Ammonia Flashing CFD Simulation By ANSYS Fluent

$140.00 $56.00 HPC

- 2D Ammonia Flashing Simulation.

- VOF model with three phases (Air, Ammonia liquid and Ammonia Vapor).

- Lee Model for Evaporation of Ammonia.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Description

Ammonia Flashing of Liquid Ammonia injected into a small orifice nozzle is numerically simulated. Flash boiling is a rapid evaporation process triggered by a sudden pressure drop, leading to an unstable liquid that undergoes fast phase change. Using the VOF multiphase model in ANSYS Fluent, the interaction between liquid ammonia, its vapor, and the surrounding gas is resolved in time. The simulation captures jet breakup, phase transition, and the subsequent development of the two-phase ammonia flow inside the computational domain.

Geometry and Mesh

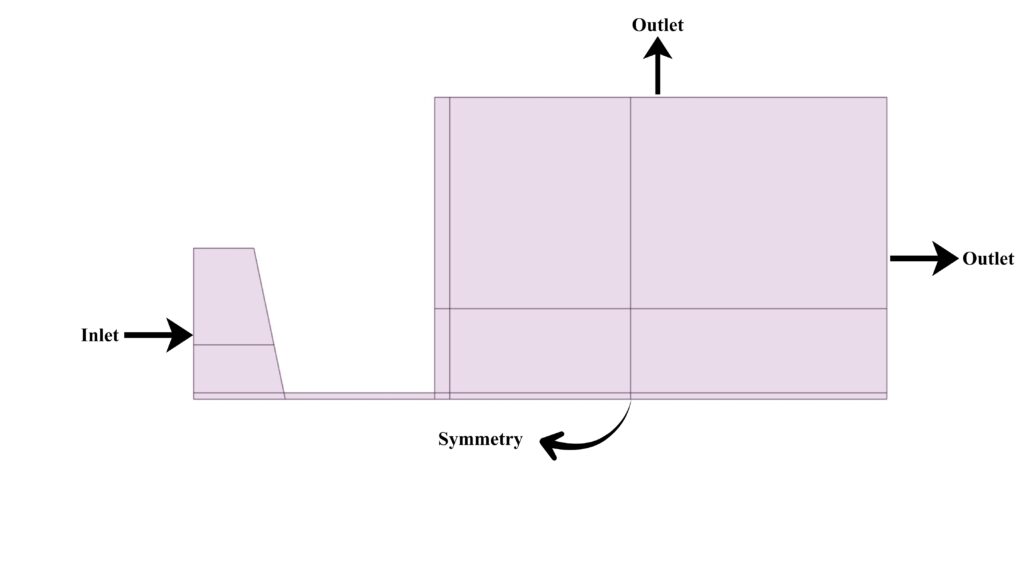

The geometry of this Ammonia Flashing case is created in ANSYS SpaceClaim as a 2D symmetric domain. The lower horizontal line acts as a symmetry boundary, so only half of the physical domain is modeled to reduce the computational cost. The geometry consists of an inlet nozzle section and a larger downstream chamber where the flashing and mixing occur. The locations of the inlet and two outlets are clearly defined on the schematic to specify the boundary conditions in the simulation.

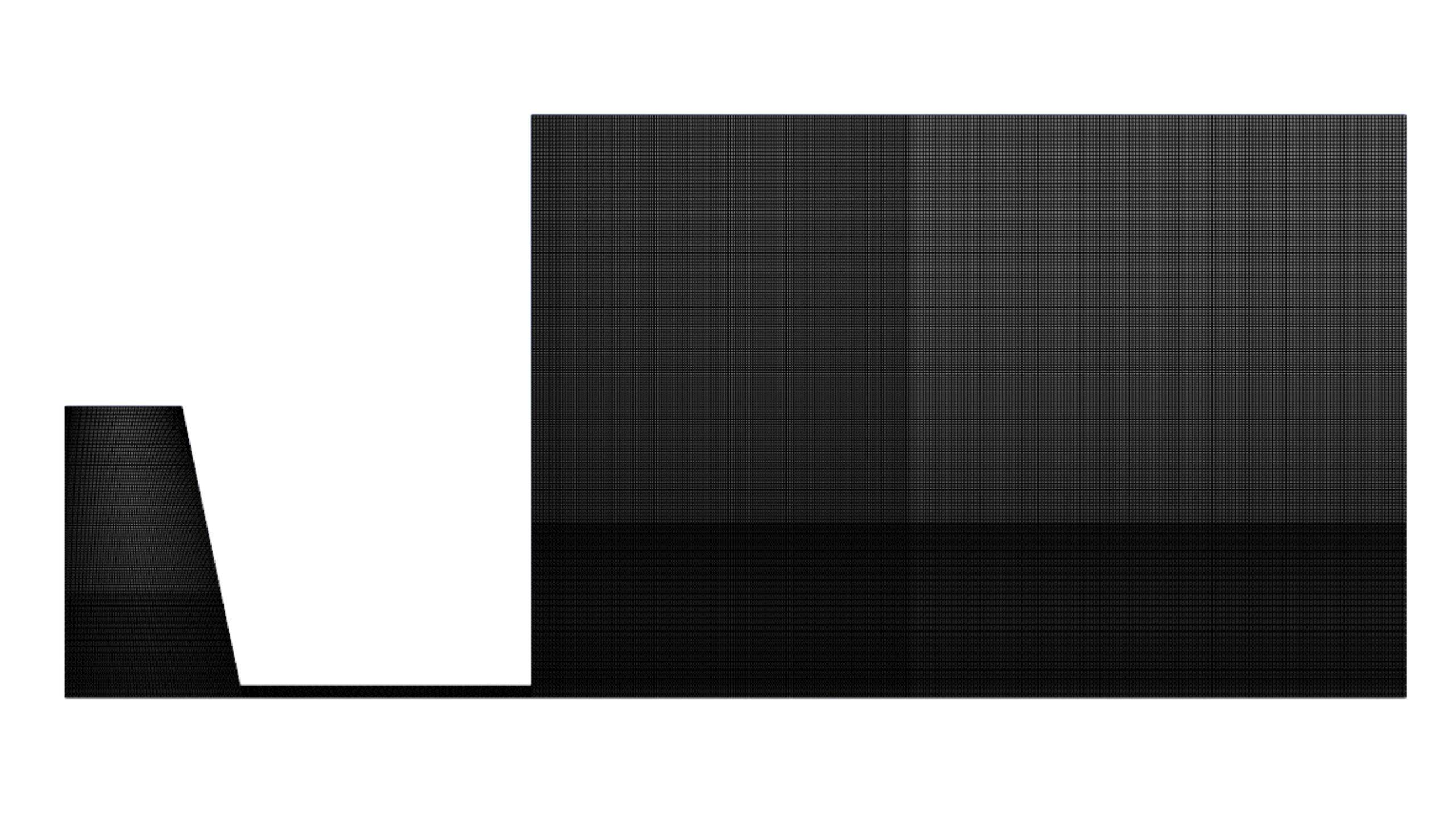

For meshing the Ammonia Flashing geometry, approximately 95,000 high quality structured elements are generated in ANSYS Meshing Software to ensure numerical stability and accuracy of the ammonia flashing simulation.

Solver Settings

The simulation of Ammonia Flashing employs a transient, incompressible, pressure based CFD solver to resolve the unsteady behavior of the flow field. k-ω SST turbulence model is used to accurately capture boundary layer separation and unstable vertical structures in the ammonia jet. For the multiphase treatment, the VOF model tracks the interfaces between air, liquid ammonia, and ammonia vapor. The Lee evaporation–condensation model is coupled with VOF to represent the phase change process from liquid ammonia to ammonia vapor within the flashing region.

Results

In the simulation of Ammonia Flashing, the injected liquid ammonia jet is observed to expand into the larger chamber and rapidly convert to a two phase mixture. Volume fraction contours clearly show the formation of a liquid film near the bottom wall, with increasing ammonia vapor fraction downstream as flashing and evaporation intensify. The velocity field reveals a high speed jet on the lower boundary and a large recirculation zone in the upper chamber, indicating strong mixing between phases. Temperature contours confirm cooling in the liquid rich region (around 270 K) and a warmer vapor-dominated layer (approaching 300 K), consistent with energy consumption during phase change.

You must be logged in to post a review.

Reviews

There are no reviews yet.