further questions or require more training, we are always at your service.