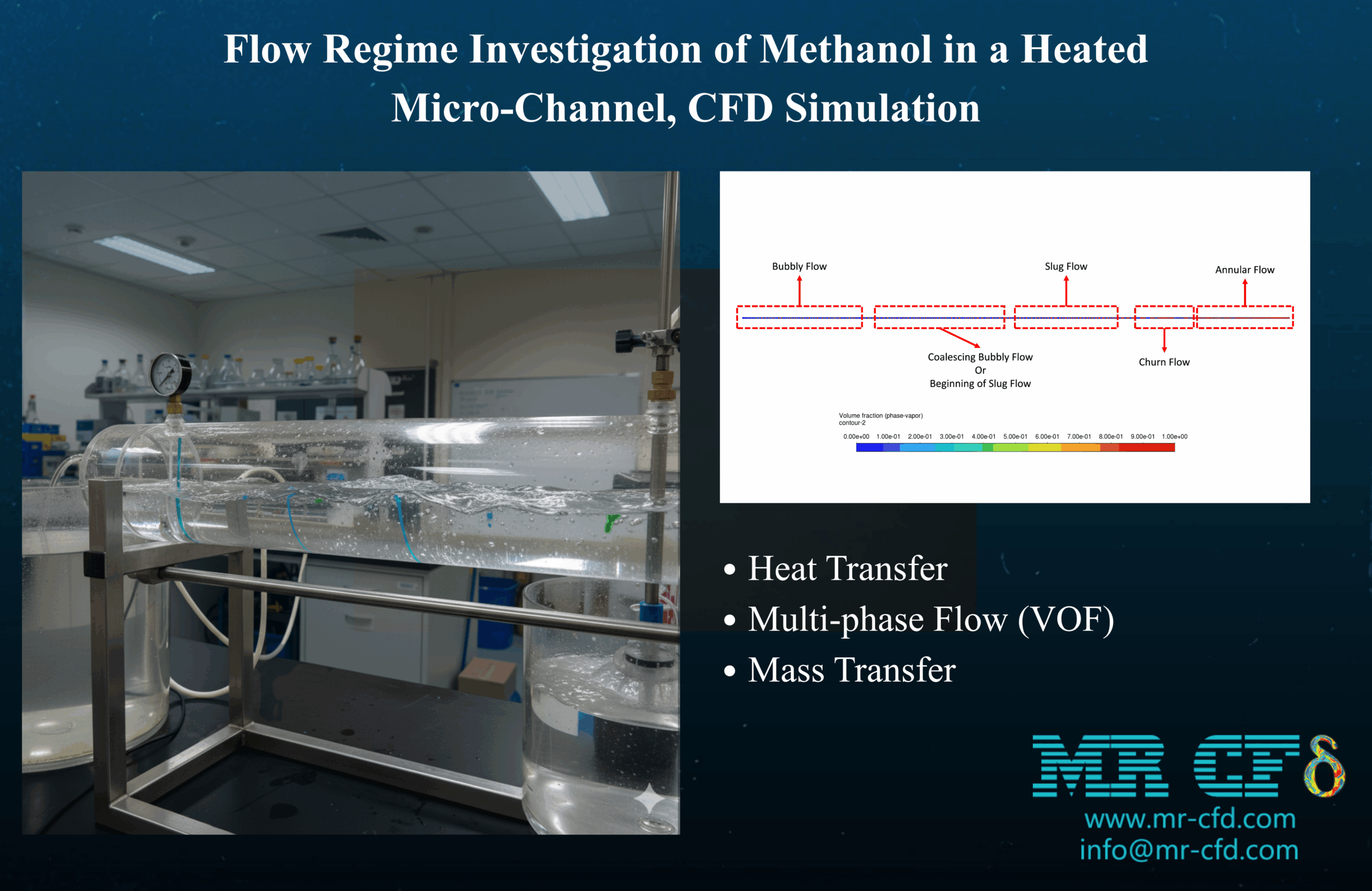

Flow Regime Investigation of Methanol in a Heated Micro-Channel, CFD Simulation

$120.00 $48.00 HPC

- This report presents a simulation that investigates the two-phase flow boiling of methanol in a heated horizontal micro-channel.

- The development and transition of different flow regimes (bubbly, slug, churn, and annular) along the channel were analyzed.

- The 2D geometry of the micro-channel was created using ANSYS SpaceClaim software.

- A high-quality structured mesh was generated using ANSYS Meshing software.

- Appropriate multiphase model settings and boundary conditions were applied to correctly simulate the evaporation process and the resulting flow patterns.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Two-Phase Flow Boiling: Investigating Methanol Flow Regimes in a Micro-Channel.

Numerous engineering applications require an understanding of the dynamics of two-phase flow in microchannels. Heating a liquid in such a small area causes it to boil, a complicated phase-change process that creates unique and changing flow patterns called flow regimes. The design and optimization of micro-scale thermal systems depend critically on the ability to predict the transition between these regimes. Therefore, the goal of this study is to simulate the evaporation of liquid methanol in a microchannel that is uniformly heated in order to examine and describe the series of flow patterns that emerge along the channel’s length.

Using ANSYS Fluent software, a comprehensive numerical investigation was conducted to analyze the coupled heat transfer, mass transfer, and multiphase fluid dynamics. The micro-channel geometry was designed in ANSYS SpaceClaim, and a high-fidelity structured mesh was generated using ANSYS Meshing (500,000 elements) to ensure accurate resolution of the liquid-vapor interface and near-wall physics. The study evaluates the qualitative progression of flow regimes along the channel, providing valuable physical insight into the boiling process of methanol under the specified conditions.

Methodology

A pressure-based, transient solver was employed to capture the development of the two-phase flow over time. Liquid methanol and methanol vapor were used as the working fluids, with the energy equation enabled to model heat transfer. The flow was considered laminar based on the inlet velocity. The Volume of Fluid (VOF) model was selected for the multiphase simulation due to its precision in tracking the interface between the liquid and vapor phases. The primary phase was set to liquid methanol and the secondary phase to methanol vapor, with a surface tension coefficient of 0.022 N/m. Mass transfer between the phases was modeled using the Evaporation-Condensation mechanism.

Results and Conclusion

From the simulation, the following results are obtained:

- The vapor volume fraction contours show a clear and logical transition of flow patterns as the fluid moves from the inlet to the outlet, driven by the continuous heat addition from the walls.

- Bubbly flow is observed near the channel inlet, where the first vapor bubbles nucleate at the hot walls and are carried into the liquid stream.

- Further downstream, these bubbles grow and merge, leading to the formation of larger, elongated “coalescing bubbles,” which is characteristic of beginning of slug flow.

- After the flow has advanced further, the bubbles assume a completely regular shape and the slug flow regime fully occurs.

- As vapor generation continues, the slugs become longer and the interface grows more unstable, transitioning into a highly chaotic and oscillatory churn flow regime.

- Near the outlet, the vapor phase forms a continuous core in the center of the channel, with the remaining liquid flowing as a thin film along the walls, indicating a fully developed annular flow.

You must be logged in to post a review.

Reviews

There are no reviews yet.