Color Spraying on the Wall with Conical Injection

$80.00 Student Discount

In this project, color spraying on the wall has been simulated and the results of this simulation have been investigated.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Color Spraying on the Wall with Conical Injection, CFD Simulation Ansys Fluent Training

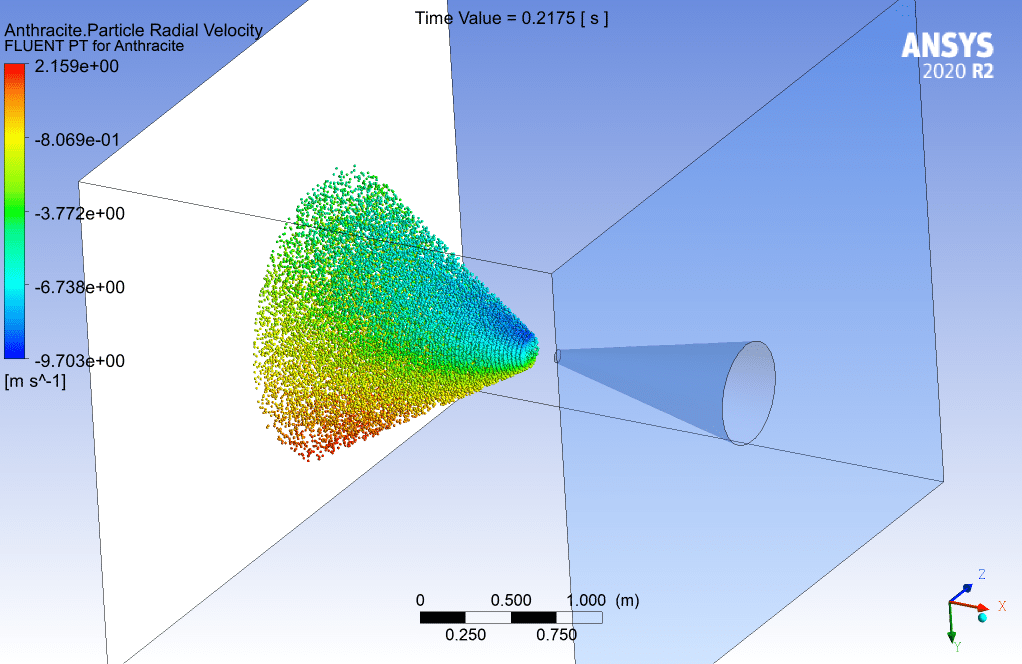

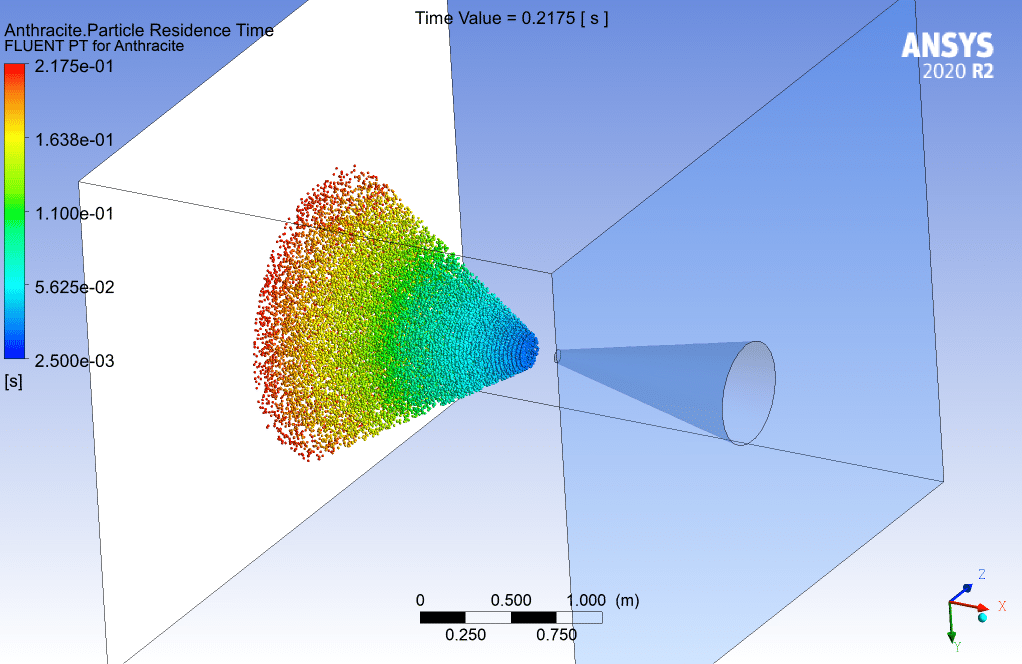

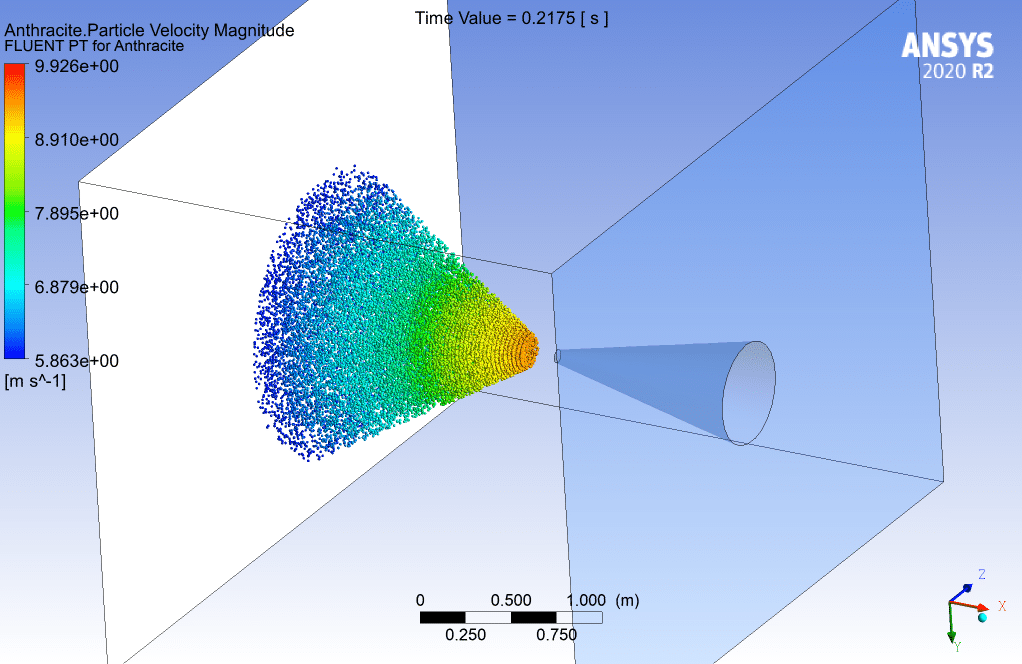

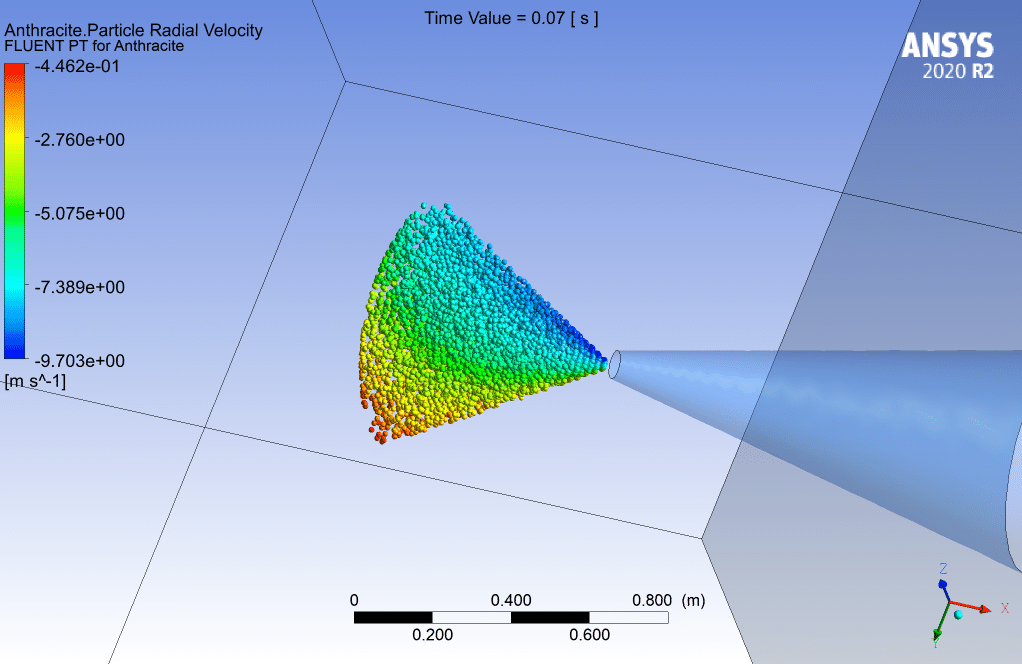

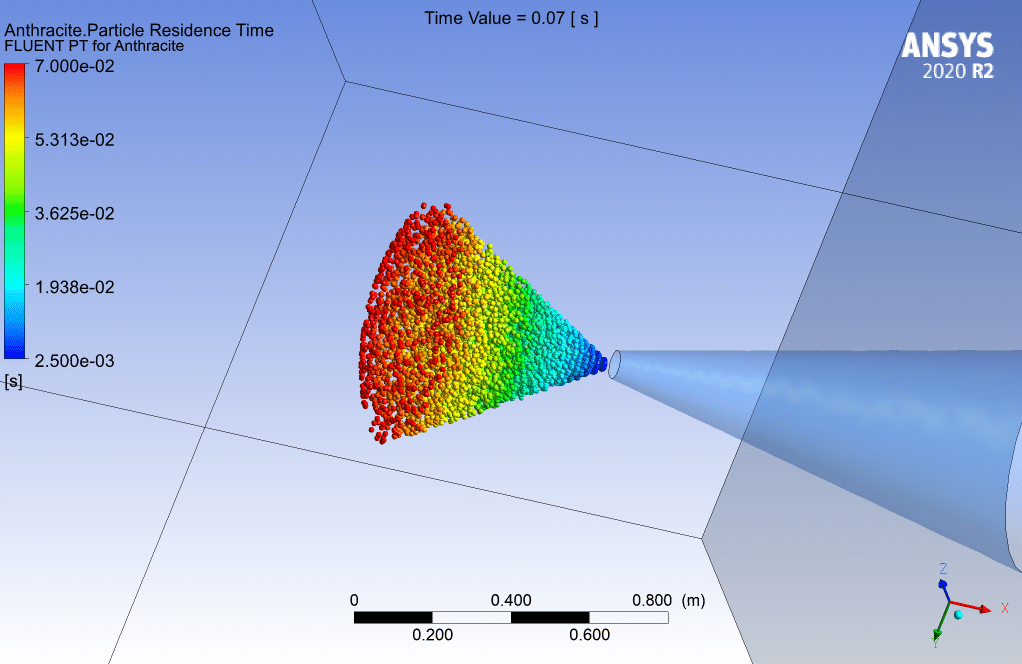

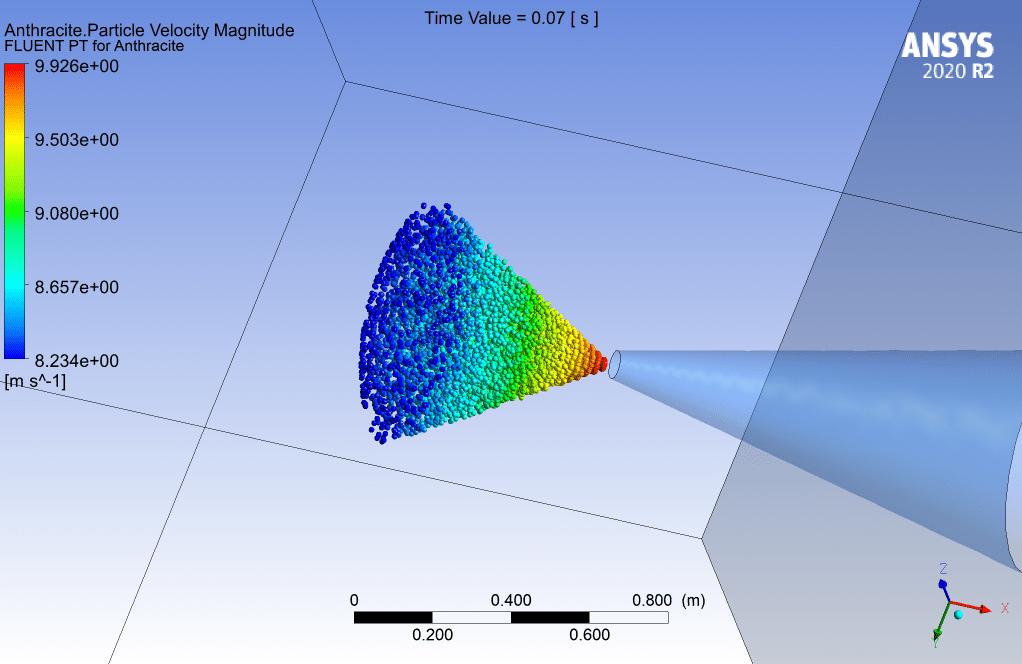

In this project, Color Spraying on the Wall with Conical Injection has been simulated by Ansys Fluent software. We used the one-way DPM to simulate the discrete phase. The injection type is a cone and the velocity of the particles is equal to 10 with a cone angle of 30 degrees.

Geometry & Mesh

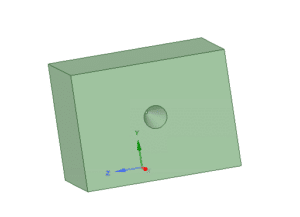

The 3D geometry of this project has been produced with SpaceClaim software. The length and width of the computational area are 3 m, and its height is 4 m.

Mesh is created with Ansys Meshing software and the mesh type is unstructured. The number of cells is 254934.

To simulate the present model, we consider several assumptions:

- The solver is pressure-based.

- The current simulation is unsteady in terms of time.

- We ignored the gravity effect.

Here is a summary of the steps for defining the problem and its solution in the following table:

| Models | |||

| Viscous model | laminar | ||

| Discrete phase | on | ||

| particle treatment | unsteady particle tracking | ||

| material in injection | Color Spray | ||

| particle type in injection | inert | ||

| injection type | cone | ||

| Boundary conditions | |||

| Wall & wall back | |||

| wall motion | stationary wall | ||

| discrete phase BC type | escape | ||

| top wall | |||

| wall motion | stationary wall | ||

| discrete phase BC type | trap | ||

| Solution Methods | |||

| Pressure-velocity coupling | simple | ||

| Spatial discretization | pressure | second-order | |

| momentum | second-order upwind | ||

| Modified turbulent viscosity | first-order upwind | ||

| Initialization | |||

| Initialization method | standard | ||

Color Spraying Results

In this simulation, the spray paint on the wall is simulated using an injector to insert the particles in a conical injection manner. According to the conical angle, the range of motion of the particles is determined.

Prof. Afton Bahringer III –

I recently went through the ‘Color Spraying on the Wall with Conical Injection’ CFD course and wow, the visuals were impressive! I never really understood particle tracking in ANSYS before this. It was awesome to actually see the spray’s cone shape and how changing the angle modified coverage. Keep these great trainings coming!

MR CFD Support –

Thank you so much for the positive feedback! We’re thrilled to hear that you found the course visuals impressive and that it significantly enhanced your understanding of particle tracking in ANSYS. It’s fantastic to know the practical demonstrations were helpful. Looking forward to providing you with more enriching learning experiences!

Dr. Jaqueline Bartell MD –

Can you explain why gravity was ignored in this simulation of color spraying?

MR CFD Support –

In this particular simulation, gravity was ignored to simplify the analysis of the spray dynamics. This can be due to the assumption that the influence of gravity on the small paint particles over the short spraying distance is negligible compared to the forces exerted by the high-velocity injection.

Cleo Hermiston –

Thanks to this training, I’m now quite familiar with spraying simulations. Just wonder if gravity was ignored, do particles’ weight still affect the simulation?

MR CFD Support –

That’s a great point you’ve raised! We chose to ignore the effects of gravity in this simulation to focus on understanding the particle behaviors in terms of their interaction with the spray dynamics. The particle weight due to gravity is not considered in this analysis, which is often reasonable when studying the immediate impact of the spray force or when gravity’s influence is minimal relative to other forces in the system. However, typically, the particles’ weight or inertia would indeed influence their trajectory in a real-world scenario.

Brent Robel –

I am really thrilled with how detailed the CFD analysis of color spraying with conical injection was! But I was wondering, could the effect of gravity be significant in a real-life application scenario?

MR CFD Support –

Thank you for your review and insightful question! The effect of gravity can indeed be significant in real-life applications of color spraying, as it can affect the trajectory and the deposition pattern of the particles on the wall. However, for the purpose of this CFD simulation, the gravity effect has been ignored to simplify the computation and focus on the basic behavior of the particle spray pattern without gravity. Ignoring gravity is a common practice in simulations seeking to isolate specific phenomena, but for a comprehensive analysis that reflects real-world behavior, including gravity in the simulation can provide a more accurate result.

Emmy Conn –

I’m pleased with how comprehensive the simulation appears, but could you please clarify how the color viscosity affects the simulation results in this specific setup?

MR CFD Support –

In this type of simulation, viscosity is a crucial factor affecting how the color particles interact with the air and the wall. Specifically, a higher color viscosity may result in less splatter and a more uniform layer on the wall as the particles will have a higher resistance against the airflow. Conversely, lower viscosity could lead to more splattering and irregular deposition. Our simulation setup would consider the viscosity of the color spray to accurately reflect the spray painting dynamics, but detailed results on viscosity effects would require a deeper look into the simulation data.

Prof. Daron Lind IV –

The visuals are really immersive and the process is incredibly detailed. I’m impressed with how well the simulation captured the conical paint distribution pattern.

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear that our simulation met your expectations and provided you with a detailed and clear visualization. We strive to deliver high-quality simulations that capture real-world phenomena accurately. Your feedback is greatly appreciated!