Color Spraying with Wall Film CFD Simulation

$140.00 Student Discount

In this project, color spraying on the wall with wall film has been simulated, and the results of this simulation have been investigated.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Color Spraying with Wall Film, CFD Simulation by Ansys Fluent Training

In this project, the spraying color on the wall has been simulated with Ansys Fluent software. We used one-way DPM to simulate the discrete phase. The cone injection and particle velocity are equal to the first simulation 10 with a particle diameter of 0.001 m and a spray angle of 45 °. This project aims to determine whether velocity and particle diameter affect the staining. The velocity is 20 meters per second for the second simulation, and the particle diameter is 0.1m. Also, the cone angle is 45 degrees. The DPM Boundary condition Type is wall film so that the color particles stick to the wall. The present simulation process is performed unsteady and in a time step equal to 0.0025 s.

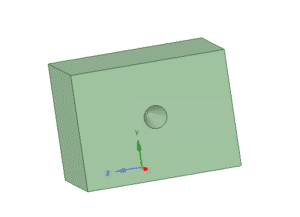

Geometry & Mesh

The 3D geometry of this project has been produced with SpaceClaim software. The length and width of the computational area are 3 m, and its height is 4 m.

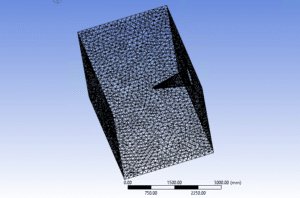

Mesh is created with Ansys Meshing software, and the mesh type is unstructured. The number of cells is 254934.

Color Spraying CFD Simulation

To simulate the color spraying on the wall with wall film, we consider several assumptions:

- The solver is pressure-based.

- The current simulation is unsteady in terms of time.

- We ignored the gravity effect.

Here is a summary of the steps for defining the problem and its solution in the following table:

| Models | ||

| Viscous model | laminar | |

| Discrete phase | on | |

| particle treatment | unsteady particle tracking | |

| material in injection | Color Spray | |

| particle type in injection | inert | |

| injection type | cone | |

| Number of streams | 400 | |

| Point properties | ||

| Cone-Type | Point-cone | |

| Start time | 0s | |

| Stop time | 0.2s | |

| Diameter | RUN1:0.001m

RUN2:0.1m RUN3:0.1m |

|

| Velocity magnitude | RUN1:10m/s

RUN2:20m/s RUN3:20m/s |

|

| Cone angle | RUN1:45deg

RUN2:45deg RUN3:30deg |

|

| Total flow rate | 1-e20 | |

| Boundary conditions | ||

| Wall & wall back | wall | |

| wall motion | stationary wall | |

| discrete phase BC type | scape | |

| top wall | Wall | |

| wall motion | stationary wall | |

| discrete phase BC type | Wall film | |

| Solution Methods | ||

| Pressure-velocity coupling | simple | |

| Spatial discretization | pressure | second-order |

| momentum | second-order upwind | |

| Modified turbulent viscosity | first-order upwind | |

| Initialization | ||

| Initialization method | standard | |

Color Spraying Results

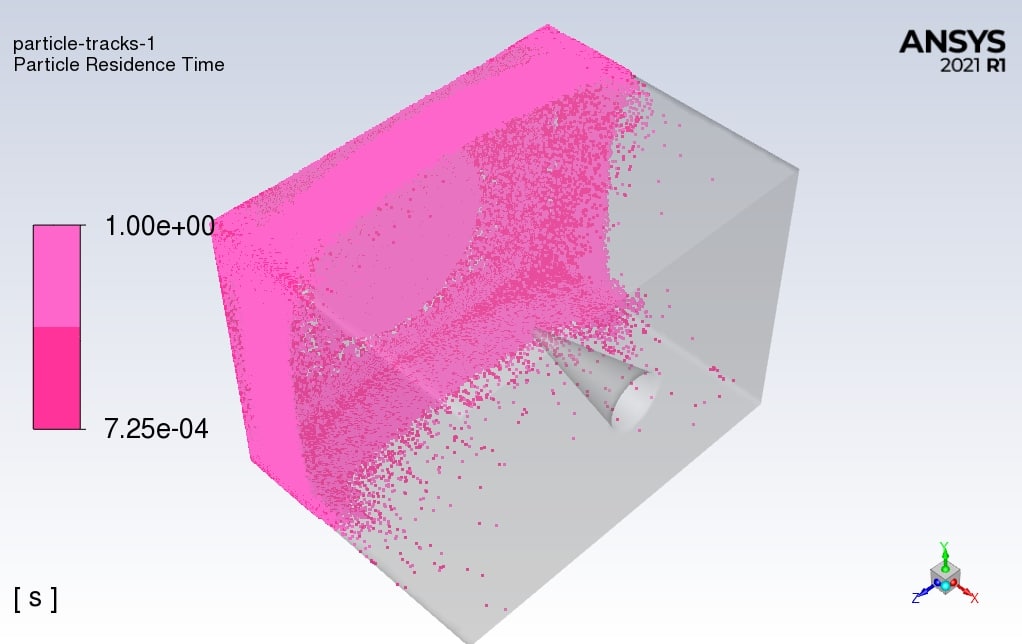

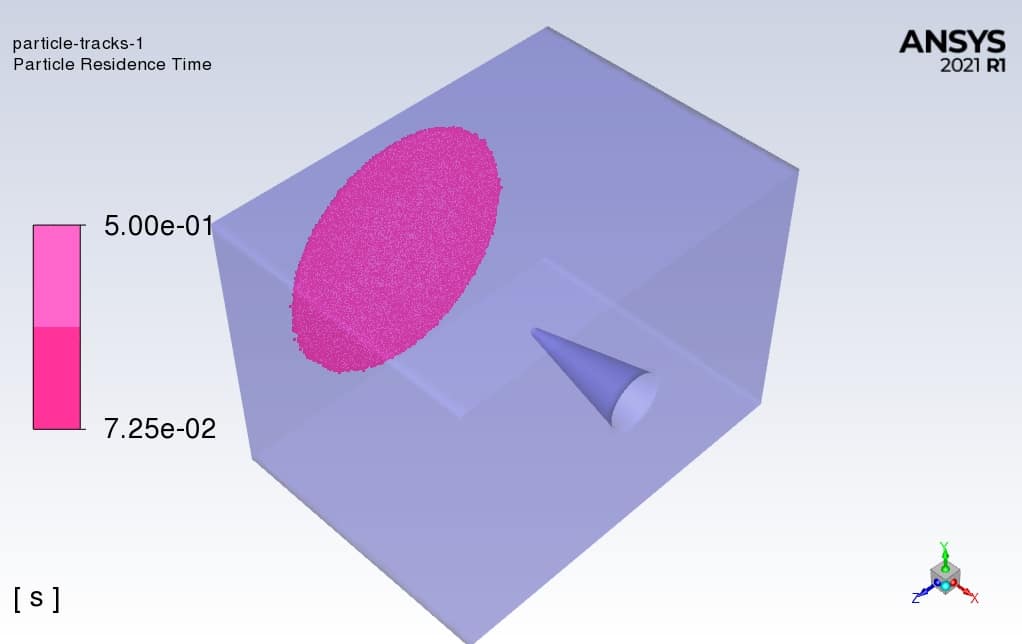

In this simulation, the spray paint on the wall is simulated using an injector to insert the particles conically. According to the conical angle, the range of motion of the particles is determined.

As mentioned earlier, this project aims to determine whether increasing the velocity and diameter of color particles affects staining. At first, a simulation with a smaller diameter and velocity was performed, which had a good result. Then, in the next simulation, the velocity and diameter of the colored particles increased, so it was observed that the particles spread on the wall. In the next simulation, we reduced the spray angle so that the spraying might be done correctly, which did not happen, and the best way to paint was the first simulation.

William Cummerata –

The review captures nicely how the project aims to investigate the effect of particle velocity and diameter on painting quality. Good work on the simulations too.

MR CFD Support –

Thank you for your positive feedback! We are delighted to hear that the simulations met your expectations and provided valuable insights. If you have further inquiries or need assistance with your projects, feel free to reach out.

Carroll Rohan –

Is there a particular reason why an unstructured mesh was chosen for this Color Spraying CFD Simulation, and how does it affect the results?

MR CFD Support –

The unstructured mesh is selected for this Color Spraying CFD Simulation due to its flexibility in handling the complex geometries associated with the spraying process. It allows for refined local meshing around the regions of interest, like the spray nozzle and the wall film, ensuring accurate capturing of the spray characteristics without excessively increasing the computational cost. The mesh type influences result accuracy, convergence, and computation time, and in such simulations, an unstructured mesh can provide a more precise prediction of the spray dynamics and wall film interactions.

Alfreda Hayes –

I really appreciated the level of detail in the tutorial for the Color Spraying with Wall Film CFD Simulation. The step-by-step setup for the DPM and variations in diameter and velocity provided clear insights for different staining outcomes.

MR CFD Support –

Thank you for your positive feedback! We’re glad to hear the tutorial was detailed and helpful. Ensuring our users gain clear and comprehensive insights from our simulations is our top priority. If you need further guidance, don’t hesitate to reach out!

Devon Ziemann –

The detailed analysis you provided indicates this CFD simulation captures the color spraying process effectively. I would love to see a visualization or animation of the spray development over time. Excellent insights into particle behavior changes with speed and size adjustments. Thank you for clearly outlining the simulation steps and parameters.

MR CFD Support –

Thank you for your positive feedback and interest in visualizing the simulation. We are thrilled to hear that our detailed analysis successfully conveyed the complexity and dynamics of the color spraying process, and that the adjustments in particle properties in our study provided valuable insights. Stay tuned for more immersive and illustrative representations of our simulations in the future!

Dr. Kaylah Beahan –

The product review was extremely detailed and highlighted the effectiveness of increasing particle velocity and diameter. I especially appreciated the comparison of results between different simulations!

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to know that our detailed simulations provided valuable insights and that you appreciated the comparison of different scenarios. It’s great that the level of detail met your expectations. If you have any further questions or need assistance with similar simulations, please don’t hesitate to contact us.

Elmira Tremblay –

The simulation has really provided clear insights into stain effect based on velocity and particle size. The results have certainly answered key questions regarding spray painting techniques. Great work!

MR CFD Support –

We appreciate your positive feedback on our CFD simulation training for spray painting on walls. It’s gratifying to know the simulation results offered valuable insights for you. Thanks for taking the time to leave us a review!

Darryl Bechtelar –

This training course seems thorough and valuable! The level of detail provided for the simulation setup, particularly the particle dynamics for the color staining effect, paints a vivid picture of what to expect from it. Between managing different variables like particle diameter, velocity, and the cone angle, it’s impressive how these influence the end results. Hands down, learning how each plays a role in spraying patterns will be instrumental in developing my CFD skills for multiphase flows!

MR CFD Support –

Thank you for your positive review! We’re delighted to hear that you find the training course thorough and valuable. It’s great to know that the detailed explanation of the simulation setup, including particle dynamics, has painted a clear picture of the process for you. Understanding the influence of variables like particle diameter, velocity, and cone angle is indeed crucial for mastering multiphase flow simulations. We appreciate your enthusiasm and are glad that our product has been instrumental in developing your CFD skills. If there is anything else we can help you with your learning journey, please let us know!

Delphine Hyatt –

After the adjustment in the third run, did you manage to achieve an even paint distribution like in the first simulation?

MR CFD Support –

The third run simulation demonstrated that a reduction in spray angle did not yield an even paint distribution comparable to the first simulation. The ideal result for spray distribution was evident in the first scenario with lower particle diameter and velocity, highlighting the importance of particle properties in achieving the desired outcome.

Sim O’Connell I –

Fantastic educational material! This CFD simulation perfectly demonstrated how various particle velocities and sizes influence the distribution of spray on a surface. It’s impressive to observe, especially through the detailed analytics, how these adjustments affect the coverage and flow on the wall. The step-by-step project description successfully empowers users to grasp the complexities of simulate wall film phenomena. Thank you team for a comprehensive and insightful simulation training!

MR CFD Support –

We really appreciate your positive feedback! It’s wonderful to hear that the Color Spraying with Wall Film, CFD Simulation training has been valuable and effective in demonstrating the intricate details of spray distribution. We’re delighted to have facilitated your understanding of such a complex topic. If you ever have more questions or need further assistance, our support team is always here to help. Thank you for choosing our training materials!

Eula O’Hara –

The training course was very detailed. Learning about how different particle velocities and diameters impact the spray quality has given me a better understanding of the painting processes. The step-by-step approach helped me effectively grasp the concepts of wall film simulation in Ansys Fluent.

MR CFD Support –

We appreciate your positive feedback and are thrilled to hear that the training course has enhanced your understanding of wall film simulations in Ansys Fluent. Your success in grasping these concept speaks volumes about your dedication to learning CFD. Thank you for choosing MR CFD as your learning partner!

Tyrell Eichmann –

The training material is very detailed and gives a clear overview of the entire process of simulating color spraying. The multiphase approach and fine control over the injection parameters allow for an informative study on how the particle properties and spray conditions affect the coverage and behavior of the paint on the walls.

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that the clarity and detail of the training material met your expectations. If there are any further insights or specific features of the simulation you’d like to learn more about, please let us know!

Ms. Brittany Hirthe –

The color spraying project provided crucial insights on impact of particle diameter and velocity. Could you detail how the increased velocity and diameter influenced the spread of the paint on the wall in terms of the physics involved?

MR CFD Support –

In the color spraying simulation, increasing the particle velocity and diameter affects the momentum of the paint particles. Higher velocity and larger particles carry more momentum, causing them to spread out more upon impact with the wall. This results in a broader and possibly less uniform distribution of paint due to greater inertia overcoming the adhesive and cohesive forces that keep the paint localized. Furthermore, larger paint drops are more affected by aerodynamic forces, leading to an increased likelihood of rebound or splatter, which can also contribute to a less precise paint application.