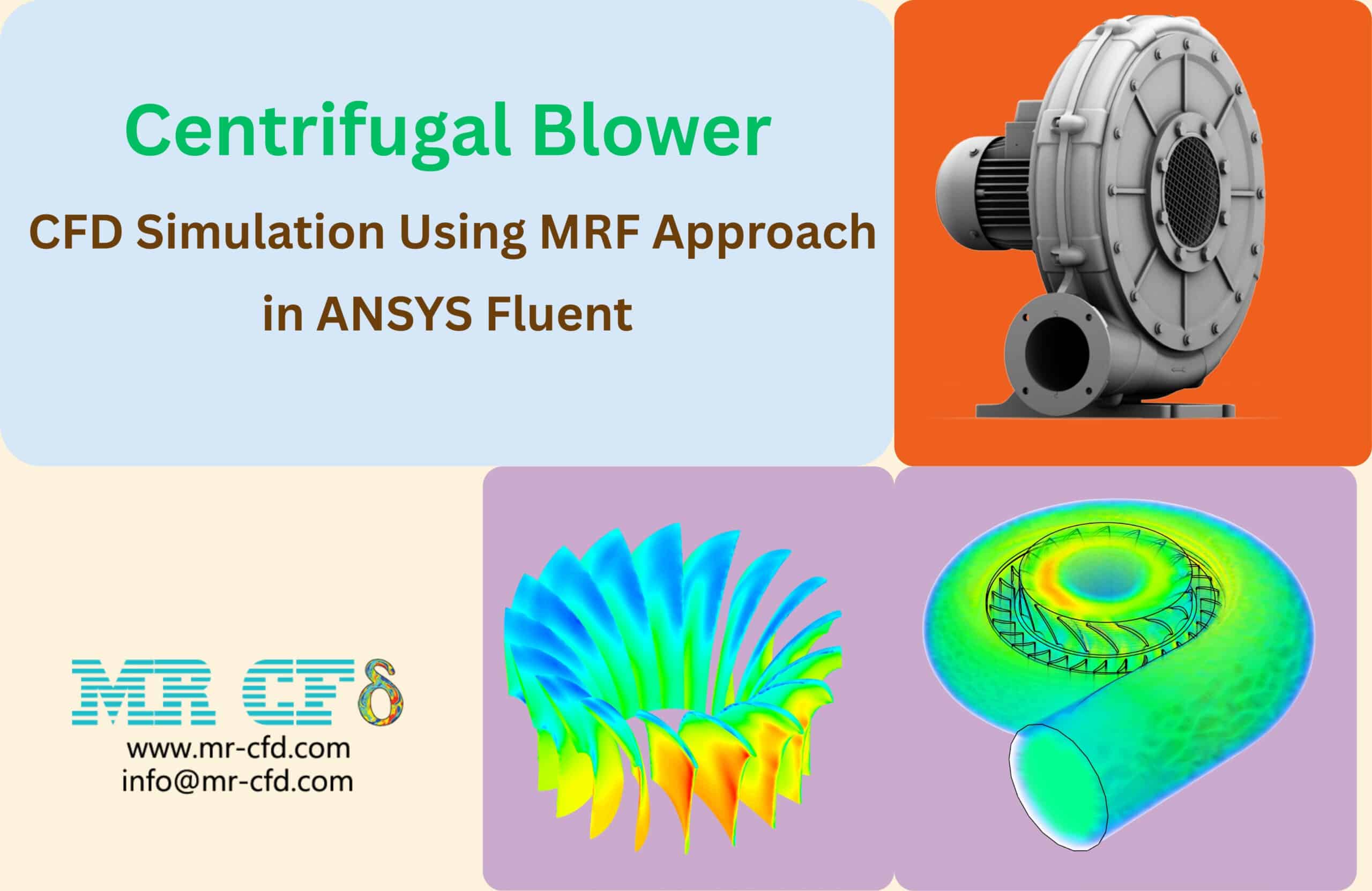

Centrifugal Pump CFD Simulation Using MRF Approach in ANSYS Fluent

$100.00 $40.00 HPC

- This project presents a CFD analysis of a centrifugal pump using ANSYS Fluent.

- The 3D geometry was modeled in SpaceClaim and meshed with about 2 million tetrahedral elements.

- The simulation used a steady pressure-based solver with the k-ω SST turbulence model and MRF for rotation at 1500 RPM.

- Results show a clear velocity increase up to ~300 m/s and a significant pressure rise across the impeller and volute.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Centrifugal Pump CFD Simulation Using Multiple Reference Frame (MRF) Approach in ANSYS Fluent

Description

A centrifugal pump was modeled and analyzed using ANSYS Fluent to study its aerodynamic performance. The impeller and volute geometry were created in SpaceClaim/DesignModeler and simulated under steady-state conditions at 1500 RPM with an inlet velocity of 140 m/s. The aim was to evaluate velocity distribution and pressure rise across the pump.

Geometry and Mesh

The 3D centrifugal pump, including impeller blades and volute casing, was meshed with about 2 million tetrahedral cells in ANSYS Meshing. A refined mesh was applied around blade passages and the volute to capture turbulence and pressure gradients accurately.

Models and Solver Settings

The simulation used a pressure-based steady solver with the k-ω SST turbulence model, well-suited for rotating machinery. The impeller motion was modeled using the MRF approach. Boundary conditions included a velocity inlet (140 m/s) and a pressure outlet, while the Coupled algorithm ensured stable pressure–velocity convergence.

Results

The pump showed strong acceleration of air through the impeller, with outlet velocities reaching about 300 m/s. Pressure contours highlighted a clear rise from inlet to outlet, with high pressure on the blade pressure side and low pressure on the suction side. The flow pattern inside the volute confirmed efficient energy transfer from impeller rotation to the fluid, validating the chosen design and CFD setup.

You must be logged in to post a review.

Reviews

There are no reviews yet.