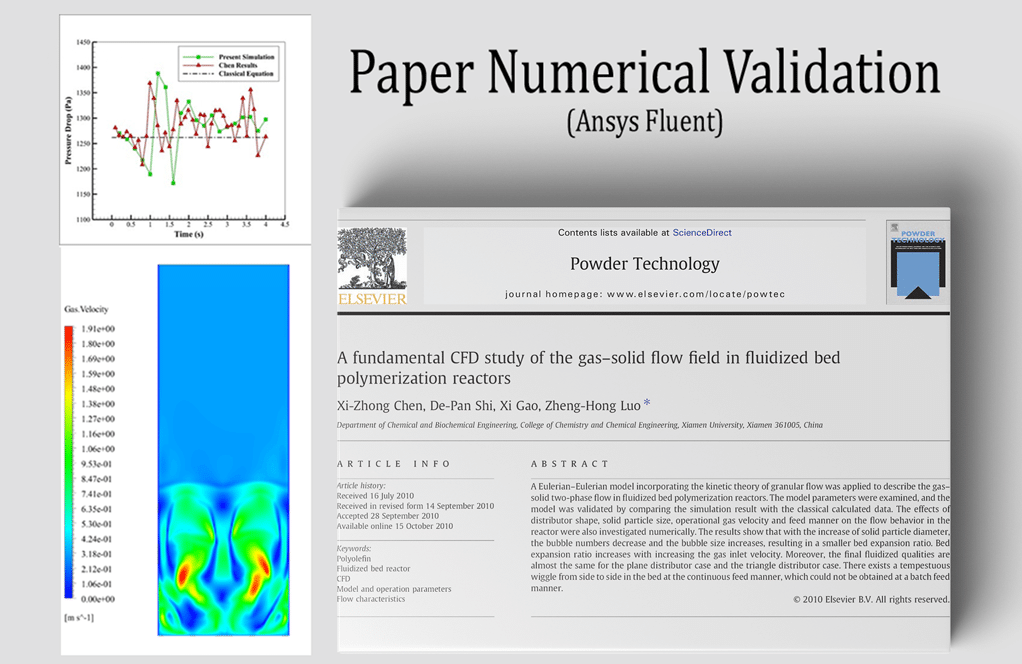

Co-firing Biomass with Coal Gasification, Paper Validation

$390.00 $156.00 HPC

- Co-firing Biomass with Coal Gasification.

- This project involves the simulation of coal and biomass co-firing in a furnace using CFD techniques.

- The primary objectives are to examine the combustion characteristics and validate the simulation results against the study by Ghenai and Janajreh.

- The furnace is defined with specific boundary conditions, and simulations are performed using an unsteady, incompressible flow model.

- The turbulent flow within the furnace is modeled using the k-e RNG turbulent model, thermal radiation is simulated with the P1 model, and combustion is analyzed with a PDF model.

- The simulation incorporates the kinetics/diffusion-limited rate model for particle combustion and the two competing rates Kobayashi model for devolatilization.

- Results are compared in terms of temperature contours and particle trajectories, confirming the simulation’s accuracy with a maximum error of approximately 5% in particle temperature ranges.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Simulation of co-firing coal/biomass (High Sulfur Bituminous Coal with Wheat Straw Biomass)-paper validation

Abstract

In co-firing projects, coal gasification with biomass in a gasifier was simulated using Fluent software, and the results were validated with the existing paper. The probability density function (PDF) model has been used to simulate the combustion phenomenon in the furnace. The DPM model has also been used to inject Canadian high-sulfur bituminous coal into the computational domain. Factors such as thermophoretic force, Saffman’s lift force, particle radiation interaction, and stochastic collision have been considered to simulate particle motion and their effect on the flow regime and heat transfer as accurately as possible. On the other hand, the devolatilization phenomenon for coal particles has also been simulated using the two computing rate model. By examining and comparing the contours obtained in this simulation and the existing study, it has been determined that there is a good agreement between them. This is while some values and constants of the equations are presented in a few scientific sources, which can be obtained in this project.

Project definition

In co-firing projects, coal combustion in a furnace was simulated, and the results were validated with the existing paper [1]. In the paper by Ghenai and Janajreh [1], in addition to using Canadian high-sulfur bituminous coal, biomass with percentages of 10 and 20% was burned in the furnace. Here, we only used the combustion of Canadian high-sulfur bituminous coal in the simulation. Therefore, it is easy to simulate other materials with the method presented in this project for these systems.

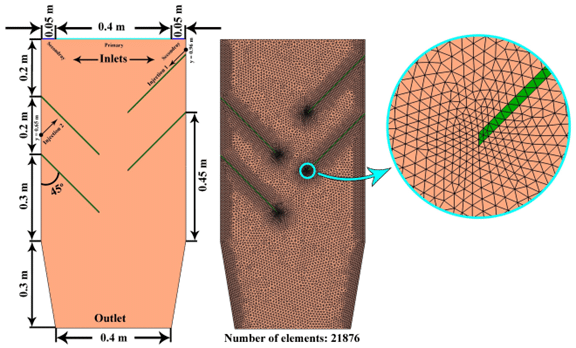

The geometry and mesh of the Co-firing Biomass are shown in Figure 1. The boundary conditions are such that the primary inlet air flow enters the furnace at a velocity of 20 m/s and a temperature of 1500 K, and the secondary inlet air flows at a velocity of 150 m/s and a temperature of 1500 K. The side walls of the furnace are also at a constant temperature of 1200 K. Coal/biomass particles are also injected into the furnace from injections 1 and 2 in a group. These particles are also injected at a constant temperature of 300 K and specific velocities.

Figure 1: The furnace geometry and mesh

The simulation is considered unsteady, and the fluid flow is incompressible. The k-e RNG model was used to simulate the turbulent flow inside the furnace. The P1 model is used to simulate thermal radiation, and the PDF model has also been used to simulate the combustion of emitted gases inside the furnace. The char reaction was also performed using a kinetics/diffusion-limited rate model. For particles devolatilization, the two competing rates Kobayashi model are used. The coal calculator module is defined for the software with the specifications of the proximate and ultimate analysis given in Table 1.

|

Table 1: Fuel composition analysis |

|||

|

Proximate analysis |

Ultimate analysis | ||

|

Volatile matter |

0.293 | C | 0.872121 |

|

Char |

0.56 | H |

0.053983 |

| Moisture | 0.09 | O |

0.034789 |

| Ash | 0.057 | N |

0.016795 |

| Heating value | 29.2 MJ/Kg | S |

0.022313 |

Results

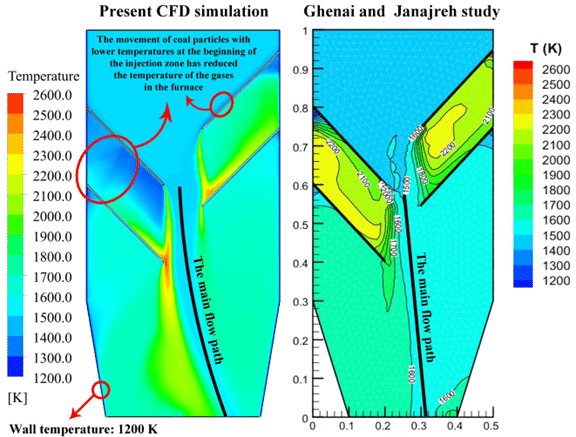

Figure 2 shows the simulated temperature contour in the Ghenai and Janajreh study and the present simulation. As can be seen, the temperature range of both contours coincides with each other. However, there are some differences between the two simulations. Due to the boundary conditions, the temperature of the side walls of the furnace should be fixed at 1200 K. This is visible in the simulation contour of this project. On the other hand, since the coal particles are injected into the furnace at a constant temperature of 300 K, the particle track is clearly visible in the simulation contour performed by the Mr-CFD group. This is while this sign is not visible in the contour presented by Ghenai and Janajreh. However, considering the temperature range as well as visual impressions of the contours, it can be concluded that the average temperature of both simulations was close to each other, and as a result, the validation was performed acceptably for this parameter.

Figure 2: Comparison of temperature contours in the present simulation and the Ghenai and Janajreh study

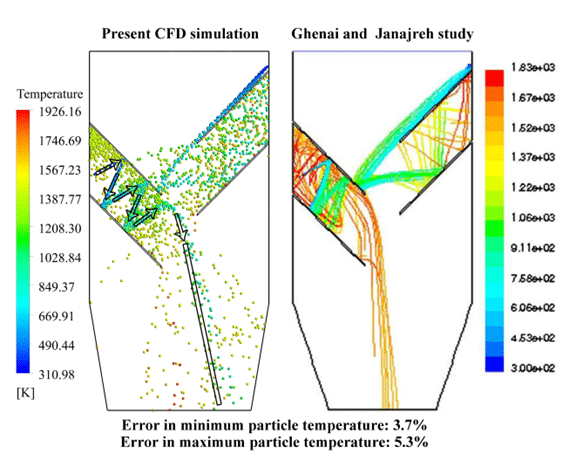

Figure 3 also confirms an acceptable validation in the present simulation. As can be seen, the particle trajectory in the present simulation is obtained very close to the study of Ghenai and Janajreh. On the other hand, the particle temperature range has also been obtained with a maximum error of close to 5%. While the furnace gas temperature has been obtained between 1200 and 2600 K., this confirms the accuracy of the simulation of the present project and, of course, the study of Ghenai and Janajreh.

Figure 3: Comparison of temperature contours in the present simulation and the Ghenai and Janajreh study

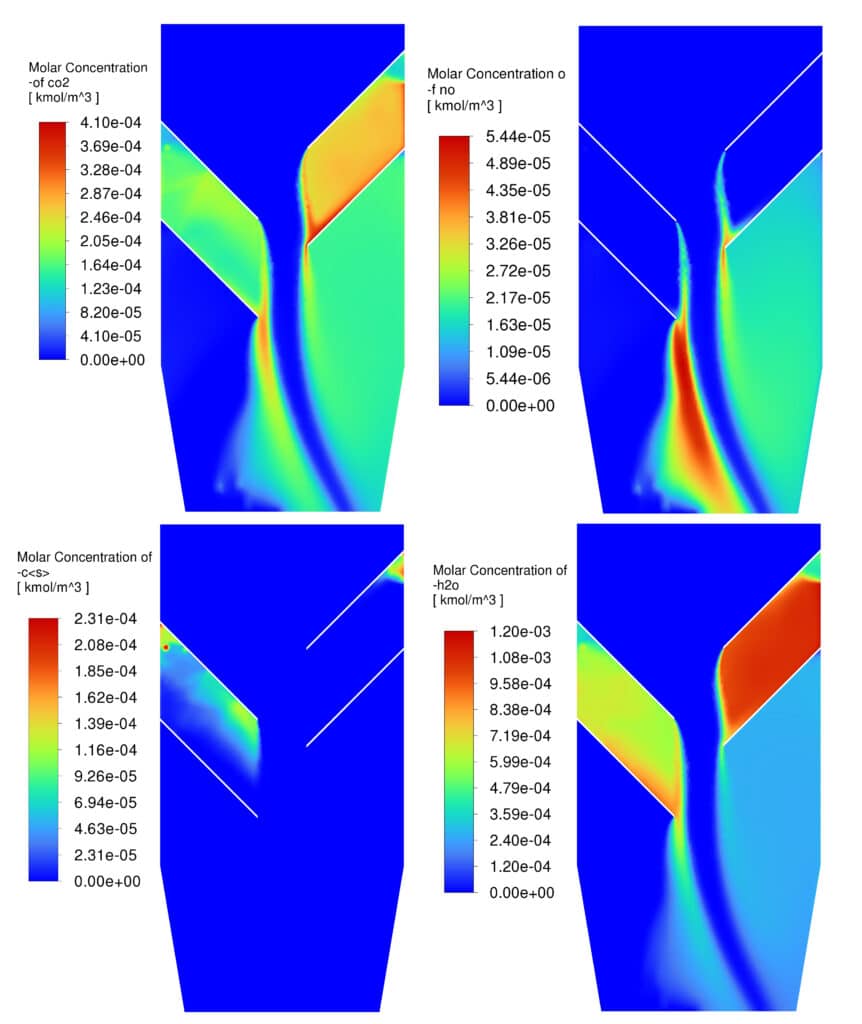

Below are some of the contours obtained in the simulation of Co-firing Biomass. In Figure 4, contours of various species, especially CO2, known as pollution, are presented.

Figure 4: The contours of various species

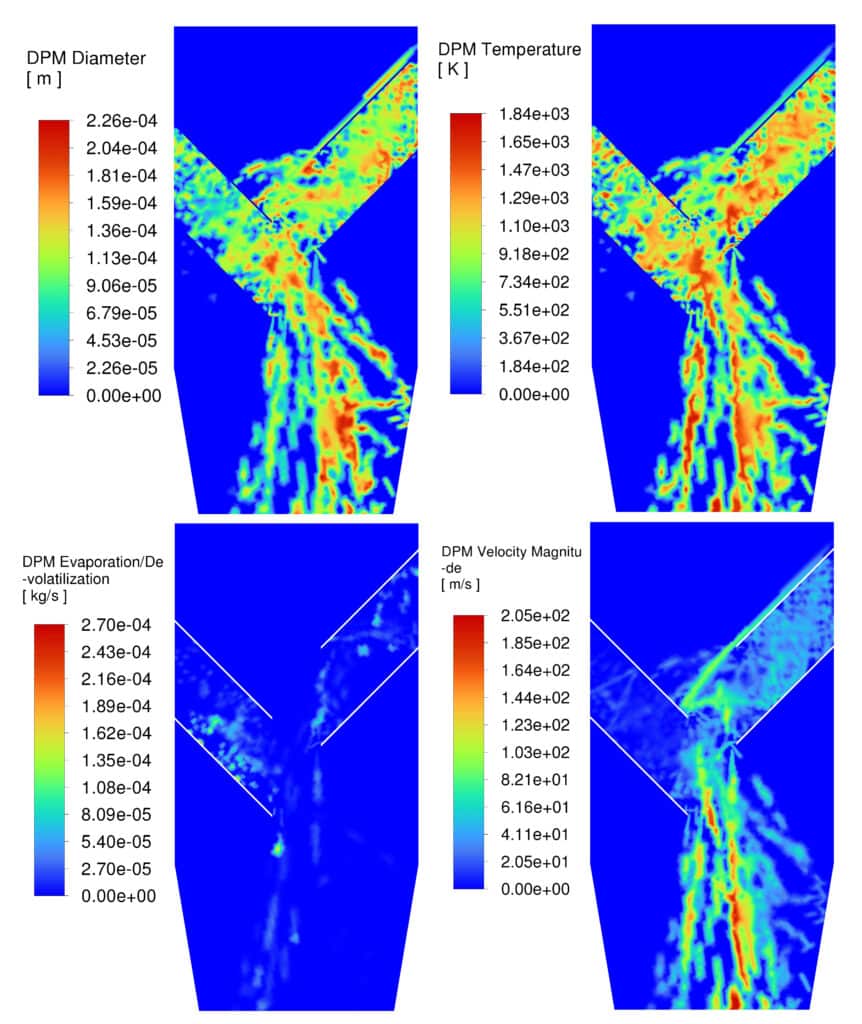

Figure 5: The contours of particle parameters

Conclusion

In co-firing projects, a coal/biomass combustion simulation was performed in a furnace, and the results obtained were validated with the existing paper. The results of gas temperatures and, of course, particle temperatures showed that the difference between this project and the Ghenai and Janajreh study is negligible. However, there are some differences between the contours. These differences could be due to the lack of sufficient information in the Ghenai and Janajreh study. For example, in the Ghenai and Janajreh study, it is said that a two-computing rate model was used for devolatilization. However, the values of the Arrhenius coefficients of this model were not provided by them. In the simulation of such systems, the choice of model for devolatilization is of great importance. For an accurate simulation, in addition to choosing the correct model for this parameter, the model coefficients are also very important. On the other hand, in the paper, Kinetics/diffusion limited was used for the particle combustion model, and the values of the coefficients of this model were not given. However, the difference between the results is acceptable, and the simulation performed in this project is highly accurate. Finally, by overlapping this project and various studies in this field, a quality education on the simulation of these types of systems can be obtained.

Reference

[1] Ghenai, Chaouki, and Isam Janajreh. “CFD analysis of the effects of co-firing biomass with coal.” Energy conversion and management 51, no. 8 (2010): 1694-1701.You must be logged in to post a review.

Reviews

There are no reviews yet.