Bioreactor Agitated by Rushton Turbine CFD Simulation

$140.00 Student Discount

- The problem numerically simulates the Bioreactor Agitated by Rushton Turbine using ANSYS Fluent software.

- We design the 3-D model by the Design Modeler software.

- We Mesh the model by ANSYS Meshing software, and the element number equals 3558726.

- We perform this simulation as unsteady (Transient).

- We use the Mesh Motion method to define rotational motion.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Bioreactor Agitated by Rushton Turbine CFD Simulation, ANSYS Fluent Tutorial

The problem simulates fluid mixing in a Bioreactor with a Rushton Turbine using ANSYS fluent software. We perform this CFD project and investigate it by CFD analysis.

Bioreactors are equipment and systems in which biochemical reactions occur and are used in various industries, including pharmaceutical, food, biochemical, perfumery, etc. The bioreactor modeled in this simulation has a cylindrical structure.

A stirrer is placed vertically inside it to rotate the fluid flow inside this model to help the fluid mix and thus the desired chemical process. The stirrer used inside this reactor is a Rushton-type turbine.

Rushton turbines are in the form of radial flow type impellers widely used in mixing applications in engineering processes.

The present model is designed in three dimensions using Design Modeler software. The model includes a bioreactor with a cylindrical structure of 0.8 m high and 0.4 m in diameter with a vertical stirrer. The vertical stirrer of this model has two rows of flat discs with six blades mounted on it.

The meshing of the model has been done using ANSYS Meshing software. The element number is 3558726. Also, the transient solver is enabled due to the nature of the problem, which is time-advancing.

Rushton Methodology

These stirrers’ structure consists of flat discs connected to a vertical rotating axis on which the flat blades are mounted vertically. The Rushton turbine in this modeling consists of two rows of wide discs with blades.

A cylindrical inner region is distinguished within the model to define the fluid’s rotational flow around this Rushton turbine stirrer, which can be applied using the Mesh Motion technique.

The rotational velocity value in this region is equal to 143 rpm and is defined around the model’s vertical central axis (Y-axis). Also, three rows of baffles are designed on the bioreactor cylindrical body’s inner surface, which is used to break the vortices inside the device.

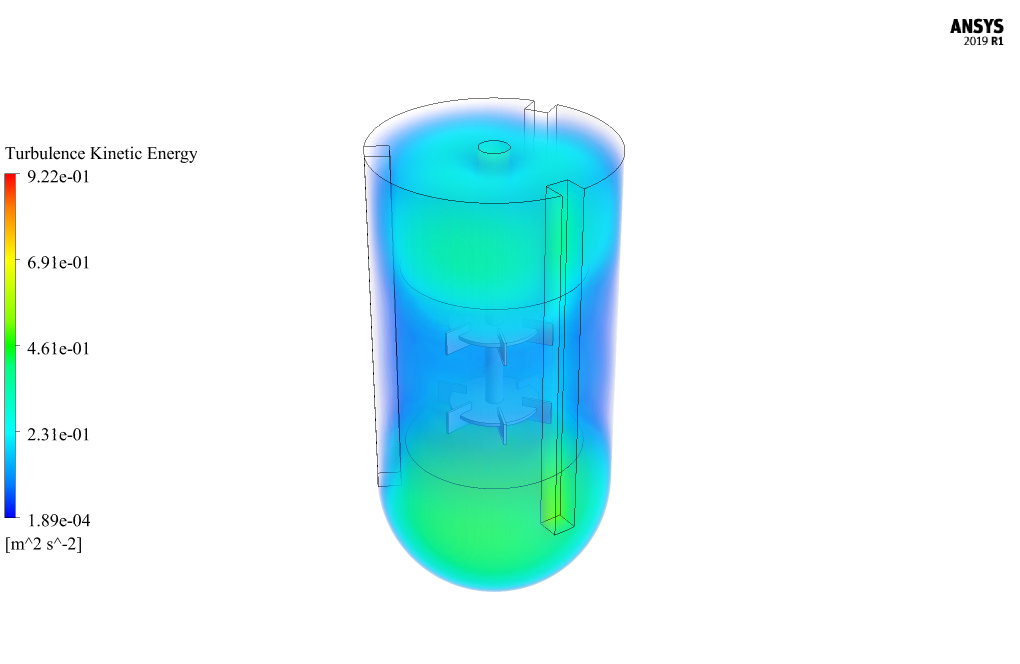

Furthermore, the RNG k-epsilon model is used to solve turbulent fluid equations.

Rushton Conclusion

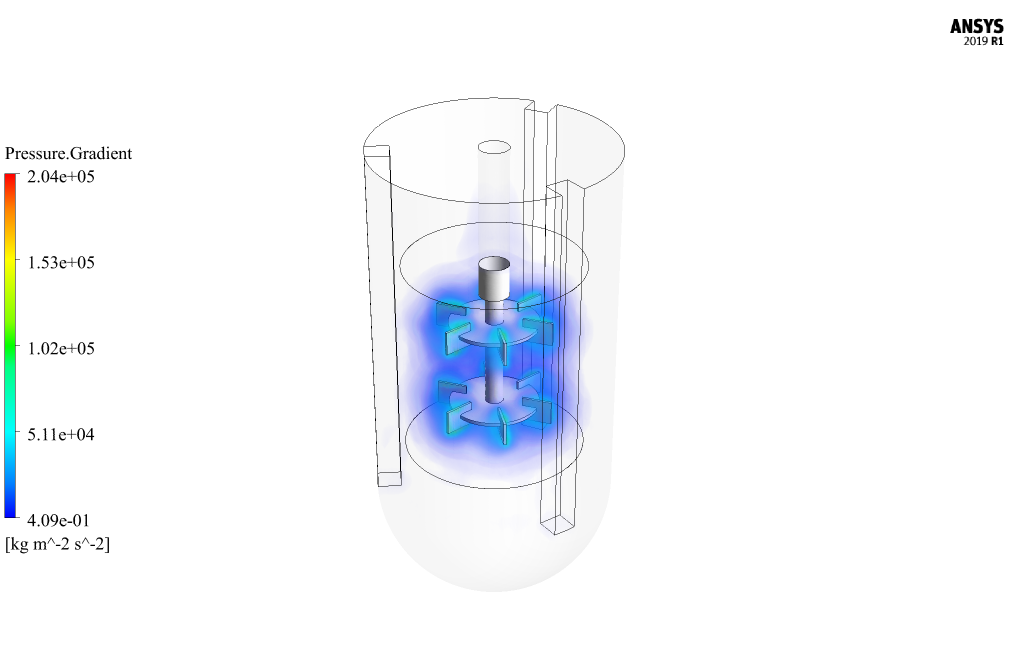

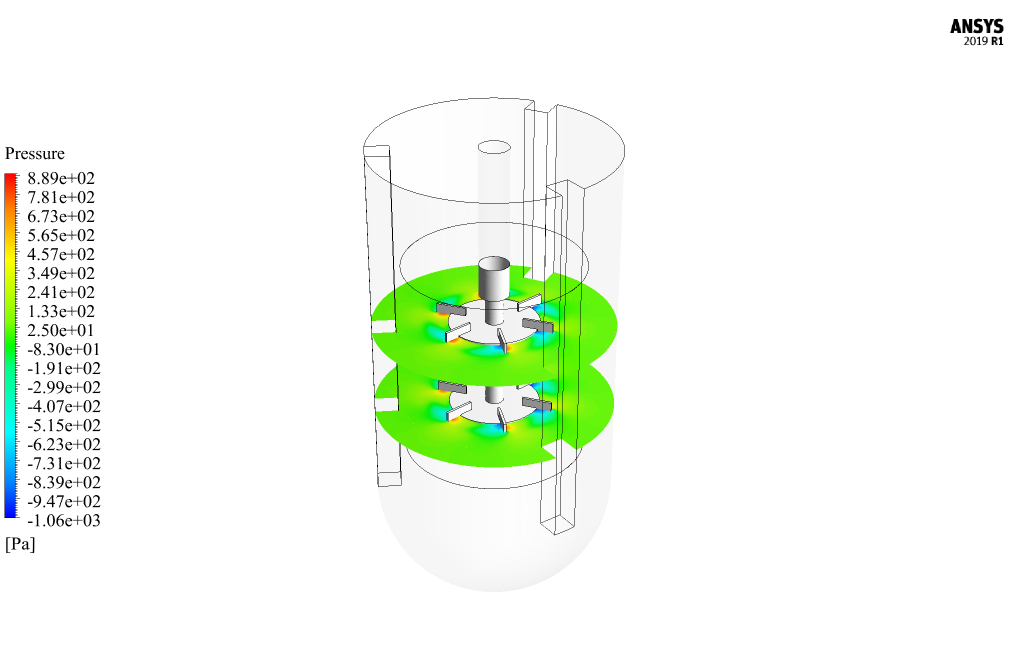

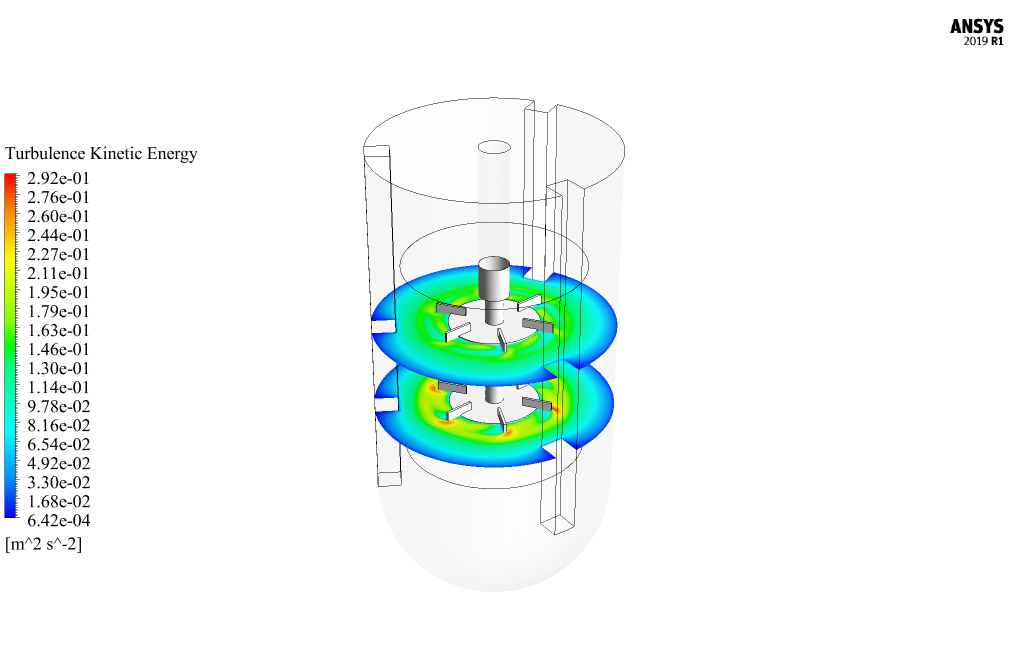

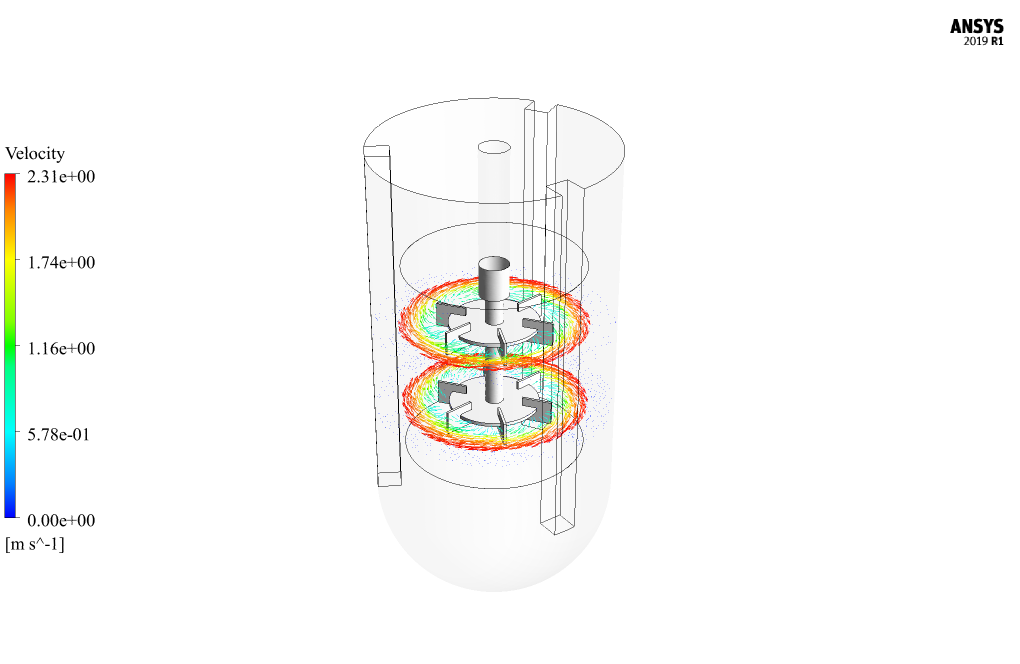

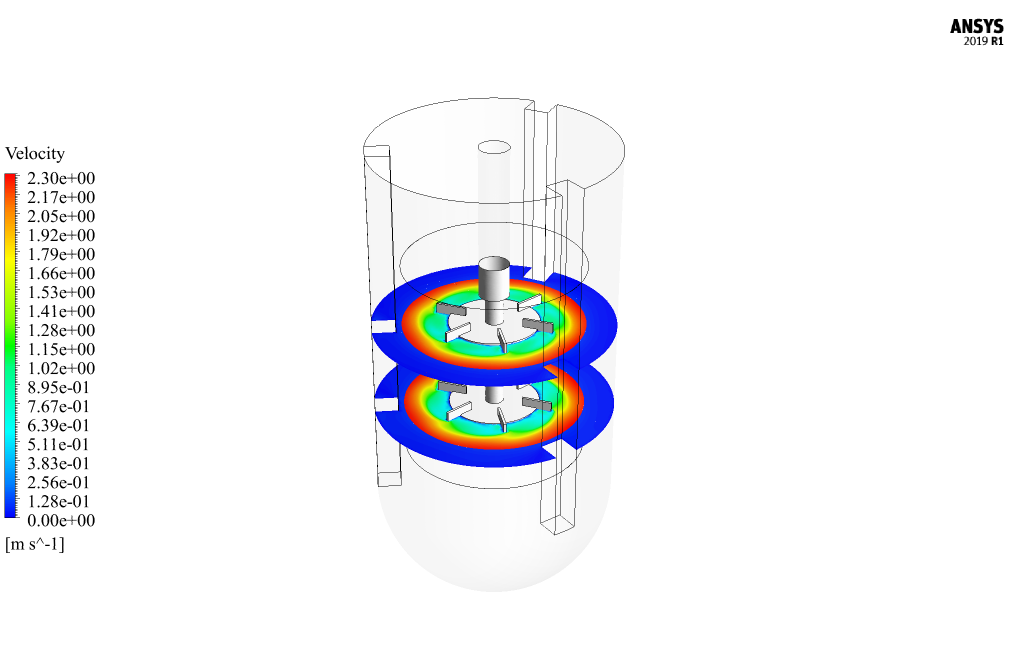

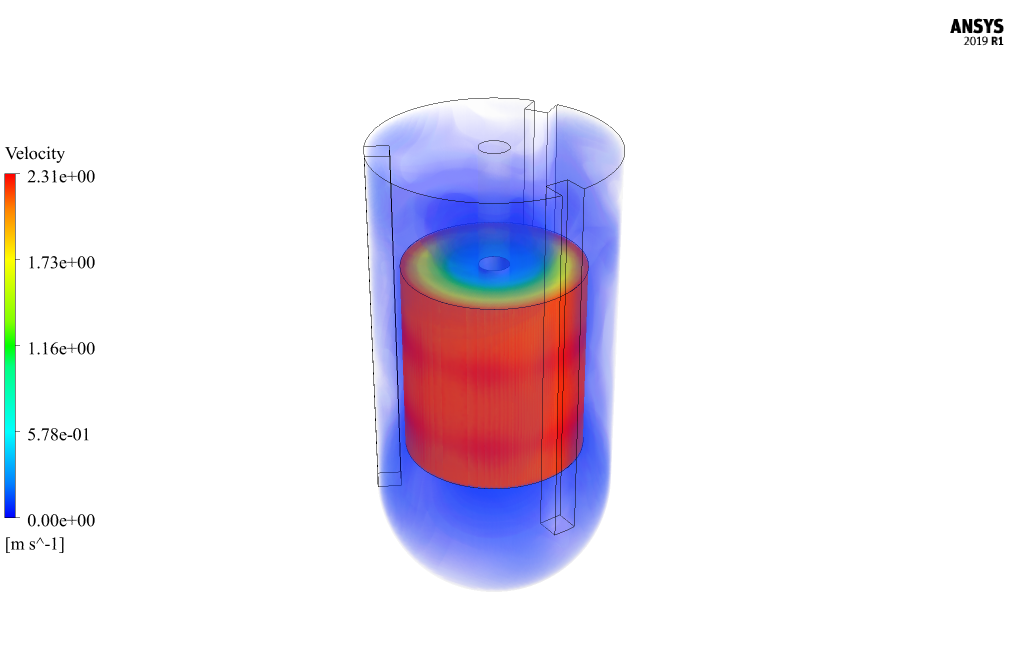

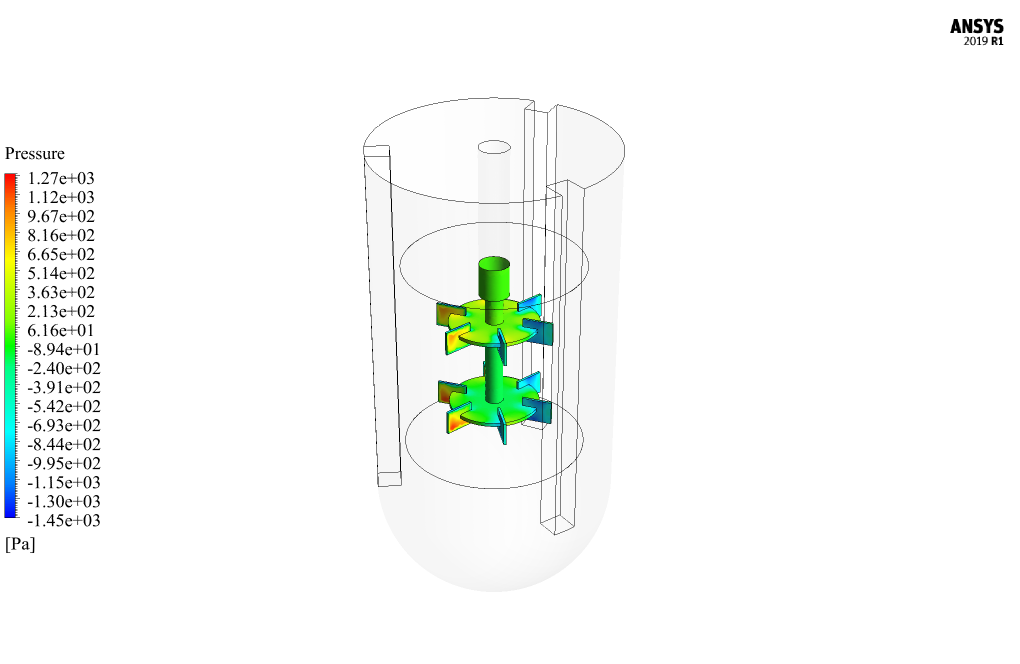

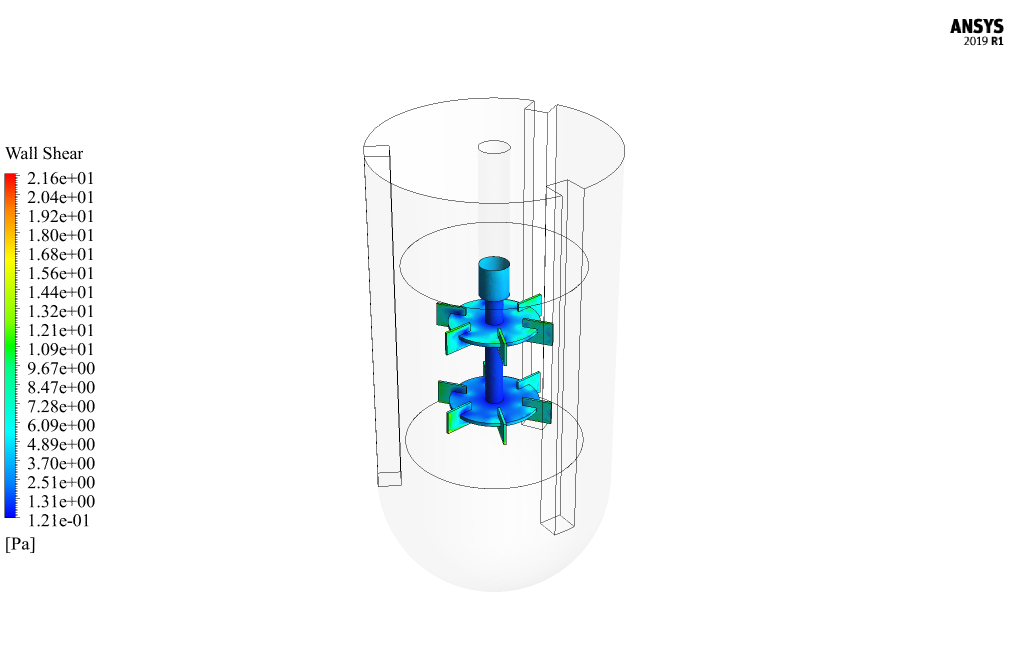

At the end of the solution process, three-dimensional contours related to the pressure gradient, velocity, and turbulent kinetic energy of the device’s water flow are obtained.

Two-dimensional contours of pressure, velocity, and turbulent kinetic energy of water flow in two two-dimensional sections perpendicular to the stirrer’s axis and passing through two stirrer disks are obtained.

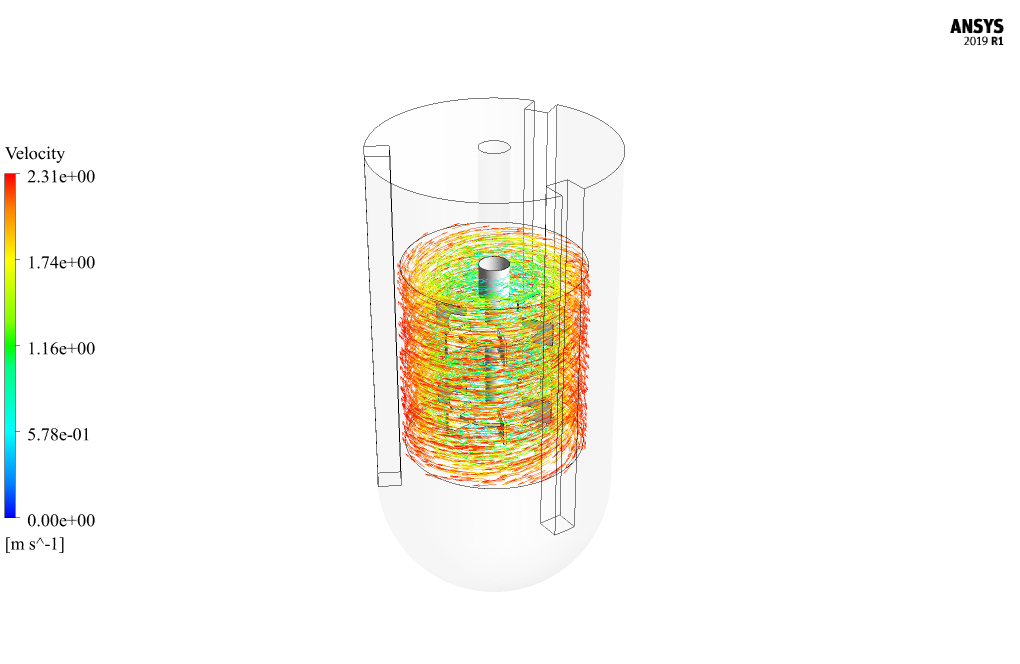

The contours show the increase in velocity and rotation of the flow around the impeller turbine impellers. Also, water velocity vectors around the stirrer axis are obtained in two and three dimensions.

Examining these velocity vectors’ trajectories makes it clear that the fluid flow rotates entirely around the stirrer’s axis of rotation.

Shane Roob –

How accurate is this simulation in predicting the behavior of a bioreactor agitated by a Rushton turbine?

MR CFD Support –

This simulation uses advanced numerical methods and accurate models of the bioreactor and Rushton turbine to provide a highly accurate prediction of the bioreactor’s behavior. However, like all simulations, it should be used in conjunction with other engineering analyses and not as a sole decision-making tool.

Cindy Lockman –

Can this simulation model the growth of microorganisms in the bioreactor?

MR CFD Support –

Yes, the simulation can model the growth of microorganisms in the bioreactor. You just need to define the specific growth kinetics of the microorganisms in the simulation setup.

Coleman Medhurst –

The explanation of the Rushton turbine’s effects on the fluid inside the bioreactor is really clear. Great job!

MR CFD Support –

Thank you so much for your kindness and for taking the time to provide your feedback! We’re thrilled to hear that you found the explanations clear and informative. Your compliments are truly appreciated, and we aim to continue providing high-quality learning materials. If you have any more questions or need further assistance in the future, please feel free to reach out!

Meghan McLaughlin –

The Rushton turbine mix results are fascinating! Great to see the detail in flow rotation and kinetic energy distributions.

MR CFD Support –

Thank you for the kind words! We’re delighted to hear that you found the CFD simulation results of the Rushton turbine in the bioreactor insightful. It’s great to know that our efforts to detail and analyze fluid dynamics are appreciated. If you have any more feedback or need further information about our products, feel free to reach out!

Prof. Alexanne Swift –

What options are there in ANSYS Fluent for simulating the mixing in bioreactors apart from the Rushton turbine, and could you use the same setup?

MR CFD Support –

Apart from the Rushton turbine, ANSYS Fluent allows for the simulation of various mixing technologies like hydrofoil impellers, pitched blade turbines, and anchor stirrers, depending on the application’s goals and the pattern of mixing needed. Setup replication is possible, though adjustments would be necessary to reflect the changed geometry and possibly the flow model if the mixing pattern differs significantly.

Miss Verdie Doyle –

This tutorial provided so much value—seeing the Rushton turbine’s effect on fluid dynamics in the bioreactor with such clarity was helpful. The visuals were particularly enlightening. Well executed!

MR CFD Support –

Thank you for your kind feedback! We’re delighted to hear that the tutorial on the Bioreactor Agitated by Rushton Turbine was clear and enlightening. Your satisfaction with our CFD simulation, especially the visual aspects, is extremely important to us. We appreciate you taking the time to share your experience!

Mr. Clay Johnston III –

The tutorial was superb! Learned a lot about bioreactor simulation with a Rushton Turbine. It clarified many of my doubts, especially about setting boundary conditions and meshing for complex movements.

MR CFD Support –

We’re thrilled to hear that our Bioreactor Agitated by Rushton Turbine CFD Simulation tutorial was instrumental in enhancing your understanding of boundary conditions and meshing complexities. Thank you for sharing your positive experience!

Prof. Jadyn McDermott MD –

I’m so impressed with the detailed analysis provided in this tutorial for a Rushton turbine in a bioreactor system. The information on flow patterns and velocity profiles provides deep insights necessary for optimizing mixing efficiency. The use of the RNG k-epsilon model in the simulation seemed to capture the turbulence well. Great job on incorporating the mesh motion technique to reflect the stirrer’s rotation.

MR CFD Support –

We’re delighted to hear that the tutorial on fluid mixing in a Bioreactor using a Rushton Turbine met your expectations and that you found the analysis detailed and informative. Your satisfaction with the RNG k-epsilon model and mesh motion technique application gives us much pride. We strive to provide comprehensive CFD solutions and educational materials. Thank you for acknowledging our efforts!

Leonora Cummings –

Can this simulation handle different operating conditions?

MR CFD Support –

Yes, the simulation can handle different operating conditions. You can adjust the speed of the Rushton turbine, the temperature of the bioreactor, and other operating conditions in the simulation setup.

Sedrick Schultz –

I am so impressed with the detailed analysis presented in the simulation. The presentation of three-dimensional contours was especially helpful in understanding the fluid dynamics within the bioreactor.

MR CFD Support –

Thank you for your positive feedback! We’re pleased to hear that our detailed analysis and presentation of three-dimensional contours enhanced your understanding of the fluid dynamics involved in the bioreactor simulation. If you have any further questions or need assistance, feel free to reach out!

Prof. Retta Welch –

I’m quite impressed with the results demonstrated through the Bioreactor Agitated by Rushton Turbine CFD Simulation product. The level of detail and the provided data allowed me to fully grasp the fluid dynamics involved in the stirring process. Understanding pressure gradients and turbulent kinetic energy distribution has enhanced my knowledge in bioreactor design and optimization. Kudos to the team for creating such an in-depth tutorial!

MR CFD Support –

We are delighted to hear that the tutorial on the Bioreactor Agitated by Rushton Turbine CFD Simulation was so valuable for your understanding and design work. We aim to provide detailed analysis to help our customers fully grasp complex fluid dynamics in practical applications. Thank you for your positive feedback, and please feel free to explore more of our tutorials for further learning!

Rupert Schaden Sr. –

I recently purchased the tutorial for the ‘Bioreactor Agitated by Rushton Turbine CFD Simulation’, and it provided very good insights into handling complex fluid mixing within ANSYS Fluent. The step-by-step guide was detailed, and the simulation aspects, such as setting up boundary conditions, solver settings, and post-processing, were thoroughly covered. The inclusion of images and video tutorials really helped me understand the process much better. Kudos to MR CFD for creating such an informative and practical tutorial, that will surely be beneficial for many projects to come!

MR CFD Support –

Thank you for your kind words! We’re delighted to hear that our ‘Bioreactor Agitated by Rushton Turbine CFD Simulation’ tutorial met your expectations and was helpful for your projects. Your feedback motivates us to continue providing high-quality learning materials. If there’s anything more we can assist you with, do let us know. We look forward to serving you again!

Edward Hessel –

Excellent learning tool for visualizing mixing dynamics within a bioreactor. The detailed simulation using a Rushton turbine is insightful for understanding the impact of impeller design on fluid flow characteristics.

MR CFD Support –

We’re glad to hear that our bioreactor simulation with a Rushton turbine was beneficial for your learning experience. We appreciate you taking the time to share your positive feedback!

Prof. Buddy Beatty II –

The tutorial was super helpful! Following each step really made understanding the setup and analysis of a bioreactor stirred by a Rushton turbine much clearer.

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that the tutorial was effective in making the CFD setup and analysis of the bioreactor with a Rushton turbine clear and understandable. If you have any more questions or need further assistance, don’t hesitate to reach out. We’re here to help!

Ora Wyman –

I’m very pleased with the insights gained from the contours showing pressure gradient, velocity, and turbulent kinetic energy. It greatly enhanced my understanding of the flow behaviours in bioreactors. Great tutorial!

MR CFD Support –

We’re thrilled to know that the tutorial on the ‘Bioreactor Agitated by Rushton Turbine CFD Simulation’ was helpful to you! Your feedback is appreciated, and we’re glad that the visualization of the contours provided useful insights into the flow dynamics within the bioreactor. Thank you for choosing our simulation tutorial to further your understanding!