Boiling inside a Nanotube CFD Simulation Training

$160.00 Student Discount

- The problem numerically simulates the boiling process inside a nanotube using ANSYS Fluent software.

- We design the 3-D model by the Design Modeler software.

- We mesh the model by ANSYS Meshing software.

- The mesh type is Structured,, and the element number equals 757886.

- We define a boiling model with the Eulerian multiphase model.

- We use a mass transfer to define the phase conversion process from liquid to gas.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Boiling inside a Nanotube CFD Simulation by ANSYS Fluent, Training

The present problem simulates the boiling process inside a nanotube using ANSYS Fluent software.

A nanotube is a tube that is made at the nano-scale by nano-particles. This type of tube’s diameter can be about a few nanometers, While its length can reach several millimeters.

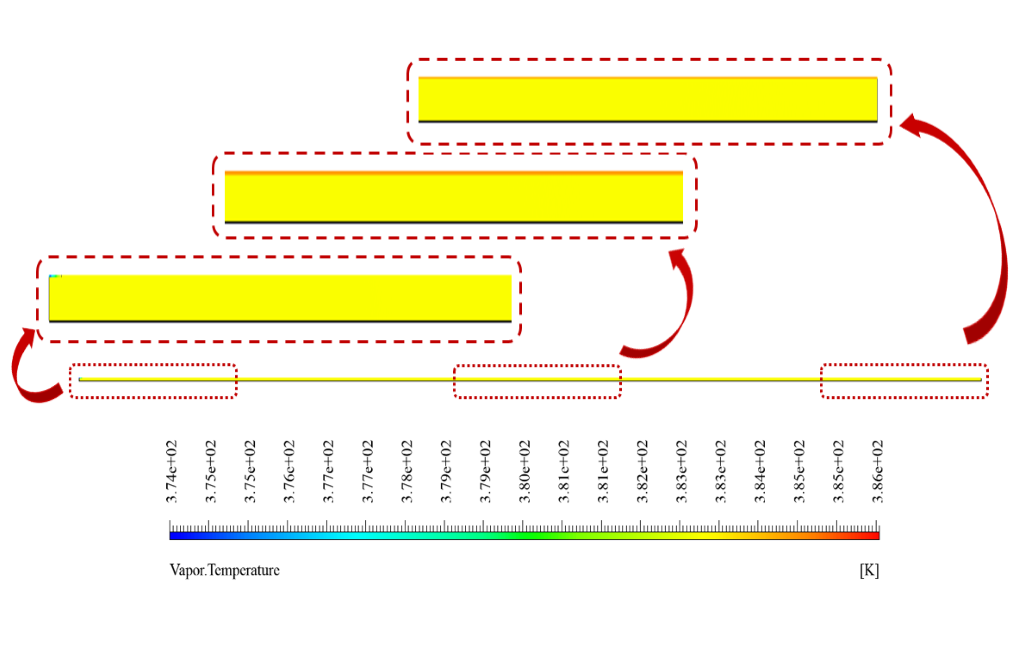

This simulation assumes that the water saturation temperature is 383.15 K; at this temperature, a phase change from liquid water to water vapor occurs.

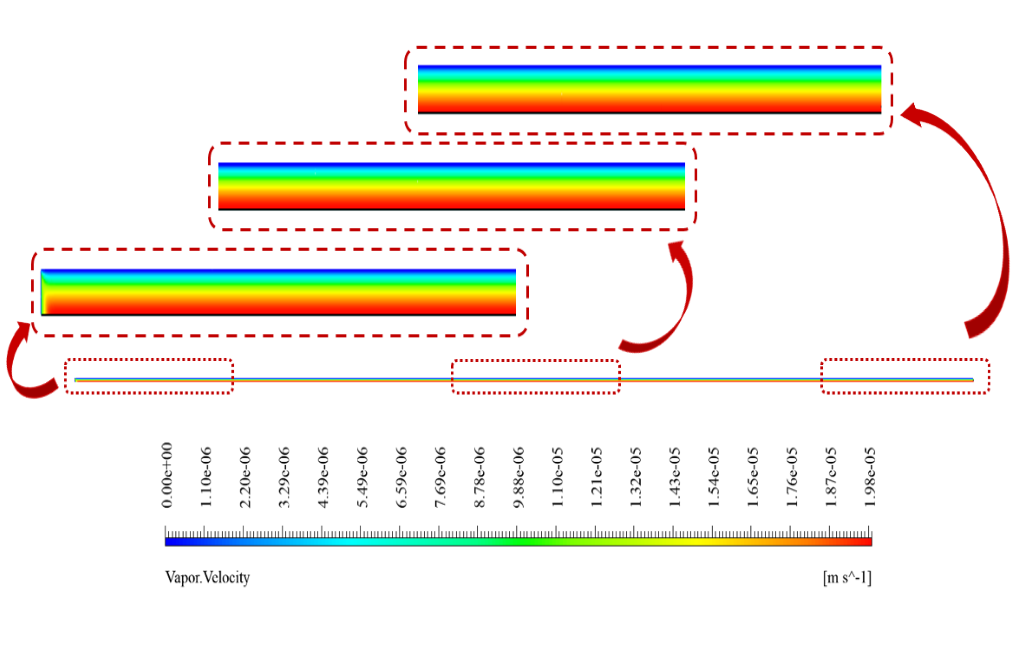

The water stream enters the pipe at a speed of 1e-5 and a temperature of 373.15 K, and since this water stream is close to the saturation temperature, it can be said that it is ready for the boiling process.

The present model is designed in two dimensions using Design Modeler software. The model is a nanotube drawn in two dimensions due to its symmetrical geometric structure and reduced computational cost.

This pipe is of nanotube type and has a length of 0.00005 m and a radius equal to 0.00000015 m.

We carry out the model’s meshing using ANSYS Meshing software, and the mesh type is structured. The element number is 100000.

Boiling Methodology

It is assumed that the pipe wall has a constant heat flux boundary condition equal to 100,000,000 W/m2 and can transfer this heat to water flow through the pipe. The water flow reaches the temperature above saturation by receiving heat from the pipe body and is in a superheated state.

As a result, when the water temperature reaches saturation temperature, the water turns into water vapor. Therefore, in the present simulation, a multiphase model is used; its primary phase is liquid water, and its second phase is water vapor. To define the multiphase model, the Eulerian model is used.

This model is the most complex multiphase model and can solve a set of momentum and energy equations for each phase separately. Since this modeling is supposed to deal with the boiling process, the Eulerian multiphase model should be used, and the boiling model option should be activated.

Also, to define the phase conversion process from liquid to gas, a mass transfer with a saturation temperature of 383.15 K must be specified.

Boiling Conclusion

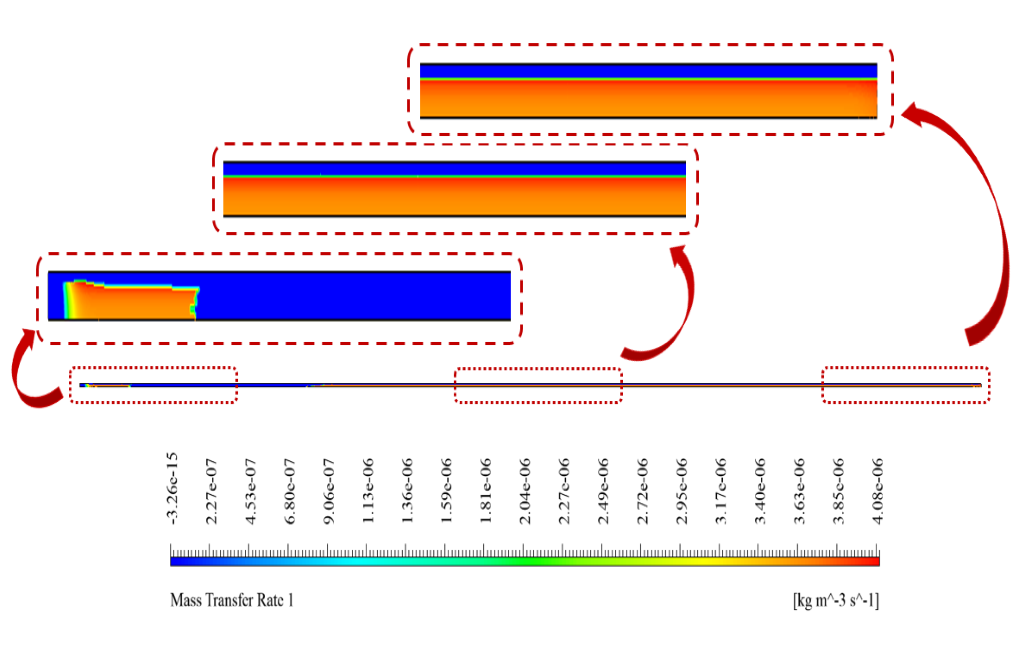

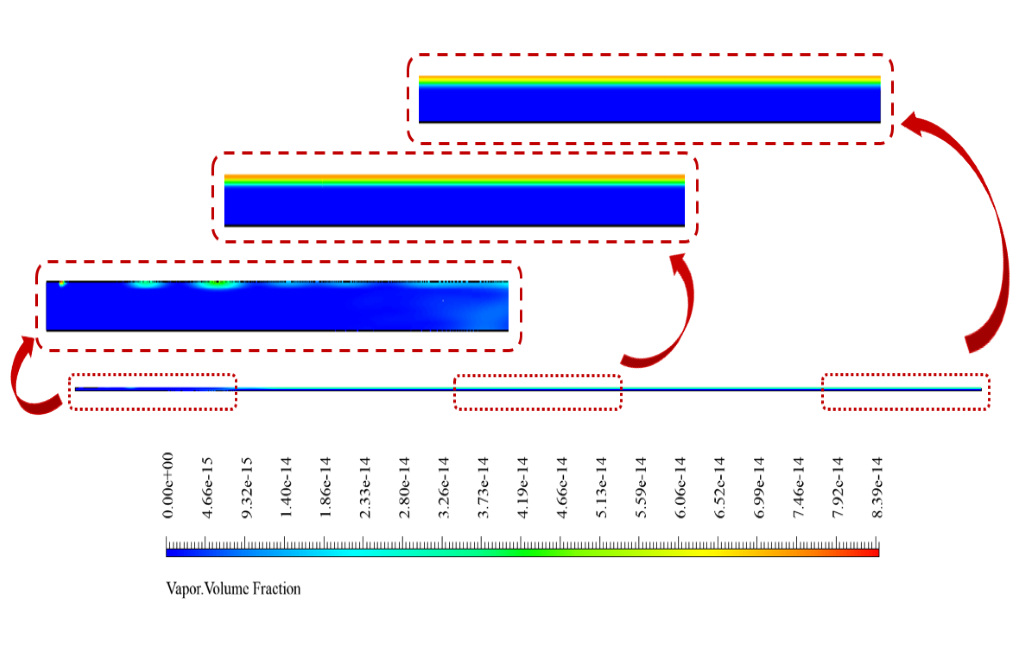

At the end of the solution process, two-dimensional parameters related to pressure, water vapor velocity, water vapor temperature, water vapor volume fraction, and mass transfer rate from water to vapor (boiling) are obtained.

As the pictures show, water flow under the heat caused by the heat flux applied to the pipe wall increases with temperature. After reaching the defined saturation temperature, it turns into steam, or the so-called boiling process occurs.

Anibal Fritsch III –

I was impressed with how the simulation captures the boiling process at the nano-scale. The level of detail in these results is fantastic!

MR CFD Support –

Thank you for your positive feedback! We are thrilled to hear that you were impressed with the nano-scale boiling process simulation. Our team works diligently to ensure our simulations offer detailed and accurate insights. If you have any further questions or need more information, please feel free to reach out.

Trudie Terry –

I was able to run the simulation, but I’m struggling with visualizing the vapor formation in the post-processing stage. Could you advise on the best way to clearly see the phase change in the nanotube?

MR CFD Support –

To visualize vapor formation and phase changes in the post-processing stage, you can utilize the volume fraction contours in ANSYS Fluent. First, ensure that you select the water vapor as the phase you want to visualize. Then, look at the volume fraction contour plots, as these will indicate where the water turns into vapor along the nanotube. Setting a proper scale for volume fraction values—from 0 for liquid water to 1 for steam—will help you discern the phase change more clearly. Additionally, you can use animations to see the boiling process over time, which can provide a better understanding of the vapor formation dynamics.

Mariana Gorczany DVM –

Phenomenal learning resource! The detailed breakdown of boiling inside a nanotube was enlightening. Through graphical demonstrations and simulations, mastering difficult concepts became much simpler. By providing step-by-step guidance, MR CFD’s training allowed me to grasp the complexities of the process and the software capabilities perfectly.

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that our training on boiling inside a nanotube has been so helpful for you. We strive to provide clear and detailed instructions to support thorough understanding and application. Your success in mastering the concepts validates our efforts. If you have more questions or need further assistance with CFD simulations, don’t hesitate to reach out!

Andres Schmeler –

Truly impressed with the level of detail in the modeling of the boiling process inside the nanotube. The feature to transfer heat from the pipe to the water efficiently leading to phase change at nano-scale is fascinating!

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear that you appreciated the intricacies of the boiling simulation model. If you’re curious to learn more about the nano-scale heat transfer and phase change processes, feel free to explore more of our simulations and training materials.

Sophia Reinger –

I truly appreciated the level of detail in the ‘Boiling inside a Nanotube CFD Simulation Training’. The application of a constant heat flux boundary condition to induce the boiling was fascinating. Great content for understanding complex phenomena in micro-scales!

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that you found our simulation training resource informative and helpful for understanding boiling at the nano-scale. Your appreciation motivates us to continue providing high-quality, detailed learning materials. If you have any more questions or need further assistance, feel free to reach out. Thank you for choosing our product!

Ms. Lulu Hegmann –

I’m incredibly impressed with how the simulation captures the details of the boiling process inside such a tiny nanotube using ANSYS Fluent. The accuracy and possibility to visualize the phase change at nano-scale is nothing short of astonishing. Great work!

MR CFD Support –

Thank you for your kind words! We’re glad to hear that you recognize the precision and value of our simulation training. Our team works diligently to provide detailed and accurate modeling that helps users understand complex processes, even at the nano-scale. We appreciate your positive feedback!

Stewart Wilkinson –

I thoroughly enjoyed the practical aspects of using CFD to simulate boiling inside a nanotube. Your training material made understanding the complex heat transfer and phase change phenomena quite accessible. Kudos on creating such insightful simulation training!

MR CFD Support –

Thank you so much for your positive feedback! We’re thrilled to hear that you found the training material helpful and that it enhanced your understanding of heat transfer and phase change phenomena in nanoscale simulations. Your appreciation means a lot to us, and we’re committed to continuing to provide high-quality training experiences. If you have any further questions or need assistance with future CFD simulations, please don’t hesitate to reach out. Thanks again for choosing our training!

Mr. Lorenza Hagenes III –

Are there any special considerations taken into account due to the small scale of the nanotube in this simulation?

MR CFD Support –

The small scale of the nanotube in the simulation indeed requires special considerations. Due to the nano-scale size of the pipe, the tendency of the fluid particles to adhere to the wall is quite high because of the high surface to volume ratio. As such, a precise definition of wall treatment and careful meshing to capture the near-wall phenomena accurately are essential. Furthermore, the simulation considers the effects of buoyancy less impactful due to the scale, focusing instead on surface forces such as surface tension and molecular forces.

Dr. Lamar D’Amore –

The product provided a comprehensive understanding of nanotube boiling simulation. The level of detail in the methodology section was exquisite, and it allowed me to grasp the intricacies involved in macroscale phenomena at the nanoscale. I was particularly impressed by the precision with which the boundary conditions and meshing were addressed, which underscores the quality it brings to educational CFD simulations. Excellent work!

MR CFD Support –

Thank you for taking the time to leave such a positive review! We are delighted that you are impressed with the intricacy and precision of our nanotube boiling simulation training. It is wonderful to hear that the detailed methodology has enhanced your understanding of nano-scale CFD principles. We aspire to maintain a high standard of educational material, and your feedback is very encouraging for our team. Thanks again!

Amira Flatley –

I’m very impressed with the level of detail in the data analysis of this boiling simulation inside a nanotube. Would you be able to highlight how the multiphase interactions were visualized in the results, particularly how the transition from liquid to steam was showcased?

MR CFD Support –

We are glad you appreciated the analysis. In the results, the transition from liquid water to steam during the boiling process was visualized using two-dimensional contours. These included the water vapor volume fraction contours, which showed the phase distribution within the nanotube, with clear demarcation between liquid and vapor regions. Additionally, mass transfer rate contours indicated the areas where boiling was most intense. Velocity and temperature profiles further illustrated the changes in the flow dynamics and thermal conditions throughout the simulation.

Dr. Arlo Swift II –

The seamless integration of different techniques in the simulation resulted in a cohesive learning experience. The ability to visualize and analyze the complex boiling process in micro-scale structures was particularly impressive.

MR CFD Support –

Thank you for taking the time to review our Nanotube Boiling CFD Simulation Training. We’re thrilled to hear that you found the visualization and analysis components effective for understanding such a complex process. Your satisfaction with the learning experience is our top priority!

Dr. Shannon Rutherford –

Absolutely essential for those wanting to understand nanoscale boiling phenomena! The details in methodology are incredible.

MR CFD Support –

Thank you for your positive review! We’re thrilled to hear that you found the training materials on nanoscale boiling simulation informative and helpful. Your appreciation motivates us to continue providing detailed and thorough CFD learning resources.

Walton Cole –

In this training session, does the simulation account for critical heat flux (CHF) and where might it become significant in the nanotube boiling process?

MR CFD Support –

During this training, critical heat flux isn’t specifically addressed in the given description. CHF refers to the point where a boiling surface transitions to film boiling, resulting in a rapid increase in surface temperature. If included in the simulation, it would likely become significant where the heat flux is strongest and where the water’s phase change occurs.

Jamaal Schmidt –

The explanation of the boiling process in the nanotube was fascinating. The visual representations provided along with the training material made it much easier to understand the crucial stages of the boiling simulation.

MR CFD Support –

Thank you for the kind words! We’re thrilled to hear that our visual aids have made the training material easy to understand and that the simulation of boiling inside a nanotube has captured your interest. If you have any more feedback or require further assistance, let us know. We’re here to help!

Dr. Lea Williamson –

You’ve visualized the boiling process inside the nanotube so well. Very informative and precise explanation of the methodology!

MR CFD Support –

Thank you for your positive feedback! We’re glad you found the explanation of our Boiling inside a Nanotube CFD Simulation informative. If you have any more questions or need further training on any aspect of the process, don’t hesitate to reach out to us.

Jany Schimmel –

I just completed the ‘Boiling inside a Nanotube CFD Simulation Training’ and I’m absolutely impressed with how well the course material was presented. It’s incredible to see ANSYS Fluent handling such a complex simulation with precision. The relation between heat flux, water temperature, and the phase transition from liquid to vapor was depicted clearly. I’m particularly appreciative of the structured explanations around the Eulerian multiphase model and the detailed illustration of mass transfer during the boiling process. Great job on putting together such an informative training module!

MR CFD Support –

Thank you so much for your encouraging feedback! We’re thrilled to hear that our training on ‘Boiling inside a Nanotube CFD Simulation’ met your expectations and provided you with clear and detailed understanding of the simulation in ANSYS Fluent. It’s fantastic to know that the complexities of the multiphase model and the phase transition mechanism were well-received. If you have any further questions or need more insight into the CFD simulations, please don’t hesitate to reach out! We’re here to help you with your continuous learning journey.

Prof. Reese Durgan DDS –

The explanation on how the wall’s heat flux affects the water temperature was very comprehensive. I now have a vivid understanding of the boiling process within a nanotube!

MR CFD Support –

Thank you for your kind words! We’re delighted to hear that the simulation has enhanced your understanding of the boiling process in nanoscale systems. We always strive to provide clear explanations and visualizations to facilitate learning.

Arlie Altenwerth Sr. –

Can you explain how heat flux influences the boiling process in this simulation, especially given such a high value of heat flux?

MR CFD Support –

In this simulation, the high heat flux applied to the wall of the nanotube directly affects the rate at which the water absorbs heat. It is this absorption that raises the water temperature, allowing it to reach the saturation point where boiling occurs. The applied heat then sustains and progresses the phase change from liquid to vapor inside the nanotube.

Mrs. Opal Kulas II –

I’m impressed with how detailed the results of the simulation are. Reading about the boiling process at such a granular level inside a nanotube is fascinating!

MR CFD Support –

Thank you so much for your kind review! We are delighted to hear that you found the simulation details fascinating and valuable for understanding the boiling process inside a nanotube. We strive to provide thorough simulations to help our users comprehend complex phenomena better. If you have any further questions or need clarification on any aspect, please don’t hesitate to reach out!

Sally West –

I’m highly impressed with the intricate heat flux settings that the simulation uses to trigger the boiling process. The precision in configuring the heat transfer to reach the dynamics of boiling inside such a tiny space is commendable.

MR CFD Support –

Thank you for your appreciation! We are glad to know that the details of the simulation, especially the heat flux settings and their impact on the boiling process, impressed you. We strive to offer our customers high-quality simulations with accurate and intricate details. Your feedback is encouraging for our team!

Lonzo Hegmann V –

I’ve concluded the training with strong foundational knowledge. Especially intrigued by the precision needed in simulation scaling – a leap from mere theory to practical application. The methodology was superbly explained. Kudos to MR CFD for great content!

MR CFD Support –

Thank you for your kind words and positive feedback on our training module! We’re delighted to hear that you found the transition from theory to practice enlightening and that the methodology was clear and comprehensive. It’s our pleasure to provide valuable content, and we appreciate your recognition. If you have any further questions or require additional support in your future simulations, don’t hesitate to reach out. Happy simulating!

Raphael Effertz DDS –

I’ve just completed the ‘Boiling inside a Nanotube CFD Simulation Training’, and the detail and precision in this training package amazed me. The way it explains the complex phase-change phenomena at such a microscopic level was both insightful and accessible. Using ANSYS Fluent to model such intricate processes reaffirmed my confidence in computational methods for nano-scale applications. Superb work!

MR CFD Support –

Thank you for your feedback! We’re thrilled to hear that our ‘Boiling inside a Nanotube CFD Simulation Training’ met your expectations and provided valuable insights into nano-scale phenomena using ANSYS Fluent. We’re committed to offering high-quality training that empowers our users, and your success is the best measure of our work. If you have any further questions or need assistance with your future CFD projects, don’t hesitate to reach out.

Reyna Upton –

The simulation explanation is very in-depth and covers things in great detail. It’s fascinating to see how advanced CFD applications like boiling inside a nanotube are being simulated. The results must be quite intriguing. Can you expand on how the phase transition is monitored within the software?

MR CFD Support –

In the software, the phase transition from liquid to vapor is monitored by defining a mass transfer mechanism based on the specified saturation temperature. This is done consistently with the Eulerian multiphase model, which can simulate separate momentum and energy equations for each phase. When liquid water, represented as the primary phase, reaches the saturation temperature (in this case, 383.15 K), the defined mass transfer kicks in to simulate boiling, indicating the formation of water vapor, the secondary phase.

Kiera Bailey –

The nanotube simulation was quite insightful! It gave me a deep understanding of heat transfer and phase changes at the nano-scale.

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that our simulation on boiling inside a nanotube provided you with valuable insights into nano-scale heat transfer and phase changes. It’s great to know our training material was informative and helpful to your understanding.

Prof. Kayleigh Toy –

I appreciated the detailed outcomes and methodologies explained in the ‘Boiling inside a Nanotube’ CFD Simulation Training. I was particularly impressed by the precision of the nano-scale modeling and the structured mesh that made such an intricate study possible.

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear our efforts in creating a meticulous simulation to model the boiling process inside a nanotube met your expectations. Precision in nano-scale modeling is critical, and your acknowledgment is greatly appreciated. If you ever have any questions or need further insight into our simulations, please feel free to reach out.